Gas Metal Arc Welding Pulse . Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Basic spray gas metal arc. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Argon is one of the most expensive industrial welding gases used in gmaw, while carbon dioxide is the least expensive. In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal.

from mewelding.com

Basic spray gas metal arc. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. Argon is one of the most expensive industrial welding gases used in gmaw, while carbon dioxide is the least expensive.

MIG Welding (GMAW)

Gas Metal Arc Welding Pulse Argon is one of the most expensive industrial welding gases used in gmaw, while carbon dioxide is the least expensive. In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Argon is one of the most expensive industrial welding gases used in gmaw, while carbon dioxide is the least expensive. Basic spray gas metal arc. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Because the arc current is pulsed, the total average current is lower than with a conventional spray arc.

From weldguru.com

How To MIG Weld Stainless Steel A Beginners Guide Gas Metal Arc Welding Pulse Basic spray gas metal arc. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Gas metal arc welding (gmaw), commonly known. Gas Metal Arc Welding Pulse.

From www.researchgate.net

Pulsed gas metal arc welding section of maximal and minimal arc length Gas Metal Arc Welding Pulse Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Argon is one. Gas Metal Arc Welding Pulse.

From www.researchgate.net

(PDF) Effect of current waveforms on metal transfer in pulsed gas metal Gas Metal Arc Welding Pulse Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. In applications that. Gas Metal Arc Welding Pulse.

From www.researchgate.net

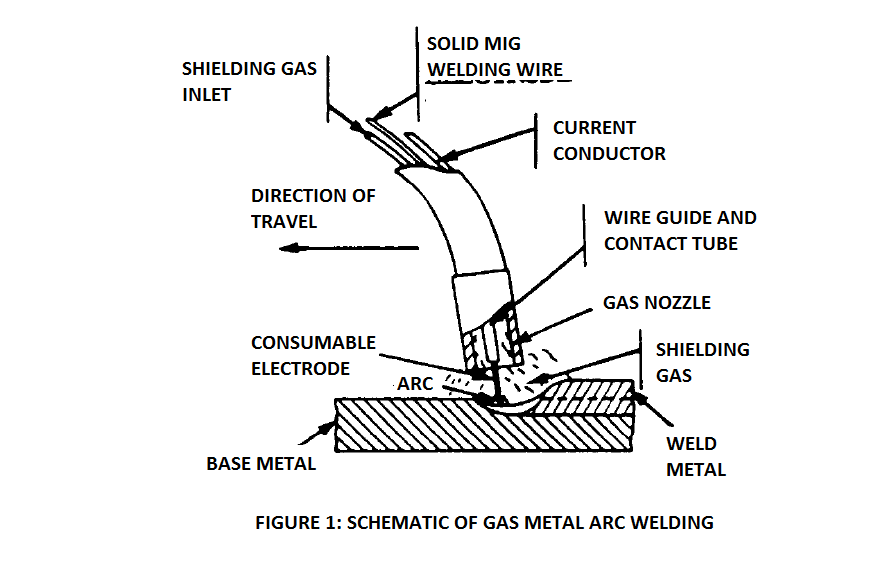

Schematic of gas metal arc welding. Download Scientific Diagram Gas Metal Arc Welding Pulse Basic spray gas metal arc. In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag. Gas Metal Arc Welding Pulse.

From www.gemathis.com

Understanding Gas Metal Arc Welding G.E. MATHIS COMPANY Gas Metal Arc Welding Pulse Argon is one of the most expensive industrial welding gases used in gmaw, while carbon dioxide is the least expensive. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas). Gas Metal Arc Welding Pulse.

From www.youtube.com

Processo de solda Pulsed Gas Metal Arc Welding (GMAWP) YouTube Gas Metal Arc Welding Pulse Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Argon is one of the most expensive industrial welding gases used in gmaw, while carbon dioxide is the least expensive. Because. Gas Metal Arc Welding Pulse.

From www.youtube.com

Differences between Gas Metal Arc Welding (GMAW) and FluxCored Arc Gas Metal Arc Welding Pulse Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Basic spray gas metal arc. In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Gas metal arc welding (gmaw), by definition,. Gas Metal Arc Welding Pulse.

From www.scribd.com

Assessment of WeldEnd Solidification Cracking in PulsedTandem Gas Gas Metal Arc Welding Pulse Basic spray gas metal arc. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is.. Gas Metal Arc Welding Pulse.

From www.researchgate.net

(PDF) Effect of current waveforms on metal transfer in pulsed gas metal Gas Metal Arc Welding Pulse In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Before getting into. Gas Metal Arc Welding Pulse.

From www.pngegg.com

Gas tungsten arc welding Shielded metal arc welding Welder Gas Metal Arc Welding Pulse Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Basic spray gas metal arc. Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. Argon is one of the most expensive industrial welding gases used in. Gas Metal Arc Welding Pulse.

From bakerti.org

Advanced Gas Metal Arc Welding (GMAW) and Flux Cored Arc Welding (FCAW Gas Metal Arc Welding Pulse Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Basic spray gas metal arc. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag. Gas Metal Arc Welding Pulse.

From slidetodoc.com

CHAPTER 10 Gas Metal Arc Welding Equipment Setup Gas Metal Arc Welding Pulse Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Argon is one of the most expensive industrial welding gases used in. Gas Metal Arc Welding Pulse.

From www.nitttrkol.ac.in

NITTTR, Kolkata Gas Metal Arc Welding Pulse In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Gas. Gas Metal Arc Welding Pulse.

From proleantech.com

Arc Welding Vs. Gas Welding What's the Difference? Gas Metal Arc Welding Pulse Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Basic spray gas metal arc. Because the arc current is pulsed, the. Gas Metal Arc Welding Pulse.

From mewelding.com

MIG Welding (GMAW) Gas Metal Arc Welding Pulse Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Basic spray gas metal arc. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces. Gas Metal Arc Welding Pulse.

From www.youtube.com

Fronius Pulse Arc Welder Seam Welding Weld Plus YouTube Gas Metal Arc Welding Pulse Argon is one of the most expensive industrial welding gases used in gmaw, while carbon dioxide is the least expensive. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Gas metal arc welding (gmaw), by definition, is. Gas Metal Arc Welding Pulse.

From www.mdpi.com

Applied Sciences Free FullText Perspective on Double Pulsed Gas Gas Metal Arc Welding Pulse Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Basic spray gas metal arc. In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Argon is one of the most expensive. Gas Metal Arc Welding Pulse.

From www.researchgate.net

(PDF) Application of pulsed gas metal arc welding Gas Metal Arc Welding Pulse Basic spray gas metal arc. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Because the arc current is pulsed, the. Gas Metal Arc Welding Pulse.

From slidetodoc.com

CHAPTER 10 Gas Metal Arc Welding Equipment Setup Gas Metal Arc Welding Pulse Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Argon is one of the most expensive industrial welding gases used in gmaw, while carbon dioxide is the least expensive. Gas metal arc welding (gmaw), by definition, is. Gas Metal Arc Welding Pulse.

From dokumen.tips

(PPT) Gas Metal Arc Welding GMAW Modes of Metal Transfer Spray Globular Gas Metal Arc Welding Pulse Argon is one of the most expensive industrial welding gases used in gmaw, while carbon dioxide is the least expensive. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal. Gas Metal Arc Welding Pulse.

From www.mdpi.com

Metals Free FullText Effect of DoublePulse Characteristics on Gas Metal Arc Welding Pulse Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Basic spray gas metal arc. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas). Gas Metal Arc Welding Pulse.

From www.mech4study.com

Gas Welding Principle, Working, Equipment, Application, Advantages Gas Metal Arc Welding Pulse Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Because the arc. Gas Metal Arc Welding Pulse.

From welderplanet.com

Gas Metal Arc Welding Welder Gas Metal Arc Welding Pulse Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Argon is one of the most expensive industrial welding gases used in gmaw, while carbon dioxide is the least. Gas Metal Arc Welding Pulse.

From www.researchgate.net

CURRENT PULSE PROFILE AND THE DYNAMIC OF METAL TRANSFER AND HEAT INPUT Gas Metal Arc Welding Pulse In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Basic spray gas metal arc. Argon is one of the most expensive industrial welding gases used in gmaw, while. Gas Metal Arc Welding Pulse.

From www.researchgate.net

Schematic of gas metal arc welding process In this research, the wire Gas Metal Arc Welding Pulse Basic spray gas metal arc. Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. Argon is one of the most expensive industrial welding gases used in gmaw, while carbon dioxide is the least expensive. In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Before. Gas Metal Arc Welding Pulse.

From www.researchgate.net

(PDF) Application of pulsed gas metal arc welding Gas Metal Arc Welding Pulse Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. Basic spray gas metal arc. Argon is one of the most expensive industrial welding gases used in gmaw, while. Gas Metal Arc Welding Pulse.

From slidetodoc.com

Physics of Welding Continued Physics of Welding Continued Gas Metal Arc Welding Pulse In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Before getting into the basics of pulsed mig welding, it’s important to. Gas Metal Arc Welding Pulse.

From www.researchgate.net

Gas Metal Arc Welding setup for cladding process Download Scientific Gas Metal Arc Welding Pulse Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. Basic spray gas metal arc. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. In applications that require high. Gas Metal Arc Welding Pulse.

From www.researchgate.net

(PDF) Optimization of Weld Bead in Pulsed Gas Metal Arc Gas Metal Arc Welding Pulse Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Basic spray gas metal arc. Argon is one of the most expensive industrial welding gases used in gmaw, while carbon dioxide is the least expensive. Because the arc current is pulsed, the total average current is lower. Gas Metal Arc Welding Pulse.

From weldguru.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru Gas Metal Arc Welding Pulse Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. In applications that require high deposition rates, pulse welding reduces. Gas Metal Arc Welding Pulse.

From blog.thepipingmart.com

Gas Metal Arc Welding Advantages and Disadvantages Gas Metal Arc Welding Pulse Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Because the arc current is pulsed, the total average current is lower than with a conventional spray arc. In applications that require high deposition rates, pulse welding reduces. Gas Metal Arc Welding Pulse.

From mubashirghori.blogspot.com

Muhammad Mubashir Ghori Understand the Gas Metal Arc Welding (GMAW) Gas Metal Arc Welding Pulse In applications that require high deposition rates, pulse welding reduces heat input, even with cored wires. Basic spray gas metal arc. Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Because the arc current is pulsed, the total average current is lower than with. Gas Metal Arc Welding Pulse.

From www.mdpi.com

Applied Sciences Free FullText Perspective on Double Pulsed Gas Gas Metal Arc Welding Pulse Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Basic spray gas. Gas Metal Arc Welding Pulse.

From blog.thepipingmart.com

Pulse MIG Welding Mild Steel What You Need to Know Gas Metal Arc Welding Pulse Before getting into the basics of pulsed mig welding, it’s important to first understand the different modes of arc transfer in mig or gas metal. Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. In applications that. Gas Metal Arc Welding Pulse.

From www.researchgate.net

Schematic arc length determination using pulsed gas metal arc welding Gas Metal Arc Welding Pulse Gas metal arc welding (gmaw), commonly known as mig (metal inert gas) or mag (metal active gas) welding, is a versatile and widely used welding process in which an electric arc is. Gas metal arc welding (gmaw), by definition, is an arc welding process which produces the coalescence of metals by heating them with an. Before getting into the basics. Gas Metal Arc Welding Pulse.