Surface Roughness And Tool Wear . The importance of understanding these factors to improve machining sustainability is highlighted through three case studies,. In a cutting process, many factors can lead to cutting vibration. This work aims to optimize the cutting parameters (cp): Therefore, current study presents surface integrity, tool wear characteristics and initiatives to improve them during the. First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for.

from www.semanticscholar.org

First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. This work aims to optimize the cutting parameters (cp): Therefore, current study presents surface integrity, tool wear characteristics and initiatives to improve them during the. In a cutting process, many factors can lead to cutting vibration. The importance of understanding these factors to improve machining sustainability is highlighted through three case studies,. Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for.

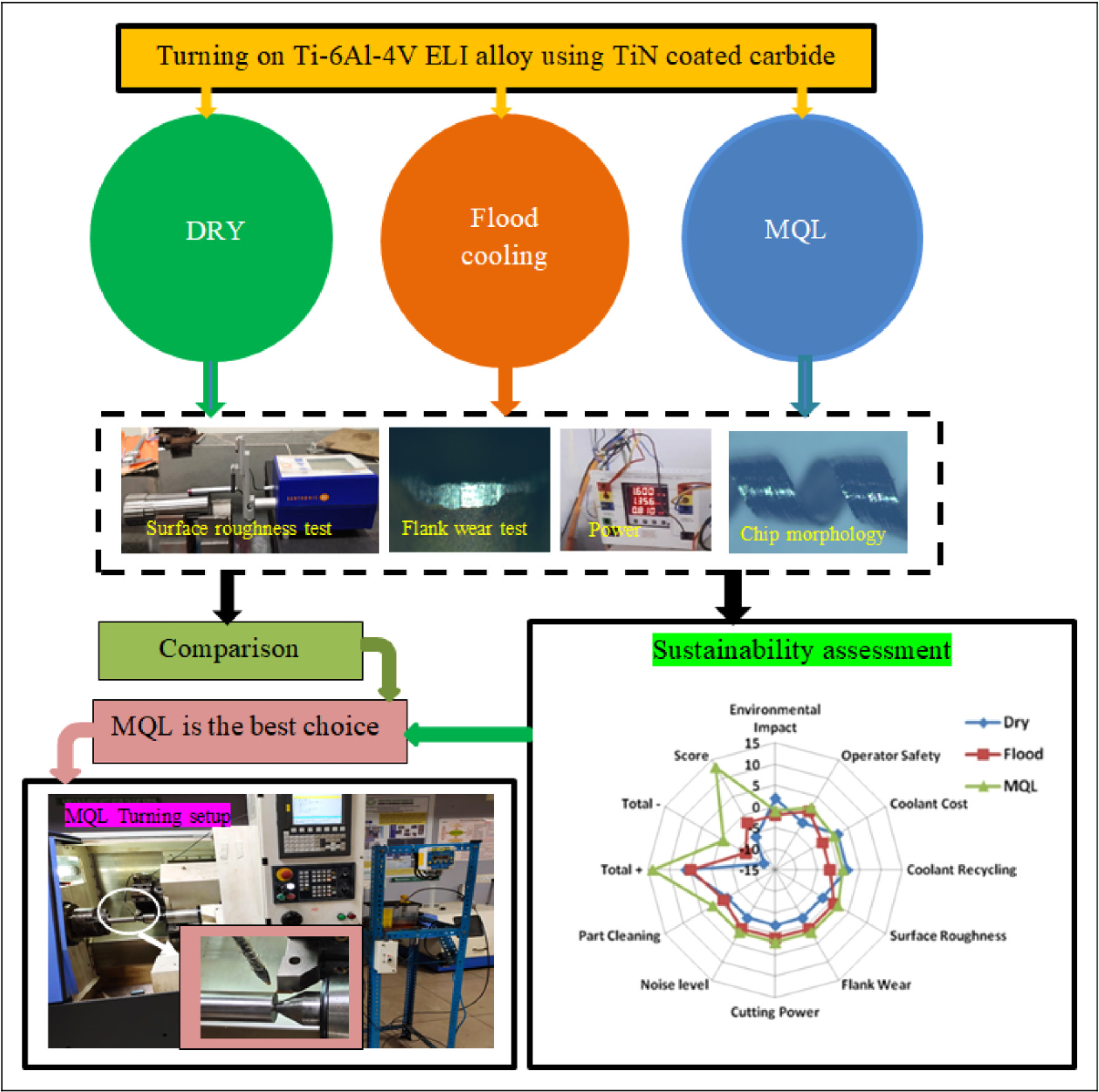

Figure 1 from Investigation on surface roughness, tool wear and cutting

Surface Roughness And Tool Wear Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. This work aims to optimize the cutting parameters (cp): Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. Therefore, current study presents surface integrity, tool wear characteristics and initiatives to improve them during the. In a cutting process, many factors can lead to cutting vibration. First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. The importance of understanding these factors to improve machining sustainability is highlighted through three case studies,. Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the.

From www.researchgate.net

Experimental values of tool wear and surface roughness for tested Surface Roughness And Tool Wear This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. The importance of understanding these factors to improve machining sustainability is highlighted through three case studies,. Therefore, current study presents. Surface Roughness And Tool Wear.

From www.researchgate.net

Relationship between Tool Wear and Surface Roughness. Download Surface Roughness And Tool Wear Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. Therefore, current study presents surface integrity, tool wear characteristics and initiatives to improve them during the. This study presents a novel approach. Surface Roughness And Tool Wear.

From www.researchgate.net

Relationship between Tool Wear and Surface Roughness. Download Surface Roughness And Tool Wear Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. This work aims to optimize the cutting parameters (cp): Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control. Surface Roughness And Tool Wear.

From www.semanticscholar.org

Figure 1 from Investigation on surface roughness, tool wear and cutting Surface Roughness And Tool Wear This work aims to optimize the cutting parameters (cp): Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. First, by defining the tool wear area s and the wear position angle. Surface Roughness And Tool Wear.

From www.researchgate.net

(PDF) influenceoftoolgeometryonsurfaceroughnessandtoolwear Surface Roughness And Tool Wear This work aims to optimize the cutting parameters (cp): This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling. Surface Roughness And Tool Wear.

From www.researchgate.net

Rear tool surface wear and workpiece surface roughness of different Surface Roughness And Tool Wear This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. Therefore, current study presents surface integrity, tool wear characteristics and initiatives to improve them during the. Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. Therefore, in actual machining. Surface Roughness And Tool Wear.

From www.researchgate.net

(PDF) Experimental evaluation of tool wear and surface roughness under Surface Roughness And Tool Wear Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. The importance of understanding these factors to improve machining sustainability is highlighted through three case studies,. Therefore, current study presents surface integrity,. Surface Roughness And Tool Wear.

From www.researchgate.net

Effect of tool wear on surface roughness Download Scientific Diagram Surface Roughness And Tool Wear Therefore, current study presents surface integrity, tool wear characteristics and initiatives to improve them during the. This work aims to optimize the cutting parameters (cp): The importance of understanding these factors to improve machining sustainability is highlighted through three case studies,. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process,. Surface Roughness And Tool Wear.

From www.researchgate.net

Tool wearcutting powersurface roughness tradeoff surface Download Surface Roughness And Tool Wear In a cutting process, many factors can lead to cutting vibration. Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. The importance of understanding these factors to improve machining sustainability is. Surface Roughness And Tool Wear.

From www.researchgate.net

Relation between tool wear and surface roughness. Download Scientific Surface Roughness And Tool Wear This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. Therefore, in actual machining processes, on the premise of meeting the requirements for. Surface Roughness And Tool Wear.

From www.researchgate.net

Example of cuttingtool wear impact on surface roughness. Download Surface Roughness And Tool Wear First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. This work aims to optimize the cutting parameters (cp): Therefore, current study presents. Surface Roughness And Tool Wear.

From www.mdpi.com

Investigations on Surface Roughness and Tool Wear Characteristics in Surface Roughness And Tool Wear Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. The importance of understanding these factors to improve machining sustainability is highlighted through three case studies,. This work aims to optimize the. Surface Roughness And Tool Wear.

From www.scribd.com

Experimental Investigation of Surface Roughness and Tool Wear of Surface Roughness And Tool Wear The importance of understanding these factors to improve machining sustainability is highlighted through three case studies,. First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine. Surface Roughness And Tool Wear.

From www.researchgate.net

Effect of tool wear on surface roughness Download Scientific Diagram Surface Roughness And Tool Wear Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. This work aims to optimize the cutting parameters (cp): The importance of understanding these factors to improve machining sustainability is highlighted through. Surface Roughness And Tool Wear.

From www.researchgate.net

Average surface roughness and tool wear results Download Scientific Surface Roughness And Tool Wear Therefore, current study presents surface integrity, tool wear characteristics and initiatives to improve them during the. This work aims to optimize the cutting parameters (cp): First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. The importance of understanding these factors to improve machining sustainability is. Surface Roughness And Tool Wear.

From github.com

GitHub kidozh/toolwearrelationwithsurfaceroughnessindrilling Surface Roughness And Tool Wear Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. Therefore, current study presents surface integrity, tool wear characteristics and initiatives to improve them during the. First, by defining the. Surface Roughness And Tool Wear.

From www.researchgate.net

Tool wear rate and surface roughness of the parts machined under Surface Roughness And Tool Wear This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. In a cutting process, many factors can lead to cutting vibration. The importance. Surface Roughness And Tool Wear.

From www.researchgate.net

Experimental results of surface roughness, tool wear and RMS of Surface Roughness And Tool Wear This work aims to optimize the cutting parameters (cp): The importance of understanding these factors to improve machining sustainability is highlighted through three case studies,. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. First, by defining the tool wear area s and the wear position. Surface Roughness And Tool Wear.

From www.researchgate.net

Rear tool surface wear and surface roughness of different tool Surface Roughness And Tool Wear In a cutting process, many factors can lead to cutting vibration. The importance of understanding these factors to improve machining sustainability is highlighted through three case studies,. First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. This work aims to optimize the cutting parameters (cp):. Surface Roughness And Tool Wear.

From www.researchgate.net

Effects of tool wear on tool shape. (a) Surface roughness of complete Surface Roughness And Tool Wear This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and. Surface Roughness And Tool Wear.

From www.researchgate.net

Influence of tool wear time on cutting surface roughness Download Surface Roughness And Tool Wear Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process,. Surface Roughness And Tool Wear.

From www.researchgate.net

(PDF) Uncertainty Analysis of Tool Wear and Surface Roughness in End Surface Roughness And Tool Wear First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. Therefore, in actual machining processes, on the premise of meeting the requirements for. Surface Roughness And Tool Wear.

From www.researchgate.net

Surface roughness and tool wear impacted by feed rate and cutting speed Surface Roughness And Tool Wear This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of. Surface Roughness And Tool Wear.

From www.researchgate.net

(PDF) Comprehensive analysis of tool wear, surface roughness and chip Surface Roughness And Tool Wear Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. The importance of understanding these factors to improve machining sustainability is highlighted through three case studies,. This study presents. Surface Roughness And Tool Wear.

From www.researchgate.net

(PDF) Impact of nose radius and machining parameters on surface Surface Roughness And Tool Wear Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. In a cutting process, many factors can lead to cutting vibration. This work aims to optimize the cutting parameters (cp): This study. Surface Roughness And Tool Wear.

From www.researchgate.net

(PDF) Tool wear and surface roughness evaluation of mill insert tools Surface Roughness And Tool Wear Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial. Surface Roughness And Tool Wear.

From www.researchgate.net

Influence of tool wear on surface roughness. Download Scientific Diagram Surface Roughness And Tool Wear Therefore, current study presents surface integrity, tool wear characteristics and initiatives to improve them during the. First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. This work aims. Surface Roughness And Tool Wear.

From dokumen.tips

(PDF) Experimentation on Tool Wear and Surface Roughness in AISI Surface Roughness And Tool Wear Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial. Surface Roughness And Tool Wear.

From www.researchgate.net

(PDF) Comparison of Tool Wear, Surface Roughness, Cutting Forces, Tool Surface Roughness And Tool Wear This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. This work aims to optimize the cutting parameters (cp): The importance of understanding these factors to improve machining sustainability is highlighted through three case studies,. Therefore, in actual machining processes, on the premise of meeting the requirements. Surface Roughness And Tool Wear.

From www.researchgate.net

(PDF) Experimental Investigation On Surface Roughness, Tool Wear And Surface Roughness And Tool Wear Therefore, current study presents surface integrity, tool wear characteristics and initiatives to improve them during the. First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. This work aims to optimize the cutting parameters (cp): Tool wear, workpiece surface roughness and cutting forces were measured and. Surface Roughness And Tool Wear.

From www.mdpi.com

Micromachines Free FullText Effect of Milling Processing Surface Roughness And Tool Wear This work aims to optimize the cutting parameters (cp): This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. Therefore, current study presents surface integrity, tool wear characteristics and initiatives. Surface Roughness And Tool Wear.

From www.researchgate.net

Dependence of surface roughness on tool wear during turning 100Cr6 Surface Roughness And Tool Wear Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial. Surface Roughness And Tool Wear.

From www.researchgate.net

(PDF) Exploring the Impact of Turning of AISI 4340 Steel on Tool Wear Surface Roughness And Tool Wear Therefore, current study presents surface integrity, tool wear characteristics and initiatives to improve them during the. Tool wear, workpiece surface roughness and cutting forces were measured and these parameters were correlated with the. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial for. In a cutting process,. Surface Roughness And Tool Wear.

From www.researchgate.net

Surface roughness and tool wear impacted by feed rate and cutting speed Surface Roughness And Tool Wear Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force and vibration. This study presents a novel approach to monitor and predict surface roughness and tool wear in the turning process, which is crucial. Surface Roughness And Tool Wear.

From www.researchgate.net

Influence of tool wear on surface roughness [33] Download Scientific Surface Roughness And Tool Wear First, by defining the tool wear area s and the wear position angle ψ, the cutting edge line model of the tool is determined. Therefore, in actual machining processes, on the premise of meeting the requirements for rigidity and surface roughness of a machine tool, properly increasing the cutting velocity and milling depth can improve productivity and control cutting force. Surface Roughness And Tool Wear.