Bevel Gear Reverse Rotation . Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. change the direction of a rotating shaft: the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. Hypoid gears with optimal offsets are superior to. bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. the bevel gear is a basic component that is essential for redirecting rotational motion. Its unique conical shape makes it easily recognizable. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels.

from www.slideserve.com

Hypoid gears with optimal offsets are superior to. Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. Its unique conical shape makes it easily recognizable. the bevel gear is a basic component that is essential for redirecting rotational motion. Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. change the direction of a rotating shaft:

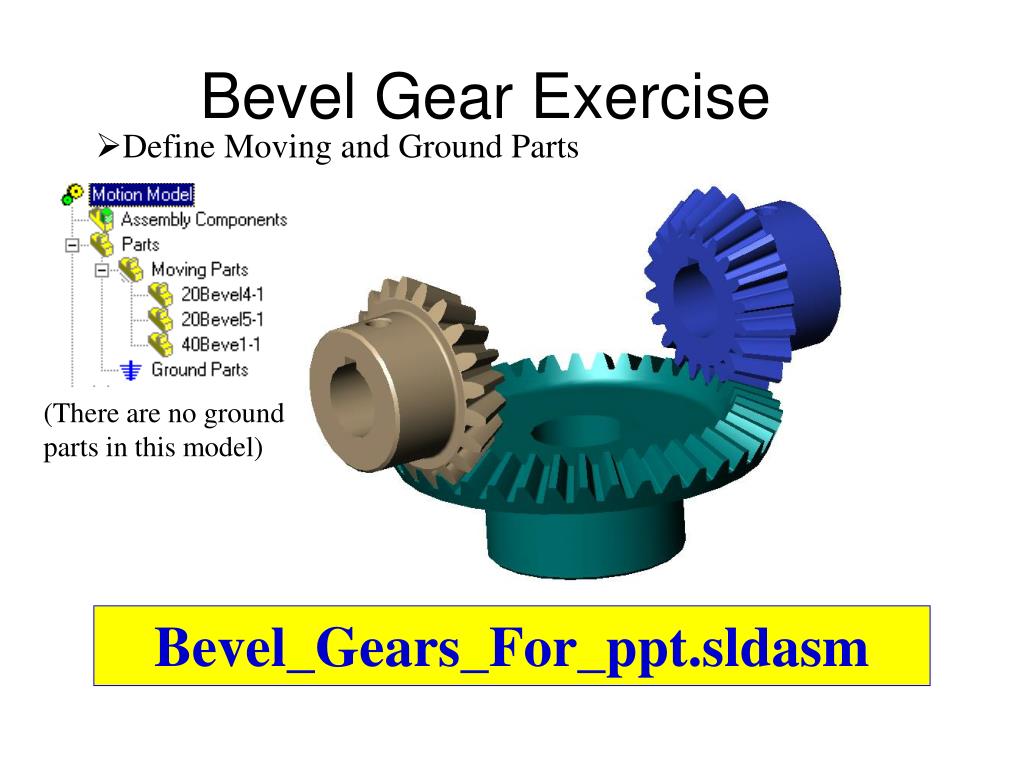

PPT Bevel Gear Exercise PowerPoint Presentation, free download ID

Bevel Gear Reverse Rotation determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. the bevel gear is a basic component that is essential for redirecting rotational motion. Hypoid gears with optimal offsets are superior to. Its unique conical shape makes it easily recognizable. change the direction of a rotating shaft:

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Bevel Gear Reverse Rotation determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. change the direction of a rotating shaft: Hypoid gears with optimal offsets are superior to. the bevel gear is a. Bevel Gear Reverse Rotation.

From www.youtube.com

Bevel Gears Reducer Mechanism 3D Model YouTube Bevel Gear Reverse Rotation Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. change the direction of a rotating shaft: determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. Its unique conical shape makes it easily recognizable. the bevel gear. Bevel Gear Reverse Rotation.

From www.researchgate.net

The dynamic model of a spiral bevel gear system with rotational degrees Bevel Gear Reverse Rotation Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. the bevel gear is a basic component that is essential for redirecting rotational motion. change the direction of a rotating shaft: . Bevel Gear Reverse Rotation.

From www.researchgate.net

Direction of thrust and rotational forces in a spiral bevel gear Bevel Gear Reverse Rotation the bevel gear is a basic component that is essential for redirecting rotational motion. Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. Its unique conical shape makes it easily recognizable. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. Hypoid gears with. Bevel Gear Reverse Rotation.

From www.zhygear.com

Straight bevel Gears vs. Hypoid Gears Choosing the Right Gear Type Bevel Gear Reverse Rotation Hypoid gears with optimal offsets are superior to. change the direction of a rotating shaft: the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. Bevel gears in differential. Bevel Gear Reverse Rotation.

From www.pinterest.com

Different types of Gears. Gears, Spiral bevel gear, Bevel gear Bevel Gear Reverse Rotation determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. Its unique. Bevel Gear Reverse Rotation.

From www.slideserve.com

PPT Bevel Gear Exercise PowerPoint Presentation, free download ID Bevel Gear Reverse Rotation Its unique conical shape makes it easily recognizable. bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. change the direction of a rotating shaft: the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. determining the direction of. Bevel Gear Reverse Rotation.

From www.youtube.com

Bevel gear clutch for changing rotation direction YouTube Bevel Gear Reverse Rotation bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. change the direction of a rotating shaft: Bevel gears in differential gear setup, with the carrier (the axle on which. Bevel Gear Reverse Rotation.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Bevel Gear Reverse Rotation Hypoid gears with optimal offsets are superior to. Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. the aim of mechanism design with gears is to acquire the necessary rotational number by. Bevel Gear Reverse Rotation.

From www.youtube.com

Analysis of Bevel Epicyclic gear train used in differential gear box Bevel Gear Reverse Rotation the bevel gear is a basic component that is essential for redirecting rotational motion. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. Its unique conical shape makes it. Bevel Gear Reverse Rotation.

From www.belongear.com

News Bevel gear reverse engineering Bevel Gear Reverse Rotation determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. . Bevel Gear Reverse Rotation.

From www.slideserve.com

PPT MANUAL TRANSMISSIONS/TRANSAXLES PowerPoint Presentation, free Bevel Gear Reverse Rotation Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. Its unique conical shape makes it easily recognizable. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. the aim of mechanism design with gears is to acquire the. Bevel Gear Reverse Rotation.

From rightanglegearbox.blogspot.com

right angle drive shaft, bevel gear 90 degree 1/2" shaft, bevel gearbox Bevel Gear Reverse Rotation determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. Its unique conical shape makes it easily recognizable. Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one. Bevel Gear Reverse Rotation.

From docs.studica.com

Step 7 Bevel Gear Alignment — Studica FTC Docs 0.0.1 documentation Bevel Gear Reverse Rotation Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. change the direction of a rotating shaft: the aim of mechanism design with gears is to acquire the. Bevel Gear Reverse Rotation.

From dxofwzeih.blob.core.windows.net

Bevel Gears Rotate at Paula Phelan blog Bevel Gear Reverse Rotation determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. Hypoid gears with optimal offsets are superior to. the bevel gear is a basic component that is essential for redirecting rotational motion. the aim of mechanism design with gears is to acquire the necessary rotational number by combining several. Bevel Gear Reverse Rotation.

From www.screw-jack.com

1/4 inch shaft 90 degree gear drive,rotation reversing gearbox,right Bevel Gear Reverse Rotation Hypoid gears with optimal offsets are superior to. Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. Its unique conical shape makes it easily recognizable. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. change the direction of a rotating shaft: Meshing two. Bevel Gear Reverse Rotation.

From www.youtube.com

Solidworks tutorial Bevel gear and pinion mechanism in Solidworks Bevel Gear Reverse Rotation Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. Hypoid gears with optimal offsets are superior to. change the direction of a rotating shaft: Meshing two gears reverses their rotation, which is useful. Bevel Gear Reverse Rotation.

From www.youtube.com

Rotating Bevel Gear YouTube Bevel Gear Reverse Rotation determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. change the direction of a rotating shaft: the bevel gear is a basic component that is essential for redirecting. Bevel Gear Reverse Rotation.

From www.dreamstime.com

Bevel Gear. Gear Transmission Rotation Angle. 3D Rendering Stock Bevel Gear Reverse Rotation the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. change the direction of a rotating shaft: the bevel gear is a basic component that is essential for redirecting rotational motion. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within. Bevel Gear Reverse Rotation.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Reverse Rotation the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. Its unique conical shape makes it easily recognizable. Hypoid gears with optimal offsets are superior to. Bevel gears in differential gear. Bevel Gear Reverse Rotation.

From www.tec-science.com

Bevel gears tecscience Bevel Gear Reverse Rotation Hypoid gears with optimal offsets are superior to. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. the aim of mechanism design with gears is to acquire the necessary rotational number by combining several. Bevel Gear Reverse Rotation.

From dxofwzeih.blob.core.windows.net

Bevel Gears Rotate at Paula Phelan blog Bevel Gear Reverse Rotation the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. the. Bevel Gear Reverse Rotation.

From www.youtube.com

Design of bevel gear I YouTube Bevel Gear Reverse Rotation Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. change the direction of a rotating shaft: Its unique conical shape makes it easily recognizable. Hypoid gears with optimal offsets are superior to. the aim of mechanism design with gears is to acquire the necessary rotational number. Bevel Gear Reverse Rotation.

From www.tec-science.com

How does a differential gear work? tecscience Bevel Gear Reverse Rotation Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. Its unique conical shape makes it easily recognizable. change the direction of a rotating shaft: Hypoid gears with optimal offsets are superior to. the bevel gear is a basic component that is essential for redirecting rotational motion. the aim of mechanism design. Bevel Gear Reverse Rotation.

From www.gmeinder.com

Bevel gearbox with shiftable reverse Gmeinder Bevel Gear Reverse Rotation the bevel gear is a basic component that is essential for redirecting rotational motion. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. change the direction of a rotating shaft: Hypoid gears with optimal offsets are superior to. Meshing two gears reverses their rotation, which is useful for. Bevel Gear Reverse Rotation.

From engineering.stackexchange.com

mechanical engineering How to reverse the direction of rotational Bevel Gear Reverse Rotation Its unique conical shape makes it easily recognizable. change the direction of a rotating shaft: Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. the aim of mechanism design with gears. Bevel Gear Reverse Rotation.

From blogs.sw.siemens.com

Simulate Bevel Gears Accurately and Efficiently Simcenter Bevel Gear Reverse Rotation Hypoid gears with optimal offsets are superior to. the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within. Bevel Gear Reverse Rotation.

From www.amazon.in

2Pcs Bevel Gear Tapered Bevel Pinion Gear Bevel Gears 2 Module 20 Teeth Bevel Gear Reverse Rotation determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. the bevel gear is a basic component that is essential for redirecting rotational motion. Meshing two gears reverses their rotation, which is useful for changing. Bevel Gear Reverse Rotation.

From atbautomation.eu

Reversing spiral bevel gearbox Tandler W ATB Automation Bevel Gear Reverse Rotation Hypoid gears with optimal offsets are superior to. change the direction of a rotating shaft: Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. the bevel gear is a basic component. Bevel Gear Reverse Rotation.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Bevel Gear Reverse Rotation Its unique conical shape makes it easily recognizable. Hypoid gears with optimal offsets are superior to. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. Bevel gears in differential gear. Bevel Gear Reverse Rotation.

From studylib.net

Bevel Gears Bevel Gear Reverse Rotation Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. Hypoid gears with optimal offsets are superior to. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. the bevel gear is a basic component that is essential for redirecting rotational motion. bevel gears. Bevel Gear Reverse Rotation.

From www.chegg.com

Solved In the bevel gear train illustrated in the figure, Bevel Gear Reverse Rotation the bevel gear is a basic component that is essential for redirecting rotational motion. the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. Meshing two gears reverses their rotation, which is useful for changing rotational direction in applications like conveyor belts or rotating wheels. determining the direction of. Bevel Gear Reverse Rotation.

From www.dreamstime.com

Bevel Gear. Gear Transmission Rotation Angle of Helicopter RC Stock Bevel Gear Reverse Rotation Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. Its unique conical shape makes it easily recognizable. the bevel gear is a basic component that is essential for redirecting rotational motion. the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. Hypoid gears with. Bevel Gear Reverse Rotation.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Reverse Rotation bevel gears can include straight, spiral, zerol, hypoid and spiroid (to address the differences between each one is beyond. determining the direction of rotation in bevel gears is crucial for ensuring proper functionality and alignment within a. the bevel gear is a basic component that is essential for redirecting rotational motion. Its unique conical shape makes it. Bevel Gear Reverse Rotation.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Reverse Rotation the aim of mechanism design with gears is to acquire the necessary rotational number by combining several gears. the bevel gear is a basic component that is essential for redirecting rotational motion. Hypoid gears with optimal offsets are superior to. Bevel gears in differential gear setup, with the carrier (the axle on which the intermediate. Meshing two gears. Bevel Gear Reverse Rotation.