Dilution Steam Process . Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. Below is a synopsis of the chemical treatment program. Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. An amine is injected at quench water tower bottoms and dilution steam generator. This process is called pyrolysis. The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. Coalescer applications ethylene processing — dilution steam systelll problem in an. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating.

from pharmacyscope.com

The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. Below is a synopsis of the chemical treatment program. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. Coalescer applications ethylene processing — dilution steam systelll problem in an. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. This process is called pyrolysis. An amine is injected at quench water tower bottoms and dilution steam generator.

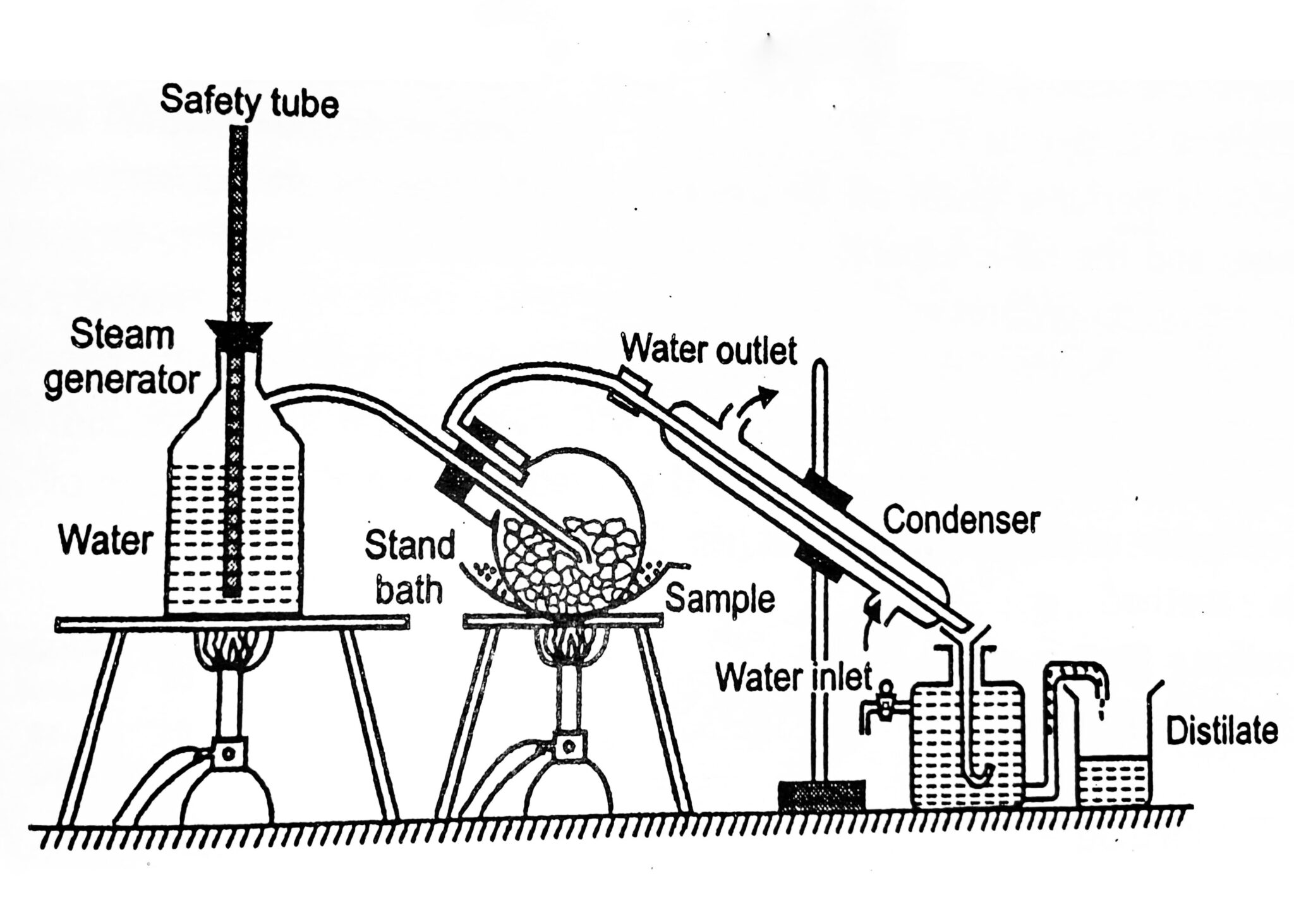

How do you calculate the efficiency of steam distillation? Principle

Dilution Steam Process Coalescer applications ethylene processing — dilution steam systelll problem in an. Below is a synopsis of the chemical treatment program. An amine is injected at quench water tower bottoms and dilution steam generator. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. Coalescer applications ethylene processing — dilution steam systelll problem in an. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. This process is called pyrolysis.

From www.researchgate.net

Schematic illustration of predilution and postdilution online Dilution Steam Process Coalescer applications ethylene processing — dilution steam systelll problem in an. Below is a synopsis of the chemical treatment program. This process is called pyrolysis. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed. Dilution Steam Process.

From www.askiitians.com

Organic Chemistry Purification of organic compounds askIITians Dilution Steam Process The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. This process is called pyrolysis. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends). Dilution Steam Process.

From wahlco.com

Aqueous Ammonia Systems Wahlco, Inc Dilution Steam Process The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. Coalescer applications ethylene processing — dilution steam systelll problem in an. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. This process is. Dilution Steam Process.

From www.medicine.mcgill.ca

Serial Dilutions Dilution Steam Process Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. This process is called pyrolysis. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. An amine is injected at quench water tower bottoms and dilution steam generator. Unique technology for. Dilution Steam Process.

From dokumen.tips

(PDF) Ethylene Processing Dilution Steam System · PDF fileCOALESCER Dilution Steam Process In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other. Dilution Steam Process.

From www.researchgate.net

5 Schematic overview of firebox, convection section and quench/steam Dilution Steam Process In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. The first. Dilution Steam Process.

From www.emersonautomationexperts.com

Efficiently Cracking Hydrocarbons in Ethylene Furnaces Dilution Steam Process Coalescer applications ethylene processing — dilution steam systelll problem in an. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. An amine is injected at quench water tower bottoms. Dilution Steam Process.

From www.researchgate.net

Process flow diagram of water quench tower and dilution steam generator Dilution Steam Process Below is a synopsis of the chemical treatment program. An amine is injected at quench water tower bottoms and dilution steam generator. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution. Dilution Steam Process.

From www.researchgate.net

Schematic illustration of the central steam generation system of the Dilution Steam Process Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. Coalescer applications ethylene processing — dilution steam systelll problem in an. In the ethylene process (hot section),. Dilution Steam Process.

From www.researchgate.net

Process flow diagram of water quench tower and dilution steam generator Dilution Steam Process An amine is injected at quench water tower bottoms and dilution steam generator. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. The first step in the production of ethylene is. Dilution Steam Process.

From www.doterra.com

Steam Distillation dōTERRA Essential Oils Dilution Steam Process First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. This process is called pyrolysis. Below is a synopsis of the chemical treatment program. An amine is injected at quench water tower. Dilution Steam Process.

From www.semanticscholar.org

[PDF] Improve the Reliability of High Flux Reboilers A Treatment Dilution Steam Process Below is a synopsis of the chemical treatment program. This process is called pyrolysis. Coalescer applications ethylene processing — dilution steam systelll problem in an. Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion. Dilution Steam Process.

From www.researchgate.net

Comparison between different mechanisms for 10 steam dilution and Dilution Steam Process Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. Coalescer applications ethylene processing — dilution steam systelll problem in an. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or. Dilution Steam Process.

From www.expii.com

Dilution of Solutions — Overview & Examples Expii Dilution Steam Process The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. This process is called pyrolysis. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. Below is a synopsis of the chemical treatment program. First, feed. Dilution Steam Process.

From www.researchgate.net

Simplified PFD of the Cracking Process 1. Cracking units consist of Dilution Steam Process Below is a synopsis of the chemical treatment program. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. An amine is injected at quench water tower bottoms and dilution. Dilution Steam Process.

From www.semanticscholar.org

Table 1 from Improve the Reliability of High Flux Reboilers A Treatment Dilution Steam Process Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. An amine is injected at quench water tower bottoms and dilution steam generator. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. Water quench and dilution steam l petrotec™ emulsion breaker. Dilution Steam Process.

From chem.libretexts.org

14.7 Solution Dilution Chemistry LibreTexts Dilution Steam Process Below is a synopsis of the chemical treatment program. An amine is injected at quench water tower bottoms and dilution steam generator. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked. Dilution Steam Process.

From bio.libretexts.org

15 Determination of Bacterial Numbers Biology LibreTexts Dilution Steam Process First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. This process is called pyrolysis. Coalescer applications ethylene processing — dilution steam systelll problem in an. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. Water quench and dilution steam l. Dilution Steam Process.

From www.researchgate.net

A schematic flow chart of the Steam Distillation Extraction (SDE) pilot Dilution Steam Process This process is called pyrolysis. Coalescer applications ethylene processing — dilution steam systelll problem in an. Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. Below is a synopsis of. Dilution Steam Process.

From www.researchgate.net

Process and Exergy/Lost Work (LW) Schematics (A) Steam cracking of Dilution Steam Process This process is called pyrolysis. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. Water quench and dilution steam l petrotec™ emulsion breaker program significantly. Dilution Steam Process.

From www.researchgate.net

Measurement results at increasing rates of steam dilution (top to Dilution Steam Process Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. Coalescer applications ethylene processing — dilution steam systelll problem in an. An amine is injected at quench water tower bottoms and dilution steam. Dilution Steam Process.

From winnerseducation.com

Reaction of Metals with water, steam and dilute acid (1) Winners Dilution Steam Process This process is called pyrolysis. Below is a synopsis of the chemical treatment program. Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. Coalescer applications ethylene processing — dilution steam systelll problem. Dilution Steam Process.

From www.researchgate.net

Comparison of different mechanisms with dilution varying (a) from 0 to Dilution Steam Process An amine is injected at quench water tower bottoms and dilution steam generator. Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. This process is called pyrolysis. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. The first step in the. Dilution Steam Process.

From www.aiche.org

Continuous onLine pH Monitoring and Control for Dilution Steam System Dilution Steam Process In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. Coalescer applications ethylene processing — dilution steam systelll problem in an. This process is called pyrolysis. An amine is injected at quench water tower bottoms and dilution steam generator. Below is a synopsis of the chemical treatment program. First,. Dilution Steam Process.

From www.researchgate.net

4 Diagram of pilotscale diluteH 2 SO 4 catalyzed steam explosion Dilution Steam Process First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. An amine is injected at quench water tower bottoms and dilution steam generator. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. The first step in the production of ethylene is. Dilution Steam Process.

From www.researchgate.net

Process flow diagram of water quench tower and dilution steam generator Dilution Steam Process Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. Coalescer applications ethylene processing — dilution steam systelll problem in an. An amine is injected at quench water tower bottoms and dilution steam generator. The first step in the production of ethylene is to take the feedstock and crack it into ethylene. Dilution Steam Process.

From sciencequery.com

What is serial dilution method? And how to calculate? Science Query Dilution Steam Process Below is a synopsis of the chemical treatment program. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. Coalescer applications ethylene processing — dilution steam systelll problem in an. Water quench. Dilution Steam Process.

From www.youtube.com

Steam Distillation Technique Basic Principles and Techniques in Dilution Steam Process An amine is injected at quench water tower bottoms and dilution steam generator. The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. Coalescer applications ethylene. Dilution Steam Process.

From www.researchgate.net

Diagrams of methods measuring glass dissolution under nondilute Dilution Steam Process First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. Below is a synopsis of the chemical treatment program. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. This process is called pyrolysis. An amine is injected at quench. Dilution Steam Process.

From www.emerson.com

Steam Cracking Furnace Dilution Control Emerson MX Dilution Steam Process The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. Coalescer applications ethylene processing — dilution steam systelll problem in an. Below is a synopsis of the chemical treatment program. Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil. Dilution Steam Process.

From www.researchgate.net

Effect of steam dilution on the flammability limits of acetone. At Dilution Steam Process Below is a synopsis of the chemical treatment program. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion after preheating. This process is called pyrolysis. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. In the ethylene process (hot section), gas feedstocks. Dilution Steam Process.

From wahlco.com

Aqueous Ammonia Systems Wahlco, Inc Dilution Steam Process In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed. Dilution Steam Process.

From pharmacyscope.com

How do you calculate the efficiency of steam distillation? Principle Dilution Steam Process Coalescer applications ethylene processing — dilution steam systelll problem in an. Unique technology for mitigating emulsion, fouling, foaming and corrosion from the quench water tower to the dilution steam generators. The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. An amine is injected at. Dilution Steam Process.

From www.bakersjournal.com

HRS offers steam injection for sterilization and dilution of plant Dilution Steam Process This process is called pyrolysis. An amine is injected at quench water tower bottoms and dilution steam generator. The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. First, feed is sent into a cracking furnace and mixed with dilution steam in a certain proportion. Dilution Steam Process.

From www.semanticscholar.org

Figure 1 from Pretreatment efficiency and structural characterization Dilution Steam Process Water quench and dilution steam l petrotec™ emulsion breaker program significantly reduces dsg feed oil and gas content. Coalescer applications ethylene processing — dilution steam systelll problem in an. In the ethylene process (hot section), gas feedstocks (ethane, propane, blends) or liquid feedstocks (naphtha, gas oil) are cracked in a. This process is called pyrolysis. Unique technology for mitigating emulsion,. Dilution Steam Process.