Additive Manufacturing Aluminum Powder . Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to.

from globemetal.com

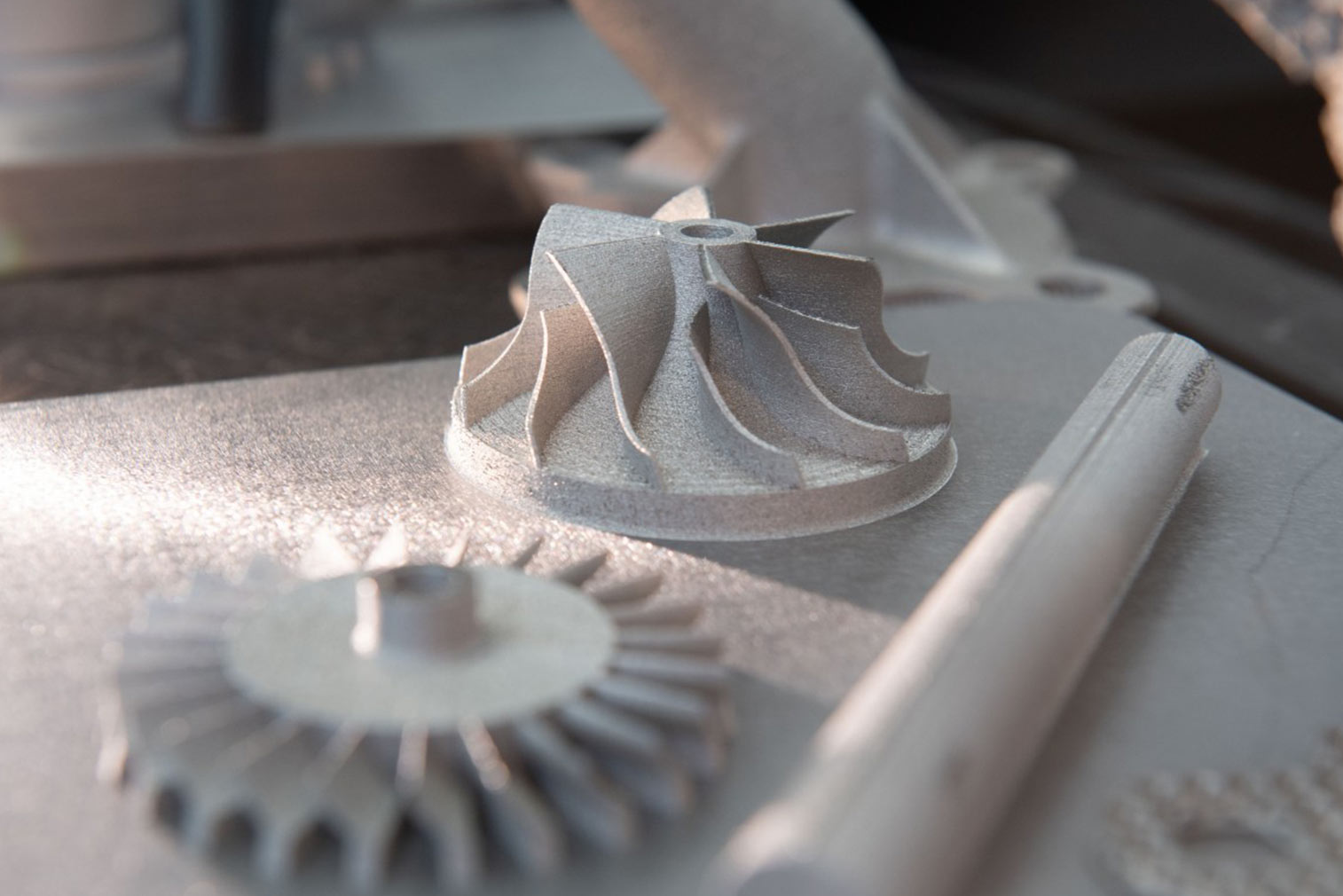

Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production.

Recycling Hazardous Waste from the Additive Manufacturing (3D Printing

Additive Manufacturing Aluminum Powder Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production.

From www.youtube.com

Metal Powder Recovery System for Additive Manufacturing YouTube Additive Manufacturing Aluminum Powder Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Additive manufacturing of aluminum alloys faced unique difficulties that prompted. Additive Manufacturing Aluminum Powder.

From www.aluminum.org

An Aluminum First Standards for 3D Printing The Aluminum Association Additive Manufacturing Aluminum Powder Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas. Additive Manufacturing Aluminum Powder.

From fitech.en.made-in-china.com

Additive Manufacturing AISI10mg Alloy Powder in 3D Printing/Laser Additive Manufacturing Aluminum Powder Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Additive manufacturing of aluminum. Additive Manufacturing Aluminum Powder.

From www.alcircle.com

FIA approves ApWorks’ additive manufacturing aluminium alloy for the Additive Manufacturing Aluminum Powder As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Spherical powder with a. Additive Manufacturing Aluminum Powder.

From www.youtube.com

Advanced plasma atomization process How powder is made for additive Additive Manufacturing Aluminum Powder A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Laser powder bed fusion (lpbf). Additive Manufacturing Aluminum Powder.

From www.voestalpine.com

Metal Powders for Additive Manufacturing voestalpine HPM Canada Additive Manufacturing Aluminum Powder A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were. Additive Manufacturing Aluminum Powder.

From globemetal.com

Recycling Hazardous Waste from the Additive Manufacturing (3D Printing Additive Manufacturing Aluminum Powder Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. As the dominant additive manufacturing technology. Additive Manufacturing Aluminum Powder.

From www.lightmetalage.com

Aeromet Achieves High Strength Aluminum Powder for Additive Additive Manufacturing Aluminum Powder A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Spherical powder with a. Additive Manufacturing Aluminum Powder.

From www.materials-talks.com

Unlocking Powder Recycling in Polymer Additive Manufacturing Additive Manufacturing Aluminum Powder Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm. Additive Manufacturing Aluminum Powder.

From luxfermagtech.com

Magnesium Alloy Powders for Powder Metallurgy and Additive Additive Manufacturing Aluminum Powder Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Laser powder bed fusion (lpbf) is one of the major additive manufacturing. Additive Manufacturing Aluminum Powder.

From www.azom.com

Particle Analysis Applied to Additive Manufacturing Feedstocks Additive Manufacturing Aluminum Powder Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. A new, direct low energy, solid state production process for powdered feedstock. Additive Manufacturing Aluminum Powder.

From shlaiwu.en.made-in-china.com

AISI10mg Aluminum Alloy Powder for Additive Manufacturing (3D printing Additive Manufacturing Aluminum Powder Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. A new, direct low energy, solid. Additive Manufacturing Aluminum Powder.

From www.3dnatives.com

A20X is the strongest aluminium powder for additive manufacturing Additive Manufacturing Aluminum Powder As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Spherical powder with a nominal composition. Additive Manufacturing Aluminum Powder.

From umi-innovation.com

Aluminum powder for additive manufacturing UMI Additive Manufacturing Aluminum Powder A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were. Additive Manufacturing Aluminum Powder.

From www.metal-am.com

An introduction to metal powders for Additive Manufacturing Additive Manufacturing Aluminum Powder Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. A new, direct low energy, solid state production process for powdered feedstock. Additive Manufacturing Aluminum Powder.

From equispheres.com

Press Release Unique Powder Outperforms In Additive Manufacturing Additive Manufacturing Aluminum Powder Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Spherical powder with a nominal composition. Additive Manufacturing Aluminum Powder.

From www.metal-am.com

Understanding the impact of powder reuse in metal Additive Manufacturing Additive Manufacturing Aluminum Powder As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm. Additive Manufacturing Aluminum Powder.

From www.researchgate.net

(PDF) Additive manufacturing of a highperformance aluminum alloy from Additive Manufacturing Aluminum Powder A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. As the dominant additive manufacturing technology. Additive Manufacturing Aluminum Powder.

From www.toyal.co.jp

Toyal Toyo Aluminium K.K. Product Information Powder & Paste Additive Manufacturing Aluminum Powder Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas. Additive Manufacturing Aluminum Powder.

From gzslam.en.made-in-china.com

China High Purity Aluminum Alloy Powder 6061 Powder for Additive Additive Manufacturing Aluminum Powder Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. As the dominant additive manufacturing technology for aluminum alloys, an. Additive Manufacturing Aluminum Powder.

From www.alibaba.com

Hot Sale Additive Manufacturing Alsi10mg 3d Printing Metal Powder Additive Manufacturing Aluminum Powder Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Additive manufacturing of aluminum alloys faced unique difficulties that prompted. Additive Manufacturing Aluminum Powder.

From www.3dnatives.com

A New Tungsten Powder Compatible with Additive Manufacturing 3Dnatives Additive Manufacturing Aluminum Powder A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Spherical powder with a nominal. Additive Manufacturing Aluminum Powder.

From www.researchgate.net

Diagrammatic representation of the LWAM's bead deposition mechanism Additive Manufacturing Aluminum Powder Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm. Additive Manufacturing Aluminum Powder.

From hexagon.com

Scalable and Reliable Additive Manufacturing Hexagon Additive Manufacturing Aluminum Powder Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. A new, direct low energy, solid. Additive Manufacturing Aluminum Powder.

From kbmadvanced.com

Powdered Aluminum Direct Aluminum Distribution KBM Additive Manufacturing Aluminum Powder Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is. Additive Manufacturing Aluminum Powder.

From www.cnclathing.com

Metal 3D Printing vs. Metal Injection Molding The Differences Between Additive Manufacturing Aluminum Powder Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. Spherical powder with a nominal composition. Additive Manufacturing Aluminum Powder.

From www.sae.org

Highstrength aluminum powder developed for additive manufacturing in Additive Manufacturing Aluminum Powder Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm. Additive Manufacturing Aluminum Powder.

From www.thefabricator.com

What metal additive manufacturing means for the metal fabricator Additive Manufacturing Aluminum Powder A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm. Additive Manufacturing Aluminum Powder.

From 0c5f2f760a90586c.en.made-in-china.com

China Iron Based Powder Manufacturer, Aluminum Based Powder, Titanium Additive Manufacturing Aluminum Powder Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. A new, direct low energy, solid state production process for. Additive Manufacturing Aluminum Powder.

From www.researchgate.net

Flowsheet for conventional and additive manufacturing aluminum PM Additive Manufacturing Aluminum Powder A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. Laser powder bed fusion (lpbf) is one of the major. Additive Manufacturing Aluminum Powder.

From www.reade.com

3D Printing Powders / Additive Manufacturing Powders Additive Manufacturing Aluminum Powder As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15. Additive Manufacturing Aluminum Powder.

From elcanindustries.com

Additive Manufacturing Powders Elcan Industries Additive Manufacturing Aluminum Powder As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. A new, direct low energy, solid. Additive Manufacturing Aluminum Powder.

From www.slammetalpowder.cn

Spherical pure aluminum powder for additive manufacturing from China Additive Manufacturing Aluminum Powder Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. As the dominant additive manufacturing technology for aluminum alloys, an emphasis is put on the laser powder bed fusion. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were. Additive Manufacturing Aluminum Powder.

From www.lightmetalage.com

ARTICLE Additive Manufacturing of Aluminum Alloys Light Metal Age Additive Manufacturing Aluminum Powder A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Spherical powder with a nominal composition of al 92 ti 2 fe 2 co 2 ni 2 (at.%) satisfying −53 + 15 µm were gas atomized by atlantic equipment engineering, inc. Additive manufacturing of aluminum alloys faced unique difficulties that prompted. Additive Manufacturing Aluminum Powder.

From www.sae.org

Highstrength aluminum powder developed for additive manufacturing in Additive Manufacturing Aluminum Powder A new, direct low energy, solid state production process for powdered feedstock termed cold mechanically derived (cmd) powder production. Laser powder bed fusion (lpbf) is one of the major additive manufacturing techniques that industries have adopted to. Additive manufacturing of aluminum alloys faced unique difficulties that prompted creative solutions from not only processing, but. Spherical powder with a nominal composition. Additive Manufacturing Aluminum Powder.