What Causes Cnc Coolant To Foam . Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. Foam acts as an insulator, preventing the coolant from. What are the risks of poor coolant. Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. This is very simple, and many times the cause for excessive foam. Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. What is cnc coolant and why is it important? What is the life expectancy of cnc coolant and can it go bad? “if you have two 90° elbows in. Coolant foaming can cause several problems: Obviously, if the chip tray gets too full and coolant is foamy it.

from www.cnccookbook.com

Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. What is cnc coolant and why is it important? Foam acts as an insulator, preventing the coolant from. Obviously, if the chip tray gets too full and coolant is foamy it. What are the risks of poor coolant. Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. “if you have two 90° elbows in. Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. Coolant foaming can cause several problems:

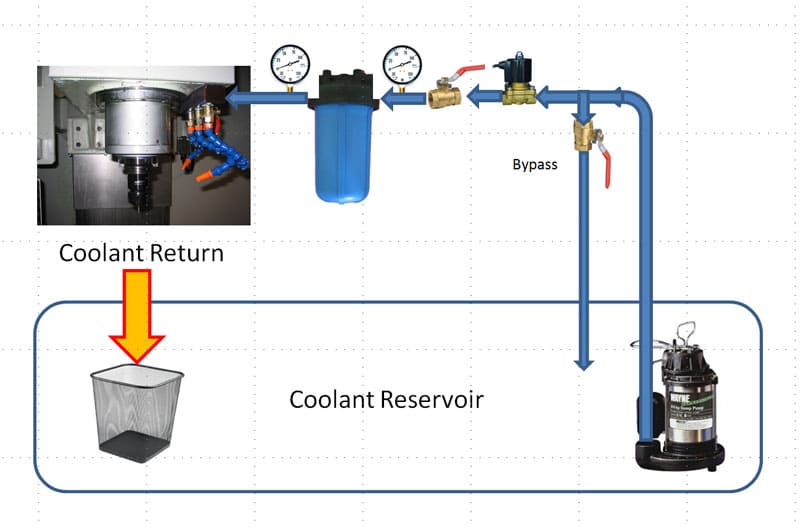

Not Filtering Your Coolant? Find Out How to Do It Cheaply and Easily

What Causes Cnc Coolant To Foam Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. “if you have two 90° elbows in. What is the life expectancy of cnc coolant and can it go bad? Foam acts as an insulator, preventing the coolant from. Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. This is very simple, and many times the cause for excessive foam. Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. Coolant foaming can cause several problems: What are the risks of poor coolant. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. Obviously, if the chip tray gets too full and coolant is foamy it. What is cnc coolant and why is it important?

From www.reddit.com

what is this foam in my radiator? it’s been giving me problems for What Causes Cnc Coolant To Foam Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. Obviously, if the chip tray gets too full and coolant is foamy it. Foam acts as an insulator, preventing the coolant from. Coolant should flow in as straight a line as possible, but sometimes plumbing. What Causes Cnc Coolant To Foam.

From www.sumipol.com

6 เคล็ดลับการเพิ่มประสิทธิภาพ งานกลึง Sumipol What Causes Cnc Coolant To Foam What are the risks of poor coolant. Obviously, if the chip tray gets too full and coolant is foamy it. What is the life expectancy of cnc coolant and can it go bad? “if you have two 90° elbows in. This is very simple, and many times the cause for excessive foam. Coolant should flow in as straight a line. What Causes Cnc Coolant To Foam.

From www.youtube.com

How to change coolant in your CNC // Axiom Precision CNC YouTube What Causes Cnc Coolant To Foam Coolant foaming can cause several problems: Obviously, if the chip tray gets too full and coolant is foamy it. “if you have two 90° elbows in. Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface. What Causes Cnc Coolant To Foam.

From epictool.ca

Coolants Used in CNC Operations Epic Tool What Causes Cnc Coolant To Foam What are the risks of poor coolant. Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. Obviously, if the chip tray gets too full and coolant is foamy it. Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in. What Causes Cnc Coolant To Foam.

From mechanicbase.com

7 Causes of a Coolant Leak How to Fix It (& Repair Cost) What Causes Cnc Coolant To Foam What is the life expectancy of cnc coolant and can it go bad? Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. This is very simple, and many times the cause for excessive foam. What is cnc coolant and why is it important? Foaming. What Causes Cnc Coolant To Foam.

From www.bioblend.com

What Causes Hydraulic Fluid to Foam BioBlend Lubricants & Industrial What Causes Cnc Coolant To Foam Obviously, if the chip tray gets too full and coolant is foamy it. Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. Foam acts as an insulator, preventing the coolant from. Foaming in cnc machining coolant systems is a common issue that can lead. What Causes Cnc Coolant To Foam.

From www.haascnc.com

Chip & Coolant Management What Causes Cnc Coolant To Foam Foam acts as an insulator, preventing the coolant from. Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. “if you have two 90° elbows in. What is the life expectancy of cnc coolant and can it go bad? What are the risks of poor coolant. This is very simple, and many times the. What Causes Cnc Coolant To Foam.

From www.cnccookbook.com

Not Filtering Your Coolant? Find Out How to Do It Cheaply and Easily What Causes Cnc Coolant To Foam Foam acts as an insulator, preventing the coolant from. Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. Obviously, if the chip tray gets too full and coolant is foamy it. What. What Causes Cnc Coolant To Foam.

From garagespammerceleema.z13.web.core.windows.net

Coolant Not Circulating Through Engine What Causes Cnc Coolant To Foam Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. Coolant foaming can cause several problems: “if you have two 90° elbows in. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. Foam acts as an insulator, preventing. What Causes Cnc Coolant To Foam.

From reillyfoam.com

Types of CNC Foam Cutting Reilly Foam Corporation What Causes Cnc Coolant To Foam “if you have two 90° elbows in. Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. What is the life expectancy of cnc coolant and can it go bad? Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming. What Causes Cnc Coolant To Foam.

From www.reddit.com

What caused the coolant to do this? r/MechanicAdvice What Causes Cnc Coolant To Foam “if you have two 90° elbows in. Obviously, if the chip tray gets too full and coolant is foamy it. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. Coolant foaming can cause several problems: What is cnc coolant and why is it important?. What Causes Cnc Coolant To Foam.

From www.youtube.com

Ep1 DIY CNC Mist Coolant system ! YouTube What Causes Cnc Coolant To Foam Foam acts as an insulator, preventing the coolant from. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. What is the life expectancy of cnc coolant and can it go bad? “if you have two 90° elbows in. What is cnc coolant and why. What Causes Cnc Coolant To Foam.

From www.subaruoutback.org

Gen 4 Foam in coolant Subaru Outback Forums What Causes Cnc Coolant To Foam Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. This is very simple, and many times the cause for excessive foam. Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. What is the life expectancy of cnc coolant and can it. What Causes Cnc Coolant To Foam.

From mechanicbarraretzb0d.z19.web.core.windows.net

Antifreeze Leaking From Bottom Of Engine What Causes Cnc Coolant To Foam This is very simple, and many times the cause for excessive foam. Foam acts as an insulator, preventing the coolant from. Obviously, if the chip tray gets too full and coolant is foamy it. Coolant foaming can cause several problems: What is the life expectancy of cnc coolant and can it go bad? Foaming in cnc machining coolant systems is. What Causes Cnc Coolant To Foam.

From knowhow.napaonline.com

How to Fix a Coolant Leak » NAPA Blog What Causes Cnc Coolant To Foam Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. “if you have two 90° elbows in. Foam acts as an insulator, preventing the coolant from. Coolant foaming can. What Causes Cnc Coolant To Foam.

From www.justanswer.com

I noticed my coolant is really thick foam in my expansion tank I have What Causes Cnc Coolant To Foam Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. What is cnc coolant and why is it important? Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. What. What Causes Cnc Coolant To Foam.

From www.youtube.com

5 Reasons To Keep Machining Coolant Clean YouTube What Causes Cnc Coolant To Foam This is very simple, and many times the cause for excessive foam. Coolant foaming can cause several problems: Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. Obviously, if the chip tray. What Causes Cnc Coolant To Foam.

From www.tsikot.com

Foam in radiator coolant Page 2 What Causes Cnc Coolant To Foam What is cnc coolant and why is it important? This is very simple, and many times the cause for excessive foam. What are the risks of poor coolant. Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. “if you have two 90° elbows in. Foam acts as an insulator, preventing the coolant from. Obviously, if the chip. What Causes Cnc Coolant To Foam.

From www.mscdirect.com

Monroe Fluid Technology AntiFoam, Coolant, Cutting, Drilling What Causes Cnc Coolant To Foam “if you have two 90° elbows in. Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. What is the. What Causes Cnc Coolant To Foam.

From www.hai-lu-oil.com

What causes FOAMING COOLANT? Metalworking Fluid & Oil & Lubricant What Causes Cnc Coolant To Foam “if you have two 90° elbows in. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. Foam acts as an insulator, preventing the coolant from. Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which. What Causes Cnc Coolant To Foam.

From www.reddit.com

Foam when flushing coolant r/G37 What Causes Cnc Coolant To Foam Foam acts as an insulator, preventing the coolant from. Obviously, if the chip tray gets too full and coolant is foamy it. What are the risks of poor coolant. Coolant foaming can cause several problems: This is very simple, and many times the cause for excessive foam. What is cnc coolant and why is it important? “if you have two. What Causes Cnc Coolant To Foam.

From www.youtube.com

Finding a coolant leak and fixing it. YouTube What Causes Cnc Coolant To Foam Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. Foam acts as an insulator, preventing the coolant from. “if. What Causes Cnc Coolant To Foam.

From mechanicbase.com

What Causes Bubbles in the Coolant Reservoir? What Causes Cnc Coolant To Foam Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. Foaming in cnc machining coolant systems is. What Causes Cnc Coolant To Foam.

From upgradedvehicle.com

Coolant Foaming Causes & Solutions Upgraded Vehicle What Causes Cnc Coolant To Foam What is cnc coolant and why is it important? Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. What is the life expectancy of cnc coolant and can. What Causes Cnc Coolant To Foam.

From www.lab-testinstruments.com

Coolant Foam Propensity Tester ASTM D1881 Engine Coolant Bubble What Causes Cnc Coolant To Foam Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. What is the life expectancy of cnc coolant and can it go bad? What is cnc coolant and why is it important? Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. “if. What Causes Cnc Coolant To Foam.

From mechanicbase.com

Why Is There Rust In My Coolant? What Causes Cnc Coolant To Foam Obviously, if the chip tray gets too full and coolant is foamy it. What is cnc coolant and why is it important? What are the risks of poor coolant. Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. Coolant foaming can cause several problems:. What Causes Cnc Coolant To Foam.

From www.youtube.com

KWF02CNC coolant tank cleaningSludge Cleaner (English) YouTube What Causes Cnc Coolant To Foam Coolant foaming can cause several problems: Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. This is very simple, and many times the cause for excessive foam. Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. What is the life expectancy. What Causes Cnc Coolant To Foam.

From lns-northamerica.com

How High Pressure Coolant Delivery Improves Profits & Productivity for What Causes Cnc Coolant To Foam Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. “if you have two 90° elbows in. Coolant foaming can cause several problems: Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. Foam acts as an insulator, preventing the coolant from. Foaming in cnc machining coolant systems is a common issue. What Causes Cnc Coolant To Foam.

From www.riansclub.com

Understand The Types Of CNC Coolant Delivery Systems In CNC Machining What Causes Cnc Coolant To Foam This is very simple, and many times the cause for excessive foam. What is cnc coolant and why is it important? Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. What are the risks of poor coolant. What is the life expectancy of cnc coolant and can it go bad? Obviously, if the chip tray gets too. What Causes Cnc Coolant To Foam.

From kentcnc.com

5 Things To Know About HighPressure Coolant Systems Kent CNC What Causes Cnc Coolant To Foam What are the risks of poor coolant. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. Foam acts as an insulator, preventing the coolant from. Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. Foaming in cnc. What Causes Cnc Coolant To Foam.

From www.machines4u.com.au

Quick Tips to Prolong Your Metalworking Coolant What Causes Cnc Coolant To Foam Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. “if you have two 90° elbows in. This is very simple, and many times the cause for excessive foam. What are the risks of poor coolant. Obviously, if the chip tray gets too full and coolant is foamy it. Foam overs not only create. What Causes Cnc Coolant To Foam.

From www.penninelubricants.co.uk

8 Reasons your Coolant is Foaming & How to Stop it. Pennine Lubricants What Causes Cnc Coolant To Foam Foaming in cnc coolant systems can significantly hinder machining performance and efficiency. Coolant should flow in as straight a line as possible, but sometimes plumbing causes foaming issues. Coolant foaming can cause several problems: Obviously, if the chip tray gets too full and coolant is foamy it. “if you have two 90° elbows in. What are the risks of poor. What Causes Cnc Coolant To Foam.

From www.cnccookbook.com.s3-website-us-east-1.amazonaws.com

Total Guide to CNC Router Vacuum Tables What Causes Cnc Coolant To Foam Foam acts as an insulator, preventing the coolant from. Obviously, if the chip tray gets too full and coolant is foamy it. Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. This is very simple, and many times the cause for excessive foam. “if. What Causes Cnc Coolant To Foam.

From www.youtube.com

CNC Coolant Systems & Basics Flood Coolant, Dry, MQL & More! YouTube What Causes Cnc Coolant To Foam Foam overs not only create a mess but cause downtime to clean and allow the foam to dissipate, which leads to a loss in production. What is cnc coolant and why is it important? Foaming in cnc machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the. Coolant. What Causes Cnc Coolant To Foam.

From www.riansclub.com

Understand The Types Of CNC Coolant Delivery Systems In CNC Machining What Causes Cnc Coolant To Foam This is very simple, and many times the cause for excessive foam. “if you have two 90° elbows in. What are the risks of poor coolant. Foam acts as an insulator, preventing the coolant from. Obviously, if the chip tray gets too full and coolant is foamy it. Coolant foaming can cause several problems: Coolant should flow in as straight. What Causes Cnc Coolant To Foam.