Primary Shaping Process Example . These processes form the overall shape of the product, or the components that will be joined to form the final. Secondary processes further improve the properties, quality, tolerance, etc. Describe the types of sheet metal work. (a) directly make parts of needed shape or (b). This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. Describe the processes of metal forging, extrusion, rolling and drawing. This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. Primary processes convert raw material to a basic shaped product. • shaping process for polymers metals & ceramics. Primary shaping processes are manufacturing of a product from an amorphous material.

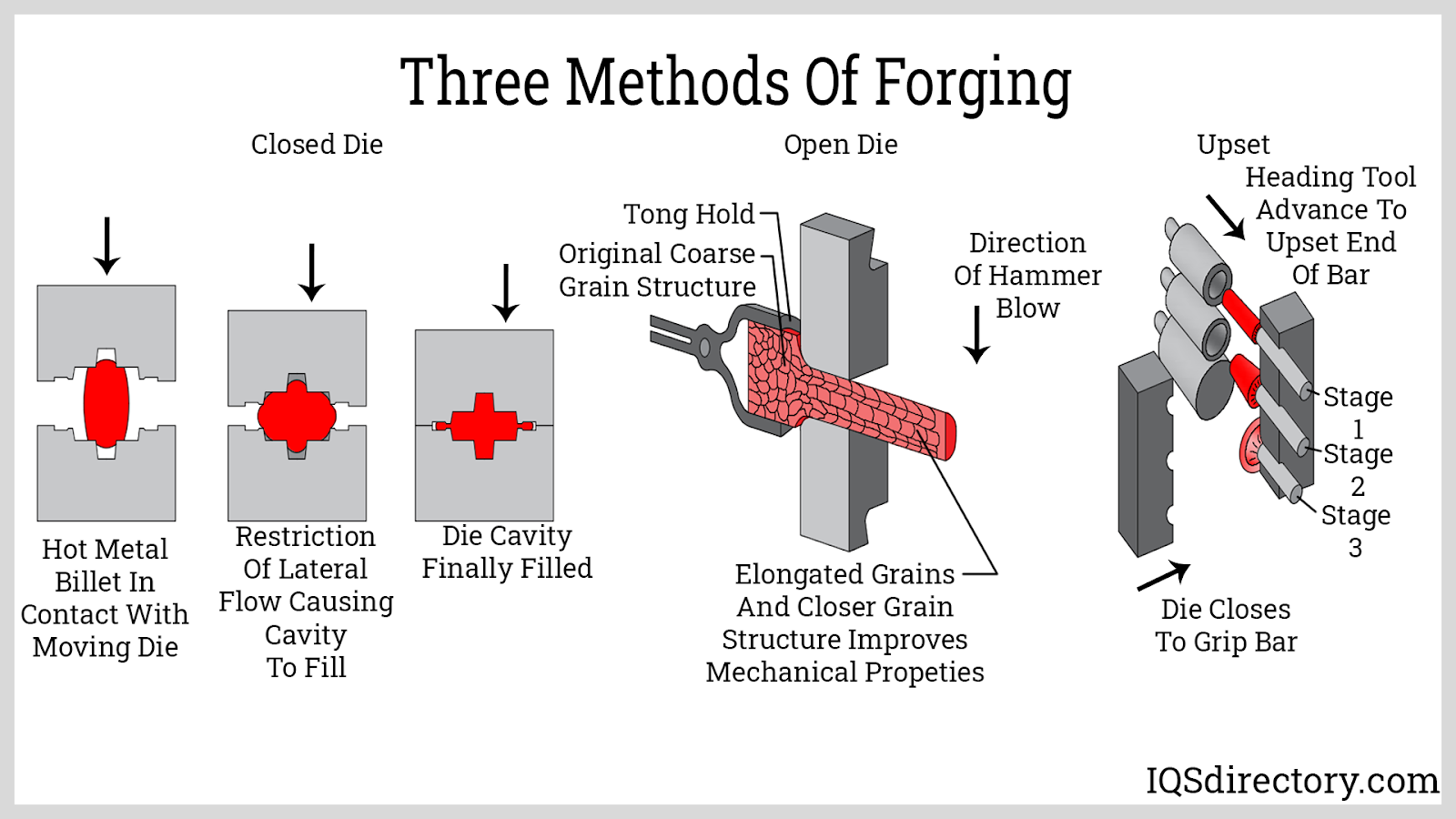

from www.iqsdirectory.com

Primary processes convert raw material to a basic shaped product. Secondary processes further improve the properties, quality, tolerance, etc. This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. • shaping process for polymers metals & ceramics. Describe the processes of metal forging, extrusion, rolling and drawing. (a) directly make parts of needed shape or (b). Primary shaping processes are manufacturing of a product from an amorphous material. Describe the types of sheet metal work. This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. These processes form the overall shape of the product, or the components that will be joined to form the final.

What Is It? How Does It Work? Types Of, Uses

Primary Shaping Process Example Describe the types of sheet metal work. (a) directly make parts of needed shape or (b). This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. Secondary processes further improve the properties, quality, tolerance, etc. • shaping process for polymers metals & ceramics. Describe the types of sheet metal work. This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. Primary processes convert raw material to a basic shaped product. Describe the processes of metal forging, extrusion, rolling and drawing. These processes form the overall shape of the product, or the components that will be joined to form the final. Primary shaping processes are manufacturing of a product from an amorphous material.

From www.youtube.com

Forming and Shaping Processes Lecture 1 YouTube Primary Shaping Process Example Secondary processes further improve the properties, quality, tolerance, etc. This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. Describe the types of sheet metal work. • shaping process for polymers metals & ceramics. These processes form the overall shape of the product, or the components that will be joined to form the. Primary Shaping Process Example.

From www.linkedin.com

GOM Metrology on LinkedIn inar How to Master Assembly Situations Primary Shaping Process Example This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. • shaping process for polymers metals & ceramics. Primary shaping processes are manufacturing of a product from. Primary Shaping Process Example.

From www.slideserve.com

PPT Lecture 7 PROCESSING OF CERAMICS AND CERMETS PowerPoint Primary Shaping Process Example Primary shaping processes are manufacturing of a product from an amorphous material. These processes form the overall shape of the product, or the components that will be joined to form the final. This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. Secondary processes. Primary Shaping Process Example.

From engineeringproductdesign.com

What are Manufacturing processes and their applications Primary Shaping Process Example These processes form the overall shape of the product, or the components that will be joined to form the final. Primary shaping processes are manufacturing of a product from an amorphous material. Secondary processes further improve the properties, quality, tolerance, etc. Describe the types of sheet metal work. This unit gives learners the opportunity to explore some of the primary. Primary Shaping Process Example.

From www.youtube.com

Shaping process Manufacturing Process 👌👌👌 YouTube Primary Shaping Process Example (a) directly make parts of needed shape or (b). Secondary processes further improve the properties, quality, tolerance, etc. Primary processes convert raw material to a basic shaped product. These processes form the overall shape of the product, or the components that will be joined to form the final. • shaping process for polymers metals & ceramics. Describe the processes of. Primary Shaping Process Example.

From slideplayer.com

Family Trees Organising Materials and Processes into Trees ppt download Primary Shaping Process Example Describe the processes of metal forging, extrusion, rolling and drawing. (a) directly make parts of needed shape or (b). This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. These processes form the overall shape of the product, or the components that will be. Primary Shaping Process Example.

From helpfulprofessor.com

18 Best Socialization Examples (Sociology Concepts) (2024) Primary Shaping Process Example These processes form the overall shape of the product, or the components that will be joined to form the final. Primary processes convert raw material to a basic shaped product. Primary shaping processes are manufacturing of a product from an amorphous material. Describe the types of sheet metal work. • shaping process for polymers metals & ceramics. Secondary processes further. Primary Shaping Process Example.

From present5.com

Chapter 0 General Introduction Manufacturing Engineering Technology Primary Shaping Process Example Describe the types of sheet metal work. (a) directly make parts of needed shape or (b). This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. Primary shaping processes are manufacturing of a product from an amorphous material. This chapter gives a brief introduction. Primary Shaping Process Example.

From www.revimage.org

What Are Processes That Shape Earth S Surface The Earth Images Primary Shaping Process Example This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. Describe the processes of metal forging, extrusion, rolling and drawing. Describe the types of sheet metal work.. Primary Shaping Process Example.

From techqualitypedia.com

Manufacturing Processes Types Manufacturing Processes List Primary Shaping Process Example This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. Primary processes convert raw material to a basic shaped product. Describe the processes of metal forging, extrusion, rolling and drawing. • shaping process for polymers metals & ceramics. (a) directly make parts of needed shape or (b). Describe the types of sheet metal. Primary Shaping Process Example.

From www.zhygear.com

Blank shaping process of driven spiral bevel gear ZHY Gear Primary Shaping Process Example These processes form the overall shape of the product, or the components that will be joined to form the final. Secondary processes further improve the properties, quality, tolerance, etc. Primary shaping processes are manufacturing of a product from an amorphous material. Primary processes convert raw material to a basic shaped product. • shaping process for polymers metals & ceramics. This. Primary Shaping Process Example.

From www.researchgate.net

1. Classification of AM processes according to the aggregate state of Primary Shaping Process Example Describe the processes of metal forging, extrusion, rolling and drawing. Primary shaping processes are manufacturing of a product from an amorphous material. Secondary processes further improve the properties, quality, tolerance, etc. This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. • shaping process for polymers metals & ceramics. Describe the types of. Primary Shaping Process Example.

From www.chegg.com

Solved A brief definition of each box and an example Primary Shaping Process Example Primary shaping processes are manufacturing of a product from an amorphous material. Describe the processes of metal forging, extrusion, rolling and drawing. Describe the types of sheet metal work. • shaping process for polymers metals & ceramics. Secondary processes further improve the properties, quality, tolerance, etc. These processes form the overall shape of the product, or the components that will. Primary Shaping Process Example.

From www.slideserve.com

PPT Forming and Shaping PowerPoint Presentation, free download ID Primary Shaping Process Example This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. These processes form the overall shape of the product, or the components that will be joined to form the final. Describe the types of sheet metal work. Primary processes convert raw material to a. Primary Shaping Process Example.

From slideplayer.com

FORMING AND SHAPING PROCESSES ppt download Primary Shaping Process Example • shaping process for polymers metals & ceramics. These processes form the overall shape of the product, or the components that will be joined to form the final. This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. Describe the processes of metal forging, extrusion, rolling and drawing. Secondary processes further improve the. Primary Shaping Process Example.

From www.difference.minaprem.com

Difference Between Shaping and Planing Primary Shaping Process Example This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. • shaping process for polymers metals & ceramics. Describe the processes of metal forging, extrusion, rolling and drawing. These processes form the overall shape of the product, or the components that will be joined. Primary Shaping Process Example.

From helpfulprofessor.com

15 Shaping Examples (Psychology) (2024) Primary Shaping Process Example • shaping process for polymers metals & ceramics. Secondary processes further improve the properties, quality, tolerance, etc. These processes form the overall shape of the product, or the components that will be joined to form the final. Primary shaping processes are manufacturing of a product from an amorphous material. Describe the processes of metal forging, extrusion, rolling and drawing. This. Primary Shaping Process Example.

From www.youtube.com

GEAR SHAPING PROCESS YouTube Primary Shaping Process Example Primary processes convert raw material to a basic shaped product. Describe the processes of metal forging, extrusion, rolling and drawing. • shaping process for polymers metals & ceramics. Describe the types of sheet metal work. These processes form the overall shape of the product, or the components that will be joined to form the final. Secondary processes further improve the. Primary Shaping Process Example.

From slidetodoc.com

Manufacturing Processes Syllabus Manufacturing Processes Manufacturing Primary Shaping Process Example Describe the types of sheet metal work. This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. • shaping process for polymers metals & ceramics. Primary shaping processes are manufacturing of a product from an amorphous material. Secondary processes further improve the properties, quality,. Primary Shaping Process Example.

From www.scribd.com

Primary Shaping Process PDF Casting (Metalworking) Primary Shaping Process Example Describe the processes of metal forging, extrusion, rolling and drawing. Primary shaping processes are manufacturing of a product from an amorphous material. This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. (a) directly make parts of needed shape or (b). These processes form the overall shape of the product, or the components. Primary Shaping Process Example.

From engineeringproductdesign.com

What are Manufacturing processes and their applications Primary Shaping Process Example • shaping process for polymers metals & ceramics. Describe the types of sheet metal work. Describe the processes of metal forging, extrusion, rolling and drawing. This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. (a) directly make parts of needed shape or (b). Primary shaping processes are manufacturing of a product from. Primary Shaping Process Example.

From learnmech.com

Metal Forming Basic, Types , Diagram , Classification Primary Shaping Process Example (a) directly make parts of needed shape or (b). These processes form the overall shape of the product, or the components that will be joined to form the final. Secondary processes further improve the properties, quality, tolerance, etc. Describe the processes of metal forging, extrusion, rolling and drawing. Primary processes convert raw material to a basic shaped product. This unit. Primary Shaping Process Example.

From pollen.am

Pollen AM Shaping process Primary Shaping Process Example Primary processes convert raw material to a basic shaped product. These processes form the overall shape of the product, or the components that will be joined to form the final. (a) directly make parts of needed shape or (b). Secondary processes further improve the properties, quality, tolerance, etc. Describe the types of sheet metal work. This chapter gives a brief. Primary Shaping Process Example.

From joiqiivdi.blob.core.windows.net

What Is Machining Process And Its Types at Darnell Hutcherson blog Primary Shaping Process Example Describe the types of sheet metal work. (a) directly make parts of needed shape or (b). Primary processes convert raw material to a basic shaped product. Primary shaping processes are manufacturing of a product from an amorphous material. Secondary processes further improve the properties, quality, tolerance, etc. Describe the processes of metal forging, extrusion, rolling and drawing. This unit gives. Primary Shaping Process Example.

From higheducationhere.com

What is Shaping in Psychology? Definition & Examples Primary Shaping Process Example Describe the processes of metal forging, extrusion, rolling and drawing. Secondary processes further improve the properties, quality, tolerance, etc. These processes form the overall shape of the product, or the components that will be joined to form the final. This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to. Primary Shaping Process Example.

From www.researchgate.net

Training simulators in primary shaping processes Download Scientific Primary Shaping Process Example Describe the processes of metal forging, extrusion, rolling and drawing. These processes form the overall shape of the product, or the components that will be joined to form the final. Primary shaping processes are manufacturing of a product from an amorphous material. Describe the types of sheet metal work. Secondary processes further improve the properties, quality, tolerance, etc. This unit. Primary Shaping Process Example.

From ar.inspiredpencil.com

Forming Process Primary Shaping Process Example This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. Primary shaping processes are manufacturing of a product from an amorphous material. Describe the types of sheet metal work. Primary processes convert raw material to a basic shaped product. These processes form the overall. Primary Shaping Process Example.

From mechasource.blogspot.com

An Introduction to Methods of forming and cutting Primary Shaping Process Example Describe the processes of metal forging, extrusion, rolling and drawing. Primary shaping processes are manufacturing of a product from an amorphous material. This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. Describe the types of sheet metal work. Primary processes convert raw material. Primary Shaping Process Example.

From www.youtube.com

Manufacturing Processes overview YouTube Primary Shaping Process Example These processes form the overall shape of the product, or the components that will be joined to form the final. (a) directly make parts of needed shape or (b). • shaping process for polymers metals & ceramics. Describe the processes of metal forging, extrusion, rolling and drawing. Primary processes convert raw material to a basic shaped product. This chapter gives. Primary Shaping Process Example.

From engineeringproductdesign.com

What is Investment Casting Advantage & Disadvantages Primary Shaping Process Example Primary shaping processes are manufacturing of a product from an amorphous material. Secondary processes further improve the properties, quality, tolerance, etc. This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. (a) directly make parts of needed shape or (b). • shaping process for. Primary Shaping Process Example.

From www.researchgate.net

Basic scheme of the integrated shaping process. Download Scientific Primary Shaping Process Example Primary shaping processes are manufacturing of a product from an amorphous material. Primary processes convert raw material to a basic shaped product. This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. (a) directly make parts of needed shape or (b). Secondary processes further. Primary Shaping Process Example.

From www.iqsdirectory.com

What Is It? How Does It Work? Types Of, Uses Primary Shaping Process Example Describe the types of sheet metal work. Secondary processes further improve the properties, quality, tolerance, etc. Primary shaping processes are manufacturing of a product from an amorphous material. This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. • shaping process for polymers metals & ceramics. Describe the processes of metal forging, extrusion,. Primary Shaping Process Example.

From www.slideserve.com

PPT Unit Operations in Polymer Processing PowerPoint Presentation Primary Shaping Process Example Describe the types of sheet metal work. Primary processes convert raw material to a basic shaped product. Primary shaping processes are manufacturing of a product from an amorphous material. • shaping process for polymers metals & ceramics. This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a. Primary Shaping Process Example.

From www.slideserve.com

PPT SHAPING PROCESSES FOR PLASTICS Chapter 13 Part 1 Properties of Primary Shaping Process Example Primary shaping processes are manufacturing of a product from an amorphous material. These processes form the overall shape of the product, or the components that will be joined to form the final. This chapter gives a brief introduction to crystal growth processes and exemplarily addresses the primary shaping of. Primary processes convert raw material to a basic shaped product. Describe. Primary Shaping Process Example.

From www.youtube.com

Differences between Shaping and Planing. YouTube Primary Shaping Process Example This unit gives learners the opportunity to explore some of the primary forming processes found in engineering that are used to make a range of different. • shaping process for polymers metals & ceramics. (a) directly make parts of needed shape or (b). Describe the processes of metal forging, extrusion, rolling and drawing. Primary processes convert raw material to a. Primary Shaping Process Example.