Induction Heater For Brazing . There is one key difference associated when heating a magnetic part vs. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. They come complete with induction heater, coil, brazing material, flux,. induction brazing is the process of joining two or more metals using induction heating. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. Induction heating can be used to heat very specific areas of a workpiece, without. induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. the advantages include:

from www.fabtechexpo.com

induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. There is one key difference associated when heating a magnetic part vs. Induction heating can be used to heat very specific areas of a workpiece, without. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. They come complete with induction heater, coil, brazing material, flux,. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. induction brazing is the process of joining two or more metals using induction heating. the advantages include:

Brazing 101 Induction Heating FABTECH

Induction Heater For Brazing Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. the advantages include: Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. Induction heating can be used to heat very specific areas of a workpiece, without. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. There is one key difference associated when heating a magnetic part vs. induction brazing is the process of joining two or more metals using induction heating. They come complete with induction heater, coil, brazing material, flux,.

From ipillar.en.made-in-china.com

Induction Heater for Hardening Brazing Soldering IGBT Induction Induction Heater For Brazing They come complete with induction heater, coil, brazing material, flux,. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. Induction. Induction Heater For Brazing.

From www.fabtechexpo.com

Brazing 101 Induction Heating FABTECH Induction Heater For Brazing the advantages include: There is one key difference associated when heating a magnetic part vs. induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional. Induction Heater For Brazing.

From dongguangy.en.made-in-china.com

High Frequency Induction Heater for Brazing Fitting Carbide Metal Induction Heater For Brazing Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. There is one key difference associated when heating a magnetic part vs. Induction heating can be used to heat very specific areas of. Induction Heater For Brazing.

From www.desertcart.nz

Buy Induction Heater Kit 1000W 110V Induction Coil Heater Bolt Induction Heater For Brazing induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. They come complete. Induction Heater For Brazing.

From dw-inductionheater.com

induction Brazing copper rods to brass strips connection joints Induction Heater For Brazing induction brazing is the process of joining two or more metals using induction heating. There is one key difference associated when heating a magnetic part vs. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. Induction heating can be used to heat. Induction Heater For Brazing.

From dw-inductionheater.com

portable induction brazing machine for brazing copper,brass,steel pipes,etc Induction Heater For Brazing Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. induction brazing is the process of joining two or more metals using induction heating. They come complete with induction heater, coil, brazing. Induction Heater For Brazing.

From inductionheater.blogspot.com

induction heating handheld induction brazing machine Induction Heater For Brazing They come complete with induction heater, coil, brazing material, flux,. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. induction heating is a noncontact heating method that is extremely fast and efficient when compared. Induction Heater For Brazing.

From ultraflexpower.com

Automated Induction Brazing of Heat Exchangers UltraFlex Induction Heater For Brazing There is one key difference associated when heating a magnetic part vs. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. They come complete with induction heater, coil, brazing material, flux,. induction heating is a noncontact heating method that is extremely fast. Induction Heater For Brazing.

From ultraflexpower.com

Automated Induction Brazing of Heat Exchangers UltraFlex Induction Heater For Brazing They come complete with induction heater, coil, brazing material, flux,. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. the advantages include: There is one key difference associated when heating a magnetic part vs. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic.. Induction Heater For Brazing.

From www.inductionmachinery.com

UltraHigh Frequency Induction Brazing Machine3.2KW to 12KW /2001100KHz Induction Heater For Brazing induction brazing is the process of joining two or more metals using induction heating. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. There is one key difference associated when heating a magnetic part vs. our induction brazing systems offer revolutionary. Induction Heater For Brazing.

From dw-inductionheater.com

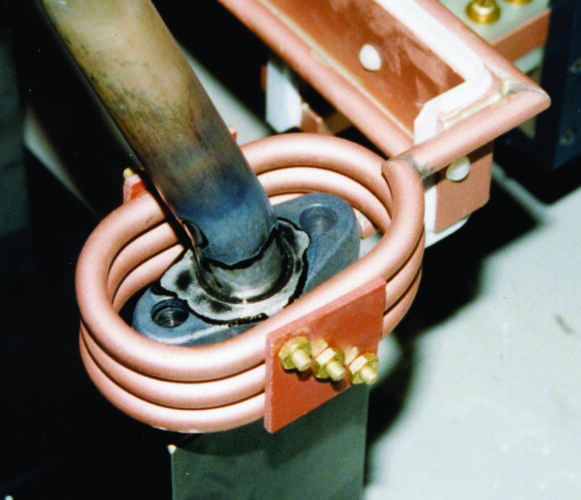

Brazing Steel Automotive Parts With Induction Heating System Induction Heater For Brazing They come complete with induction heater, coil, brazing material, flux,. induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. Induction heating can be used to heat very specific areas of a workpiece, without. induction. Induction Heater For Brazing.

From www.htc.co.nz

Induction Heater For Hire HTC Induction Heater For Brazing Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. There is one key difference associated when heating a magnetic part vs. Induction heating can be used to heat very specific areas of a workpiece, without. our induction brazing systems offer revolutionary solutions. Induction Heater For Brazing.

From www.ambrell.com

The Benefits of Using Induction Heating for Brazing Induction Heater For Brazing Induction heating can be used to heat very specific areas of a workpiece, without. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. There is one key difference associated when heating a magnetic part vs. Also, our systems use up to 90% less energy than traditional. Induction Heater For Brazing.

From dw-inductionheater.com

Induction Heating Stainless Steel With IGBT Induction Heater Induction Heater For Brazing They come complete with induction heater, coil, brazing material, flux,. induction brazing is the process of joining two or more metals using induction heating. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. Induction heating can be used to heat very specific areas of a. Induction Heater For Brazing.

From dw-inductionheater.com

Induction Brazing T Shaped Copper Tubing Assemblies Induction Heater For Brazing induction brazing is the process of joining two or more metals using induction heating. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. There is one key difference associated when heating. Induction Heater For Brazing.

From geellychina.en.made-in-china.com

Handheld Induction Heater Brazing Machine for Copper Tube Pipe Brazing Induction Heater For Brazing They come complete with induction heater, coil, brazing material, flux,. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. There is one key difference associated when heating a magnetic part vs. our induction brazing. Induction Heater For Brazing.

From dw-inductionheater.com

Brazing Copper Tubing with Induction Brazing System Induction Heater For Brazing induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. Induction heating can be used to heat very specific areas of a workpiece, without. There is one key difference associated when heating a magnetic part vs. induction brazing is the process of joining two or more. Induction Heater For Brazing.

From trademojo.co

Induction Welding / Brazing Heaters StoneWay Engineering Work Induction Heater For Brazing induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. They come complete with induction heater, coil, brazing material, flux,. . Induction Heater For Brazing.

From smithermal.en.made-in-china.com

230V Hf15 kVA High Frequency Induction Heater for Brazing Diamond Tool Induction Heater For Brazing induction brazing is the process of joining two or more metals using induction heating. Induction heating can be used to heat very specific areas of a workpiece, without. They come complete with induction heater, coil, brazing material, flux,. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional. Induction Heater For Brazing.

From www.mdpi.com

Processes Free FullText A Development of an Induction Heating Induction Heater For Brazing our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. the advantages include: induction brazing is the process of joining two or more metals using induction heating. There is one key difference associated when. Induction Heater For Brazing.

From www.youtube.com

Brazing with induction heating YouTube Induction Heater For Brazing Induction heating can be used to heat very specific areas of a workpiece, without. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. induction heating is a noncontact heating method that. Induction Heater For Brazing.

From www.dodomachine.com

Induction Heater For Brazing Solution By Dodo Mitsubishi Controls Induction Heater For Brazing the advantages include: There is one key difference associated when heating a magnetic part vs. induction brazing is the process of joining two or more metals using induction heating. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. Induction heating can. Induction Heater For Brazing.

From inductionheater.blogspot.com

induction heating induction brazing stainless steel to copper Induction Heater For Brazing the advantages include: Induction heating can be used to heat very specific areas of a workpiece, without. They come complete with induction heater, coil, brazing material, flux,. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. Induction heating can heat any electrically. Induction Heater For Brazing.

From geellychina.en.made-in-china.com

Induction Heater HandHold for Moving Heating Brazing Welding Induction Heater For Brazing induction brazing is the process of joining two or more metals using induction heating. Induction heating can be used to heat very specific areas of a workpiece, without. induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. There is one key difference associated when heating. Induction Heater For Brazing.

From dw-inductionheater.com

portable induction brazing machine for brazing copper,brass,steel pipes,etc Induction Heater For Brazing They come complete with induction heater, coil, brazing material, flux,. There is one key difference associated when heating a magnetic part vs. induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. Induction heating can be used to heat very specific areas of a workpiece, without. Induction. Induction Heater For Brazing.

From dw-inductionheater.com

portable induction brazing machine for brazing copper,brass,steel pipes,etc Induction Heater For Brazing Induction heating can be used to heat very specific areas of a workpiece, without. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. the advantages include: Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. our induction brazing systems. Induction Heater For Brazing.

From yuelon.en.made-in-china.com

China Handheld Induction Heater for Brazing (HF30AB) Photos & Pictures Induction Heater For Brazing Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. Induction heating can be used to heat very specific areas of. Induction Heater For Brazing.

From dw-inductionheater.com

High Frequency Induction Brazing copper to copper pipes Induction Heater For Brazing There is one key difference associated when heating a magnetic part vs. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for. Induction Heater For Brazing.

From dw-inductionheater.com

portable induction brazing machine for brazing copper,brass,steel pipes,etc Induction Heater For Brazing There is one key difference associated when heating a magnetic part vs. They come complete with induction heater, coil, brazing material, flux,. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. the advantages include: induction brazing is the process of joining two or more metals using induction heating. Induction heating can be used to heat very. Induction Heater For Brazing.

From geellychina.en.made-in-china.com

1MHz 7kw Induction Heater for Small Screws Heating Spray Dispensing Induction Heater For Brazing induction brazing is the process of joining two or more metals using induction heating. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. They come complete with induction heater, coil, brazing material, flux,. the advantages include: There is one key difference associated when heating. Induction Heater For Brazing.

From www.hfinductionheater.com

Portable Induction Heater Machine I 10+ Years Hfinduction Induction Heater For Brazing induction brazing is the process of joining two or more metals using induction heating. Induction heating can be used to heat very specific areas of a workpiece, without. Also, our systems use up to 90% less energy than traditional brazing and soldering methods, making them the perfect choice for a more sustainable production process. the advantages include: . Induction Heater For Brazing.

From www.inductionmachinery.com

ODM. ZGHFW Series Portable/handholding/moveable type induction Induction Heater For Brazing There is one key difference associated when heating a magnetic part vs. the advantages include: They come complete with induction heater, coil, brazing material, flux,. Induction heating can be used to heat very specific areas of a workpiece, without. induction brazing is the process of joining two or more metals using induction heating. induction heating is a. Induction Heater For Brazing.

From precisioniaindia.com

Induction Heater for ShortCircuit Rings Brazing manufacturer, supplier Induction Heater For Brazing our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. Induction heating can heat any electrically conductive material, magnetic and nonmagnetic. the advantages. Induction Heater For Brazing.

From www.prweb.com

Portable Induction Brazing Heaters From DaWei Induction Heating Machine Induction Heater For Brazing our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. They come complete with induction heater, coil, brazing material, flux,. induction heating is a noncontact heating method that is extremely fast and efficient when compared to other heating technologies used for brazing. Induction heating can heat. Induction Heater For Brazing.

From dw-inductionheater.com

Induction Brazing copper,bronze,brazing steel heater Induction Heater For Brazing induction brazing is the process of joining two or more metals using induction heating. our induction brazing systems offer revolutionary solutions to your brazing needs with faster, cleaner, and more repeatable results than traditional torch brazing. Induction heating can be used to heat very specific areas of a workpiece, without. the advantages include: They come complete with. Induction Heater For Brazing.