Compressed Air In Sterile Processing . Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment booms (see figure 1). Sterile air is a key requirement and utilising. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. For classes a and b, a 0.2 µm point of use filter must ensure the sterility and the required reduction of the particle load for. Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. A medical gas that is not respired, is filtered. Portable medical compressed air for single applications. The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. Completing a risk assessment can help account for each of these factors and determine the appropriate purity classes for your compressed air. The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms.

from www.airbestpractices.com

A medical gas that is not respired, is filtered. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. Sterile air is a key requirement and utilising. For classes a and b, a 0.2 µm point of use filter must ensure the sterility and the required reduction of the particle load for. Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. Completing a risk assessment can help account for each of these factors and determine the appropriate purity classes for your compressed air. Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment booms (see figure 1). The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms. Portable medical compressed air for single applications. The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production.

Air Quality Standards ISO 8573.1 & ISO12500 Compressed Air Best Practices

Compressed Air In Sterile Processing For classes a and b, a 0.2 µm point of use filter must ensure the sterility and the required reduction of the particle load for. Portable medical compressed air for single applications. Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment booms (see figure 1). Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. A medical gas that is not respired, is filtered. Completing a risk assessment can help account for each of these factors and determine the appropriate purity classes for your compressed air. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms. Sterile air is a key requirement and utilising. For classes a and b, a 0.2 µm point of use filter must ensure the sterility and the required reduction of the particle load for. The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production.

From www.donaldson.com

LifeTec™ PSRF V Sterile Vent Filter Element Donaldson Compressed Air & Process Compressed Air In Sterile Processing Completing a risk assessment can help account for each of these factors and determine the appropriate purity classes for your compressed air. Sterile air is a key requirement and utilising. A medical gas that is not respired, is filtered. The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. Gases and air coming. Compressed Air In Sterile Processing.

From sollantcompressor.com

Oil Free Air Compressor for Pharmaceutical Industry Compressed Air In Sterile Processing The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms. Portable medical compressed air for single applications. For classes a and b, a 0.2 µm point of use filter. Compressed Air In Sterile Processing.

From www.industrialair.co.nz

Sterile & Process Compressed Air Layout Free Guidelines IAS Compressed Air In Sterile Processing The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms. A medical gas that is not respired, is filtered. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. Gases and. Compressed Air In Sterile Processing.

From www.donaldson.com

How to Meet SQF Food Safety Standard Donaldson Compressed Air & Process Compressed Air In Sterile Processing Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment booms (see figure 1). A medical gas that is not respired, is filtered. For classes a and b, a 0.2 µm point of use filter must ensure the sterility and the required reduction of the particle load for. Sterile air is a key requirement and. Compressed Air In Sterile Processing.

From www.ultra-filter.com

Process Air Compressed Air In Sterile Processing For classes a and b, a 0.2 µm point of use filter must ensure the sterility and the required reduction of the particle load for. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. Sterile air is a key requirement and utilising. Surgical suites. Compressed Air In Sterile Processing.

From www.airbestpractices.com

Air Quality Standards ISO 8573.1 & ISO12500 Compressed Air Best Practices Compressed Air In Sterile Processing A medical gas that is not respired, is filtered. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. Portable medical compressed air for single. Compressed Air In Sterile Processing.

From www.donaldson.com

LifeTec™ PSRF V Sterile Vent Filter Element Donaldson Compressed Air & Process Compressed Air In Sterile Processing Sterile air is a key requirement and utilising. The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms. A medical gas that is not respired, is filtered. Portable medical compressed air for single applications. Gases and air coming into contact with a pharmaceutical product must be. Compressed Air In Sterile Processing.

From exosisuhg.blob.core.windows.net

Compressed Air Filter Requirements For Food Processing at Judith Robinson blog Compressed Air In Sterile Processing A medical gas that is not respired, is filtered. The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. Portable medical compressed air for single applications. Completing a. Compressed Air In Sterile Processing.

From www.youtube.com

How to Test Compressed Air for Microbial Contamination Parker Hannifin YouTube Compressed Air In Sterile Processing Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment booms (see figure 1). Sterile air is a key requirement and utilising. Portable medical compressed air for single applications. The removal of airborne microorganisms in. Compressed Air In Sterile Processing.

From www.dreamstime.com

Sterilization Process, with Instruments Being Placed in Autoclave and Heated To High Temperature Compressed Air In Sterile Processing The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms. Portable medical compressed air for single applications. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. For classes a and. Compressed Air In Sterile Processing.

From shdenair.en.made-in-china.com

100 Clean Air Oil Free Screw Air Compressor for Sterile Processing Industry China Oil Free Compressed Air In Sterile Processing Sterile air is a key requirement and utilising. For classes a and b, a 0.2 µm point of use filter must ensure the sterility and the required reduction of the particle load for. Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. The ispe good practice guide (2016) states. Compressed Air In Sterile Processing.

From www.airbestpractices.com

Sterile Compressed Air Filters Remove Bacteria Compressed Air Best Practices Compressed Air In Sterile Processing Portable medical compressed air for single applications. Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. A medical gas that is not respired, is filtered. Sterile air is a key requirement and utilising. The three areas in a healthcare building most likely to require compressed air are surgical suites,. Compressed Air In Sterile Processing.

From www.donaldson.com

What Is Sterile Air and Why It Matters Donaldson Compressed Air & Process Compressed Air In Sterile Processing The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms. A medical gas that is not respired, is filtered. The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. For classes a and b, a 0.2 µm point of. Compressed Air In Sterile Processing.

From microbeonline.com

Autoclave Sterilization Principle, Procedure, Types, Uses • Microbe Online Compressed Air In Sterile Processing For classes a and b, a 0.2 µm point of use filter must ensure the sterility and the required reduction of the particle load for. Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment booms (see figure 1). Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical,. Compressed Air In Sterile Processing.

From www.donaldson.com

How to Meet SQF Food Safety Standard Donaldson Compressed Air & Process Compressed Air In Sterile Processing A medical gas that is not respired, is filtered. Completing a risk assessment can help account for each of these factors and determine the appropriate purity classes for your compressed air. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. Surgical suites typically need. Compressed Air In Sterile Processing.

From sterile.com

SMA Compressed Air/Gas Sampler Veltek Associates, Inc. Compressed Air In Sterile Processing The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms. The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. A medical gas that is not respired, is filtered. For classes a and b, a 0.2 µm point of. Compressed Air In Sterile Processing.

From www.tbjinc.com

TBJ Selecta Air and Water Pistols TBJ Incorporated Compressed Air In Sterile Processing Portable medical compressed air for single applications. Sterile air is a key requirement and utilising. Completing a risk assessment can help account for each of these factors and determine the appropriate purity classes for your compressed air. The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work. Compressed Air In Sterile Processing.

From www.donaldson.com

LifeTec™ PSRF V Sterile Vent Filter Element Donaldson Compressed Air & Process Compressed Air In Sterile Processing The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. Sterile air is a key requirement and utilising. Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment. Compressed Air In Sterile Processing.

From www.donaldson.com

Compressed Air & Process Filtration Donaldson Compressed Air & Process Compressed Air In Sterile Processing The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms. Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment booms. Compressed Air In Sterile Processing.

From catr.com.au

STERILE COMPRESSED AIR FILTERS CATR Compressed Air In Sterile Processing Sterile air is a key requirement and utilising. Portable medical compressed air for single applications. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment booms (see figure 1). Gases. Compressed Air In Sterile Processing.

From dts-retort.en.made-in-china.com

Manufacture Intelligent Steam and Air Retort/Sterilizer for Vacuum Packed Food ASME CE Dosh Compressed Air In Sterile Processing For classes a and b, a 0.2 µm point of use filter must ensure the sterility and the required reduction of the particle load for. Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. A medical gas that is not respired, is filtered. The three areas in a healthcare. Compressed Air In Sterile Processing.

From www.csofl.com

LeeSar Sterile Processing Cooperative Services of Florida Compressed Air In Sterile Processing Sterile air is a key requirement and utilising. Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment booms (see figure 1). The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. Completing a risk assessment can help account for each of these factors and determine the appropriate. Compressed Air In Sterile Processing.

From www.alamy.com

Drying of surgical instruments with medical compressed air, Zentrale Compressed Air In Sterile Processing Completing a risk assessment can help account for each of these factors and determine the appropriate purity classes for your compressed air. Sterile air is a key requirement and utilising. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. Portable medical compressed air for. Compressed Air In Sterile Processing.

From www.donaldson.com

Filter Design for Culinary Steam Requirements Donaldson Compressed Air & Process Compressed Air In Sterile Processing The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms. Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. A medical gas that is not respired, is filtered. Surgical suites typically need compressed air to. Compressed Air In Sterile Processing.

From cssdtechnicianhub.com

Sterile Processing Guidelines and Objectives CSSD Technician Hub Compressed Air In Sterile Processing The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. The removal of airborne microorganisms in air compressor environments is essential. Compressed Air In Sterile Processing.

From www.donaldson.com

Sterile Air Checklist for Fermentation Processors Donaldson Compressed Air and Process Compressed Air In Sterile Processing Portable medical compressed air for single applications. A medical gas that is not respired, is filtered. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. For classes a and b, a 0.2 µm point of use filter must ensure the sterility and the required. Compressed Air In Sterile Processing.

From www.pinterest.com

Central Sterile Processing and Distribution CSSD Technician Hub Sterile processing tech Compressed Air In Sterile Processing The three areas in a healthcare building most likely to require compressed air are surgical suites, sterile processing areas and maintenance shops/biomedical work rooms. The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. Completing a risk assessment can help account for each of these factors and determine the appropriate purity classes for. Compressed Air In Sterile Processing.

From www.donaldson.com

Filter Design for Culinary Steam Requirements Donaldson Compressed Air & Process Compressed Air In Sterile Processing A medical gas that is not respired, is filtered. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. Surgical suites typically need compressed air to drive tools. Compressed Air In Sterile Processing.

From www.donaldson.com

Keep Your Product Recovery System Sterile Donaldson Compressed Air & Process Compressed Air In Sterile Processing Portable medical compressed air for single applications. The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment booms. Compressed Air In Sterile Processing.

From valortecs.com

H2O2 sterilization — VALORTECS Process technologies Compressed Air In Sterile Processing Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment booms (see figure 1). The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. Completing a risk assessment can help account for each of these factors and determine the appropriate. Compressed Air In Sterile Processing.

From www.donaldson.com

Sterile & Ventilation Filter Test Center Donaldson Compressed Air & Process Compressed Air In Sterile Processing For classes a and b, a 0.2 µm point of use filter must ensure the sterility and the required reduction of the particle load for. The ispe good practice guide (2016) states that sample points should be regularly maintained and should not introduce a risk of contamination to the system. Portable medical compressed air for single applications. Completing a risk. Compressed Air In Sterile Processing.

From shdenair.en.made-in-china.com

Dww Series Dry Oil Free Rotary Screw Air Compressor for Sterile Processing Oil Free Air Compressed Air In Sterile Processing Surgical suites typically need compressed air to drive tools and for pneumatic brakes in equipment booms (see figure 1). A medical gas that is not respired, is filtered. Sterile air is a key requirement and utilising. Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. The removal of airborne. Compressed Air In Sterile Processing.

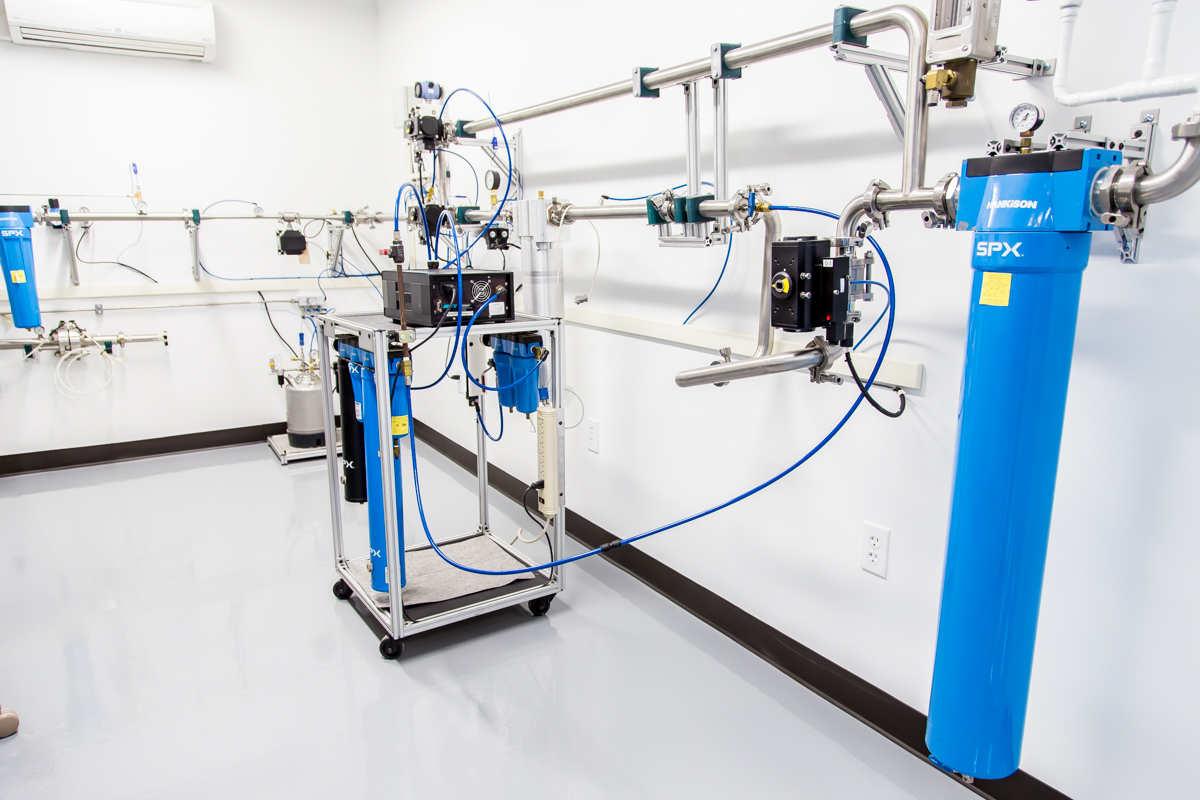

From www.hospitalfs.com

STERILE PROCESSING DECONTAMINATION LAB AIR COMPRESSOR Compressed Air In Sterile Processing Completing a risk assessment can help account for each of these factors and determine the appropriate purity classes for your compressed air. The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. Sterile air is a key requirement and utilising. Portable medical compressed air for single applications. For classes a and b, a. Compressed Air In Sterile Processing.

From www.hospitalfs.com

STERILE PROCESSING DECONTAMINATION LAB AIR COMPRESSOR Compressed Air In Sterile Processing The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. For classes a and b, a 0.2 µm point of use filter must ensure the sterility and the required reduction of the particle load for. A medical gas that is not respired, is filtered. Gases and air coming into contact with a pharmaceutical. Compressed Air In Sterile Processing.

From jobs.northwell.edu

Day in the life Central Sterile Processing Technician Northwell Careers Compressed Air In Sterile Processing The removal of airborne microorganisms in air compressor environments is essential to successful food and beverage production. Sterile air is a key requirement and utilising. Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. The three areas in a healthcare building most likely to require compressed air are surgical. Compressed Air In Sterile Processing.