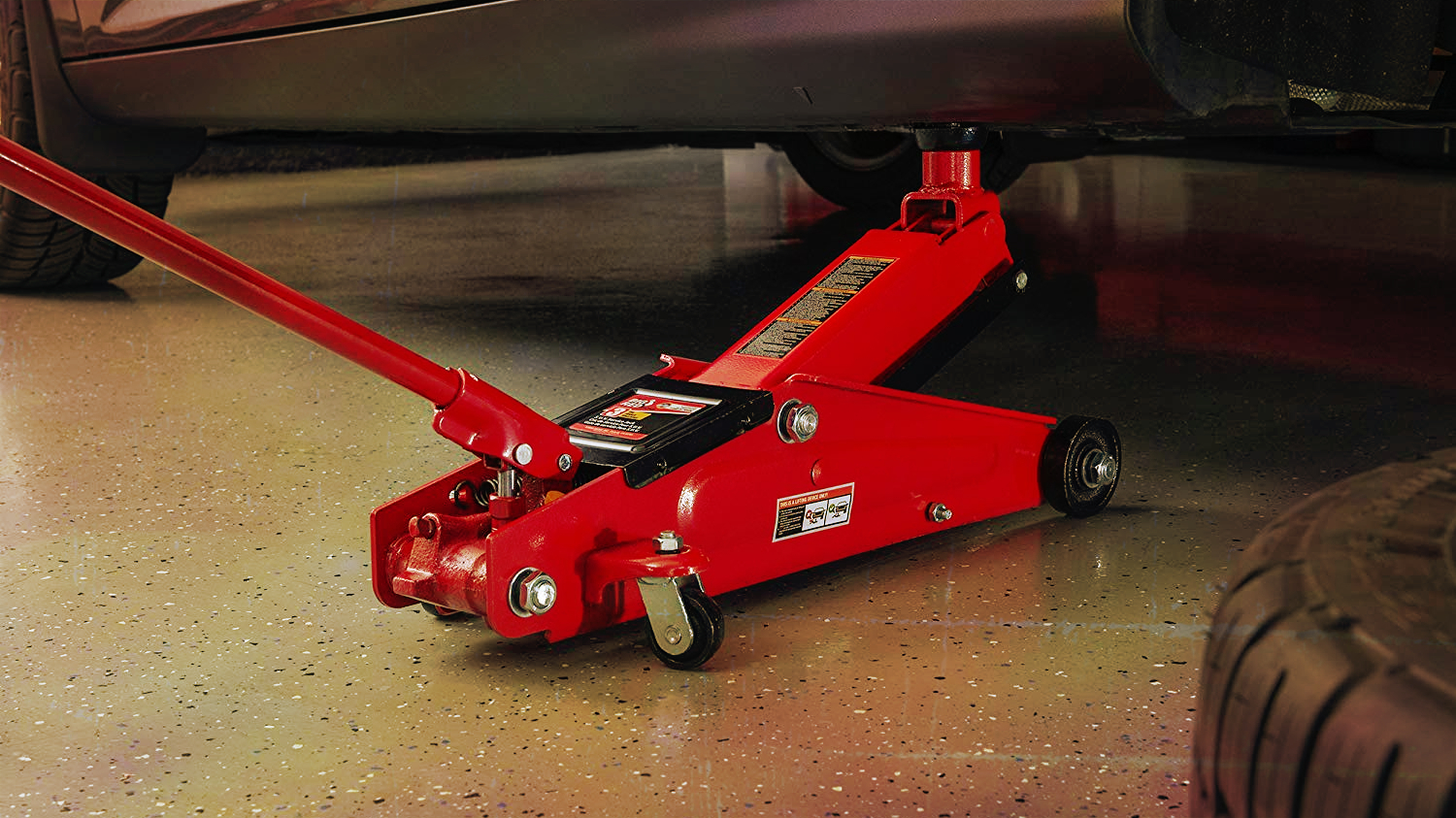

Floor Jacks Repair . Here are the steps you should follow: In this video i show you how to fix a few common problems with your hydraulic floor jack. If you notice any of these problems, it is important to address them as soon as possible. Perform overall inspection once again. In most cases, the solution is quite simple. The first step in repairing your hydraulic floor jack is to identify the problem. Common problems include slow lifting, leaking fluid, and an inability to hold a load. They are easy to repair and it can save. First of all, take a deep breath, and calm down. So what can you do with a floor jack that won’t hold pressure? Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. So you need to get the air out of the hydraulic oil. These three problems can usually all be solved by bleeding the floor jack of trapped air. Check the hydraulic fluid level; Unlike hydraulic oil, air can be compressed.

from www.knockoutengine.com

Here are the steps you should follow: Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. First of all, take a deep breath, and calm down. Check the hydraulic fluid level; So what can you do with a floor jack that won’t hold pressure? If you notice any of these problems, it is important to address them as soon as possible. So you need to get the air out of the hydraulic oil. Perform overall inspection once again. Common problems include slow lifting, leaking fluid, and an inability to hold a load. They are easy to repair and it can save.

Most Common Floor Jack Problems and Their Fixes KnockOutEngine

Floor Jacks Repair Perform overall inspection once again. Unlike hydraulic oil, air can be compressed. In this video i show you how to fix a few common problems with your hydraulic floor jack. If you notice any of these problems, it is important to address them as soon as possible. Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. Common problems include slow lifting, leaking fluid, and an inability to hold a load. They are easy to repair and it can save. The first step in repairing your hydraulic floor jack is to identify the problem. Check the hydraulic fluid level; In most cases, the solution is quite simple. These three problems can usually all be solved by bleeding the floor jack of trapped air. First of all, take a deep breath, and calm down. Here are the steps you should follow: So you need to get the air out of the hydraulic oil. So what can you do with a floor jack that won’t hold pressure? Perform overall inspection once again.

From jxzhongwan.en.made-in-china.com

2.75 Ton Hydraulic Pressure Floor Jacks Repair Shop Tools for Lifting Jacks 28kg China Floor Jacks Repair Check the hydraulic fluid level; In this video i show you how to fix a few common problems with your hydraulic floor jack. Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. They are easy to repair and it can save. In most cases, the solution. Floor Jacks Repair.

From www.youtube.com

Floor Jack Rebuild leaking down solved ? harbor freight jack performance tool floor jack kit Floor Jacks Repair If you notice any of these problems, it is important to address them as soon as possible. Unlike hydraulic oil, air can be compressed. So you need to get the air out of the hydraulic oil. Here are the steps you should follow: Perform overall inspection once again. Common problems include slow lifting, leaking fluid, and an inability to hold. Floor Jacks Repair.

From viewfloor.co

Pro Lift Floor Jack Repair Kit Viewfloor.co Floor Jacks Repair If you notice any of these problems, it is important to address them as soon as possible. Check the hydraulic fluid level; First of all, take a deep breath, and calm down. Perform overall inspection once again. So what can you do with a floor jack that won’t hold pressure? Common problems include slow lifting, leaking fluid, and an inability. Floor Jacks Repair.

From imagetou.com

Craftsman 4 Ton Floor Jack Rebuild Kit Image to u Floor Jacks Repair Check the hydraulic fluid level; These three problems can usually all be solved by bleeding the floor jack of trapped air. So you need to get the air out of the hydraulic oil. In this video i show you how to fix a few common problems with your hydraulic floor jack. The first step in repairing your hydraulic floor jack. Floor Jacks Repair.

From www.amazon.ca

328.12160 for Sears Floor Jack Rebuild Kit 2 Ton Floor Jack Repair Kit Fit for Sears Craftsman Floor Jacks Repair So you need to get the air out of the hydraulic oil. They are easy to repair and it can save. Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. So what can you do with a floor jack that won’t hold pressure? First of all,. Floor Jacks Repair.

From imagetou.com

How To Rebuild A Craftsman Floor Jack Image to u Floor Jacks Repair If you notice any of these problems, it is important to address them as soon as possible. So you need to get the air out of the hydraulic oil. They are easy to repair and it can save. Check the hydraulic fluid level; In this video i show you how to fix a few common problems with your hydraulic floor. Floor Jacks Repair.

From nordhomypefixmachine.z13.web.core.windows.net

Floor Jack Repair Kits Floor Jacks Repair First of all, take a deep breath, and calm down. Here are the steps you should follow: Unlike hydraulic oil, air can be compressed. In this video i show you how to fix a few common problems with your hydraulic floor jack. Check the hydraulic fluid level; Common problems include slow lifting, leaking fluid, and an inability to hold a. Floor Jacks Repair.

From carpet.vidalondon.net

Allied Floor Jack Repair Kits Carpet Vidalondon Floor Jacks Repair So what can you do with a floor jack that won’t hold pressure? They are easy to repair and it can save. First of all, take a deep breath, and calm down. In this video i show you how to fix a few common problems with your hydraulic floor jack. Check the hydraulic fluid level; Since the main operating principle. Floor Jacks Repair.

From jxzhongwan.en.made-in-china.com

3 Ton Hydraulic Pressure Floor Jacks Repair Shop Tools for Lifting Jacks 43kg China Hydraulic Floor Jacks Repair These three problems can usually all be solved by bleeding the floor jack of trapped air. Check the hydraulic fluid level; So what can you do with a floor jack that won’t hold pressure? Perform overall inspection once again. The first step in repairing your hydraulic floor jack is to identify the problem. In this video i show you how. Floor Jacks Repair.

From www.youtube.com

Repairing a Leaky Shinn Fu (ProLift) 21/2 Ton Floor Jack YouTube Floor Jacks Repair They are easy to repair and it can save. Perform overall inspection once again. If you notice any of these problems, it is important to address them as soon as possible. These three problems can usually all be solved by bleeding the floor jack of trapped air. First of all, take a deep breath, and calm down. So you need. Floor Jacks Repair.

From wirelistunscaling.z19.web.core.windows.net

Michelin 3.5 Ton Floor Jack Repair Floor Jacks Repair Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. Check the hydraulic fluid level; So you need to get the air out of the hydraulic oil. Perform overall inspection once again. If you notice any of these problems, it is important to address them as soon. Floor Jacks Repair.

From garagespot.com

How to Repair A Floor Jack That Won't Hold Pressure GarageSpot Floor Jacks Repair Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. In this video i show you how to fix a few common problems with your hydraulic floor jack. These three problems can usually all be solved by bleeding the floor jack of trapped air. Check the hydraulic. Floor Jacks Repair.

From irpsiea4schematic.z21.web.core.windows.net

Michelin G735 Floor Jack Parts Floor Jacks Repair First of all, take a deep breath, and calm down. Common problems include slow lifting, leaking fluid, and an inability to hold a load. So you need to get the air out of the hydraulic oil. So what can you do with a floor jack that won’t hold pressure? Unlike hydraulic oil, air can be compressed. In most cases, the. Floor Jacks Repair.

From jxzhongwan.en.made-in-china.com

3 Ton Hydraulic Pressure Floor Jacks Repair Shop Tools for Lifting Jacks Orange China Floor Jacks Repair If you notice any of these problems, it is important to address them as soon as possible. So what can you do with a floor jack that won’t hold pressure? First of all, take a deep breath, and calm down. So you need to get the air out of the hydraulic oil. Check the hydraulic fluid level; In most cases,. Floor Jacks Repair.

From palesilverroyalhomerenewal.netlify.app

Allied Hydraulic Floor Jack Repair Kit Floor Jacks Repair Common problems include slow lifting, leaking fluid, and an inability to hold a load. First of all, take a deep breath, and calm down. If you notice any of these problems, it is important to address them as soon as possible. Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a. Floor Jacks Repair.

From jxzhongwan.en.made-in-china.com

3 Ton Hydraulic Pressure Floor Jacks Repair Shop Tools for Lifting Jacks 36kg China Hydraulic Floor Jacks Repair The first step in repairing your hydraulic floor jack is to identify the problem. Unlike hydraulic oil, air can be compressed. They are easy to repair and it can save. Here are the steps you should follow: In most cases, the solution is quite simple. In this video i show you how to fix a few common problems with your. Floor Jacks Repair.

From www.youtube.com

MVP SuperLift Floor Jack Repair Pt 1 YouTube Floor Jacks Repair Check the hydraulic fluid level; Unlike hydraulic oil, air can be compressed. They are easy to repair and it can save. Common problems include slow lifting, leaking fluid, and an inability to hold a load. In most cases, the solution is quite simple. So you need to get the air out of the hydraulic oil. The first step in repairing. Floor Jacks Repair.

From www.wikihow.com

6 Ways to Maintain a Pro Lift F Series Hydraulic Floor Jack Floor Jacks Repair They are easy to repair and it can save. Unlike hydraulic oil, air can be compressed. Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. In most cases, the solution is quite simple. In this video i show you how to fix a few common problems. Floor Jacks Repair.

From www.youtube.com

Sears 1 1/2 ton floor jack, Repair? Just 40 years old! YouTube Floor Jacks Repair In most cases, the solution is quite simple. So what can you do with a floor jack that won’t hold pressure? First of all, take a deep breath, and calm down. These three problems can usually all be solved by bleeding the floor jack of trapped air. Check the hydraulic fluid level; Unlike hydraulic oil, air can be compressed. So. Floor Jacks Repair.

From repairfixsolorzanori.z21.web.core.windows.net

Floor Jack Repair Kits Floor Jacks Repair In this video i show you how to fix a few common problems with your hydraulic floor jack. Common problems include slow lifting, leaking fluid, and an inability to hold a load. If you notice any of these problems, it is important to address them as soon as possible. So you need to get the air out of the hydraulic. Floor Jacks Repair.

From carpet.vidalondon.net

Hydraulic Floor Jack Repair Parts Carpet Vidalondon Floor Jacks Repair So what can you do with a floor jack that won’t hold pressure? They are easy to repair and it can save. These three problems can usually all be solved by bleeding the floor jack of trapped air. The first step in repairing your hydraulic floor jack is to identify the problem. So you need to get the air out. Floor Jacks Repair.

From mikemelilla.blogspot.com

Ac Delco Floor Jack Rebuild Kit Floor Jacks Repair First of all, take a deep breath, and calm down. So what can you do with a floor jack that won’t hold pressure? The first step in repairing your hydraulic floor jack is to identify the problem. So you need to get the air out of the hydraulic oil. Perform overall inspection once again. In most cases, the solution is. Floor Jacks Repair.

From viewfloor.co

How To Repair A Napa Floor Jack Viewfloor.co Floor Jacks Repair If you notice any of these problems, it is important to address them as soon as possible. These three problems can usually all be solved by bleeding the floor jack of trapped air. In this video i show you how to fix a few common problems with your hydraulic floor jack. Unlike hydraulic oil, air can be compressed. They are. Floor Jacks Repair.

From www.youtube.com

Sears 2 Ton Floor Jack Complete Rebuild YouTube Floor Jacks Repair Check the hydraulic fluid level; So what can you do with a floor jack that won’t hold pressure? Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. Here are the steps you should follow: If you notice any of these problems, it is important to address. Floor Jacks Repair.

From carpet.vidalondon.net

Allied 3 Ton Floor Jack Repair Carpet Vidalondon Floor Jacks Repair Common problems include slow lifting, leaking fluid, and an inability to hold a load. Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. In this video i show you how to fix a few common problems with your hydraulic floor jack. So what can you do. Floor Jacks Repair.

From viewfloor.co

How To Fix A Broken Floor Jack Viewfloor.co Floor Jacks Repair Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. First of all, take a deep breath, and calm down. Here are the steps you should follow: So you need to get the air out of the hydraulic oil. In this video i show you how to. Floor Jacks Repair.

From imagetou.com

Repair Kit For Craftsman Floor Jack Image to u Floor Jacks Repair Check the hydraulic fluid level; Common problems include slow lifting, leaking fluid, and an inability to hold a load. Perform overall inspection once again. If you notice any of these problems, it is important to address them as soon as possible. Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a. Floor Jacks Repair.

From www.youtube.com

How to Repair A Broken Floor Jack That Won't Lift YouTube Floor Jacks Repair So what can you do with a floor jack that won’t hold pressure? So you need to get the air out of the hydraulic oil. If you notice any of these problems, it is important to address them as soon as possible. Here are the steps you should follow: They are easy to repair and it can save. Check the. Floor Jacks Repair.

From mybios.me

Larin Floor Jack Rebuild Kit My Bios Floor Jacks Repair If you notice any of these problems, it is important to address them as soon as possible. In most cases, the solution is quite simple. The first step in repairing your hydraulic floor jack is to identify the problem. So you need to get the air out of the hydraulic oil. So what can you do with a floor jack. Floor Jacks Repair.

From www.youtube.com

Cleaning and Reassembling Old Craftsman Floor Jack YouTube Floor Jacks Repair So what can you do with a floor jack that won’t hold pressure? Check the hydraulic fluid level; Perform overall inspection once again. First of all, take a deep breath, and calm down. So you need to get the air out of the hydraulic oil. Common problems include slow lifting, leaking fluid, and an inability to hold a load. In. Floor Jacks Repair.

From www.ehow.com

How to Fix a 3Ton Hydraulic Floor Jack It Still Runs Floor Jacks Repair Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. These three problems can usually all be solved by bleeding the floor jack of trapped air. Unlike hydraulic oil, air can be compressed. In most cases, the solution is quite simple. Check the hydraulic fluid level; Common. Floor Jacks Repair.

From carpet.vidalondon.net

Allied Floor Jack Repair Kits Carpet Vidalondon Floor Jacks Repair In most cases, the solution is quite simple. Here are the steps you should follow: If you notice any of these problems, it is important to address them as soon as possible. In this video i show you how to fix a few common problems with your hydraulic floor jack. These three problems can usually all be solved by bleeding. Floor Jacks Repair.

From www.knockoutengine.com

Most Common Floor Jack Problems and Their Fixes KnockOutEngine Floor Jacks Repair Check the hydraulic fluid level; They are easy to repair and it can save. So you need to get the air out of the hydraulic oil. Unlike hydraulic oil, air can be compressed. Perform overall inspection once again. If you notice any of these problems, it is important to address them as soon as possible. Common problems include slow lifting,. Floor Jacks Repair.

From www.youtube.com

How to fix a leaking floor jack YouTube Floor Jacks Repair Perform overall inspection once again. In this video i show you how to fix a few common problems with your hydraulic floor jack. Check the hydraulic fluid level; Since the main operating principle behind a floor jack is that fluid can’t be compressed, air can throw a wrench in the works. First of all, take a deep breath, and calm. Floor Jacks Repair.

From fixmachinedehartbise.z13.web.core.windows.net

Floor Jack Repair Kits Floor Jacks Repair Here are the steps you should follow: If you notice any of these problems, it is important to address them as soon as possible. Check the hydraulic fluid level; Common problems include slow lifting, leaking fluid, and an inability to hold a load. They are easy to repair and it can save. Unlike hydraulic oil, air can be compressed. First. Floor Jacks Repair.