How To Mold Car Parts . To optimize vehicle designs, engineers can use aerodynamic parts like injection molded plastic spoilers. This is the piece that you would like to replicate for casting. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing. Then start wetting out the carbon cloth with resin and laying it inside the fiberglass mold. In this guide, learn the basics of manufacturing carbon fiber parts, including the different carbon fiber layup, lamination, and molding methods, and how you can use 3d printing to make carbon fiber molds to lower costs and save time. Automotive injection molding lets designers leverage all three approaches. Molds are essential for producing multiple copies of a car part, whether for replacement, customization, or mass. It can be an existing part such as a car bumper or a canoe or it can be a new part you create out of modeling clay, wood, fiberglass and resin, sheet metal etc. The first step in making a fiberglass mold is preparing your plug. I was spending hours producing these engine bay caps, so i decided to speed things up and make a silicone split mold and. To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold.

from www.engineersrule.com

This is the piece that you would like to replicate for casting. I was spending hours producing these engine bay caps, so i decided to speed things up and make a silicone split mold and. The first step in making a fiberglass mold is preparing your plug. To optimize vehicle designs, engineers can use aerodynamic parts like injection molded plastic spoilers. Automotive injection molding lets designers leverage all three approaches. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing. To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. Then start wetting out the carbon cloth with resin and laying it inside the fiberglass mold. It can be an existing part such as a car bumper or a canoe or it can be a new part you create out of modeling clay, wood, fiberglass and resin, sheet metal etc. Molds are essential for producing multiple copies of a car part, whether for replacement, customization, or mass.

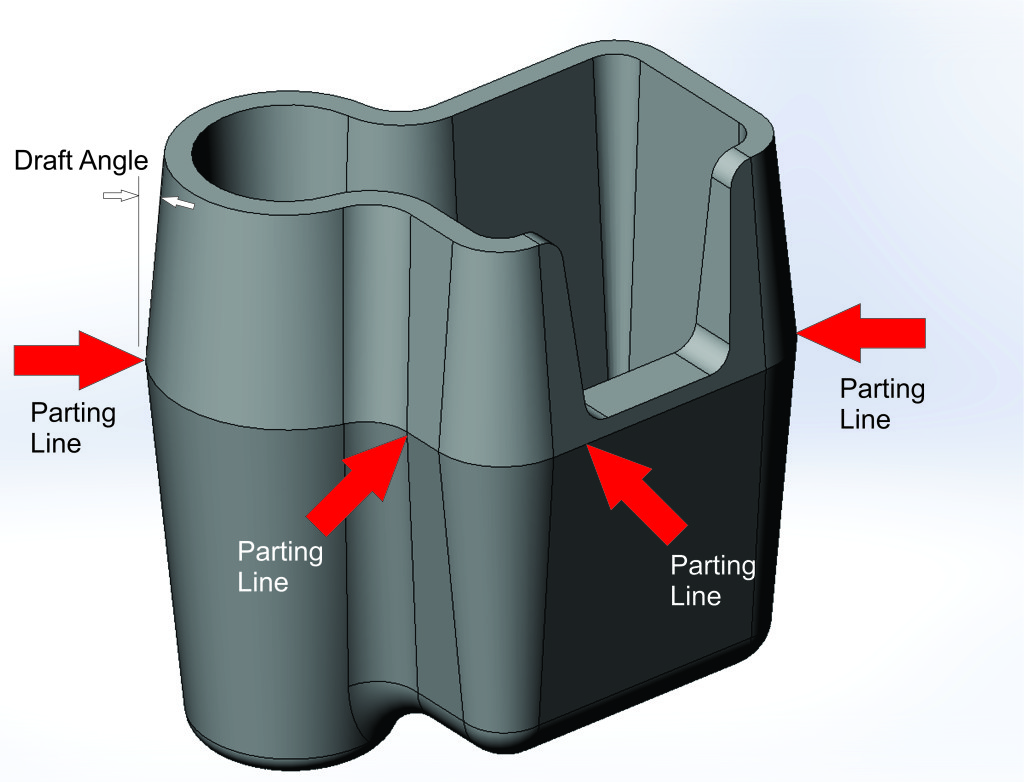

Plastic Parts Design 101 Engineers Rule

How To Mold Car Parts To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. The first step in making a fiberglass mold is preparing your plug. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing. Molds are essential for producing multiple copies of a car part, whether for replacement, customization, or mass. In this guide, learn the basics of manufacturing carbon fiber parts, including the different carbon fiber layup, lamination, and molding methods, and how you can use 3d printing to make carbon fiber molds to lower costs and save time. To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. Then start wetting out the carbon cloth with resin and laying it inside the fiberglass mold. This is the piece that you would like to replicate for casting. I was spending hours producing these engine bay caps, so i decided to speed things up and make a silicone split mold and. Automotive injection molding lets designers leverage all three approaches. To optimize vehicle designs, engineers can use aerodynamic parts like injection molded plastic spoilers. It can be an existing part such as a car bumper or a canoe or it can be a new part you create out of modeling clay, wood, fiberglass and resin, sheet metal etc.

From www.mold-and-tool.com

Auto Parts Mold Mold and Tool How To Mold Car Parts This is the piece that you would like to replicate for casting. The first step in making a fiberglass mold is preparing your plug. Then start wetting out the carbon cloth with resin and laying it inside the fiberglass mold. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup. How To Mold Car Parts.

From www.pinterest.pt

Read our article on "Auto Parts Mould and the Method of Applying it in How To Mold Car Parts Then start wetting out the carbon cloth with resin and laying it inside the fiberglass mold. It can be an existing part such as a car bumper or a canoe or it can be a new part you create out of modeling clay, wood, fiberglass and resin, sheet metal etc. In this section, we focus on the crucial steps for. How To Mold Car Parts.

From www.youtube.com

Making a two part Silicone Mold Advanced Technique YouTube How To Mold Car Parts Molds are essential for producing multiple copies of a car part, whether for replacement, customization, or mass. It can be an existing part such as a car bumper or a canoe or it can be a new part you create out of modeling clay, wood, fiberglass and resin, sheet metal etc. This is the piece that you would like to. How To Mold Car Parts.

From grace-plastic-injection-mold.blogspot.com

Grace plastic injection mold Basic Mold Components How To Mold Car Parts To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. Molds are essential for producing multiple copies of a car part, whether for replacement, customization, or mass. In this guide, learn the basics of manufacturing carbon fiber parts, including the different carbon fiber layup, lamination, and molding methods, and. How To Mold Car Parts.

From suggesthow.com

How to Get Rid of Mold in Car How To Mold Car Parts Molds are essential for producing multiple copies of a car part, whether for replacement, customization, or mass. I was spending hours producing these engine bay caps, so i decided to speed things up and make a silicone split mold and. It can be an existing part such as a car bumper or a canoe or it can be a new. How To Mold Car Parts.

From www.youtube.com

How to Make a Fiberglass Mold from an Existing Part Part 1 Preparing How To Mold Car Parts Then start wetting out the carbon cloth with resin and laying it inside the fiberglass mold. To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. The first step in making a fiberglass mold is preparing your plug. In this guide, learn the basics of manufacturing carbon fiber parts,. How To Mold Car Parts.

From carroar.com

How to Get Rid of Mold in Your Car The Only Guide You Need Car Roar How To Mold Car Parts The first step in making a fiberglass mold is preparing your plug. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing. Automotive injection molding lets designers leverage all three approaches. It can be an existing part such as a car bumper or a canoe or. How To Mold Car Parts.

From senseschina.com

Automotive Injection Mould How To Mold Car Parts The first step in making a fiberglass mold is preparing your plug. I was spending hours producing these engine bay caps, so i decided to speed things up and make a silicone split mold and. Molds are essential for producing multiple copies of a car part, whether for replacement, customization, or mass. To optimize vehicle designs, engineers can use aerodynamic. How To Mold Car Parts.

From www.hardwareinterviews.fyi

Basics of Blow Molding Consumer Hardware Guide Hardware FYI How To Mold Car Parts Then start wetting out the carbon cloth with resin and laying it inside the fiberglass mold. In this guide, learn the basics of manufacturing carbon fiber parts, including the different carbon fiber layup, lamination, and molding methods, and how you can use 3d printing to make carbon fiber molds to lower costs and save time. This is the piece that. How To Mold Car Parts.

From www.moldtoolstxs.com

Car parts precision plastic mold design and manufacturer How To Mold Car Parts This is the piece that you would like to replicate for casting. Then start wetting out the carbon cloth with resin and laying it inside the fiberglass mold. The first step in making a fiberglass mold is preparing your plug. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup. How To Mold Car Parts.

From www.youtube.com

Casting Metal Parts into 3D Printed Molds YouTube How To Mold Car Parts The first step in making a fiberglass mold is preparing your plug. To optimize vehicle designs, engineers can use aerodynamic parts like injection molded plastic spoilers. Automotive injection molding lets designers leverage all three approaches. It can be an existing part such as a car bumper or a canoe or it can be a new part you create out of. How To Mold Car Parts.

From www.petermanfirm.com

Injection Molding 101 How It Works How To Mold Car Parts To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. To optimize vehicle designs, engineers can use aerodynamic parts like injection molded plastic spoilers. It can be an existing part such as a car bumper or a canoe or it can be a new part you create out of. How To Mold Car Parts.

From restorationmasterfinder.com

How to Clean a Car of Mold or Mildew RestorationMaster How To Mold Car Parts Molds are essential for producing multiple copies of a car part, whether for replacement, customization, or mass. It can be an existing part such as a car bumper or a canoe or it can be a new part you create out of modeling clay, wood, fiberglass and resin, sheet metal etc. This is the piece that you would like to. How To Mold Car Parts.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold How To Mold Car Parts To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. Automotive injection molding lets designers leverage all three approaches. This is the piece that you would like to replicate for casting. It can be an existing part such as a car bumper or a canoe or it can be. How To Mold Car Parts.

From etmold.en.made-in-china.com

Plastic Mold Car Parts Inject Molding Rapid Tooling Mold and Plastic How To Mold Car Parts Automotive injection molding lets designers leverage all three approaches. I was spending hours producing these engine bay caps, so i decided to speed things up and make a silicone split mold and. The first step in making a fiberglass mold is preparing your plug. It can be an existing part such as a car bumper or a canoe or it. How To Mold Car Parts.

From justindetail.com

Easy Car Mold Removal Tips From an Auto Detailing Expert How To Mold Car Parts To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing. This is the piece that you would like to replicate for casting. To optimize vehicle. How To Mold Car Parts.

From bigsmobile.com

How To Get Mold Out Of Car Interior And Carpet How To Mold Car Parts I was spending hours producing these engine bay caps, so i decided to speed things up and make a silicone split mold and. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing. The first step in making a fiberglass mold is preparing your plug. To. How To Mold Car Parts.

From www.plasticmoulds.net

What Is Plastic Mold And How To Make Reliable Plastic Mold? How To Mold Car Parts Molds are essential for producing multiple copies of a car part, whether for replacement, customization, or mass. Automotive injection molding lets designers leverage all three approaches. I was spending hours producing these engine bay caps, so i decided to speed things up and make a silicone split mold and. It can be an existing part such as a car bumper. How To Mold Car Parts.

From www.adtcmold.com

Injection mold principle and structure knowledge How To Mold Car Parts Then start wetting out the carbon cloth with resin and laying it inside the fiberglass mold. To optimize vehicle designs, engineers can use aerodynamic parts like injection molded plastic spoilers. In this guide, learn the basics of manufacturing carbon fiber parts, including the different carbon fiber layup, lamination, and molding methods, and how you can use 3d printing to make. How To Mold Car Parts.

From hlmachinerygroup.en.made-in-china.com

Car Body Panel Sheet Metal Stamping Parts Press Mold/ Moulds China How To Mold Car Parts I was spending hours producing these engine bay caps, so i decided to speed things up and make a silicone split mold and. In this guide, learn the basics of manufacturing carbon fiber parts, including the different carbon fiber layup, lamination, and molding methods, and how you can use 3d printing to make carbon fiber molds to lower costs and. How To Mold Car Parts.

From novastevensville.com

Plastic industry What Is Injection Molding Used For? Your Official Guide How To Mold Car Parts In this guide, learn the basics of manufacturing carbon fiber parts, including the different carbon fiber layup, lamination, and molding methods, and how you can use 3d printing to make carbon fiber molds to lower costs and save time. It can be an existing part such as a car bumper or a canoe or it can be a new part. How To Mold Car Parts.

From www.autodetaildoctor.com

How to remove car interior mold Auto Detail Doctor How To Mold Car Parts This is the piece that you would like to replicate for casting. The first step in making a fiberglass mold is preparing your plug. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing. To mold a carbon fiber positive from the fiberglass mold you first. How To Mold Car Parts.

From www.motortrend.com

How to build a vacuum forming mold to make your own plastic parts How To Mold Car Parts Automotive injection molding lets designers leverage all three approaches. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing. This is the piece that you would like to replicate for casting. Molds are essential for producing multiple copies of a car part, whether for replacement, customization,. How To Mold Car Parts.

From seacomould.com

The bumper system actually consists of the following parts Seaco Mould How To Mold Car Parts Molds are essential for producing multiple copies of a car part, whether for replacement, customization, or mass. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing. Automotive injection molding lets designers leverage all three approaches. The first step in making a fiberglass mold is preparing. How To Mold Car Parts.

From mungfali.com

Injection Molding Machine Layout How To Mold Car Parts In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing. To optimize vehicle designs, engineers can use aerodynamic parts like injection molded plastic spoilers. In this guide, learn the basics of manufacturing carbon fiber parts, including the different carbon fiber layup, lamination, and molding methods, and. How To Mold Car Parts.

From autoprotoway.com

Automotive Injection Molding How It is Used in Auto Parts Production How To Mold Car Parts To optimize vehicle designs, engineers can use aerodynamic parts like injection molded plastic spoilers. The first step in making a fiberglass mold is preparing your plug. To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. Automotive injection molding lets designers leverage all three approaches. Molds are essential for. How To Mold Car Parts.

From www.youtube.com

How To Mold a Chassis Molding & Casting Tutorial Alumilite YouTube How To Mold Car Parts The first step in making a fiberglass mold is preparing your plug. To optimize vehicle designs, engineers can use aerodynamic parts like injection molded plastic spoilers. This is the piece that you would like to replicate for casting. I was spending hours producing these engine bay caps, so i decided to speed things up and make a silicone split mold. How To Mold Car Parts.

From www.youtube.com

Making Fiberglass Body Panels Ep 1. Roof Mold YouTube How To Mold Car Parts The first step in making a fiberglass mold is preparing your plug. Molds are essential for producing multiple copies of a car part, whether for replacement, customization, or mass. To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. Then start wetting out the carbon cloth with resin and. How To Mold Car Parts.

From buzztum.com

Benefits of Injection Molding for Automotive Parts Manufacturing How To Mold Car Parts To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. It can be an existing part such as a car bumper or a canoe or it can be a new part you create out of modeling clay, wood, fiberglass and resin, sheet metal etc. In this guide, learn the. How To Mold Car Parts.

From www.pioneerplastics.com

Complex Molding Techniques For Complex Parts Pioneer Plastics How To Mold Car Parts In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing. To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. This is the piece that you would like to replicate for casting. Then start wetting. How To Mold Car Parts.

From moldhelpforyou.com

How Do You Get Rid Of Mold In A Car? Mold Help For You How To Mold Car Parts Then start wetting out the carbon cloth with resin and laying it inside the fiberglass mold. To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. The first step in making a fiberglass mold is preparing your plug. I was spending hours producing these engine bay caps, so i. How To Mold Car Parts.

From www.xcentricmold.com

Automotive Xcentric Mold How To Mold Car Parts To optimize vehicle designs, engineers can use aerodynamic parts like injection molded plastic spoilers. To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. This is the piece that you would like to replicate for casting. Automotive injection molding lets designers leverage all three approaches. I was spending hours. How To Mold Car Parts.

From gz-plastics.en.made-in-china.com

Auto Plastic Parts Injection Mold Automotive Injection Mould Making How To Mold Car Parts I was spending hours producing these engine bay caps, so i decided to speed things up and make a silicone split mold and. Then start wetting out the carbon cloth with resin and laying it inside the fiberglass mold. In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process. How To Mold Car Parts.

From www.engineersrule.com

Plastic Parts Design 101 Engineers Rule How To Mold Car Parts In this section, we focus on the crucial steps for manufacturing carbon fiber parts, from preparing molds to the layup process and the curing. To optimize vehicle designs, engineers can use aerodynamic parts like injection molded plastic spoilers. Automotive injection molding lets designers leverage all three approaches. To mold a carbon fiber positive from the fiberglass mold you first apply. How To Mold Car Parts.

From www.injection-moldingmolds.com

NAK80 Material Car Plastic Molding , Injection Moulding Die Design For How To Mold Car Parts It can be an existing part such as a car bumper or a canoe or it can be a new part you create out of modeling clay, wood, fiberglass and resin, sheet metal etc. I was spending hours producing these engine bay caps, so i decided to speed things up and make a silicone split mold and. In this guide,. How To Mold Car Parts.