Pcb Foil Construction . Foil construction/lamination is the preferred and the recommended option than cap construction. In most cases, copper foil construction is better for layer to layer and drilling. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. As a result, the finished pcb will cost less. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Thus, foil lamination dominates the multilayer pcb industry. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. Copper is the most commonly.

from www.bridgeitc.com

Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. As a result, the finished pcb will cost less. In most cases, copper foil construction is better for layer to layer and drilling. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Copper is the most commonly. Thus, foil lamination dominates the multilayer pcb industry. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. Foil construction/lamination is the preferred and the recommended option than cap construction.

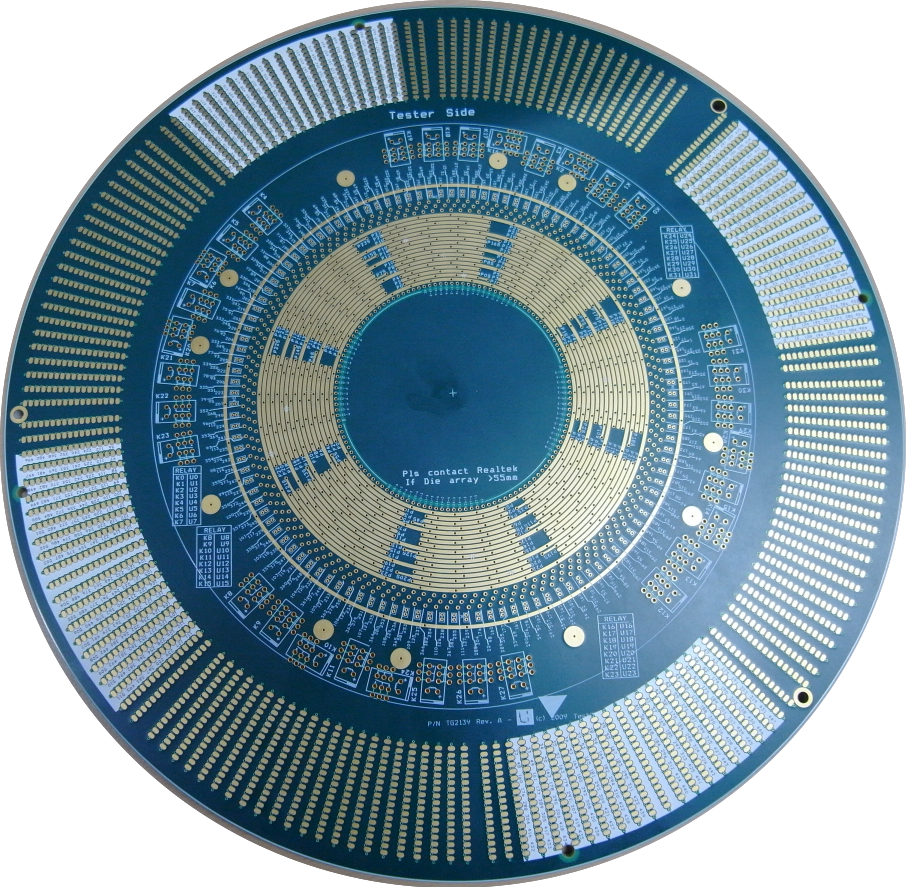

ATE PCB Photo bridgecorp

Pcb Foil Construction Thus, foil lamination dominates the multilayer pcb industry. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. Copper is the most commonly. In most cases, copper foil construction is better for layer to layer and drilling. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. As a result, the finished pcb will cost less. Thus, foil lamination dominates the multilayer pcb industry. Foil construction/lamination is the preferred and the recommended option than cap construction. During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet.

From www.civen-inc.com

News What is Copper Foil Used for PCB Manufacturing Process? Pcb Foil Construction Thus, foil lamination dominates the multilayer pcb industry. Copper is the most commonly. During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Foil construction/lamination is the preferred and the recommended option than cap construction. Foil lamination involves processing one less detail (pair of layers on a piece of laminate). Pcb Foil Construction.

From maxembedded.com

PCB Design using EAGLE Part 1 Introduction to EAGLE and Software Pcb Foil Construction Learn how to choose the right kind of copper foil for your high frequency pcb stackup. In most cases, copper foil construction is better for layer to layer and drilling. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. As a result,. Pcb Foil Construction.

From novaenginc.com

What are the Types of PCB Assembly Processes? Nova Engineering Pcb Foil Construction During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Copper is the most commonly. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. In most cases, copper foil construction is better for layer to layer and drilling.. Pcb Foil Construction.

From hillmancurtis.com

PCB core Vs. Prepreg Which Material to Choose Hillman Curtis Pcb Foil Construction Foil construction/lamination is the preferred and the recommended option than cap construction. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. During the pcb manufacturing process,. Pcb Foil Construction.

From www.bestsoldering.com

Pcb repair Hobby electronic soldering and construction Pcb Foil Construction Foil construction/lamination is the preferred and the recommended option than cap construction. As a result, the finished pcb will cost less. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Copper is the most commonly. In most cases, copper foil construction is better for layer to layer and drilling. Foil construction means that. Pcb Foil Construction.

From www.electricalelibrary.com

Coaxial cable how it works? Electrical Pcb Foil Construction Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. Copper is the most commonly. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil,. Pcb Foil Construction.

From www.copperfoilrolls.com

CCL / PCB Insulation Thickness 15um Pure Copper Foil Pcb Foil Construction Thus, foil lamination dominates the multilayer pcb industry. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Copper is the most commonly. During the pcb manufacturing. Pcb Foil Construction.

From www.theengineeringknowledge.com

Different Types of PCB The Engineering Knowledge Pcb Foil Construction Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. Foil construction/lamination is the preferred and the recommended option than cap construction.. Pcb Foil Construction.

From www.protoexpress.com

Mastering the Art of PCB Design Basics Sierra Circuits Pcb Foil Construction Thus, foil lamination dominates the multilayer pcb industry. Foil construction/lamination is the preferred and the recommended option than cap construction. In most cases, copper foil construction is better for layer to layer and drilling. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. Foil construction means that the. Pcb Foil Construction.

From technofaq.org

Outsourced PCB design agencies help you to Get back to design with PCB Pcb Foil Construction During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. As a result, the finished pcb will cost less. Thus, foil lamination dominates. Pcb Foil Construction.

From www.miraclepwb.com

custom Single Layer pcbAdvanced Circuits PCB Manufacturing Miraclepwb Pcb Foil Construction During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Thus, foil lamination dominates the multilayer pcb industry. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. In most cases, copper foil construction is better for layer to layer and drilling. Foil construction. Pcb Foil Construction.

From hillmancurtis.com

What are the Steps in Designing the Custom PCB? Hillman Curtis Pcb Foil Construction In most cases, copper foil construction is better for layer to layer and drilling. Foil construction/lamination is the preferred and the recommended option than cap construction. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done. Pcb Foil Construction.

From www.sfcircuits.com

PCB StackUp Guide & Examples San Francisco Circuits Pcb Foil Construction Copper is the most commonly. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Foil lamination involves processing one less detail (pair of layers on a. Pcb Foil Construction.

From www.raypcb.com

An introduction about PCB copper foil types RAYPCB Pcb Foil Construction Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Foil construction/lamination is the preferred and the recommended option than cap construction. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. Thus, foil lamination dominates the. Pcb Foil Construction.

From www.mtek.co.uk

Proper PCB Assembly Techniques to Ensure Longterm Reliability Pcb Foil Construction Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Thus, foil lamination dominates the multilayer pcb industry. Copper is the most commonly. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. During the pcb manufacturing process, multiple core and prepreg layers. Pcb Foil Construction.

From www.civen-inc.com

News Copper Foil Used in Printed Circuit Board Pcb Foil Construction Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. As a result, the finished pcb will cost less. During the pcb manufacturing process, multiple core and prepreg layers are combined with a. Pcb Foil Construction.

From www.circuits-diy.com

Double Layer PCB Construction And Applications Pcb Foil Construction Copper is the most commonly. Thus, foil lamination dominates the multilayer pcb industry. As a result, the finished pcb will cost less. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. Foil construction means that the top and bottom (external) layers are made from a sheet of copper. Pcb Foil Construction.

From resources.altium.com

Types of PCB Copper Foil for HighFrequency Design Zach Peterson Pcb Foil Construction Foil construction/lamination is the preferred and the recommended option than cap construction. In most cases, copper foil construction is better for layer to layer and drilling. During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Learn how to choose the right kind of copper foil for your high frequency. Pcb Foil Construction.

From cckautomations.com

The Difference Between Rigid, Flexible, and RigidFlex PCB Assemblies Pcb Foil Construction Foil construction/lamination is the preferred and the recommended option than cap construction. During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Copper is the most commonly. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. As a. Pcb Foil Construction.

From www.hemeixinpcb.com

How to design rigid flex pcb Hemeixin Pcb Foil Construction Thus, foil lamination dominates the multilayer pcb industry. Copper is the most commonly. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. Foil construction/lamination is the preferred and the recommended option than cap construction. As a result, the finished pcb will cost less. During the pcb manufacturing process,. Pcb Foil Construction.

From www.andwinpcb.com

Aluminum foil pcb Andwin Circuits Pcb Foil Construction Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. Thus, foil lamination dominates the multilayer pcb industry. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. During the pcb manufacturing. Pcb Foil Construction.

From www.dnatechindia.com

Printed Circuit Board Explained Learn about different types of PCB Pcb Foil Construction Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Thus, foil lamination dominates the multilayer pcb industry. Copper is the most commonly. Foil construction/lamination is the preferred and the recommended option than cap construction. As a result, the finished pcb will cost less. During the pcb manufacturing process, multiple core and prepreg layers. Pcb Foil Construction.

From www.linkedin.com

What is PCB Copper Foil? Pcb Foil Construction During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Thus, foil lamination dominates the multilayer pcb industry. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. Foil construction/lamination is the preferred and the recommended option than cap. Pcb Foil Construction.

From www.pinterest.com

The basic materials needed to build a multilayer PCB board are copper Pcb Foil Construction During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Copper is the most commonly. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with. Pcb Foil Construction.

From www.raypcb.com

An introduction about PCB copper foil types RAYPCB Pcb Foil Construction Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. Copper is the most commonly. During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Foil lamination involves processing one less detail (pair. Pcb Foil Construction.

From www.civen-inc.com

News Copper Foil Used in Printed Circuit Board Pcb Foil Construction Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. In most cases, copper foil construction is better for layer to layer and drilling. Copper is the most commonly. As a result, the finished pcb will cost less. Learn how to choose the. Pcb Foil Construction.

From medium.com

Detailed Information On Flexible PCBs Explained By A Flex PCB Assembly Pcb Foil Construction During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. In most cases, copper foil construction is better for layer to layer and. Pcb Foil Construction.

From www.allpcb.com

The Main Factors in Printed Circuit Board Construction Pcb Foil Construction Thus, foil lamination dominates the multilayer pcb industry. As a result, the finished pcb will cost less. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Foil construction/lamination is the preferred and the recommended option than cap construction. Foil lamination involves processing one less detail (pair of layers on a piece of laminate). Pcb Foil Construction.

From www.ourpcb.com

Practical guide for EMC/EMI improvement in PCB Layout Designs Part I Pcb Foil Construction As a result, the finished pcb will cost less. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. Foil lamination involves processing one less detail (pair. Pcb Foil Construction.

From www.reddit.com

PCB Assembly Manufacturing Services in Illinois Aimtron r/PCB Pcb Foil Construction During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. Foil lamination involves processing one less detail (pair of layers on a piece. Pcb Foil Construction.

From www.bridgeitc.com

ATE PCB Photo bridgecorp Pcb Foil Construction Thus, foil lamination dominates the multilayer pcb industry. During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Foil construction/lamination is the preferred and the recommended option than cap construction. Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Foil construction means that. Pcb Foil Construction.

From ictech.com.ua

NEW_PCB_MANUFACTURING Группа компаний ИКТ Pcb Foil Construction Thus, foil lamination dominates the multilayer pcb industry. Foil construction/lamination is the preferred and the recommended option than cap construction. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil. Pcb Foil Construction.

From morsetutor.com

pcb_foil Pcb Foil Construction Learn how to choose the right kind of copper foil for your high frequency pcb stackup. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. During the pcb manufacturing process, multiple core and prepreg layers are combined with a top and bottom copper foil sheet. Foil construction means. Pcb Foil Construction.

From www.researchgate.net

Process chart of the anode board construction, showing base materials Pcb Foil Construction Foil construction/lamination is the preferred and the recommended option than cap construction. In most cases, copper foil construction is better for layer to layer and drilling. As a result, the finished pcb will cost less. Foil lamination involves processing one less detail (pair of layers on a piece of laminate) than that done with cap lamination. Copper is the most. Pcb Foil Construction.

From peacecommission.kdsg.gov.ng

Layer Pcb Foil Construction In most cases, copper foil construction is better for layer to layer and drilling. Foil construction/lamination is the preferred and the recommended option than cap construction. Foil construction means that the top and bottom (external) layers are made from a sheet of copper foil, laminated to the rest of the layers with prepreg. Learn how to choose the right kind. Pcb Foil Construction.