Permanent Molds For Metal Casting . How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. Permanent molds can make hundreds or even thousands of identical parts, compared to. For the current needs for near net. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold casting is another form of metal casting that uses reusable molds.

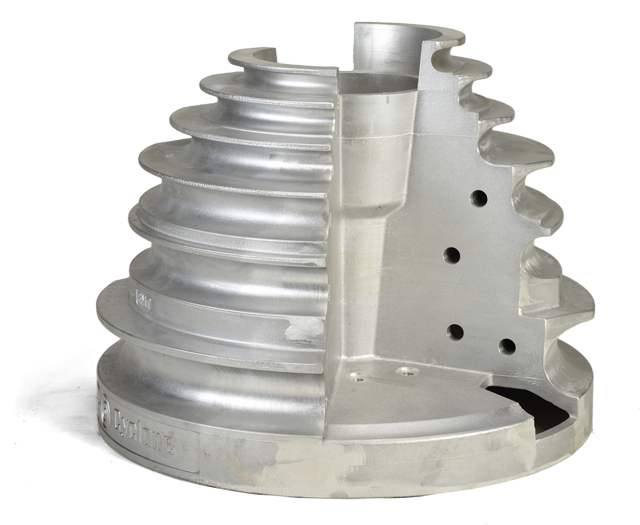

from mumfordmetalcasting.com

Permanent molds can make hundreds or even thousands of identical parts, compared to. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. For the current needs for near net. How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. Permanent mold casting is another form of metal casting that uses reusable molds. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. At the same time, many common sand casting alloys don't find favour with the permanent mold process.

Permanent Mold Casting

Permanent Molds For Metal Casting Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. For the current needs for near net. Permanent mold casting is another form of metal casting that uses reusable molds. At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. Permanent molds can make hundreds or even thousands of identical parts, compared to.

From www.andersonglobal.com

Permanent Molds Anderson Global Permanent Molds For Metal Casting Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other. Permanent Molds For Metal Casting.

From www.iqsdirectory.com

Permanent Mold Castings What Is It? How Does It Work? Advantages Permanent Molds For Metal Casting Permanent mold casting is another form of metal casting that uses reusable molds. Permanent molds can make hundreds or even thousands of identical parts, compared to. How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. For the current needs for near net. At the same time, many common. Permanent Molds For Metal Casting.

From www.iqsdirectory.com

Permanent Mold Castings What Is It? How Does It Work? Advantages Permanent Molds For Metal Casting How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. At the same time, many common sand casting alloys don't find favour with the permanent mold process. For the current needs for near net. Permanent mold casting is another form of metal casting that uses reusable molds. Permanent mold. Permanent Molds For Metal Casting.

From www.pentzcastsolutions.com

Permanent Mold Casting Permanent Repeatable Casting Molds Permanent Molds For Metal Casting How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. Permanent molds can make hundreds or even thousands of identical parts, compared to. Permanent mold casting. Permanent Molds For Metal Casting.

From www.slideserve.com

PPT Metal Casting Processes Part 2 PowerPoint Presentation, free Permanent Molds For Metal Casting Permanent molds can make hundreds or even thousands of identical parts, compared to. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. Permanent mold casting is another form of metal casting that uses reusable molds. At the same time, many common sand casting alloys don't. Permanent Molds For Metal Casting.

From www.indiamart.com

Metal Casting Mould at Rs 700000/piece Vasai Road East Thane ID Permanent Molds For Metal Casting At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. Permanent molds can make hundreds or even thousands of identical parts, compared to. Permanent mold casting uses zero to minimal. Permanent Molds For Metal Casting.

From blog.thepipingmart.com

Advantages and Disadvantages of Shell Mold Casting Permanent Molds For Metal Casting How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. Permanent molds can make hundreds or even thousands of identical parts, compared to. For the current needs for near net. Permanent mold casting is another form of metal casting that uses reusable molds. At the same time, many common. Permanent Molds For Metal Casting.

From www.iqsdirectory.com

Aluminum Casting What Is It? How Is it Made? Advantages Permanent Molds For Metal Casting Permanent mold casting is another form of metal casting that uses reusable molds. How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. For the current needs for near net. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold. Permanent Molds For Metal Casting.

From mumfordmetalcasting.com

Permanent Mold Casting Permanent Molds For Metal Casting Permanent mold casting is another form of metal casting that uses reusable molds. How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold casting describes the process by which molten. Permanent Molds For Metal Casting.

From www.iqsdirectory.com

Permanent Mold Castings What Is It? How Does It Work? Advantages Permanent Molds For Metal Casting Permanent mold casting is another form of metal casting that uses reusable molds. Permanent molds can make hundreds or even thousands of identical parts, compared to. For the current needs for near net. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. How to design. Permanent Molds For Metal Casting.

From marlboroughfoundry.com

Permanent Mold Casting Aluminium Permanent Molds For Metal Casting Permanent molds can make hundreds or even thousands of identical parts, compared to. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. For the current. Permanent Molds For Metal Casting.

From batesvilleproducts.com

Permanent Mold Casting Process Batesville Products (800) 7582372 Permanent Molds For Metal Casting For the current needs for near net. Permanent molds can make hundreds or even thousands of identical parts, compared to. Permanent mold casting is another form of metal casting that uses reusable molds. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. Permanent mold casting. Permanent Molds For Metal Casting.

From blog.thepipingmart.com

What is Permanent Mold Casting? Permanent Molds For Metal Casting Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. For the current needs for near net. Permanent mold casting is another form of metal casting that uses reusable molds. Permanent molds can make hundreds or even thousands of identical parts, compared to. How to design molds. Permanent Molds For Metal Casting.

From diecastor.com

Permanent Mold Casting Process; Material and Application. Permanent Molds For Metal Casting Permanent mold casting is another form of metal casting that uses reusable molds. At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. Permanent mold casting uses zero to minimal. Permanent Molds For Metal Casting.

From www.diecasting-mould.com

Permanent Mold Casting vs Die Casting vs Sand Casting What is Permanent Molds For Metal Casting Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. Permanent mold casting is another form of metal casting that uses reusable molds. How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. Permanent molds can. Permanent Molds For Metal Casting.

From sites.google.com

Basic Permanent Mold Casting Grozeal.in Permanent Molds For Metal Casting Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. At the same time, many common sand casting alloys don't find favour with. Permanent Molds For Metal Casting.

From www.dreamstime.com

The Metal Workers is Pouring Molten Metal To Molds. Sand Casting Allows Permanent Molds For Metal Casting How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. At the same time, many common sand casting alloys don't find favour with the permanent. Permanent Molds For Metal Casting.

From www.thelibraryofmanufacturing.com

Basic Permanent Mold Casting Permanent Molds For Metal Casting How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. For the current needs for near net. Permanent mold casting is another form of metal casting. Permanent Molds For Metal Casting.

From www.tfgusa.com

Custom Permanent Mold Casting Supplier TFG USA Permanent Molds For Metal Casting Permanent molds can make hundreds or even thousands of identical parts, compared to. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal.. Permanent Molds For Metal Casting.

From www.leclairemfg.com

Ultimate Guide to the Permanent Mold Casting Process Permanent Molds For Metal Casting How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. For the current needs for near net. At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold casting is another form of metal casting that uses reusable molds. Permanent molds. Permanent Molds For Metal Casting.

From www.ace-mold.com

Die Casting Mould Material for Industrial Applications Permanent Molds For Metal Casting Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. Permanent mold casting is another form of metal casting that uses reusable molds. At the same time, many common sand casting alloys don't find favour with the permanent mold process. How to design molds for permanent mold. Permanent Molds For Metal Casting.

From buntyllc.com

Custom Metal Casting Molds Bunty LLC Permanent Molds For Metal Casting Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. For the current needs for near net. At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold casting describes the process by which molten metal is poured. Permanent Molds For Metal Casting.

From www.indiamart.com

Aluminium Mold Casting at best price in Vasai by Shree Maa Engineering Permanent Molds For Metal Casting Permanent mold casting is another form of metal casting that uses reusable molds. At the same time, many common sand casting alloys don't find favour with the permanent mold process. For the current needs for near net. Permanent molds can make hundreds or even thousands of identical parts, compared to. Permanent mold casting describes the process by which molten metal. Permanent Molds For Metal Casting.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Permanent Molds For Metal Casting Permanent mold casting is another form of metal casting that uses reusable molds. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. For the current needs for near net. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the. Permanent Molds For Metal Casting.

From www.cic-cic.net

Permanent Mold Castings Custom Industrials Permanent Molds For Metal Casting For the current needs for near net. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. Permanent molds can make hundreds or even thousands of identical parts, compared to. Permanent mold casting is another form of metal casting that uses reusable molds. At the same. Permanent Molds For Metal Casting.

From omnidexmining.com

Permanent Mould Gravity Casting Omnidex Mining site Permanent Molds For Metal Casting At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other. Permanent Molds For Metal Casting.

From blog.eaglegroupmanufacturers.com

Getting Started with Permanent Mold Casting Permanent Molds For Metal Casting Permanent molds can make hundreds or even thousands of identical parts, compared to. Permanent mold casting is another form of metal casting that uses reusable molds. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. At the same time, many common sand casting alloys don't find. Permanent Molds For Metal Casting.

From blog.thepipingmart.com

Die Casting vs Permanent Mold Casting What's the Difference Permanent Molds For Metal Casting How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. Permanent mold casting is another form of metal casting that uses reusable molds. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. At the. Permanent Molds For Metal Casting.

From www.youtube.com

Permanent Mold Casting, Gravity Casting,Permanent mold aluminum casting Permanent Molds For Metal Casting Permanent molds can make hundreds or even thousands of identical parts, compared to. For the current needs for near net. How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold. Permanent Molds For Metal Casting.

From sites.google.com

Basic Permanent Mold Casting Grozeal.in Permanent Molds For Metal Casting Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. For the current needs for near net. Permanent mold casting uses zero to minimal levels of. Permanent Molds For Metal Casting.

From stonybrookmass.org

Mold Making and Metal Casting Stonybrook Metal Arts & Sculpture School Permanent Molds For Metal Casting For the current needs for near net. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold casting is another form of metal casting that uses reusable molds.. Permanent Molds For Metal Casting.

From www.andersonglobal.com

SemiPermanent Molds Anderson Global Permanent Molds For Metal Casting Permanent mold casting is another form of metal casting that uses reusable molds. For the current needs for near net. How to design molds for permanent mold castings m old design in permanent mold casting is different because solidification occurs much. At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold. Permanent Molds For Metal Casting.

From goodtuto-rial.blogspot.com

How To Make A Cast Mold For Silver Permanent Molds For Metal Casting Permanent mold casting is another form of metal casting that uses reusable molds. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. Permanent molds can make hundreds or even thousands of identical parts, compared to. Permanent mold casting uses zero to minimal levels of pressure or. Permanent Molds For Metal Casting.

From ermak.com

Permanent Mold Ermak Foundry & Machining, Inc. Permanent Molds For Metal Casting Permanent mold casting is another form of metal casting that uses reusable molds. For the current needs for near net. At the same time, many common sand casting alloys don't find favour with the permanent mold process. Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal.. Permanent Molds For Metal Casting.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Permanent Molds For Metal Casting Permanent mold casting describes the process by which molten metal is poured into a steel or cast iron mold to make new metal. Permanent mold casting uses zero to minimal levels of pressure or vacuum to pour metal into the mold while other processes use in excess. At the same time, many common sand casting alloys don't find favour with. Permanent Molds For Metal Casting.