Cooling Tower Splash Fill . Splash fills have been used in cooling towers for almost as long as cooling towers have existed. Discover which fill is best for cooling towers in our detailed guide. Learn about the working of splash and film fills, performance parameters, and the impact of water quality on fill pack efficiency to. The splash fill breaks the water into smaller droplets, continually. Brentwood manufactures everything you need to successfully install a splash fill system in your cooling tower. The original splash fill designs of simple wood slats hung in a gridwork system, or platforms. Splash for dirty water, film for clean water. Choose the right cooling tower fill: On the other hand, film fill medium produces a more extensive surface area and optimized. In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. Enhance heat dissipation and operational efficiency. This includes supports, hanger brackets, wire hangers, and splash clips to ensure easy. Instead of sheet surface, splash fills increase the water droplet surface. It may be the least efficient fill, but a bar type fill is easier to clean and is more. A bar type fill takes the form of splash bars throughout the tower, allowing for larger debris to be passed through.

from spxcooling.com

This includes supports, hanger brackets, wire hangers, and splash clips to ensure easy. It may be the least efficient fill, but a bar type fill is easier to clean and is more. On the other hand, film fill medium produces a more extensive surface area and optimized. In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. A bar type fill takes the form of splash bars throughout the tower, allowing for larger debris to be passed through. Either type of fill may be used in. The splash fill breaks the water into smaller droplets, continually. The original splash fill designs of simple wood slats hung in a gridwork system, or platforms. Learn about the working of splash and film fills, performance parameters, and the impact of water quality on fill pack efficiency to. Splash fills have been used in cooling towers for almost as long as cooling towers have existed.

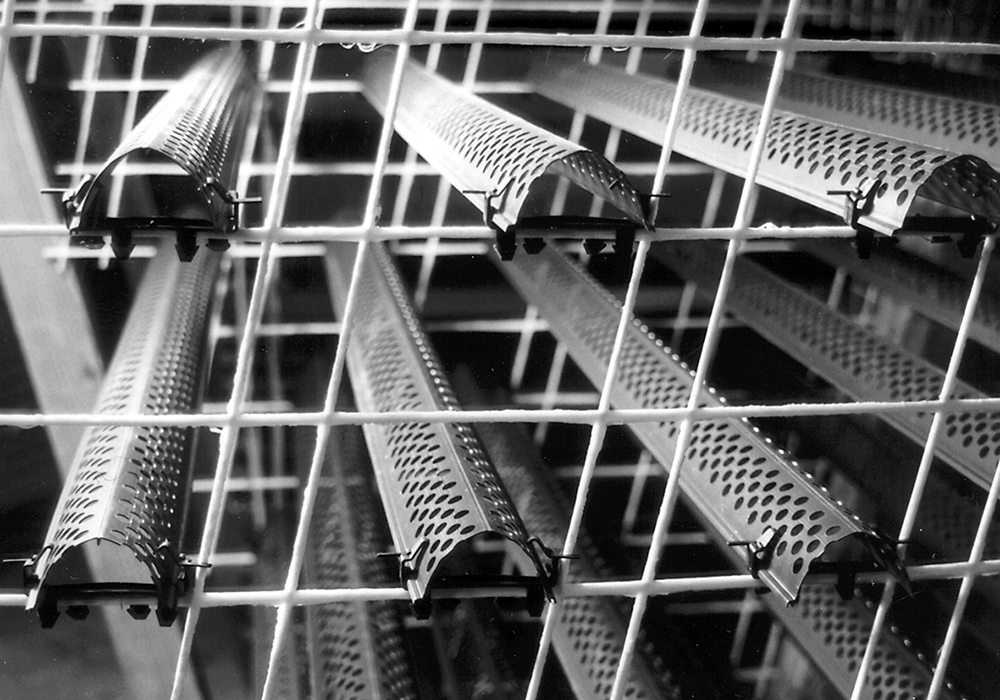

Omega Crossflow Splash Fill SPX Cooling Towers

Cooling Tower Splash Fill A bar type fill takes the form of splash bars throughout the tower, allowing for larger debris to be passed through. Splash fills have been used in cooling towers for almost as long as cooling towers have existed. On the other hand, film fill medium produces a more extensive surface area and optimized. Brentwood manufactures everything you need to successfully install a splash fill system in your cooling tower. Enhance heat dissipation and operational efficiency. In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. Learn about the working of splash and film fills, performance parameters, and the impact of water quality on fill pack efficiency to. The original splash fill designs of simple wood slats hung in a gridwork system, or platforms. It may be the least efficient fill, but a bar type fill is easier to clean and is more. This includes supports, hanger brackets, wire hangers, and splash clips to ensure easy. The splash fill breaks the water into smaller droplets, continually. Choose the right cooling tower fill: Either type of fill may be used in. A bar type fill takes the form of splash bars throughout the tower, allowing for larger debris to be passed through. Discover which fill is best for cooling towers in our detailed guide. Instead of sheet surface, splash fills increase the water droplet surface.

From cooling-solutions.blogspot.com

Cooling Tower Solutions Cooling Tower Fill Types Splash or Film Cooling Tower Splash Fill Choose the right cooling tower fill: It may be the least efficient fill, but a bar type fill is easier to clean and is more. Splash fills have been used in cooling towers for almost as long as cooling towers have existed. Splash for dirty water, film for clean water. The original splash fill designs of simple wood slats hung. Cooling Tower Splash Fill.

From spxcooling.com

Marley NC Alpha [Splash Fill] SPX Cooling Towers Cooling Tower Splash Fill Either type of fill may be used in. On the other hand, film fill medium produces a more extensive surface area and optimized. In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. The splash fill breaks the water into smaller droplets, continually. The original splash fill designs of simple. Cooling Tower Splash Fill.

From spxcooling.com

Mesa Crossflow Splash Fill SPX Cooling Towers Cooling Tower Splash Fill A bar type fill takes the form of splash bars throughout the tower, allowing for larger debris to be passed through. The original splash fill designs of simple wood slats hung in a gridwork system, or platforms. Choose the right cooling tower fill: Either type of fill may be used in. Enhance heat dissipation and operational efficiency. It may be. Cooling Tower Splash Fill.

From tianjinlatino.en.made-in-china.com

Cooling Tower Splash Grid PP Fill Cooling Tower Fill and Cooling Cooling Tower Splash Fill The splash fill breaks the water into smaller droplets, continually. Splash fills have been used in cooling towers for almost as long as cooling towers have existed. In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. A bar type fill takes the form of splash bars throughout the tower,. Cooling Tower Splash Fill.

From www.marleyflow.com.au

Which cooling tower fill is best? Find out if it's splash fill or film fill Cooling Tower Splash Fill Brentwood manufactures everything you need to successfully install a splash fill system in your cooling tower. It may be the least efficient fill, but a bar type fill is easier to clean and is more. The original splash fill designs of simple wood slats hung in a gridwork system, or platforms. Splash for dirty water, film for clean water. A. Cooling Tower Splash Fill.

From www.goldcoolingtowers.net

Cooling Tower Fills Pvc Fills Cooling Tower Manufacturer from Coimbatore Cooling Tower Splash Fill Enhance heat dissipation and operational efficiency. Instead of sheet surface, splash fills increase the water droplet surface. Choose the right cooling tower fill: A bar type fill takes the form of splash bars throughout the tower, allowing for larger debris to be passed through. The splash fill breaks the water into smaller droplets, continually. Splash for dirty water, film for. Cooling Tower Splash Fill.

From www.steadyegypt.com

Splash grid fill steady tower is a specialist provider of cooling Cooling Tower Splash Fill Brentwood manufactures everything you need to successfully install a splash fill system in your cooling tower. The splash fill breaks the water into smaller droplets, continually. Instead of sheet surface, splash fills increase the water droplet surface. Enhance heat dissipation and operational efficiency. Splash fills have been used in cooling towers for almost as long as cooling towers have existed.. Cooling Tower Splash Fill.

From www.coolingtowerinfill.com

CF1900 Film and splash fill Cooling Tower Splash Fill Discover which fill is best for cooling towers in our detailed guide. It may be the least efficient fill, but a bar type fill is easier to clean and is more. A bar type fill takes the form of splash bars throughout the tower, allowing for larger debris to be passed through. The original splash fill designs of simple wood. Cooling Tower Splash Fill.

From tianjinlatino.en.made-in-china.com

PVC Cooling Tower Splash Fill Black Color Grid Fills Cooling Tower Cooling Tower Splash Fill On the other hand, film fill medium produces a more extensive surface area and optimized. A bar type fill takes the form of splash bars throughout the tower, allowing for larger debris to be passed through. Learn about the working of splash and film fills, performance parameters, and the impact of water quality on fill pack efficiency to. Splash fills. Cooling Tower Splash Fill.

From www.tianjinlatino.com

Splash grid fill for cooling tower Cooling Tower Splash Fill This includes supports, hanger brackets, wire hangers, and splash clips to ensure easy. In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. The original splash fill designs of simple wood slats hung in a gridwork system, or platforms. Choose the right cooling tower fill: Instead of sheet surface, splash. Cooling Tower Splash Fill.

From www.indiamart.com

Cooling Tower Splash Fill Grid at best price in Mumbai by Cool Fab Cooling Tower Splash Fill Instead of sheet surface, splash fills increase the water droplet surface. This includes supports, hanger brackets, wire hangers, and splash clips to ensure easy. Learn about the working of splash and film fills, performance parameters, and the impact of water quality on fill pack efficiency to. The splash fill breaks the water into smaller droplets, continually. Discover which fill is. Cooling Tower Splash Fill.

From www.goldcoolingtowers.com

Timber Cooling Tower Splash Bar Fills, Manufacturer, Supplier, Latest Price Cooling Tower Splash Fill Splash for dirty water, film for clean water. Either type of fill may be used in. It may be the least efficient fill, but a bar type fill is easier to clean and is more. The splash fill breaks the water into smaller droplets, continually. Instead of sheet surface, splash fills increase the water droplet surface. A bar type fill. Cooling Tower Splash Fill.

From blog.allkoteliningincaz.com

Cooling Tower Fill Types Cooling Tower Splash Fill In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. Enhance heat dissipation and operational efficiency. Choose the right cooling tower fill: It may be the least efficient fill, but a bar type fill is easier to clean and is more. On the other hand, film fill medium produces a. Cooling Tower Splash Fill.

From newinmachine.en.made-in-china.com

PVC Cooling Tower Splash Fill Blue Color Grid Fills Splash Cooling Cooling Tower Splash Fill In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. Instead of sheet surface, splash fills increase the water droplet surface. Enhance heat dissipation and operational efficiency. Learn about the working of splash and film fills, performance parameters, and the impact of water quality on fill pack efficiency to. A. Cooling Tower Splash Fill.

From www.tianjinlatino.com

Supply Cooling Tower Splash PVC Fills Wholesale Factory Tianjin Cooling Tower Splash Fill On the other hand, film fill medium produces a more extensive surface area and optimized. In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. Enhance heat dissipation and operational efficiency. Either type of fill may be used in. Splash fills have been used in cooling towers for almost as. Cooling Tower Splash Fill.

From www.cotor.it

Splash fills and drift eliminators for cooling towers Cotor Cooling Tower Splash Fill Discover which fill is best for cooling towers in our detailed guide. It may be the least efficient fill, but a bar type fill is easier to clean and is more. The original splash fill designs of simple wood slats hung in a gridwork system, or platforms. Learn about the working of splash and film fills, performance parameters, and the. Cooling Tower Splash Fill.

From spxcooling.com

Omega Crossflow Splash Fill SPX Cooling Towers Cooling Tower Splash Fill Splash for dirty water, film for clean water. Choose the right cooling tower fill: Splash fills have been used in cooling towers for almost as long as cooling towers have existed. In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. Learn about the working of splash and film fills,. Cooling Tower Splash Fill.

From www.coolingtowerfiller.com

Splash Fill for Cooling Tower Cooling Tower Fill,Cooling Tower Cooling Tower Splash Fill The splash fill breaks the water into smaller droplets, continually. This includes supports, hanger brackets, wire hangers, and splash clips to ensure easy. In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. Choose the right cooling tower fill: Discover which fill is best for cooling towers in our detailed. Cooling Tower Splash Fill.

From araco.ir

Cooling tower net splash fill Cooling Tower Splash Fill Choose the right cooling tower fill: Either type of fill may be used in. Learn about the working of splash and film fills, performance parameters, and the impact of water quality on fill pack efficiency to. A bar type fill takes the form of splash bars throughout the tower, allowing for larger debris to be passed through. This includes supports,. Cooling Tower Splash Fill.

From spxcooling.com

Alpha III Crossflow Splash Fill SPX Cooling Towers Cooling Tower Splash Fill Choose the right cooling tower fill: In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. The splash fill breaks the water into smaller droplets, continually. Splash for dirty water, film for clean water. Either type of fill may be used in. Learn about the working of splash and film. Cooling Tower Splash Fill.

From tianjinlatino.en.made-in-china.com

Cooling Tower PP Material OptiGrid Splash Fill Cooling Tower Fill Cooling Tower Splash Fill Instead of sheet surface, splash fills increase the water droplet surface. The original splash fill designs of simple wood slats hung in a gridwork system, or platforms. Brentwood manufactures everything you need to successfully install a splash fill system in your cooling tower. This includes supports, hanger brackets, wire hangers, and splash clips to ensure easy. Enhance heat dissipation and. Cooling Tower Splash Fill.

From www.brentwoodindustries.com

Cooling Tower Components & Solutions Brentwood Industries Cooling Tower Splash Fill Discover which fill is best for cooling towers in our detailed guide. Instead of sheet surface, splash fills increase the water droplet surface. Splash fills have been used in cooling towers for almost as long as cooling towers have existed. Choose the right cooling tower fill: A bar type fill takes the form of splash bars throughout the tower, allowing. Cooling Tower Splash Fill.

From www.marleyflow.com.au

Which cooling tower fill is best? Find out if it's splash fill or film fill Cooling Tower Splash Fill Enhance heat dissipation and operational efficiency. Either type of fill may be used in. Choose the right cooling tower fill: The splash fill breaks the water into smaller droplets, continually. The original splash fill designs of simple wood slats hung in a gridwork system, or platforms. Learn about the working of splash and film fills, performance parameters, and the impact. Cooling Tower Splash Fill.

From www.towertechindia.com

What You Must Know About Cooling Tower Fill Media Tower Tech Cooling Tower Splash Fill Brentwood manufactures everything you need to successfully install a splash fill system in your cooling tower. Choose the right cooling tower fill: Splash fills have been used in cooling towers for almost as long as cooling towers have existed. The original splash fill designs of simple wood slats hung in a gridwork system, or platforms. Either type of fill may. Cooling Tower Splash Fill.

From tianjinlatino.en.made-in-china.com

Golden Splash Grid Fill 705*705mm for Hamon Cooling Towers Cooling Cooling Tower Splash Fill Enhance heat dissipation and operational efficiency. The splash fill breaks the water into smaller droplets, continually. In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. Discover which fill is best for cooling towers in our detailed guide. A bar type fill takes the form of splash bars throughout the. Cooling Tower Splash Fill.

From www.tianjinlatino.com

Cooling Tower Splash Grid Fill Installation From Tianjin Latino Cooling Tower Splash Fill Choose the right cooling tower fill: In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. Splash for dirty water, film for clean water. Learn about the working of splash and film fills, performance parameters, and the impact of water quality on fill pack efficiency to. Splash fills have been. Cooling Tower Splash Fill.

From spxcooling.com

Marley NC Alpha [Splash Fill] SPX Cooling Towers Cooling Tower Splash Fill Instead of sheet surface, splash fills increase the water droplet surface. The original splash fill designs of simple wood slats hung in a gridwork system, or platforms. Splash for dirty water, film for clean water. This includes supports, hanger brackets, wire hangers, and splash clips to ensure easy. Brentwood manufactures everything you need to successfully install a splash fill system. Cooling Tower Splash Fill.

From towercomponentsinc.com

Cooling Tower Basics Splash Fills Tower Components Cooling Tower Splash Fill Enhance heat dissipation and operational efficiency. In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. Choose the right cooling tower fill: Instead of sheet surface, splash fills increase the water droplet surface. Brentwood manufactures everything you need to successfully install a splash fill system in your cooling tower. Discover. Cooling Tower Splash Fill.

From tianjinlatino.en.made-in-china.com

Cooling Tower Splash Fill for Cross Flow Cooling Towers Cooling Tower Cooling Tower Splash Fill Splash fills have been used in cooling towers for almost as long as cooling towers have existed. Brentwood manufactures everything you need to successfully install a splash fill system in your cooling tower. Either type of fill may be used in. On the other hand, film fill medium produces a more extensive surface area and optimized. Enhance heat dissipation and. Cooling Tower Splash Fill.

From spxcooling.com

NC20 Counterflow Splash Fill SPX Cooling Towers Cooling Tower Splash Fill Either type of fill may be used in. The splash fill breaks the water into smaller droplets, continually. On the other hand, film fill medium produces a more extensive surface area and optimized. Instead of sheet surface, splash fills increase the water droplet surface. Brentwood manufactures everything you need to successfully install a splash fill system in your cooling tower.. Cooling Tower Splash Fill.

From newinmachine.en.made-in-china.com

Cooling Tower Splash Fill Specially Designed for Industrial Purpose Cooling Tower Splash Fill Choose the right cooling tower fill: Discover which fill is best for cooling towers in our detailed guide. Brentwood manufactures everything you need to successfully install a splash fill system in your cooling tower. It may be the least efficient fill, but a bar type fill is easier to clean and is more. In a cooling tower, splash fill and. Cooling Tower Splash Fill.

From h2ocooling.com

Splash Fill New Cooling Tower Construction, Parts, Maintenance, Upgrades Cooling Tower Splash Fill The original splash fill designs of simple wood slats hung in a gridwork system, or platforms. Brentwood manufactures everything you need to successfully install a splash fill system in your cooling tower. In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. Choose the right cooling tower fill: On the. Cooling Tower Splash Fill.

From engineeredthermalsolutions.com

Splash Fill Cooling Tower Cooling Tower Splash Fill In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. Either type of fill may be used in. Splash fills have been used in cooling towers for almost as long as cooling towers have existed. Discover which fill is best for cooling towers in our detailed guide. Enhance heat dissipation. Cooling Tower Splash Fill.

From www.indiamart.com

Cooling Tower Splash Fills at Rs 28/piece Cooling Tower Fills in Cooling Tower Splash Fill In a cooling tower, splash fill and film fill work well together to speed up the evaporation and cooling effect. This includes supports, hanger brackets, wire hangers, and splash clips to ensure easy. Either type of fill may be used in. Enhance heat dissipation and operational efficiency. It may be the least efficient fill, but a bar type fill is. Cooling Tower Splash Fill.

From spxcooling.com

VC25 Counterflow Splash Fill SPX Cooling Towers Cooling Tower Splash Fill Learn about the working of splash and film fills, performance parameters, and the impact of water quality on fill pack efficiency to. A bar type fill takes the form of splash bars throughout the tower, allowing for larger debris to be passed through. Instead of sheet surface, splash fills increase the water droplet surface. Discover which fill is best for. Cooling Tower Splash Fill.