Lubricating Oil Sampling Procedure . 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. It is followed by overviews of some key oil analysis. As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. Trend elements of equipment wear. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. • the pipe ideally will contain oil soon after draining from the wearing part. • the flow rate should ideally be turbulent to keep.

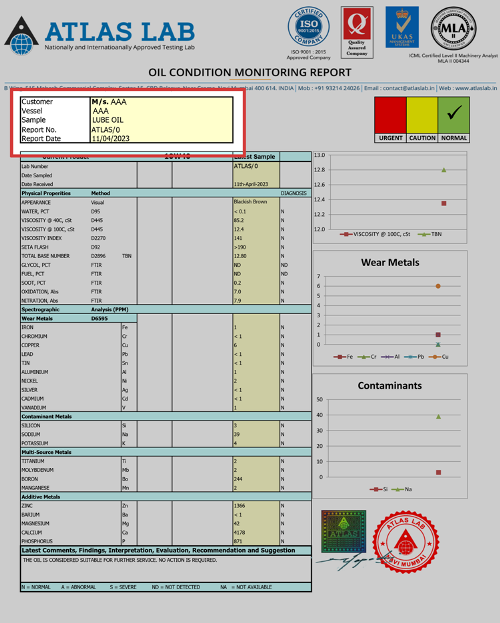

from www.atlaslab.in

An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. • the flow rate should ideally be turbulent to keep. • the pipe ideally will contain oil soon after draining from the wearing part. It is followed by overviews of some key oil analysis. As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. Trend elements of equipment wear.

lube oil testing report, lube oil analysis report

Lubricating Oil Sampling Procedure It is followed by overviews of some key oil analysis. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. Trend elements of equipment wear. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. • the flow rate should ideally be turbulent to keep. • the pipe ideally will contain oil soon after draining from the wearing part. It is followed by overviews of some key oil analysis.

From www.youtube.com

Transformer Oil Sampling Procedure YouTube Lubricating Oil Sampling Procedure • the flow rate should ideally be turbulent to keep. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. Trend elements of equipment wear. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. An effective oil. Lubricating Oil Sampling Procedure.

From www.machinerylubrication.com

How to Determine the Right Oil Sampling Frequency Lubricating Oil Sampling Procedure Trend elements of equipment wear. It is followed by overviews of some key oil analysis. • the flow rate should ideally be turbulent to keep. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and. Lubricating Oil Sampling Procedure.

From commodities.bureauveritas.com

Lubricating Oil Analysis Lubricants Testing Bureau Veritas Lubricating Oil Sampling Procedure 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. It is followed by overviews of some key oil analysis. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. Trend elements of equipment wear. • the pipe. Lubricating Oil Sampling Procedure.

From www.atlaslab.in

lube oil testing report, lube oil analysis report Lubricating Oil Sampling Procedure 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. Trend elements of equipment wear. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. It is followed by overviews of some key oil analysis. • the flow. Lubricating Oil Sampling Procedure.

From www.youtube.com

Fluid Life inar Series Oil Sampling Procedures YouTube Lubricating Oil Sampling Procedure Trend elements of equipment wear. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. • the flow rate should ideally be turbulent to keep. As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. It is followed by overviews of some. Lubricating Oil Sampling Procedure.

From www.machinerylubrication.com

The Basics of Used Oil Sampling Machinery Lubrication Lubricating Oil Sampling Procedure 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. • the pipe ideally will contain oil soon after draining from the wearing part. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. Trend elements of equipment wear. As such engine oil drain. Lubricating Oil Sampling Procedure.

From dokumen.tips

(PDF) Oil Sampling SOP Procedures DOKUMEN.TIPS Lubricating Oil Sampling Procedure An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. • the pipe ideally will contain oil soon after draining from the wearing part. 8 basics of oil analysis oil analysis can. Lubricating Oil Sampling Procedure.

From www.youtube.com

How to take lube oil analysis lab samples using a vacuum pump? YouTube Lubricating Oil Sampling Procedure • the flow rate should ideally be turbulent to keep. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. Trend elements of equipment wear. •. Lubricating Oil Sampling Procedure.

From www.slideserve.com

PPT Oil Spill Sampling PowerPoint Presentation ID243421 Lubricating Oil Sampling Procedure • the pipe ideally will contain oil soon after draining from the wearing part. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. Trend elements of equipment wear. It is followed by overviews. Lubricating Oil Sampling Procedure.

From www.scribd.com

TJH2b Oil Sampling Procedure PDF Polychlorinated Biphenyl Gases Lubricating Oil Sampling Procedure An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. It is followed by overviews of some key oil analysis. • the flow rate should ideally be turbulent to keep. As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. • the. Lubricating Oil Sampling Procedure.

From www.scribd.com

Oil Sampling Guide PDF Chemical Engineering Manufactured Goods Lubricating Oil Sampling Procedure Trend elements of equipment wear. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. As such engine oil drain intervals depend upon the engine type and design,. Lubricating Oil Sampling Procedure.

From www.machinerylubrication.com

3 Engine Oil Sampling Methods Lubricating Oil Sampling Procedure Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management.. Lubricating Oil Sampling Procedure.

From www.tribonet.org

Lubricant Testing About Tribology Lubricating Oil Sampling Procedure An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. • the flow rate should ideally be turbulent to keep. As such engine oil drain intervals depend upon the engine type and design, the. Lubricating Oil Sampling Procedure.

From www.flammabilitytestingequipment.com

Automatic Lubricating Oil Analysis Equipment / Oxidation Stability Tester Lubricating Oil Sampling Procedure An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. It is followed by overviews of some key oil analysis. • the flow rate should ideally be turbulent to keep. • the pipe ideally will contain oil soon after draining from the wearing part. Trend elements of equipment wear. 8 basics of. Lubricating Oil Sampling Procedure.

From accuraclabs.com

Oils & Lubricant Testing Physical and Chemical analysis of all kinds Lubricating Oil Sampling Procedure An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. • the pipe ideally will contain oil soon after draining from the wearing part. Trend elements of equipment wear. It is followed by overviews of some key oil analysis. As such engine oil drain intervals depend upon the engine type and design,. Lubricating Oil Sampling Procedure.

From issuu.com

Hydraulic Fluid Sampling Procedure And Particle Counting by Quaker Lubricating Oil Sampling Procedure • the pipe ideally will contain oil soon after draining from the wearing part. Trend elements of equipment wear. It is followed by overviews of some key oil analysis. As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. • the flow rate should ideally be turbulent to keep. Problems. Lubricating Oil Sampling Procedure.

From iselinc.com

Isel Three Sampling Methods Chart Lubricating Oil Sampling Procedure 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. • the flow rate should ideally be turbulent to keep. • the pipe ideally will contain oil soon after draining from the wearing part. It is followed by overviews of some key oil analysis. Problems associated with the lubricant or the machine. Lubricating Oil Sampling Procedure.

From www.acegroup.org.uk

Professional Oil Sampling & Oil Analysis Services For Air Equipment Lubricating Oil Sampling Procedure 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. Trend elements of equipment wear. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. • the pipe ideally will contain oil soon after draining from the wearing part. It is followed by overviews. Lubricating Oil Sampling Procedure.

From www.marineinsight.com

How to Test Lube Oil (Lubricating Oil) Onboard Ship? Lubricating Oil Sampling Procedure 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. Trend elements of equipment wear. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. An effective oil analysis programoil analysis is an integral part of the maintenance. Lubricating Oil Sampling Procedure.

From marinersrepository.blogspot.com

Mariners Repository Lubricating oil Testing, Analysis and Review Lubricating Oil Sampling Procedure An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. It is followed by overviews of some key oil analysis. • the flow rate should ideally be turbulent to keep. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change. Lubricating Oil Sampling Procedure.

From www.youtube.com

Engine Oil Sampling Procedure YouTube Lubricating Oil Sampling Procedure It is followed by overviews of some key oil analysis. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. 8 basics of oil analysis oil analysis can. Lubricating Oil Sampling Procedure.

From www.machinerylubrication.com

Rationalization of Lab Tests for Measurement of Insoluble Contaminants Lubricating Oil Sampling Procedure 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged.. Lubricating Oil Sampling Procedure.

From es.scribd.com

Circular Lub Oil Sampling Procedure Fleet PDF Lubricating Oil Sampling Procedure Trend elements of equipment wear. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. As such engine oil drain intervals depend upon the engine type and design,. Lubricating Oil Sampling Procedure.

From www.youtube.com

Main Lubricating Oil System YouTube Lubricating Oil Sampling Procedure • the pipe ideally will contain oil soon after draining from the wearing part. As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. Trend elements of equipment wear. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. An effective oil. Lubricating Oil Sampling Procedure.

From ro-quip.com

Oil Sampling ROQUIP Lubricating Oil Sampling Procedure • the pipe ideally will contain oil soon after draining from the wearing part. As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. • the flow rate should ideally be turbulent to keep. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance. Lubricating Oil Sampling Procedure.

From www.marineinsight.com

Ship's Main Engine Lubrication System Explained Lubricating Oil Sampling Procedure It is followed by overviews of some key oil analysis. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. Trend elements of equipment wear. • the flow rate should ideally be turbulent to keep. As such engine oil drain intervals depend upon the engine type. Lubricating Oil Sampling Procedure.

From www.advancedtech.com

What is Oil Analysis for Predictive Maintenance? ATS Lubricating Oil Sampling Procedure As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. Trend elements of equipment wear. Problems associated with the lubricant or the machine not just when a limit is breached, but when. Lubricating Oil Sampling Procedure.

From www.machinerylubrication.com

A Guide to Oil Sampling Hardware Machinery Lubrication Lubricating Oil Sampling Procedure Trend elements of equipment wear. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. • the flow rate should ideally be turbulent to keep. As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. Problems associated with the lubricant or the. Lubricating Oil Sampling Procedure.

From ro-quip.com

Oil Sampling ROQUIP Lubricating Oil Sampling Procedure An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. Trend elements of equipment wear. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. As such engine oil drain intervals depend upon the engine type and design,. Lubricating Oil Sampling Procedure.

From www.machinerylubricationindia.com

How to Visually Inspect the Health and State of Oil Lubricating Oil Sampling Procedure • the flow rate should ideally be turbulent to keep. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. An effective oil analysis programoil analysis is an integral part of the maintenance plan for power generation and. As such engine oil drain intervals depend upon the engine type and design, the. Lubricating Oil Sampling Procedure.

From www.researchgate.net

Schematic showing fluid sampling procedure. Download Scientific Diagram Lubricating Oil Sampling Procedure 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. Trend elements of equipment wear. • the flow rate should ideally be turbulent to keep. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. • the pipe. Lubricating Oil Sampling Procedure.

From sofzer.com

Lube Oil Sampling Kits Sofzer Technologies Private Limited Lubricating Oil Sampling Procedure • the flow rate should ideally be turbulent to keep. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. Trend elements of equipment wear. It is followed by overviews of some key oil analysis. Problems associated with the lubricant or the machine not just when a limit is breached, but when. Lubricating Oil Sampling Procedure.

From www.tuv-nord.com

Lube Oil / Lubricating Oil Analysis Blog TUV India Lubricating Oil Sampling Procedure • the flow rate should ideally be turbulent to keep. As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. 8 basics of oil analysis oil. Lubricating Oil Sampling Procedure.

From www.tandeltasystems.com

Tips for Effective Oil Sampling Tandelta Systems Lubricating Oil Sampling Procedure As such engine oil drain intervals depend upon the engine type and design, the lubricating oil consumption, the engine oil. It is followed by overviews of some key oil analysis. • the flow rate should ideally be turbulent to keep. Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate. Lubricating Oil Sampling Procedure.

From www.machinerylubrication.com

The Basics of Used Oil Sampling Machinery Lubrication Lubricating Oil Sampling Procedure Problems associated with the lubricant or the machine not just when a limit is breached, but when an abnormal rate of change is acknowledged. 8 basics of oil analysis oil analysis can be applied to equipment and lubricant utilization, maintenance and management. It is followed by overviews of some key oil analysis. Trend elements of equipment wear. As such engine. Lubricating Oil Sampling Procedure.