Ball Screw Vs Machine Screw . Ball screws are used in many robotic applications, including robotic arms and legs. Ball screws get their name from the ball bearings that minimize friction and optimize efficiency, while lead screws use sliding surfaces for high friction. However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create these features. Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other cnc machines. Machine screws require regular maintenance, including lubrication and periodic cleaning. Of course, whether the machine screw jack or ball screw jack is right for you will depend on your application parameters. At a high level, ground and rolled ball screws appear to function nearly identically within a wide range of mechanical applications. Ball screws use ball bearings inside. In lead screws, the nut doesn’t contain ball bearings, nor does it actively roll. Ball screws look like lead screws, but only the former has ball bearings inside the nut. Ball screws, on the other hand, contain a nut in which ball bearings circulate to support the load and reduce friction. Ball screw jacks, on the other hand, have more predictable life cycles. Machine screw jacks are more resistant to airborne particulates and corrosive chemicals, are quieter and have minimal backlash. This makes them a popular choice for applications with options other than downtime. Learn about the difference between lead screws and ball screws.

from www.youtube.com

However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create these features. Machine screw jacks are more resistant to airborne particulates and corrosive chemicals, are quieter and have minimal backlash. Ball screws look like lead screws, but only the former has ball bearings inside the nut. Of course, whether the machine screw jack or ball screw jack is right for you will depend on your application parameters. Ball screws use ball bearings inside. Lead screws are often compared to ball screws, but ball screws are usually more expensive. Ball screw jacks, on the other hand, have more predictable life cycles. Ball screws are used in many robotic applications, including robotic arms and legs. Learn about the difference between lead screws and ball screws. This makes them a popular choice for applications with options other than downtime.

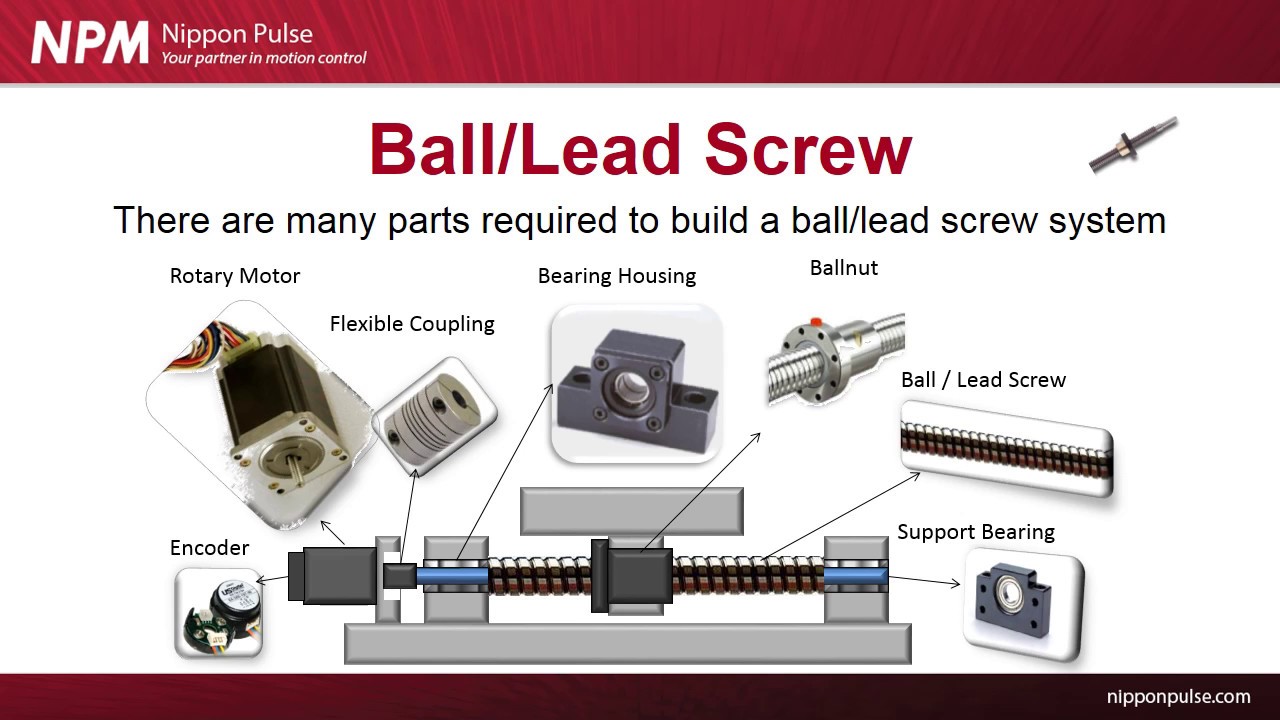

Overview of Ball Screw/Lead Screw Systems for Linear Movement YouTube

Ball Screw Vs Machine Screw Lead screws are often compared to ball screws, but ball screws are usually more expensive. In lead screws, the nut doesn’t contain ball bearings, nor does it actively roll. Learn about the difference between lead screws and ball screws. Lead screws are often compared to ball screws, but ball screws are usually more expensive. Ball screws get their name from the ball bearings that minimize friction and optimize efficiency, while lead screws use sliding surfaces for high friction. At a high level, ground and rolled ball screws appear to function nearly identically within a wide range of mechanical applications. Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other cnc machines. Ball screw jacks, on the other hand, have more predictable life cycles. Ball screws, on the other hand, contain a nut in which ball bearings circulate to support the load and reduce friction. Ball screws use ball bearings inside. Machine screw jacks are more resistant to airborne particulates and corrosive chemicals, are quieter and have minimal backlash. Machine screws require regular maintenance, including lubrication and periodic cleaning. However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create these features. Ball screws look like lead screws, but only the former has ball bearings inside the nut. This makes them a popular choice for applications with options other than downtime. Of course, whether the machine screw jack or ball screw jack is right for you will depend on your application parameters.

From blog.thepipingmart.com

Machine Screw vs Ball Screw What’s the Difference Ball Screw Vs Machine Screw Of course, whether the machine screw jack or ball screw jack is right for you will depend on your application parameters. Ball screws are used in many robotic applications, including robotic arms and legs. Ball screws get their name from the ball bearings that minimize friction and optimize efficiency, while lead screws use sliding surfaces for high friction. Learn about. Ball Screw Vs Machine Screw.

From store.boschrexroth.com

Ball screw assemblies R110599014 Rexroth Ball Screw Vs Machine Screw Ball screw jacks, on the other hand, have more predictable life cycles. Machine screw jacks are more resistant to airborne particulates and corrosive chemicals, are quieter and have minimal backlash. Ball screws look like lead screws, but only the former has ball bearings inside the nut. Lead screws are often compared to ball screws, but ball screws are usually more. Ball Screw Vs Machine Screw.

From www.ball-screws.net

Ball Screw Repair Replacement Ball Nut and Screw Regrind Ball Screw Vs Machine Screw Learn about the difference between lead screws and ball screws. Ball screws are used in many robotic applications, including robotic arms and legs. Ball screws, on the other hand, contain a nut in which ball bearings circulate to support the load and reduce friction. Ball screw jacks, on the other hand, have more predictable life cycles. Machine screw jacks are. Ball Screw Vs Machine Screw.

From www.progressiveautomations.com

Comparing Ball Screw VS Acme Screw Progressive Automations Ball Screw Vs Machine Screw Ball screws are used in many robotic applications, including robotic arms and legs. At a high level, ground and rolled ball screws appear to function nearly identically within a wide range of mechanical applications. In lead screws, the nut doesn’t contain ball bearings, nor does it actively roll. Machine screw jacks are more resistant to airborne particulates and corrosive chemicals,. Ball Screw Vs Machine Screw.

From www.ketes-cn.com

China Customized Ball Screw for CNC Machine Manufacturers Suppliers Ball Screw Vs Machine Screw Ball screws are used in many robotic applications, including robotic arms and legs. Ball screws use ball bearings inside. Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other cnc machines. Ball screws get their name from the ball bearings that minimize friction and optimize efficiency, while lead screws use sliding surfaces for. Ball Screw Vs Machine Screw.

From www.wedin.com

Ground vs. Rolled Ball Screws The Differences Ball Screw Vs Machine Screw Learn about the difference between lead screws and ball screws. Ball screws are used in many robotic applications, including robotic arms and legs. At a high level, ground and rolled ball screws appear to function nearly identically within a wide range of mechanical applications. Ball screws are used to provide the precise linear motion required in lathes, milling machines, and. Ball Screw Vs Machine Screw.

From www.progressiveautomations.com

Ball Screw vs Lead Screw in Linear Actuators Progressive Automations Ball Screw Vs Machine Screw Ball screws use ball bearings inside. However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create these features. Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other cnc machines. Learn about the difference between. Ball Screw Vs Machine Screw.

From blog.misumiusa.com

Lead Screws vs Ball Screws Differences, Benefits & Accuracy MISUMI Blog Ball Screw Vs Machine Screw Ball screws use ball bearings inside. Ball screws look like lead screws, but only the former has ball bearings inside the nut. Machine screws require regular maintenance, including lubrication and periodic cleaning. Machine screw jacks are more resistant to airborne particulates and corrosive chemicals, are quieter and have minimal backlash. Of course, whether the machine screw jack or ball screw. Ball Screw Vs Machine Screw.

From suzukigsxseries.com

What Are Ball Screws? Ball Screws What Is a Lead Screw? Lead Ball Screw Vs Machine Screw Machine screw jacks are more resistant to airborne particulates and corrosive chemicals, are quieter and have minimal backlash. Ball screws are used in many robotic applications, including robotic arms and legs. Ball screws get their name from the ball bearings that minimize friction and optimize efficiency, while lead screws use sliding surfaces for high friction. However, the raceway surfaces, which. Ball Screw Vs Machine Screw.

From mechanicaljungle.org

Ball Screws vs. Lead Screws Efficiency, Applications, and Comparisons Ball Screw Vs Machine Screw Ball screws look like lead screws, but only the former has ball bearings inside the nut. Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other cnc machines. Of course, whether the machine screw jack or ball screw jack is right for you will depend on your application parameters. Ball screws use ball. Ball Screw Vs Machine Screw.

From ae.linkedin.com

الفرق بين الـ ball screw والفتايل التانية Ball Screw Vs Machine Screw Of course, whether the machine screw jack or ball screw jack is right for you will depend on your application parameters. Ball screws look like lead screws, but only the former has ball bearings inside the nut. Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other cnc machines. In lead screws, the. Ball Screw Vs Machine Screw.

From www.thomsonlinear.com

Ball Screw or Lead Screw? Five Questions to Help You Identify the Right Ball Screw Vs Machine Screw In lead screws, the nut doesn’t contain ball bearings, nor does it actively roll. At a high level, ground and rolled ball screws appear to function nearly identically within a wide range of mechanical applications. Ball screws use ball bearings inside. Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other cnc machines.. Ball Screw Vs Machine Screw.

From www.amazon.co.uk

GooEquip Ball Screw CNC Parts SFU1204 Screw+NUT, 1pcs Ball Screw + 1pcs Ball Screw Vs Machine Screw At a high level, ground and rolled ball screws appear to function nearly identically within a wide range of mechanical applications. Ball screws look like lead screws, but only the former has ball bearings inside the nut. Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other cnc machines. Lead screws are often. Ball Screw Vs Machine Screw.

From blog.adafruit.com

CNC Build Part 4 Motors and Ball Screws 3DThursday CNC « Adafruit Ball Screw Vs Machine Screw Ball screws, on the other hand, contain a nut in which ball bearings circulate to support the load and reduce friction. Ball screws use ball bearings inside. Ball screws look like lead screws, but only the former has ball bearings inside the nut. At a high level, ground and rolled ball screws appear to function nearly identically within a wide. Ball Screw Vs Machine Screw.

From www.controlsdrivesautomation.com

CDA Highload ball screw Ball Screw Vs Machine Screw Ball screws use ball bearings inside. In lead screws, the nut doesn’t contain ball bearings, nor does it actively roll. Ball screw jacks, on the other hand, have more predictable life cycles. However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create. Ball Screw Vs Machine Screw.

From blog.thepipingmart.com

Cap Screw vs Machine Bolt What’s the Difference Ball Screw Vs Machine Screw Ball screws look like lead screws, but only the former has ball bearings inside the nut. Learn about the difference between lead screws and ball screws. Ball screw jacks, on the other hand, have more predictable life cycles. Machine screw jacks are more resistant to airborne particulates and corrosive chemicals, are quieter and have minimal backlash. However, the raceway surfaces,. Ball Screw Vs Machine Screw.

From www.medicaldesignandoutsourcing.com

What are ball screws? Medical Design and Outsourcing Ball Screw Vs Machine Screw Machine screws require regular maintenance, including lubrication and periodic cleaning. Machine screw jacks are more resistant to airborne particulates and corrosive chemicals, are quieter and have minimal backlash. However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create these features. Ball screws. Ball Screw Vs Machine Screw.

From www.matara.com

Ball screws vs lead screws for motion control applications. Ball Screw Vs Machine Screw However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create these features. Lead screws are often compared to ball screws, but ball screws are usually more expensive. Ball screws are used to provide the precise linear motion required in lathes, milling machines,. Ball Screw Vs Machine Screw.

From www.thomsonlinear.com

Lead Screws vs Ball Screws What is the Difference? Thomson Ball Screw Vs Machine Screw Machine screws require regular maintenance, including lubrication and periodic cleaning. However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create these features. Ball screws are used in many robotic applications, including robotic arms and legs. Learn about the difference between lead screws. Ball Screw Vs Machine Screw.

From mungfali.com

Ball Screw Assembly Ball Screw Vs Machine Screw However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create these features. Ball screw jacks, on the other hand, have more predictable life cycles. Ball screws are used in many robotic applications, including robotic arms and legs. In lead screws, the nut. Ball Screw Vs Machine Screw.

From www.vlr.eng.br

Ball Screw Thread vlr.eng.br Ball Screw Vs Machine Screw Ball screws, on the other hand, contain a nut in which ball bearings circulate to support the load and reduce friction. Ball screws are used in many robotic applications, including robotic arms and legs. Of course, whether the machine screw jack or ball screw jack is right for you will depend on your application parameters. Lead screws are often compared. Ball Screw Vs Machine Screw.

From www.linearmotiontips.com

When do you need a ball screw? Ball Screw Vs Machine Screw Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other cnc machines. At a high level, ground and rolled ball screws appear to function nearly identically within a wide range of mechanical applications. Learn about the difference between lead screws and ball screws. This makes them a popular choice for applications with options. Ball Screw Vs Machine Screw.

From hvhindustrial.com

What is the Difference between Ball Screws and Lead Screws? Ball Screw Vs Machine Screw Machine screws require regular maintenance, including lubrication and periodic cleaning. At a high level, ground and rolled ball screws appear to function nearly identically within a wide range of mechanical applications. Ball screws are used in many robotic applications, including robotic arms and legs. Learn about the difference between lead screws and ball screws. Ball screws get their name from. Ball Screw Vs Machine Screw.

From us.misumi-ec.com

Ball Screws Pt. 2 Ball Screw Preload MISUMI Mech Lab Blog Ball Screw Vs Machine Screw This makes them a popular choice for applications with options other than downtime. Of course, whether the machine screw jack or ball screw jack is right for you will depend on your application parameters. At a high level, ground and rolled ball screws appear to function nearly identically within a wide range of mechanical applications. Machine screws require regular maintenance,. Ball Screw Vs Machine Screw.

From www.youtube.com

Overview of Ball Screw/Lead Screw Systems for Linear Movement YouTube Ball Screw Vs Machine Screw Machine screw jacks are more resistant to airborne particulates and corrosive chemicals, are quieter and have minimal backlash. Of course, whether the machine screw jack or ball screw jack is right for you will depend on your application parameters. Ball screws are used in many robotic applications, including robotic arms and legs. Ball screws are used to provide the precise. Ball Screw Vs Machine Screw.

From www.automotioncomponents.co.uk

Lead Screws and Ball Screws from Automotion Automotion Ball Screw Vs Machine Screw Ball screws use ball bearings inside. Of course, whether the machine screw jack or ball screw jack is right for you will depend on your application parameters. In lead screws, the nut doesn’t contain ball bearings, nor does it actively roll. Learn about the difference between lead screws and ball screws. Ball screws get their name from the ball bearings. Ball Screw Vs Machine Screw.

From www.youtube.com

Ball Lead Screw Properties YouTube Ball Screw Vs Machine Screw Ball screws use ball bearings inside. Ball screws are used in many robotic applications, including robotic arms and legs. However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create these features. Machine screw jacks are more resistant to airborne particulates and corrosive. Ball Screw Vs Machine Screw.

From www.iqsdirectory.com

Ball Screw What Is It? How Does It Work? Ball Screw Vs Machine Screw Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other cnc machines. Ball screws get their name from the ball bearings that minimize friction and optimize efficiency, while lead screws use sliding surfaces for high friction. Ball screw jacks, on the other hand, have more predictable life cycles. In lead screws, the nut. Ball Screw Vs Machine Screw.

From www.tolomatic.com

Selecting the Optimal Screw Technology Tolomatic Ball Screw Vs Machine Screw However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create these features. Ball screws are used in many robotic applications, including robotic arms and legs. Learn about the difference between lead screws and ball screws. Of course, whether the machine screw jack. Ball Screw Vs Machine Screw.

From www.designworldonline.com

How rollerscrew and ballscrew actuators compare in highforce Ball Screw Vs Machine Screw Learn about the difference between lead screws and ball screws. At a high level, ground and rolled ball screws appear to function nearly identically within a wide range of mechanical applications. Machine screw jacks are more resistant to airborne particulates and corrosive chemicals, are quieter and have minimal backlash. Ball screws are used in many robotic applications, including robotic arms. Ball Screw Vs Machine Screw.

From mellowpine.com

Ball screw vs Lead Screw Which is Better? MellowPine Ball Screw Vs Machine Screw However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create these features. Lead screws are often compared to ball screws, but ball screws are usually more expensive. Machine screws require regular maintenance, including lubrication and periodic cleaning. Ball screws, on the other. Ball Screw Vs Machine Screw.

From www.ludetransmission.com

What Are The Differences Between Ball Screws And Acme Screws?Lude Ball Screw Vs Machine Screw Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other cnc machines. Ball screw jacks, on the other hand, have more predictable life cycles. Ball screws get their name from the ball bearings that minimize friction and optimize efficiency, while lead screws use sliding surfaces for high friction. Lead screws are often compared. Ball Screw Vs Machine Screw.

From blog.thepipingmart.com

Ball Screw vs Acme Screw What's the Difference Ball Screw Vs Machine Screw Ball screws are used to provide the precise linear motion required in lathes, milling machines, and other cnc machines. Machine screws require regular maintenance, including lubrication and periodic cleaning. However, the raceway surfaces, which are very similar to traditional machine screw threads found in a typical screw/nut system, are differentiated by the manufacturing process used to create these features. Of. Ball Screw Vs Machine Screw.

From www.thomsonlinear.com.cn

High Load Ball Screws The Motion Control Solution with Higher Load Ball Screw Vs Machine Screw Ball screw jacks, on the other hand, have more predictable life cycles. Ball screws are used in many robotic applications, including robotic arms and legs. This makes them a popular choice for applications with options other than downtime. Machine screw jacks are more resistant to airborne particulates and corrosive chemicals, are quieter and have minimal backlash. Ball screws look like. Ball Screw Vs Machine Screw.

From cognitadesenvolvimento.com.br

difference between bolt and set screw Ball Screw Vs Machine Screw Lead screws are often compared to ball screws, but ball screws are usually more expensive. At a high level, ground and rolled ball screws appear to function nearly identically within a wide range of mechanical applications. In lead screws, the nut doesn’t contain ball bearings, nor does it actively roll. Ball screw jacks, on the other hand, have more predictable. Ball Screw Vs Machine Screw.