Maximum Depth Of Cut For End Mills . Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. The maximum possible depth depends mainly on the. The axia depth of cut is also called stepdown and cut depth. The program limits you to a depth of cut of 1.5. The max depth you should use in a slot cut is the diameter of the end mill, so for a 1/4 od end mill, you can cut 1/4 deep at a time. Conversely, the maximum depth of cut can reach up to 10 mm, depending on the. What is the maximum depth of cut in machining? Determine the maximum axial depth of cut the tool will experience in the part. It factors in depth and width of cut when doing end milling feed and speed calculations. A typical end mill removes material from the side and. It is designated by ap or adoc. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. When cutting a full width slot you use the full diameter of the tool, maximum pressure when milling.

from www.mscdirect.com

The maximum possible depth depends mainly on the. It is designated by ap or adoc. It factors in depth and width of cut when doing end milling feed and speed calculations. The program limits you to a depth of cut of 1.5. The axia depth of cut is also called stepdown and cut depth. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. When cutting a full width slot you use the full diameter of the tool, maximum pressure when milling. Determine the maximum axial depth of cut the tool will experience in the part. What is the maximum depth of cut in machining? A typical end mill removes material from the side and.

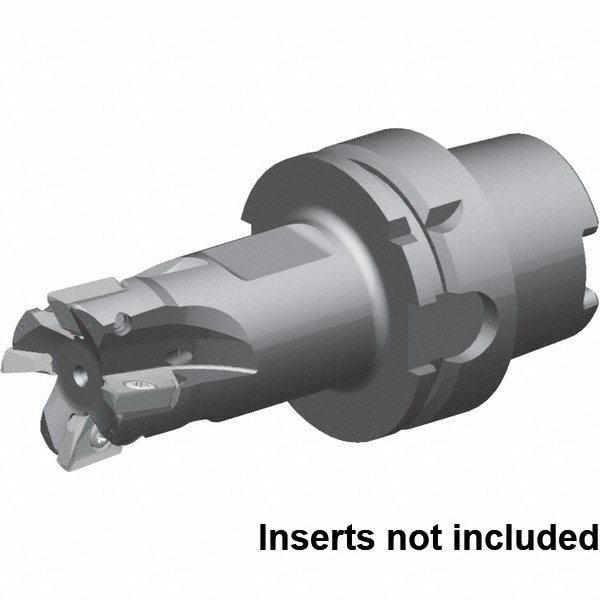

Kennametal Indexable SquareShoulder End Mill 5720VZ16HA040Z4R75, 40

Maximum Depth Of Cut For End Mills The program limits you to a depth of cut of 1.5. It is designated by ap or adoc. The max depth you should use in a slot cut is the diameter of the end mill, so for a 1/4 od end mill, you can cut 1/4 deep at a time. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. Determine the maximum axial depth of cut the tool will experience in the part. The axia depth of cut is also called stepdown and cut depth. The program limits you to a depth of cut of 1.5. A typical end mill removes material from the side and. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. What is the maximum depth of cut in machining? It factors in depth and width of cut when doing end milling feed and speed calculations. Conversely, the maximum depth of cut can reach up to 10 mm, depending on the. When cutting a full width slot you use the full diameter of the tool, maximum pressure when milling. The maximum possible depth depends mainly on the.

From www.mscdirect.com

Seco 40mm Cutting Diam, 6mm Max Depth of Cut, M16 Modular Connection Maximum Depth Of Cut For End Mills The max depth you should use in a slot cut is the diameter of the end mill, so for a 1/4 od end mill, you can cut 1/4 deep at a time. A typical end mill removes material from the side and. The optimal depth of cut for a machining process depends upon various factors such as type of material,. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Walter Indexable Copy End Mill 24 to 32 mm Cut Dia, 3.99 mm Max Maximum Depth Of Cut For End Mills Conversely, the maximum depth of cut can reach up to 10 mm, depending on the. The max depth you should use in a slot cut is the diameter of the end mill, so for a 1/4 od end mill, you can cut 1/4 deep at a time. A typical end mill removes material from the side and. When cutting a. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Sumitomo Indexable SquareShoulder End Mill WEZ11025E0420, 25 mm Maximum Depth Of Cut For End Mills What is the maximum depth of cut in machining? The program limits you to a depth of cut of 1.5. A typical end mill removes material from the side and. The maximum possible depth depends mainly on the. Determine the maximum axial depth of cut the tool will experience in the part. Conversely, the maximum depth of cut can reach. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Iscar Indexable Copy End Mill 10 to 20 mm Cut Dia, 7.5 mm Max Depth Maximum Depth Of Cut For End Mills The program limits you to a depth of cut of 1.5. Determine the maximum axial depth of cut the tool will experience in the part. It is designated by ap or adoc. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. What is the maximum depth of. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Tungaloy Indexable SquareShoulder End Mills; Minimum Cutting Maximum Depth Of Cut For End Mills The max depth you should use in a slot cut is the diameter of the end mill, so for a 1/4 od end mill, you can cut 1/4 deep at a time. The program limits you to a depth of cut of 1.5. What is the maximum depth of cut in machining? It factors in depth and width of cut. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Sumitomo Indexable SquareShoulder End Mill WEZ17030M16Z2, 30 mm Cut Maximum Depth Of Cut For End Mills It factors in depth and width of cut when doing end milling feed and speed calculations. The axia depth of cut is also called stepdown and cut depth. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. What is the maximum depth of cut in machining? The. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Seco Indexable Copy End Mill 5 mm Max Depth of Cut, Through Coolant Maximum Depth Of Cut For End Mills The axia depth of cut is also called stepdown and cut depth. It factors in depth and width of cut when doing end milling feed and speed calculations. The program limits you to a depth of cut of 1.5. When cutting a full width slot you use the full diameter of the tool, maximum pressure when milling. The optimal depth. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Ceratizit Indexable SquareShoulder End Mills; Minimum Cutting Maximum Depth Of Cut For End Mills The maximum possible depth depends mainly on the. Determine the maximum axial depth of cut the tool will experience in the part. The program limits you to a depth of cut of 1.5. The axia depth of cut is also called stepdown and cut depth. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Seco Indexable SquareShoulder End Mills; Minimum Cutting Diameter 2 Maximum Depth Of Cut For End Mills The program limits you to a depth of cut of 1.5. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. A typical end mill removes material from the side and. The axia depth of cut is also called stepdown and cut depth. When cutting a full width. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Ceratizit Indexable SquareShoulder End Mills; Minimum Cutting Maximum Depth Of Cut For End Mills It is designated by ap or adoc. The axia depth of cut is also called stepdown and cut depth. The maximum possible depth depends mainly on the. What is the maximum depth of cut in machining? The max depth you should use in a slot cut is the diameter of the end mill, so for a 1/4 od end mill,. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Sumitomo Indexable SquareShoulder End Mill TSXM13040E, 40 mm Cut Maximum Depth Of Cut For End Mills The axia depth of cut is also called stepdown and cut depth. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. The maximum possible depth depends mainly on the. A typical end mill removes material from the side and. Conversely, the maximum depth. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Walter Indexable Copy Face Mills; Maximum Depth Of Cut 8.00mm Maximum Depth Of Cut For End Mills It is designated by ap or adoc. Conversely, the maximum depth of cut can reach up to 10 mm, depending on the. What is the maximum depth of cut in machining? A typical end mill removes material from the side and. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Sumitomo Indexable SquareShoulder End Mill WEZ17040EL02, 40 mm Cut Maximum Depth Of Cut For End Mills The max depth you should use in a slot cut is the diameter of the end mill, so for a 1/4 od end mill, you can cut 1/4 deep at a time. The maximum possible depth depends mainly on the. The axia depth of cut is also called stepdown and cut depth. Generally, a shallow depth of cut is recommended. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Walter Indexable Copy End Mill 16 to 32 mm Cut Dia, 8 mm Max Depth Maximum Depth Of Cut For End Mills Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. The maximum possible depth depends mainly on the. Determine the maximum axial depth of cut the tool will experience in the part. A typical end mill removes material from the side and. When cutting a full width slot. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Tungaloy Indexable SquareShoulder End Mills; Minimum Cutting Maximum Depth Of Cut For End Mills Conversely, the maximum depth of cut can reach up to 10 mm, depending on the. It factors in depth and width of cut when doing end milling feed and speed calculations. What is the maximum depth of cut in machining? The max depth you should use in a slot cut is the diameter of the end mill, so for a. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Ceratizit Indexable SquareShoulder End Mills; Minimum Cutting Maximum Depth Of Cut For End Mills The maximum possible depth depends mainly on the. The axia depth of cut is also called stepdown and cut depth. It factors in depth and width of cut when doing end milling feed and speed calculations. Conversely, the maximum depth of cut can reach up to 10 mm, depending on the. The program limits you to a depth of cut. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Seco Indexable SquareShoulder End Mills; Minimum Cutting Diameter Maximum Depth Of Cut For End Mills It factors in depth and width of cut when doing end milling feed and speed calculations. Determine the maximum axial depth of cut the tool will experience in the part. The maximum possible depth depends mainly on the. What is the maximum depth of cut in machining? The axia depth of cut is also called stepdown and cut depth. When. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Iscar Indexable HighFeed End Mills; Cutting Diameter (mm) 7.70 Maximum Depth Of Cut For End Mills The maximum possible depth depends mainly on the. Conversely, the maximum depth of cut can reach up to 10 mm, depending on the. The program limits you to a depth of cut of 1.5. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. When cutting a full. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Iscar 30° Lead Angle, 25mm Max Cut Diam, 15.5mm Min Cut Diam, 2mm Max Maximum Depth Of Cut For End Mills What is the maximum depth of cut in machining? The maximum possible depth depends mainly on the. It factors in depth and width of cut when doing end milling feed and speed calculations. The max depth you should use in a slot cut is the diameter of the end mill, so for a 1/4 od end mill, you can cut. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Ceratizit Indexable SquareShoulder End Mills; Minimum Cutting Maximum Depth Of Cut For End Mills What is the maximum depth of cut in machining? Conversely, the maximum depth of cut can reach up to 10 mm, depending on the. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. It factors in depth and width of cut when doing. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Ceratizit Indexable SquareShoulder End Mills; Minimum Cutting Maximum Depth Of Cut For End Mills When cutting a full width slot you use the full diameter of the tool, maximum pressure when milling. The max depth you should use in a slot cut is the diameter of the end mill, so for a 1/4 od end mill, you can cut 1/4 deep at a time. Determine the maximum axial depth of cut the tool will. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Widia Indexable Chamfer & Angle End Mills; Cutting Diameter (mm) 25 Maximum Depth Of Cut For End Mills The program limits you to a depth of cut of 1.5. A typical end mill removes material from the side and. What is the maximum depth of cut in machining? The axia depth of cut is also called stepdown and cut depth. The maximum possible depth depends mainly on the. Conversely, the maximum depth of cut can reach up to. Maximum Depth Of Cut For End Mills.

From endmill.com.au

Choosing the right end mill for the job Adam's Bits Maximum Depth Of Cut For End Mills Determine the maximum axial depth of cut the tool will experience in the part. The program limits you to a depth of cut of 1.5. Conversely, the maximum depth of cut can reach up to 10 mm, depending on the. What is the maximum depth of cut in machining? The maximum possible depth depends mainly on the. The max depth. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Walter Indexable Copy End Mill 8 to 16 mm Cut Dia, 3.99 mm Max Depth Maximum Depth Of Cut For End Mills It factors in depth and width of cut when doing end milling feed and speed calculations. The program limits you to a depth of cut of 1.5. What is the maximum depth of cut in machining? Conversely, the maximum depth of cut can reach up to 10 mm, depending on the. The max depth you should use in a slot. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable Plunge End Mills; Maximum Cutting Maximum Depth Of Cut For End Mills The program limits you to a depth of cut of 1.5. It factors in depth and width of cut when doing end milling feed and speed calculations. What is the maximum depth of cut in machining? A typical end mill removes material from the side and. The axia depth of cut is also called stepdown and cut depth. It is. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Ceratizit Indexable SquareShoulder End Mills; Minimum Cutting Maximum Depth Of Cut For End Mills It is designated by ap or adoc. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. When cutting a full width slot you use the full diameter of the tool, maximum pressure when milling. Determine the maximum axial depth of cut the tool will experience in the. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Kyocera 40mm Cut Diam, 6mm Max Depth, 40mm OAL, Indexable Square Maximum Depth Of Cut For End Mills Determine the maximum axial depth of cut the tool will experience in the part. A typical end mill removes material from the side and. The maximum possible depth depends mainly on the. When cutting a full width slot you use the full diameter of the tool, maximum pressure when milling. Conversely, the maximum depth of cut can reach up to. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Widia Indexable Chamfer & Angle End Mills; Cutting Diameter (mm) 25 Maximum Depth Of Cut For End Mills What is the maximum depth of cut in machining? The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. It is designated. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Tungaloy Indexable SquareShoulder End Mills; Minimum Cutting Maximum Depth Of Cut For End Mills When cutting a full width slot you use the full diameter of the tool, maximum pressure when milling. What is the maximum depth of cut in machining? The program limits you to a depth of cut of 1.5. A typical end mill removes material from the side and. The optimal depth of cut for a machining process depends upon various. Maximum Depth Of Cut For End Mills.

From www.cnccookbook.com

Ball Nose End Mill [Easy Guide to Ball Cutters] CNCCookbook Be A Maximum Depth Of Cut For End Mills The maximum possible depth depends mainly on the. The program limits you to a depth of cut of 1.5. It is designated by ap or adoc. A typical end mill removes material from the side and. Conversely, the maximum depth of cut can reach up to 10 mm, depending on the. What is the maximum depth of cut in machining?. Maximum Depth Of Cut For End Mills.

From earthasowers.blogspot.com

end mill shank types Eartha Sowers Maximum Depth Of Cut For End Mills It factors in depth and width of cut when doing end milling feed and speed calculations. When cutting a full width slot you use the full diameter of the tool, maximum pressure when milling. It is designated by ap or adoc. The optimal depth of cut for a machining process depends upon various factors such as type of material, type. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Kennametal Indexable SquareShoulder End Mill 5720VZ16HA040Z4R75, 40 Maximum Depth Of Cut For End Mills Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. A typical end mill removes material from the side and. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. The program. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Kyocera Indexable SquareShoulder End Mill MEV32S25064T, 32 mm Cut Maximum Depth Of Cut For End Mills It is designated by ap or adoc. A typical end mill removes material from the side and. The program limits you to a depth of cut of 1.5. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. When cutting a full width slot. Maximum Depth Of Cut For End Mills.

From www.mscdirect.com

Walter Indexable Copy End Mills; Maximum Depth Of Cut 3.51mm ; Shank Maximum Depth Of Cut For End Mills The program limits you to a depth of cut of 1.5. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. What is the maximum depth of cut in machining? The optimal depth of cut for a machining process depends upon various factors such as type of material,. Maximum Depth Of Cut For End Mills.

From www.qualitytechtool.com

General Purpose End Mills Metric Quality Tech Tool Maximum Depth Of Cut For End Mills When cutting a full width slot you use the full diameter of the tool, maximum pressure when milling. A typical end mill removes material from the side and. It factors in depth and width of cut when doing end milling feed and speed calculations. The optimal depth of cut for a machining process depends upon various factors such as type. Maximum Depth Of Cut For End Mills.