Punching Slots In Sheet Metal . This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. punch forming is a highly efficient capability for adding formed features such as louvers and. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom.

from lotowebsite.mystrikingly.com

punch forming is a highly efficient capability for adding formed features such as louvers and. during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom. sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch.

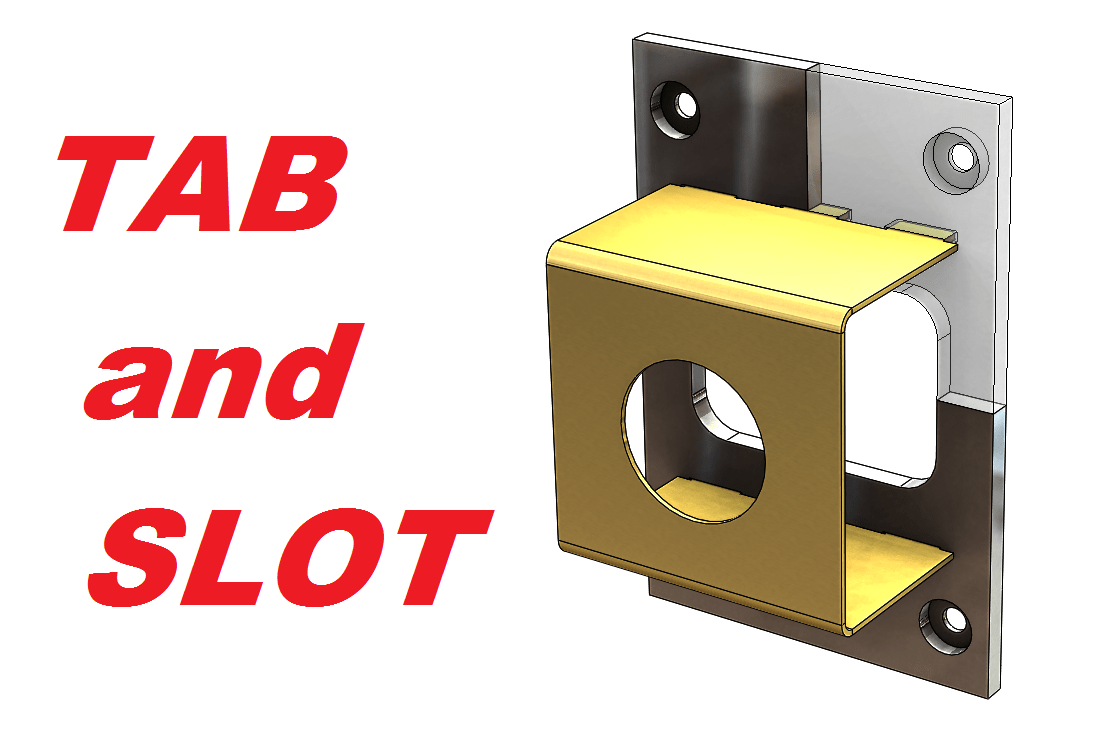

Sheet Metal Tab And Slot Design Guide

Punching Slots In Sheet Metal sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. punch forming is a highly efficient capability for adding formed features such as louvers and. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other. metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom.

From bmxracingthailand.com

How To Cut Slots In Sheet Metal? Update New Punching Slots In Sheet Metal during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or. Punching Slots In Sheet Metal.

From www.hidraulika.net

Sheet Metal Punching Punching Slots In Sheet Metal sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses. Punching Slots In Sheet Metal.

From www.protoexpedited.com

4 Tips of Sheet Metal Fabrication Proto Expedited Punching Slots In Sheet Metal during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. This process offers. Punching Slots In Sheet Metal.

From www.vandf.co.uk

CNC Punching Sheet Metal Work Punching Slots In Sheet Metal metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. in sheet metal punching, the sheet metal is positioned on a die, and the. Punching Slots In Sheet Metal.

From www.carbuilder.com

25.4mm (1") Square Sheet Metal Hole Punch Punching Slots In Sheet Metal metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials. Punching Slots In Sheet Metal.

From www.minifaber.com

5 FAQ about sheet metal punching Punching Slots In Sheet Metal punch forming is a highly efficient capability for adding formed features such as louvers and. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the. Punching Slots In Sheet Metal.

From www.vandf.co.uk

CNC punching of sheet metal work in the UK 2017 Punching Slots In Sheet Metal in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. punch forming is a highly efficient capability for adding formed features such as louvers and. This process offers several advantages, including. Punching Slots In Sheet Metal.

From www.thefabricator.com

Sheet metal fabrication basics 7 strategies for punching success Punching Slots In Sheet Metal This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on. Punching Slots In Sheet Metal.

From www.aptika.ca

Handheld Slot Punch with Adjustable Centering Guide (39431010 Punching Slots In Sheet Metal sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. punch forming is a highly efficient capability for adding formed features such as louvers and. . Punching Slots In Sheet Metal.

From kcg.com.my

Sheet metal punching KCG Punching Slots In Sheet Metal sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials. Punching Slots In Sheet Metal.

From www.youtube.com

Inventor 2012 sheet metal punch tutorial YouTube Punching Slots In Sheet Metal during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. punch forming is a highly efficient capability for adding formed features such as louvers and. . Punching Slots In Sheet Metal.

From www.thefabricator.com

Heavyduty sheet metal punching with the modern mechanical punch press Punching Slots In Sheet Metal This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes. Punching Slots In Sheet Metal.

From enginemanualschweizer.z6.web.core.windows.net

Hand Held Sheet Metal Punch Punching Slots In Sheet Metal in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses.. Punching Slots In Sheet Metal.

From h-hmetals.com

Sheet Metal Punching Plate Punching H&H Metals Punching Slots In Sheet Metal This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes. Punching Slots In Sheet Metal.

From www.pinterest.co.uk

Cluster tool and CNC punching sheet metal components Sheet metal Punching Slots In Sheet Metal metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom. during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. sheet metal punching is a metalworking technique that involves using a punch and die set to create. Punching Slots In Sheet Metal.

From blog.dahlstromrollform.com

Find A Versatile Sheet Metal Punching Partner With Roll Forming Punching Slots In Sheet Metal sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. punch forming is a highly efficient capability for adding formed features such as louvers and. metal punching is. Punching Slots In Sheet Metal.

From www.maggiorifratelli.com

Sheet metal punching Sheet metal punching and metal alloys punching Punching Slots In Sheet Metal metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. sheet metal punching is a manufacturing process that uses a punch and dies to. Punching Slots In Sheet Metal.

From www.alibaba.com

Durable Tabletop Metal Slot Punch For 3.5*15mm Oval Hole Buy Metal Punching Slots In Sheet Metal during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or. Punching Slots In Sheet Metal.

From blog.thepipingmart.com

A Brief Description Of Sheet Metal Punching ThePipingMart Blog Punching Slots In Sheet Metal sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a. Punching Slots In Sheet Metal.

From www.vandf.co.uk

CNC punching techniques for sheet metal work Punching Slots In Sheet Metal sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes.. Punching Slots In Sheet Metal.

From www.produtech.it

Sheet metal punching machine Produtech Punching Slots In Sheet Metal sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. punch forming is a highly efficient capability for adding formed features such as louvers and. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. in sheet. Punching Slots In Sheet Metal.

From www.vandf.co.uk

Where can I purchase sheet metal work in the UK Punching Slots In Sheet Metal sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. punch forming is a highly efficient capability for adding formed features such as louvers and. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. sheet metal. Punching Slots In Sheet Metal.

From whiteoutpress.com

Top 10 Advantages For Metal Punches and Die WhiteOut Press Punching Slots In Sheet Metal sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes. Punching Slots In Sheet Metal.

From www.carbuilder.com

19mm (3/4") Square Sheet Metal Hole Punch Punching Slots In Sheet Metal during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. metal punching is the. Punching Slots In Sheet Metal.

From www.walmart.com

21050 Metal Hole Punch Set with Puncher, 16 Piece, This hole punch kit Punching Slots In Sheet Metal sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other. during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. Punching Slots In Sheet Metal.

From lotowebsite.mystrikingly.com

Sheet Metal Tab And Slot Design Guide Punching Slots In Sheet Metal during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. punch forming is a highly efficient capability for adding formed features such as louvers and. . Punching Slots In Sheet Metal.

From www.workshoppress.co.uk

Slotted Hole Punch Press Order Online Punching Slots In Sheet Metal sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. punch forming. Punching Slots In Sheet Metal.

From meshscreen.en.made-in-china.com

Punching Hole Decorative Slot Hole Perforated Metal Mesh Sheet for Punching Slots In Sheet Metal metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. in sheet metal punching, the sheet metal is positioned on a die,. Punching Slots In Sheet Metal.

From www.aliexpress.com

sheet metal slotted hole punch press/punching machinein Punching Punching Slots In Sheet Metal during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide. Punching Slots In Sheet Metal.

From h-hmetals.com

Sheet Metal Punching Plate Punching H&H Metals Punching Slots In Sheet Metal punch forming is a highly efficient capability for adding formed features such as louvers and. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. This. Punching Slots In Sheet Metal.

From www.beckhoff.com

Punching and nibbling Beckhoff مصر Punching Slots In Sheet Metal sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch. sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on. Punching Slots In Sheet Metal.

From www.vandf.co.uk

CNC punching techniques for sheet metal work Punching Slots In Sheet Metal sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other. punch forming is a highly efficient capability for adding formed features such as louvers and. This. Punching Slots In Sheet Metal.

From kcg.com.my

Sheet metal punching KCG Punching Slots In Sheet Metal This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch.. Punching Slots In Sheet Metal.

From www.falconprecision.co.uk

CNC Punching Design Tips Punching Slots In Sheet Metal punch forming is a highly efficient capability for adding formed features such as louvers and. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on the metal,. sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other. sheet metal punching. Punching Slots In Sheet Metal.

From www.thefabricator.com

Reducing a manufacturer's cost per part with advanced punching technology Punching Slots In Sheet Metal during sheet metal forming, the sheets are often punched in order to make the holes for multiple purposes. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. in sheet metal punching, the sheet metal is positioned on a die, and the punch presses down on. Punching Slots In Sheet Metal.