Gouging Tip For Oxy Acetylene . The shape of the wear tip allows for both forward and back gouging. This can be as much as 300. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at the tip along side a normal oxy/acet tip. Then the cutting and gouging processes can begin to remove the metal. The oxygen must be 99.9 percent pure to produce a quality cut. There are 3 models in the range each providing a u groove of. As with the standard style h6290 g weld removal tips these nozzles must. First, preheat the steel to its kindling temperature. When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet.

from collinstools.com.au

For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at the tip along side a normal oxy/acet tip. There are 3 models in the range each providing a u groove of. Then the cutting and gouging processes can begin to remove the metal. This can be as much as 300. The shape of the wear tip allows for both forward and back gouging. The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. First, preheat the steel to its kindling temperature. When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. As with the standard style h6290 g weld removal tips these nozzles must.

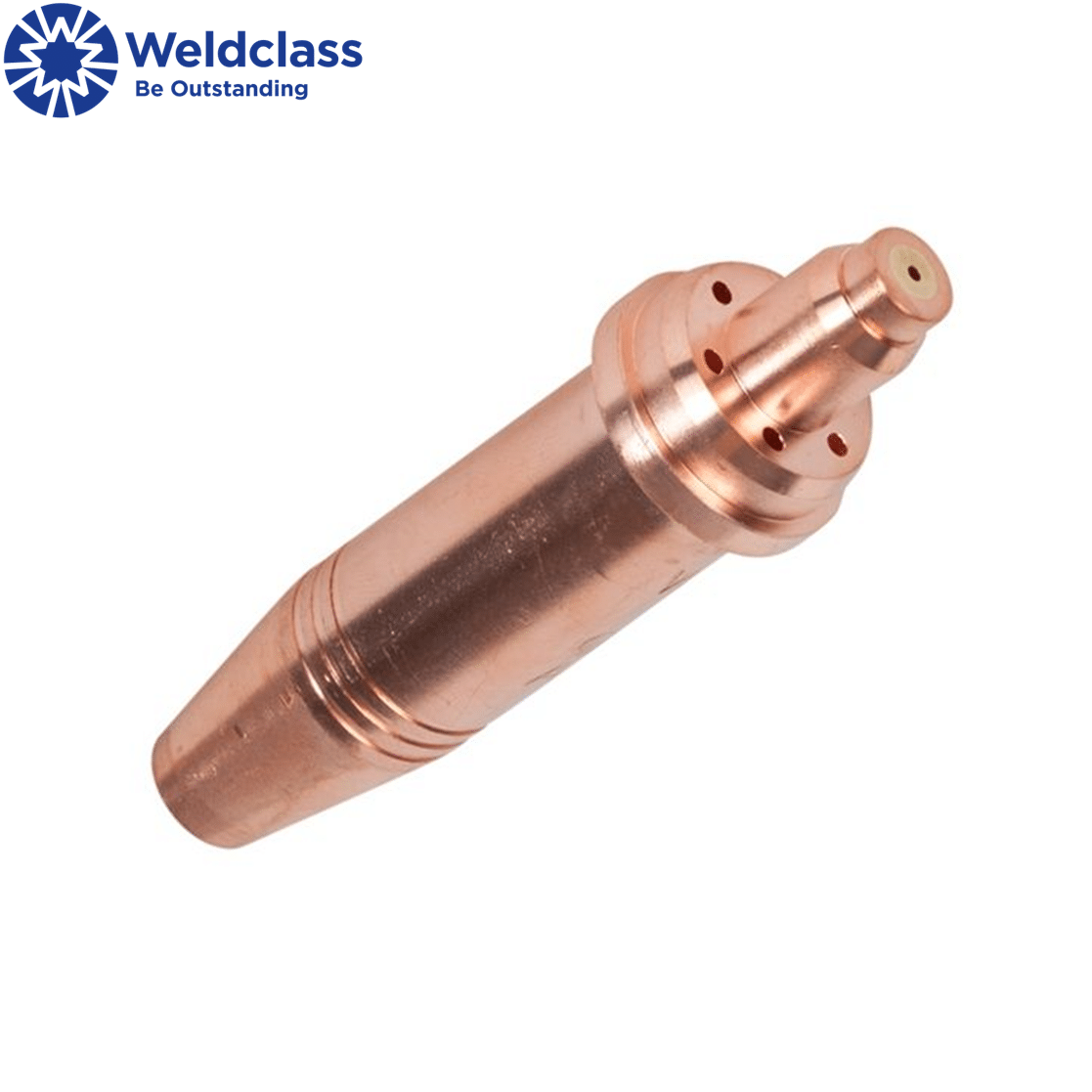

P44132GS Weldclass Oxy/Acetylene Gouging Tips Type 41 32GS Straight

Gouging Tip For Oxy Acetylene The shape of the wear tip allows for both forward and back gouging. The oxygen must be 99.9 percent pure to produce a quality cut. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at the tip along side a normal oxy/acet tip. The shape of the wear tip allows for both forward and back gouging. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. Then the cutting and gouging processes can begin to remove the metal. There are 3 models in the range each providing a u groove of. This can be as much as 300. When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. First, preheat the steel to its kindling temperature. The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. As with the standard style h6290 g weld removal tips these nozzles must.

From www.hampdon.com.au

Type 41 32GB Oxy / Acetylene Bent Gouging Tip / Nozzle Gouging Tip For Oxy Acetylene The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. Then the cutting and gouging processes can begin to remove the metal. When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. The oxygen must be 99.9 percent pure to produce a quality cut. As with. Gouging Tip For Oxy Acetylene.

From www.bobthewelder.com.au

OxyAcetylene gas cutting tips, OxyAcetylene gouging tips, Gouging Gouging Tip For Oxy Acetylene The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. There are 3 models in the range each providing a u groove of. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at the tip along side a normal oxy/acet. Gouging Tip For Oxy Acetylene.

From www.fwi.co.uk

tips A guide to oxy acetylene gas cutting and welding Gouging Tip For Oxy Acetylene When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. First, preheat the steel to its kindling temperature. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. The oxygen must be 99.9 percent pure to produce a quality cut. The shape of the wear tip. Gouging Tip For Oxy Acetylene.

From www.nationalwelding.com.au

Gouging Nozzle Oxygen/Acetylene Type 41 Gouging Tip For Oxy Acetylene The shape of the wear tip allows for both forward and back gouging. The oxygen must be 99.9 percent pure to produce a quality cut. First, preheat the steel to its kindling temperature. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. That gouging tip is ideal for getting into tight corners. Gouging Tip For Oxy Acetylene.

From michaelfarmer.z21.web.core.windows.net

Oxy Acetylene Victor Welding Tip Chart Gouging Tip For Oxy Acetylene The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at the tip along. Gouging Tip For Oxy Acetylene.

From www.hampdon.com.au

10x Type 41 32GB Oxy / Acetylene Bent Gouging Tip / Nozzle Gouging Tip For Oxy Acetylene There are 3 models in the range each providing a u groove of. First, preheat the steel to its kindling temperature. This can be as much as 300. The shape of the wear tip allows for both forward and back gouging. As with the standard style h6290 g weld removal tips these nozzles must. The gouging nozzle is designed to. Gouging Tip For Oxy Acetylene.

From www.colliermiller.com.au

GOUGING TIP BENT SIZE 32GB OXYACETYLENE TYPE 41 Collier & Miller Gouging Tip For Oxy Acetylene There are 3 models in the range each providing a u groove of. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. This can be as much as 300. Then the cutting and gouging processes can begin to remove the metal. First, preheat the steel to its kindling temperature. The gouging nozzle. Gouging Tip For Oxy Acetylene.

From bakersgas.com

Victor Acetylene Torch Tip 21101 03300006 — Baker's Gas Gouging Tip For Oxy Acetylene As with the standard style h6290 g weld removal tips these nozzles must. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at the tip along side a normal oxy/acet tip. The shape of the wear tip allows for both forward and back gouging. The gouging nozzle. Gouging Tip For Oxy Acetylene.

From www.hampdon.com.au

Type 41 32GS Oxy / Acetylene Gouging Nozzle Comet Gouging Tip For Oxy Acetylene Then the cutting and gouging processes can begin to remove the metal. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at the tip along side a normal oxy/acet tip. This can be as much as 300. The shape of the wear tip allows for both forward. Gouging Tip For Oxy Acetylene.

From www.youtube.com

OxyAcetylene welding practice time! YouTube Gouging Tip For Oxy Acetylene The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. This can be as much as 300. The shape of the wear tip allows for both forward and back gouging. There are 3 models in the range each providing a u groove of. For edge preparation, removal of welds or gouging cracked metals. Gouging Tip For Oxy Acetylene.

From www.colliermiller.com.au

GOUGING TIP STRAIGHT SIZE 32GS OXYACETYLENE TYPE 41 Collier & Miller Gouging Tip For Oxy Acetylene First, preheat the steel to its kindling temperature. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. This can be as much as 300. There are 3 models in the range each providing a u groove of. When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes. Gouging Tip For Oxy Acetylene.

From souduredepot.ca

gouging tip / OxyCentre Incsouduredepot.ca Gouging Tip For Oxy Acetylene This can be as much as 300. First, preheat the steel to its kindling temperature. As with the standard style h6290 g weld removal tips these nozzles must. The oxygen must be 99.9 percent pure to produce a quality cut. There are 3 models in the range each providing a u groove of. The shape of the wear tip allows. Gouging Tip For Oxy Acetylene.

From www.cigweld.com.au

COMET Bent Gouging Nozzle, Oxy/Acet, Type 41, Size 32GB CIGWELD Gouging Tip For Oxy Acetylene This can be as much as 300. As with the standard style h6290 g weld removal tips these nozzles must. When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at. Gouging Tip For Oxy Acetylene.

From www.hampdon.com.au

Type 41 32GS Oxy / Acetylene Gouging Nozzle Comet Gouging Tip For Oxy Acetylene The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. The shape of the wear tip allows for both forward and back gouging. This can be as much as 300. As with the standard style h6290. Gouging Tip For Oxy Acetylene.

From harrisweldingsupplies.com

Harris 62902G Acetylene Gouging Tip 1500920 Gouging Tip For Oxy Acetylene When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. The shape of the wear tip allows for both forward and back gouging. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. Then the cutting and gouging processes can begin to remove the metal. First,. Gouging Tip For Oxy Acetylene.

From americantorchtip.com

Gouging Tip Acet Med 1. OxyFuel American Torch Tip Gouging Tip For Oxy Acetylene For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. There are 3 models in the range each providing a u groove of. As with the standard style h6290 g weld removal tips these nozzles must.. Gouging Tip For Oxy Acetylene.

From www.electroweld.com.au

UNIMIG Type 41 OxyAcetylene Gouging Nozzle Bent Gouging Tip For Oxy Acetylene There are 3 models in the range each providing a u groove of. The oxygen must be 99.9 percent pure to produce a quality cut. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at the tip along side a normal oxy/acet tip. When the steel becomes. Gouging Tip For Oxy Acetylene.

From www.bobthewelder.com.au

OxyAcetylene gas cutting tips, OxyAcetylene gouging tips, Gouging Gouging Tip For Oxy Acetylene This can be as much as 300. There are 3 models in the range each providing a u groove of. As with the standard style h6290 g weld removal tips these nozzles must. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. Then the cutting and gouging processes can begin to remove. Gouging Tip For Oxy Acetylene.

From www.hampdon.com.au

10x Type 41 32GB Oxy / Acetylene Bent Gouging Tip / Nozzle Gouging Tip For Oxy Acetylene Then the cutting and gouging processes can begin to remove the metal. The shape of the wear tip allows for both forward and back gouging. The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. The. Gouging Tip For Oxy Acetylene.

From collinstools.com.au

P44132GB Weldclass Oxy/Acetylene Gouging Tips Type 41 32GS Bent Gouging Tip For Oxy Acetylene There are 3 models in the range each providing a u groove of. Then the cutting and gouging processes can begin to remove the metal. The oxygen must be 99.9 percent pure to produce a quality cut. The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. As with the standard style h6290. Gouging Tip For Oxy Acetylene.

From www.bobthewelder.com.au

OxyAcetylene gas cutting tips, OxyAcetylene gouging tips, Gouging Gouging Tip For Oxy Acetylene As with the standard style h6290 g weld removal tips these nozzles must. The shape of the wear tip allows for both forward and back gouging. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at the tip along side a normal oxy/acet tip. First, preheat the. Gouging Tip For Oxy Acetylene.

From www.weldingcity.com

WeldingCity® Acetylene Gouging/Cutting Tip 3118 Series Victor® Style Gouging Tip For Oxy Acetylene For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. Then the cutting and gouging processes can begin to remove the metal. This can be as much as 300. The shape of the wear tip allows for both forward and back gouging. There are 3 models in the range each providing a u. Gouging Tip For Oxy Acetylene.

From www.electroweld.com.au

UNIMIG Type 41 OxyAcetylene Gouging Nozzle Bent Gouging Tip For Oxy Acetylene First, preheat the steel to its kindling temperature. The shape of the wear tip allows for both forward and back gouging. There are 3 models in the range each providing a u groove of. The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. That gouging tip is ideal for getting into tight. Gouging Tip For Oxy Acetylene.

From www.motortrend.com

OxyAcetylene Welding 101 Gouging Tip For Oxy Acetylene The shape of the wear tip allows for both forward and back gouging. First, preheat the steel to its kindling temperature. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at the tip along side a normal oxy/acet tip. This can be as much as 300. There. Gouging Tip For Oxy Acetylene.

From www.weldingcity.com

WeldingCity® Acetylene Gouging/Cutting Tip 1118 Series Victor® Style Gouging Tip For Oxy Acetylene The oxygen must be 99.9 percent pure to produce a quality cut. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. Then the cutting and gouging processes can begin to remove the metal. As with the standard style h6290 g weld removal tips these nozzles must. The gouging nozzle is designed to. Gouging Tip For Oxy Acetylene.

From www.hampdon.com.au

Type 41 32GB Oxy / Acetylene Bent Gouging Tip / Nozzle Gouging Tip For Oxy Acetylene When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at the tip along. Gouging Tip For Oxy Acetylene.

From weldro.com

WeldRo AGNM GOUGING NOZZLE OXYACETYLENE GOUGING Gouging Tip For Oxy Acetylene First, preheat the steel to its kindling temperature. The shape of the wear tip allows for both forward and back gouging. As with the standard style h6290 g weld removal tips these nozzles must. When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. Then the cutting and gouging processes can begin to. Gouging Tip For Oxy Acetylene.

From americantorchtip.com

Welding Cut Charts American Torch Tip Cut Charts Gouging Tip For Oxy Acetylene When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. There are 3 models in the range each providing a u groove of. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. The oxygen must be 99.9 percent pure to produce a quality cut. The. Gouging Tip For Oxy Acetylene.

From joinjdcgj.blob.core.windows.net

How To Turn On Oxygen Acetylene Torch at Jerry Spriggs blog Gouging Tip For Oxy Acetylene That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork, take a look at the tip along side a normal oxy/acet tip. The shape of the wear tip allows for both forward and back gouging. The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging. Gouging Tip For Oxy Acetylene.

From aclconnect.com.au

Harris Type 41 32GB Gouging Tip Bent Oxy/Acet ACL Industrial Technology Gouging Tip For Oxy Acetylene Then the cutting and gouging processes can begin to remove the metal. As with the standard style h6290 g weld removal tips these nozzles must. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. The oxygen must be 99.9 percent pure to produce a quality cut. There are 3 models in the. Gouging Tip For Oxy Acetylene.

From www.electroweld.com.au

UNIMIG Type 41 OxyAcetylene Gouging Nozzle Bent Gouging Tip For Oxy Acetylene There are 3 models in the range each providing a u groove of. Then the cutting and gouging processes can begin to remove the metal. First, preheat the steel to its kindling temperature. The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. When the steel becomes “cherry red”, the added oxygen causes. Gouging Tip For Oxy Acetylene.

From collinstools.com.au

P44132GS Weldclass Oxy/Acetylene Gouging Tips Type 41 32GS Straight Gouging Tip For Oxy Acetylene As with the standard style h6290 g weld removal tips these nozzles must. There are 3 models in the range each providing a u groove of. Then the cutting and gouging processes can begin to remove the metal. The shape of the wear tip allows for both forward and back gouging. That gouging tip is ideal for getting into tight. Gouging Tip For Oxy Acetylene.

From www.ebay.com

Oxweld ESAB 1515 1516 Oxy Acetylene Propane LPG cutting gouging tips Gouging Tip For Oxy Acetylene As with the standard style h6290 g weld removal tips these nozzles must. For edge preparation, removal of welds or gouging cracked metals with a gouging capacity of 1/2 in. The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. First, preheat the steel to its kindling temperature. Then the cutting and gouging. Gouging Tip For Oxy Acetylene.

From www.hampdon.com.au

Type 41 32GB Oxy / Acetylene Bent Gouging Tip / Nozzle Gouging Tip For Oxy Acetylene This can be as much as 300. When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. That gouging tip is ideal for getting into tight corners where you don't want to damage the main steelwork,. Gouging Tip For Oxy Acetylene.

From www.ebay.com.au

OxyAcetylene Welding Tips Model WJ Compatible with "J" Series Victor Gouging Tip For Oxy Acetylene Then the cutting and gouging processes can begin to remove the metal. When the steel becomes “cherry red”, the added oxygen causes an exothermic reaction that removes the metal. The oxygen must be 99.9 percent pure to produce a quality cut. As with the standard style h6290 g weld removal tips these nozzles must. First, preheat the steel to its. Gouging Tip For Oxy Acetylene.