End Mill Wear Chart . — carbide end mills wear usually includes the following types: miracle coating is produced by adding al to the existing tin coating. — in this article, we’ll take a look at the four main factors that cause end mills to perform differently: By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium quality control. This coating layer consists of a compound solid solution of. We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. Making products having desired surface shape by. learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. Putting and moving a cutting tool on a work piece, and. ① back cutting edge wear;

from dxoehajvj.blob.core.windows.net

① back cutting edge wear; The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium quality control. miracle coating is produced by adding al to the existing tin coating. By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. This coating layer consists of a compound solid solution of. learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. Putting and moving a cutting tool on a work piece, and. We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. Making products having desired surface shape by. — in this article, we’ll take a look at the four main factors that cause end mills to perform differently:

End Mill Cutter Standard Metric Sizes at Kimberley Lay blog

End Mill Wear Chart This coating layer consists of a compound solid solution of. miracle coating is produced by adding al to the existing tin coating. ① back cutting edge wear; By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium quality control. Putting and moving a cutting tool on a work piece, and. This coating layer consists of a compound solid solution of. Making products having desired surface shape by. learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. — carbide end mills wear usually includes the following types: — in this article, we’ll take a look at the four main factors that cause end mills to perform differently:

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium quality control. This coating layer consists of a compound solid solution of. — carbide end mills wear usually includes the following types: ① back cutting edge wear; learn how to identify the most common tool wear patterns in machining, common. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart Putting and moving a cutting tool on a work piece, and. We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. The grade or quality of the carbide. End Mill Wear Chart.

From dxoehajvj.blob.core.windows.net

End Mill Cutter Standard Metric Sizes at Kimberley Lay blog End Mill Wear Chart The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium quality control. By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. miracle coating is produced by adding al to the existing tin coating. ① back cutting edge wear; — in this article, we’ll take a look at the four main factors that cause end mills. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart Making products having desired surface shape by. ① back cutting edge wear; learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. This coating. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart — carbide end mills wear usually includes the following types: We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. miracle coating is produced by adding al to the existing tin coating. By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve. End Mill Wear Chart.

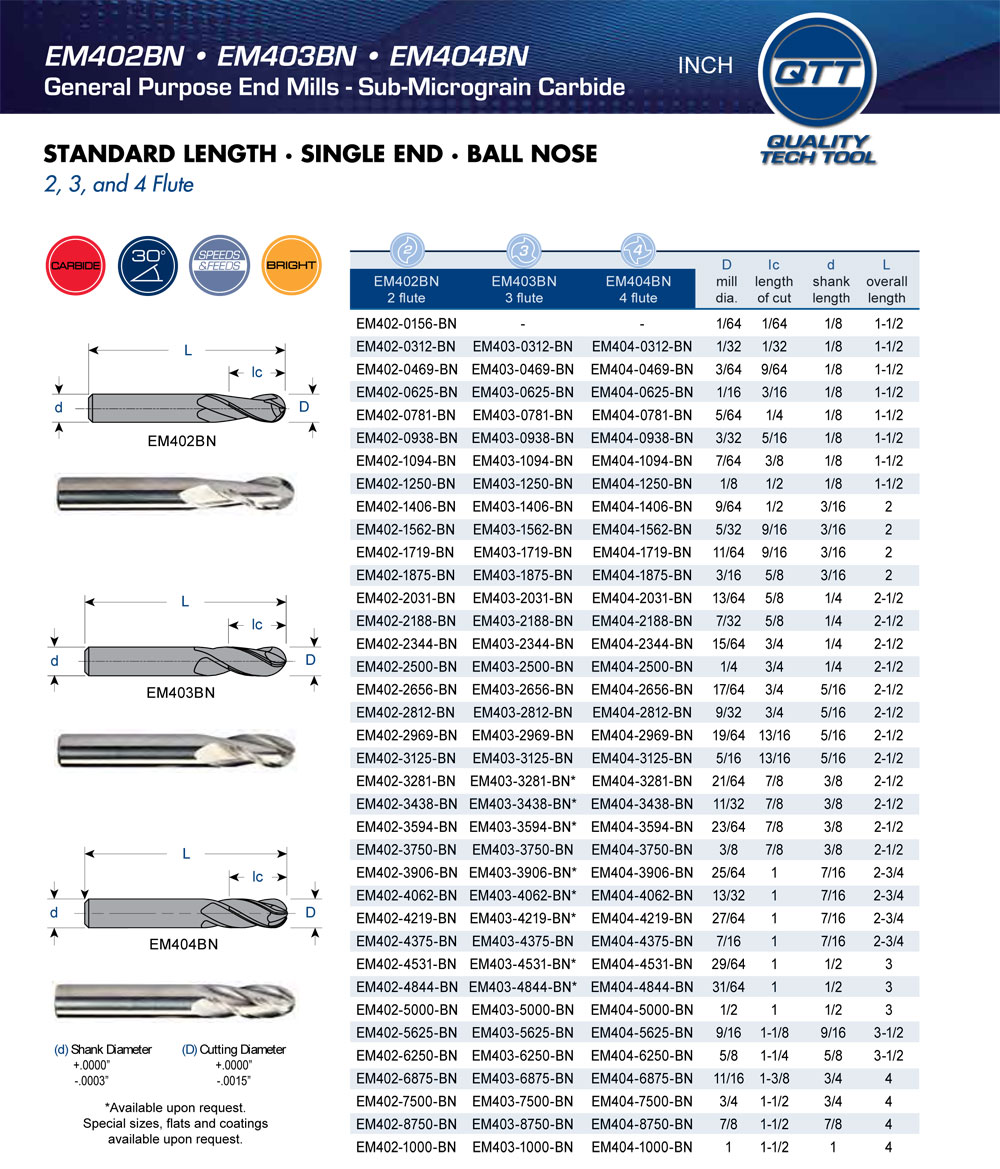

From www.qualitytechtool.com

Premium Class End Mills Metric Quality Tech Tool End Mill Wear Chart — carbide end mills wear usually includes the following types: We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. ① back cutting edge wear; This coating layer consists of a compound solid solution of. Putting and moving a cutting tool on a work piece, and. The grade or. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart This coating layer consists of a compound solid solution of. Making products having desired surface shape by. We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. Putting. End Mill Wear Chart.

From www.davehylands.com

Charts End Mill Wear Chart miracle coating is produced by adding al to the existing tin coating. ① back cutting edge wear; We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. This coating layer consists of a compound solid solution of. The grade or quality of the carbide they’re made from, their geometry,. End Mill Wear Chart.

From kristlehartmann.blogspot.com

ball end mill size chart Kristle Hartmann End Mill Wear Chart — in this article, we’ll take a look at the four main factors that cause end mills to perform differently: — carbide end mills wear usually includes the following types: miracle coating is produced by adding al to the existing tin coating. This coating layer consists of a compound solid solution of. Making products having desired surface. End Mill Wear Chart.

From mavink.com

Standard End Mill Sizes Chart End Mill Wear Chart learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. This coating layer consists of a compound solid solution of. Making products having desired surface shape by. By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart — in this article, we’ll take a look at the four main factors that cause end mills to perform differently: Making products having desired surface shape by. learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. ① back cutting edge wear; We’ll also tell. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart — carbide end mills wear usually includes the following types: Making products having desired surface shape by. We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium quality control. —. End Mill Wear Chart.

From www.tool-factory.de

HSS end mills Tool Factory End Mill Wear Chart miracle coating is produced by adding al to the existing tin coating. Making products having desired surface shape by. — in this article, we’ll take a look at the four main factors that cause end mills to perform differently: ① back cutting edge wear; — carbide end mills wear usually includes the following types: We’ll also tell. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart ① back cutting edge wear; We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. Making products having desired surface shape by. Putting and moving a. End Mill Wear Chart.

From www.qualitytechtool.com

Premium Class End Mills Metric Quality Tech Tool End Mill Wear Chart learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. — carbide end mills wear usually includes the following types: This coating layer consists of a compound solid solution of. ① back cutting edge wear; By defining and comprehending carbide end mill wear, makers and. End Mill Wear Chart.

From www.researchgate.net

Development of wear over the flank of the end mill used for the End Mill Wear Chart — carbide end mills wear usually includes the following types: ① back cutting edge wear; Making products having desired surface shape by. learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. Putting and moving a cutting tool on a work piece, and. We’ll also. End Mill Wear Chart.

From www.speedtigertools.com

End Mill Size Standards Chart & IntroductionSPEED TIGER End Mill Wear Chart — in this article, we’ll take a look at the four main factors that cause end mills to perform differently: learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. — carbide end mills wear usually includes the following types: By defining and comprehending. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. This coating layer consists of a compound solid solution of. miracle coating is produced by adding al to the existing tin coating. Putting and moving a cutting tool on a work piece, and. learn how to identify the. End Mill Wear Chart.

From www.qualitytechtool.com

General Purpose End Mills Metric Quality Tech Tool End Mill Wear Chart Making products having desired surface shape by. By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. Putting and moving a cutting tool on a work piece, and. miracle coating is produced by adding al to the existing tin coating. — in this article, we’ll take. End Mill Wear Chart.

From onlinesupply.ca

Skookum End Mills End Mill Wear Chart miracle coating is produced by adding al to the existing tin coating. By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. Putting. End Mill Wear Chart.

From www.alibaba.com

End Mill Cutter Sizes;2flute Flattened End Mills With Straight Shank End Mill Wear Chart ① back cutting edge wear; The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium quality control. By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. miracle coating is produced by adding al to the existing tin coating.. End Mill Wear Chart.

From www.qualitytechtool.com

General Purpose End Mills Inch Quality Tech Tool End Mill Wear Chart This coating layer consists of a compound solid solution of. Putting and moving a cutting tool on a work piece, and. learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. — in this article, we’ll take a look at the four main factors that. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart Making products having desired surface shape by. ① back cutting edge wear; — carbide end mills wear usually includes the following types: The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium quality control. This coating layer consists of a compound solid solution of. — in this article, we’ll take. End Mill Wear Chart.

From www.carbideanddiamondtooling.com

Radius 1/32 Shank Dia 3/8 Largest Dia 7/16 Overall Length 2 1 End Mill Wear Chart This coating layer consists of a compound solid solution of. By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. miracle coating is produced by adding al to the existing tin coating. Putting and moving a cutting tool on a work piece, and. learn how to. End Mill Wear Chart.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools End Mill Wear Chart By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium. End Mill Wear Chart.

From mungfali.com

End Mill Cutting Chart End Mill Wear Chart The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium quality control. Making products having desired surface shape by. ① back cutting edge wear; — in this article, we’ll take a look at the four main factors that cause end mills to perform differently: This coating layer consists of a compound. End Mill Wear Chart.

From support.bantamtools.com

End Mill Identification Guide Bantam Tools End Mill Wear Chart — carbide end mills wear usually includes the following types: learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. This coating layer. End Mill Wear Chart.

From exoiopcib.blob.core.windows.net

Standard End Mill Sizes Chart at Joann Pellegrin blog End Mill Wear Chart — in this article, we’ll take a look at the four main factors that cause end mills to perform differently: learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. This coating layer consists of a compound solid solution of. By defining and comprehending carbide. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart Putting and moving a cutting tool on a work piece, and. miracle coating is produced by adding al to the existing tin coating. — carbide end mills wear usually includes the following types: — in this article, we’ll take a look at the four main factors that cause end mills to perform differently: learn how to. End Mill Wear Chart.

From support.bantamtools.com

End Mill Identification Guide Bantam Tools End Mill Wear Chart The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium quality control. learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. Making products having desired surface shape by. Putting and moving a cutting tool on a work. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. This coating layer consists of a compound solid solution of. The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium quality control. We’ll also tell you the secret. End Mill Wear Chart.

From earthasowers.blogspot.com

end mill shank types Eartha Sowers End Mill Wear Chart Making products having desired surface shape by. The grade or quality of the carbide they’re made from, their geometry, the end mill coatings, and premium quality control. ① back cutting edge wear; We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. — carbide end mills wear usually includes. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart We’ll also tell you the secret to evaluating the economics of whether premium endmills make sense for you or not. ① back cutting edge wear; — carbide end mills wear usually includes the following types: learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best.. End Mill Wear Chart.

From www.endmills-wotek.com

Protocol for end mill wear measurement in micromillingend mill WOTEK End Mill Wear Chart By defining and comprehending carbide end mill wear, makers and users of cutting tools may improve the lifespan of carbide end mills. ① back cutting edge wear; learn how to identify the most common tool wear patterns in machining, common causes, and what to do to control them the best. — in this article, we’ll take a look. End Mill Wear Chart.