Bottle Neck Diagram . A bottleneck is any point where the output of one area is building up in another area nearby. Managers can use the bottleneck analysis to gain insights and implement process improvements designed to eliminate the issues. A bottleneck refers to a point in a system where the flow of data or processes is limited, leading to a slowdown in overall performance. A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that. Because of this, the entire process takes more time as compared to the expected time to finish the work. It constrains the ability to process goods or services according to plan. A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). Identifying and resolving such bottlenecks. How do you reduce or eliminate bottleneck effects?. Bottleneck analysis is the method of identifying the bottleneck in the process, where the actual problem in the process is occurring. It involves identifying and prioritizing the steps that take the most time, resources, or effort and analyzing them to identify the root causes of the inefficiencies. Bottleneck analysis is a management tool used to identify constraints and inefficiencies in a system or process that limit its capacity and productivity. How do you detect a workflow bottleneck?

from www.slideteam.net

A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). How do you reduce or eliminate bottleneck effects?. Bottleneck analysis is a management tool used to identify constraints and inefficiencies in a system or process that limit its capacity and productivity. Because of this, the entire process takes more time as compared to the expected time to finish the work. A bottleneck refers to a point in a system where the flow of data or processes is limited, leading to a slowdown in overall performance. Bottleneck analysis is the method of identifying the bottleneck in the process, where the actual problem in the process is occurring. It involves identifying and prioritizing the steps that take the most time, resources, or effort and analyzing them to identify the root causes of the inefficiencies. How do you detect a workflow bottleneck? A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that. Managers can use the bottleneck analysis to gain insights and implement process improvements designed to eliminate the issues.

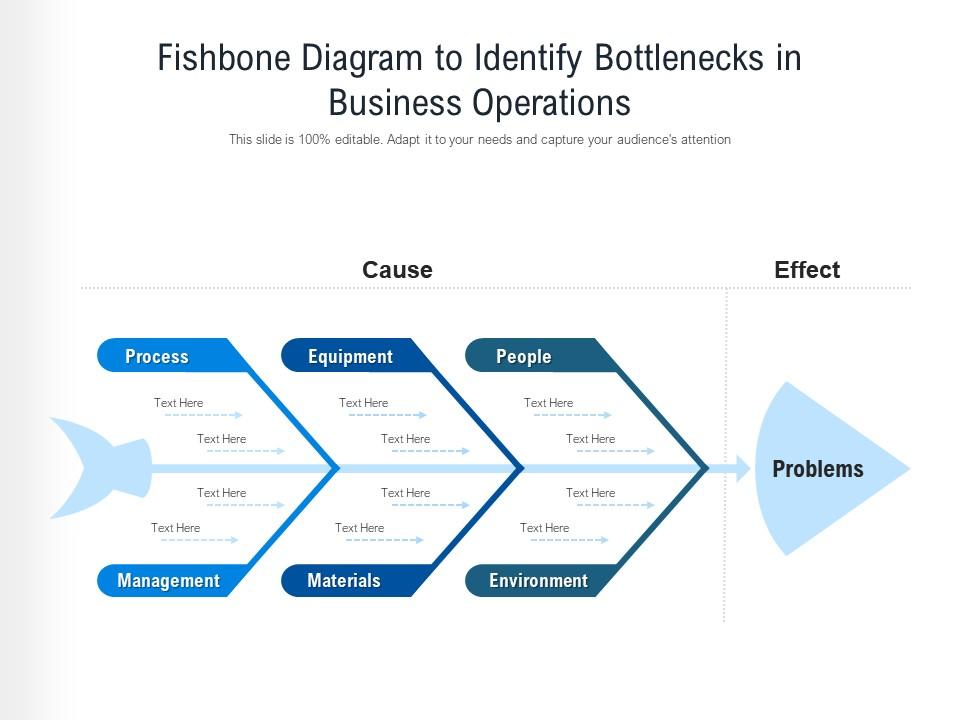

Fishbone Diagram To Identify Bottlenecks In Business Operations

Bottle Neck Diagram A bottleneck refers to a point in a system where the flow of data or processes is limited, leading to a slowdown in overall performance. A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that. How do you reduce or eliminate bottleneck effects?. Bottleneck analysis is the method of identifying the bottleneck in the process, where the actual problem in the process is occurring. It constrains the ability to process goods or services according to plan. How do you detect a workflow bottleneck? A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). Identifying and resolving such bottlenecks. A bottleneck refers to a point in a system where the flow of data or processes is limited, leading to a slowdown in overall performance. Managers can use the bottleneck analysis to gain insights and implement process improvements designed to eliminate the issues. Bottleneck analysis is a management tool used to identify constraints and inefficiencies in a system or process that limit its capacity and productivity. Because of this, the entire process takes more time as compared to the expected time to finish the work. It involves identifying and prioritizing the steps that take the most time, resources, or effort and analyzing them to identify the root causes of the inefficiencies. A bottleneck is any point where the output of one area is building up in another area nearby.

From leansigmavn.com

Bottleneck Analysis Khóa học phân tích nút thắt cổ chai Bottleneck Bottle Neck Diagram A bottleneck is any point where the output of one area is building up in another area nearby. A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). A bottleneck refers to a point in a system where the flow of data or processes is. Bottle Neck Diagram.

From www.howimportant.com

The Importance Of Wine Terminology When Buying A White Wine How Important Bottle Neck Diagram A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). Bottleneck analysis is the method of identifying the bottleneck in the process, where the actual problem in the process is occurring. Bottleneck analysis is a management tool used to identify constraints and inefficiencies in a. Bottle Neck Diagram.

From www.animalia-life.club

Bottleneck Diagram Bottle Neck Diagram How do you detect a workflow bottleneck? A bottleneck is any point where the output of one area is building up in another area nearby. A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that. Bottleneck analysis is a management tool used to identify constraints and inefficiencies in. Bottle Neck Diagram.

From powerslides.com

Bottleneck Analysis Template Unclog Inefficiencies Bottle Neck Diagram Managers can use the bottleneck analysis to gain insights and implement process improvements designed to eliminate the issues. A bottleneck is any point where the output of one area is building up in another area nearby. A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that. Bottleneck analysis. Bottle Neck Diagram.

From www.animalia-life.club

Bottleneck Diagram Bottle Neck Diagram How do you detect a workflow bottleneck? Because of this, the entire process takes more time as compared to the expected time to finish the work. How do you reduce or eliminate bottleneck effects?. A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). Managers. Bottle Neck Diagram.

From www.researchgate.net

An illustrative diagram of the bottleneck. Download Scientific Diagram Bottle Neck Diagram Identifying and resolving such bottlenecks. A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). Managers can use the bottleneck analysis to gain insights and implement process improvements designed to eliminate the issues. Bottleneck analysis is the method of identifying the bottleneck in the process,. Bottle Neck Diagram.

From dev.powerslides.com

SEO Diagrams Download & Edit PowerSlides™ Bottle Neck Diagram How do you reduce or eliminate bottleneck effects?. It involves identifying and prioritizing the steps that take the most time, resources, or effort and analyzing them to identify the root causes of the inefficiencies. Identifying and resolving such bottlenecks. Bottleneck analysis is a management tool used to identify constraints and inefficiencies in a system or process that limit its capacity. Bottle Neck Diagram.

From bottleinfo.historicbottles.com

Bottle Morphology Bottle Neck Diagram Bottleneck analysis is the method of identifying the bottleneck in the process, where the actual problem in the process is occurring. It constrains the ability to process goods or services according to plan. Bottleneck analysis is a management tool used to identify constraints and inefficiencies in a system or process that limit its capacity and productivity. How do you detect. Bottle Neck Diagram.

From quizlet.com

Bottleneck Ex 1 Diagram Quizlet Bottle Neck Diagram It involves identifying and prioritizing the steps that take the most time, resources, or effort and analyzing them to identify the root causes of the inefficiencies. Because of this, the entire process takes more time as compared to the expected time to finish the work. A bottleneck analysis is an important process in manufacturing that can help remove or mitigate. Bottle Neck Diagram.

From www.youtube.com

Session 1 Bottleneck & Process Mapping YouTube Bottle Neck Diagram Bottleneck analysis is the method of identifying the bottleneck in the process, where the actual problem in the process is occurring. A bottleneck refers to a point in a system where the flow of data or processes is limited, leading to a slowdown in overall performance. It constrains the ability to process goods or services according to plan. It involves. Bottle Neck Diagram.

From old.sermitsiaq.ag

Bottle Neck Label Template Bottle Neck Diagram It involves identifying and prioritizing the steps that take the most time, resources, or effort and analyzing them to identify the root causes of the inefficiencies. Bottleneck analysis is a management tool used to identify constraints and inefficiencies in a system or process that limit its capacity and productivity. How do you detect a workflow bottleneck? Bottleneck analysis is the. Bottle Neck Diagram.

From engineeringwithmanagement.com

Bottleneck operation in manufacturing processes Engineering with Bottle Neck Diagram It involves identifying and prioritizing the steps that take the most time, resources, or effort and analyzing them to identify the root causes of the inefficiencies. How do you detect a workflow bottleneck? A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). A bottleneck. Bottle Neck Diagram.

From accountinguide.com

Bottleneck in Production Definition Example Solution Accountinguide Bottle Neck Diagram Because of this, the entire process takes more time as compared to the expected time to finish the work. Bottleneck analysis is the method of identifying the bottleneck in the process, where the actual problem in the process is occurring. A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and. Bottle Neck Diagram.

From bigomics.ch

The Shifting Bottleneck in Genome Data Research Bottle Neck Diagram Because of this, the entire process takes more time as compared to the expected time to finish the work. It constrains the ability to process goods or services according to plan. A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). How do you reduce. Bottle Neck Diagram.

From www.mangolive.com

Bottleneck Analysis Bottle Neck Diagram A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). It constrains the ability to process goods or services according to plan. How do you reduce or eliminate bottleneck effects?. A bottleneck refers to a point in a system where the flow of data or. Bottle Neck Diagram.

From www.animalia-life.club

Bottleneck Diagram Bottle Neck Diagram A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that. Identifying and resolving such bottlenecks. Managers can use the bottleneck analysis to gain insights and implement process improvements designed to eliminate the issues. It involves identifying and prioritizing the steps that take the most time, resources, or effort. Bottle Neck Diagram.

From www.slidekit.com

Bottleneck Diagram Slide Template SlideKit Bottle Neck Diagram Because of this, the entire process takes more time as compared to the expected time to finish the work. A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that. Identifying and resolving such bottlenecks. It constrains the ability to process goods or services according to plan. It involves. Bottle Neck Diagram.

From slidemodel.com

5 Steps Bottleneck Diagram 2 Arrow PPT SlideModel Bottle Neck Diagram It involves identifying and prioritizing the steps that take the most time, resources, or effort and analyzing them to identify the root causes of the inefficiencies. Bottleneck analysis is the method of identifying the bottleneck in the process, where the actual problem in the process is occurring. A bottleneck is a point of congestion in a production system such as. Bottle Neck Diagram.

From www.cgdirector.com

When Should You Upgrade Your CPU? Bottle Neck Diagram Because of this, the entire process takes more time as compared to the expected time to finish the work. It involves identifying and prioritizing the steps that take the most time, resources, or effort and analyzing them to identify the root causes of the inefficiencies. A bottleneck is a point of congestion in a production system such as a manufacturing. Bottle Neck Diagram.

From www.slideteam.net

Fishbone Diagram To Identify Bottlenecks In Business Operations Bottle Neck Diagram A bottleneck refers to a point in a system where the flow of data or processes is limited, leading to a slowdown in overall performance. A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that. Because of this, the entire process takes more time as compared to the. Bottle Neck Diagram.

From clipground.com

Bottle neck clipart 20 free Cliparts Download images on Clipground 2024 Bottle Neck Diagram It constrains the ability to process goods or services according to plan. How do you detect a workflow bottleneck? A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that. Because of this, the entire process takes more time as compared to the expected time to finish the work.. Bottle Neck Diagram.

From slidemodel.com

Free Bottleneck Diagram Template for PowerPoint SlideModel Bottle Neck Diagram Bottleneck analysis is a management tool used to identify constraints and inefficiencies in a system or process that limit its capacity and productivity. How do you detect a workflow bottleneck? A bottleneck is any point where the output of one area is building up in another area nearby. Because of this, the entire process takes more time as compared to. Bottle Neck Diagram.

From slidesdocs.com

Diagram Of Bottle Neck Diagram With Arrows Pointing In Different Bottle Neck Diagram Bottleneck analysis is the method of identifying the bottleneck in the process, where the actual problem in the process is occurring. Identifying and resolving such bottlenecks. It constrains the ability to process goods or services according to plan. A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that.. Bottle Neck Diagram.

From www.animalia-life.club

Bottleneck Diagram Bottle Neck Diagram It constrains the ability to process goods or services according to plan. How do you detect a workflow bottleneck? A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that. It involves identifying and prioritizing the steps that take the most time, resources, or effort and analyzing them to. Bottle Neck Diagram.

From thenaturalhistorian.com

The Great Bottleneck that Contradicts Ken Ham’s Radical Bottle Neck Diagram A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). A bottleneck refers to a point in a system where the flow of data or processes is limited, leading to a slowdown in overall performance. Bottleneck analysis is the method of identifying the bottleneck in. Bottle Neck Diagram.

From www.vrogue.co

5 Insightful Bottleneck Analysis Examples Mosimtec vrogue.co Bottle Neck Diagram Bottleneck analysis is the method of identifying the bottleneck in the process, where the actual problem in the process is occurring. Bottleneck analysis is a management tool used to identify constraints and inefficiencies in a system or process that limit its capacity and productivity. Because of this, the entire process takes more time as compared to the expected time to. Bottle Neck Diagram.

From wordpress.condatis.org.uk

How Condatis works and screenshots Bottle Neck Diagram How do you reduce or eliminate bottleneck effects?. A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that. It constrains the ability to process goods or services according to plan. A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive. Bottle Neck Diagram.

From ar.inspiredpencil.com

Bottleneck Diagram Bottle Neck Diagram Because of this, the entire process takes more time as compared to the expected time to finish the work. A bottleneck is any point where the output of one area is building up in another area nearby. Managers can use the bottleneck analysis to gain insights and implement process improvements designed to eliminate the issues. A bottleneck refers to a. Bottle Neck Diagram.

From www.expii.com

What is the Bottleneck Effect? — Definition & Examples Expii Bottle Neck Diagram A bottleneck is any point where the output of one area is building up in another area nearby. Identifying and resolving such bottlenecks. A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). It involves identifying and prioritizing the steps that take the most time,. Bottle Neck Diagram.

From slidemodel.com

5Step Bottleneck Diagram PowerPoint Template SlideModel Bottle Neck Diagram Because of this, the entire process takes more time as compared to the expected time to finish the work. It involves identifying and prioritizing the steps that take the most time, resources, or effort and analyzing them to identify the root causes of the inefficiencies. It constrains the ability to process goods or services according to plan. A bottleneck is. Bottle Neck Diagram.

From www.berlinpackaging.com

Anatomy of a Bottle from Top to Bottom Berlin Packaging Bottle Neck Diagram How do you detect a workflow bottleneck? A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that. How do you reduce or eliminate bottleneck effects?. It constrains the ability to process goods or services according to plan. Because of this, the entire process takes more time as compared. Bottle Neck Diagram.

From www.myxxgirl.com

Editable Arrows Powerpoint Diagram Bottleneck Slidemodel My XXX Hot Girl Bottle Neck Diagram How do you detect a workflow bottleneck? Bottleneck analysis is a management tool used to identify constraints and inefficiencies in a system or process that limit its capacity and productivity. Identifying and resolving such bottlenecks. Because of this, the entire process takes more time as compared to the expected time to finish the work. A bottleneck is any point where. Bottle Neck Diagram.

From stgblog.rheincs.net

How to Identify Bottlenecks in Your Manufacturing Process Bottle Neck Diagram A bottleneck is any point where the output of one area is building up in another area nearby. Because of this, the entire process takes more time as compared to the expected time to finish the work. Managers can use the bottleneck analysis to gain insights and implement process improvements designed to eliminate the issues. Bottleneck analysis is the method. Bottle Neck Diagram.

From www.cgdirector.com

What is Bottlenecking My PC and How Do I Fix It? Bottle Neck Diagram Because of this, the entire process takes more time as compared to the expected time to finish the work. A bottleneck analysis is an important process in manufacturing that can help remove or mitigate production holdups, drive efficiency, and improve overall equipment effectiveness (oee). It involves identifying and prioritizing the steps that take the most time, resources, or effort and. Bottle Neck Diagram.

From www.pipedrive.com

What Is a Bottleneck in Business? Pipedrive Bottle Neck Diagram Because of this, the entire process takes more time as compared to the expected time to finish the work. Managers can use the bottleneck analysis to gain insights and implement process improvements designed to eliminate the issues. A bottleneck is any point where the output of one area is building up in another area nearby. It constrains the ability to. Bottle Neck Diagram.