Sterilization In Place Process . 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact surfaces of the. Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. Sterilization is usually carried out by means of. Sterilization in place refers to the sterilization of production equipment without prior disassembly. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2.

from medicaldeviceacademy.com

Sterilization in place refers to the sterilization of production equipment without prior disassembly. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2. Sterilization is usually carried out by means of. 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact surfaces of the. Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean.

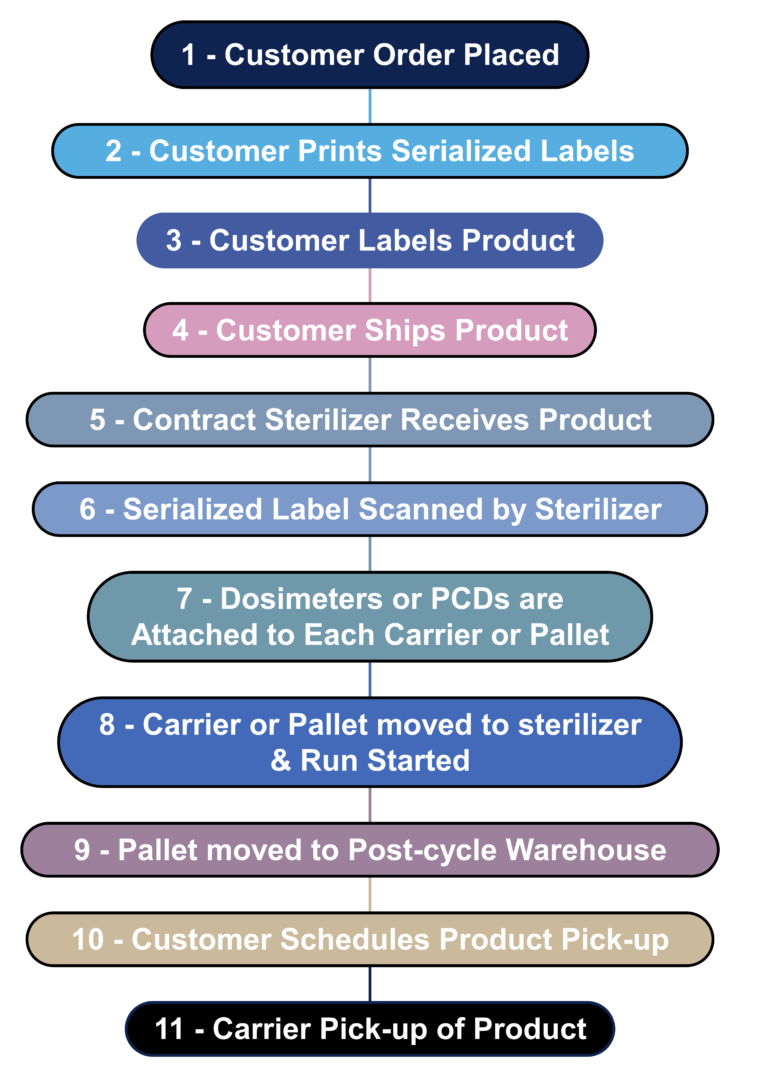

Generic Sterilization Process Flow Diagram Medical Device Academy

Sterilization In Place Process 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact surfaces of the. 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact surfaces of the. Sterilization is usually carried out by means of. Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. Sterilization in place refers to the sterilization of production equipment without prior disassembly. Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2.

From www.slideserve.com

PPT Steam sterilization theory and equipment PowerPoint Presentation Sterilization In Place Process This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. Sterilization in place refers to. Sterilization In Place Process.

From www.dreamstime.com

Sterilization Process with the Use of Autoclave and Instruments Tray Sterilization In Place Process This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2. Sterilization is usually carried out by means of. Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. Sterilization. Sterilization In Place Process.

From www.rsd-engineering.com

Ethylene oxide sterilization Process RSD Industrial sterilization Sterilization In Place Process Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. Sterilization is usually carried out by means of. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to. Sterilization In Place Process.

From dentagama.com

Autoclave 101 Knowing Its Uses and Sterilization Process News Sterilization In Place Process This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2. Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. Sterilization in place refers to the sterilization of production. Sterilization In Place Process.

From www.dentalclinic-knet.com

Dental Sterilization A StepbyStep Process Dental Clinic Sterilization In Place Process Sterilization in place refers to the sterilization of production equipment without prior disassembly. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures. Sterilization In Place Process.

From www.dreamstime.com

Sterilization Process with the Use of Autoclave and Instruments Tray Sterilization In Place Process Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product. Sterilization In Place Process.

From www.researchgate.net

Sterilization process. Download Scientific Diagram Sterilization In Place Process Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. Sterilization is usually carried out by means of. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using. Sterilization In Place Process.

From www.rtix.com

BioCleanse® Tissue Sterilization Process RTI Surgical Sterilization In Place Process This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2. Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. Sterilization in place (sip) is a crucial process. Sterilization In Place Process.

From cssdtechnicianhub.com

Sterile Processing Duties and Responsibilities CSSD Technician Hub Sterilization In Place Process Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2. Sterilization in place (sip) is a crucial process. Sterilization In Place Process.

From medicaldeviceacademy.com

Generic Sterilization Process Flow Diagram Medical Device Academy Sterilization In Place Process 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact surfaces of the. Sterilization is usually carried out by means of. Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. Sterilization in place (sip) is a crucial process employed in pharmaceutical. Sterilization In Place Process.

From jewelprecision.com

What Is The Autoclave Process? Learn Here! Sterilization In Place Process Sterilization is usually carried out by means of. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. Steam in place (sip) is a widely used method. Sterilization In Place Process.

From studylib.net

Sterilization and Canning Process Sterilization In Place Process Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. Sterilization in place refers to the sterilization of production equipment without prior disassembly. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. Sterilization is usually carried. Sterilization In Place Process.

From mycoscience.com

MycoScience What Is Sterilization In Place? Sterilization In Place Process Sterilization is usually carried out by means of. Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2. Sterilization. Sterilization In Place Process.

From jody929lee.wordpress.com

Sterilization Exploración de Odontología Sterilization In Place Process Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. Sterilization in place refers to the sterilization of production equipment without prior disassembly. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. 1.1 this part of iso. Sterilization In Place Process.

From www.blogmedicine.org

How is the Process of Sterilization Takes Place? Blog Medicine Sterilization In Place Process Sterilization in place refers to the sterilization of production equipment without prior disassembly. Sterilization is usually carried out by means of. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. This ensures that any microorganisms still active in the system are killed off with hot water. Sterilization In Place Process.

From drgarine.com

Sterilization Protocol COVID 19 Garine Prosthodontics Sterilization In Place Process Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact surfaces of the. This ensures that any microorganisms still active in the system are killed off with hot. Sterilization In Place Process.

From www.researchgate.net

Supercritical CO 2 sterilization process diagram. Download Scientific Sterilization In Place Process Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. Sterilization in place refers to the sterilization of production equipment without prior disassembly. Sterilization is usually carried out by means of. Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean.. Sterilization In Place Process.

From jobs.northwell.edu

Day in the life Central Sterile Processing Technician Northwell Careers Sterilization In Place Process Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2. Sterilization is usually carried out by means of.. Sterilization In Place Process.

From www.youtube.com

Sterilization process YouTube Sterilization In Place Process Sterilization in place refers to the sterilization of production equipment without prior disassembly. 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact surfaces of the. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (>. Sterilization In Place Process.

From erd-us.com

Steam Sterilization Solutions for Your Healthcare facility ERD Sterilization In Place Process This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2. Sterilization is usually carried out by means of. 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact surfaces. Sterilization In Place Process.

From www.alamy.com

Prevacuum autoclave sterilization method, sterilization plant Stock Sterilization In Place Process Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact surfaces of the. Sterilization in place refers to the sterilization of production equipment without prior disassembly. Sterilization is usually carried out by. Sterilization In Place Process.

From microbeonline.com

Moist heat sterilization Definition, Principle, Advantages and Sterilization In Place Process Sterilization in place refers to the sterilization of production equipment without prior disassembly. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2. 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip). Sterilization In Place Process.

From www.slideserve.com

PPT Central Sterile Processing PowerPoint Presentation ID3007762 Sterilization In Place Process Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. Sterilization is usually carried out by means of. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2.. Sterilization In Place Process.

From www.youtube.com

Sterilization in Place YouTube Sterilization In Place Process Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. Sterilization is usually carried out by means of. Sterilization in place refers to the sterilization of production equipment without prior disassembly. 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact. Sterilization In Place Process.

From www.wpi-europe.com

World Precision Instruments Quick Reference for Sterilization of Sterilization In Place Process Sterilization is usually carried out by means of. 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact surfaces of the. Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. Steam in place (sip) is a widely used method in. Sterilization In Place Process.

From microbeonline.com

Sterilization and Disinfection Methods Microbe Online Sterilization In Place Process Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. Sterilization is usually carried out by means of. Sterilization in place refers to the sterilization of production equipment without prior disassembly. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure. Sterilization In Place Process.

From bhsi.com.pk

ETO Commercial Sterilization B & H Surgical Instrument Sterilization In Place Process 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact surfaces of the. Sterilization is usually carried out by means of. Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. Sterilization in place refers to the sterilization of production equipment without. Sterilization In Place Process.

From pharmacyscope.com

Physical Methods of Sterilization Pharmacy Scope Sterilization In Place Process Sterilization is usually carried out by means of. Sterilization in place refers to the sterilization of production equipment without prior disassembly. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. This ensures that any microorganisms still active in the system are killed off with hot water. Sterilization In Place Process.

From cssdtechnicianhub.com

Central Sterile Processing and Distribution CSSD Technician Hub Sterilization In Place Process Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2. Sterilization in place (sip) is a crucial process. Sterilization In Place Process.

From kerone.com

Different Types of Sterilization Process Sterilization In Place Process This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using an autoclave 2. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. Steam in place (sip) is. Sterilization In Place Process.

From www.steriflowvalve.com

What Are the Fundamentals of Process Equipment Steam Sterilization (SIP)? Sterilization In Place Process Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. Sterilization in place refers to the sterilization of production equipment without prior disassembly. Sterilization is usually carried out by means of. 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact. Sterilization In Place Process.

From www.alamy.com

Autoclave sterilization method, sterilization plant. Hospital Stock Sterilization In Place Process 1.1 this part of iso 13408 specifies the general requirements for sterilization in place (sip) applied to product contact surfaces of the. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. This ensures that any microorganisms still active in the system are killed off with hot. Sterilization In Place Process.

From www.sepsservices.com

5 Common Methods of Lab Sterilization SEPS Services Sterilization In Place Process Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. Sterilization is usually carried out by means of. Sterilization in place refers to the sterilization of production equipment. Sterilization In Place Process.

From www.dreamstime.com

Sterilization Process, with Instruments Being Placed in Autoclave and Sterilization In Place Process Sterilization in place refers to the sterilization of production equipment without prior disassembly. Steam in place (sip) is a widely used method in the production industry for sterilizing equipment and associated pipelines. Sip (sterilize, or steam in place) is a timed sterilization of the upstream and downstream biopharmaceutical production train using clean. 1.1 this part of iso 13408 specifies the. Sterilization In Place Process.

From www.dvidshub.net

DVIDS Images Sterilization In Process [Image 4 of 5] Sterilization In Place Process Sterilization in place (sip) is a crucial process employed in pharmaceutical plants to ensure the sterility of equipment and maintain aseptic manufacturing conditions. Sterilization is usually carried out by means of. This ensures that any microorganisms still active in the system are killed off with hot water or with saturated pure steam at high temperatures (> 121 °c), without using. Sterilization In Place Process.