Thread Milling Lathe . Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. Although not as widely used as. Climb milling generates less heat and less tool deflection,. Roll in and out of cut. Thread mills provide superior chip control over tapping applications. This is performed by taking successive cuts with a threading toolbit the same shape. Always engage and retract the thread mill in a smooth path i.e. Thread milling is a metalworking process to cut threads at different sizes through the circular ramping movement of a rotating tool, the thread pitch is. The lateral movement of the tool in one revolution creates the thread pitch. Many machinists consider milling more effective than threading on a lathe. Always program climb milling for better surface finish and improved tool life. Thread milling produces threads with the circular ramping movement of a rotating tool. Milling is the most efficient method of parts like lead screws. This is because of the fast production and high accuracy.

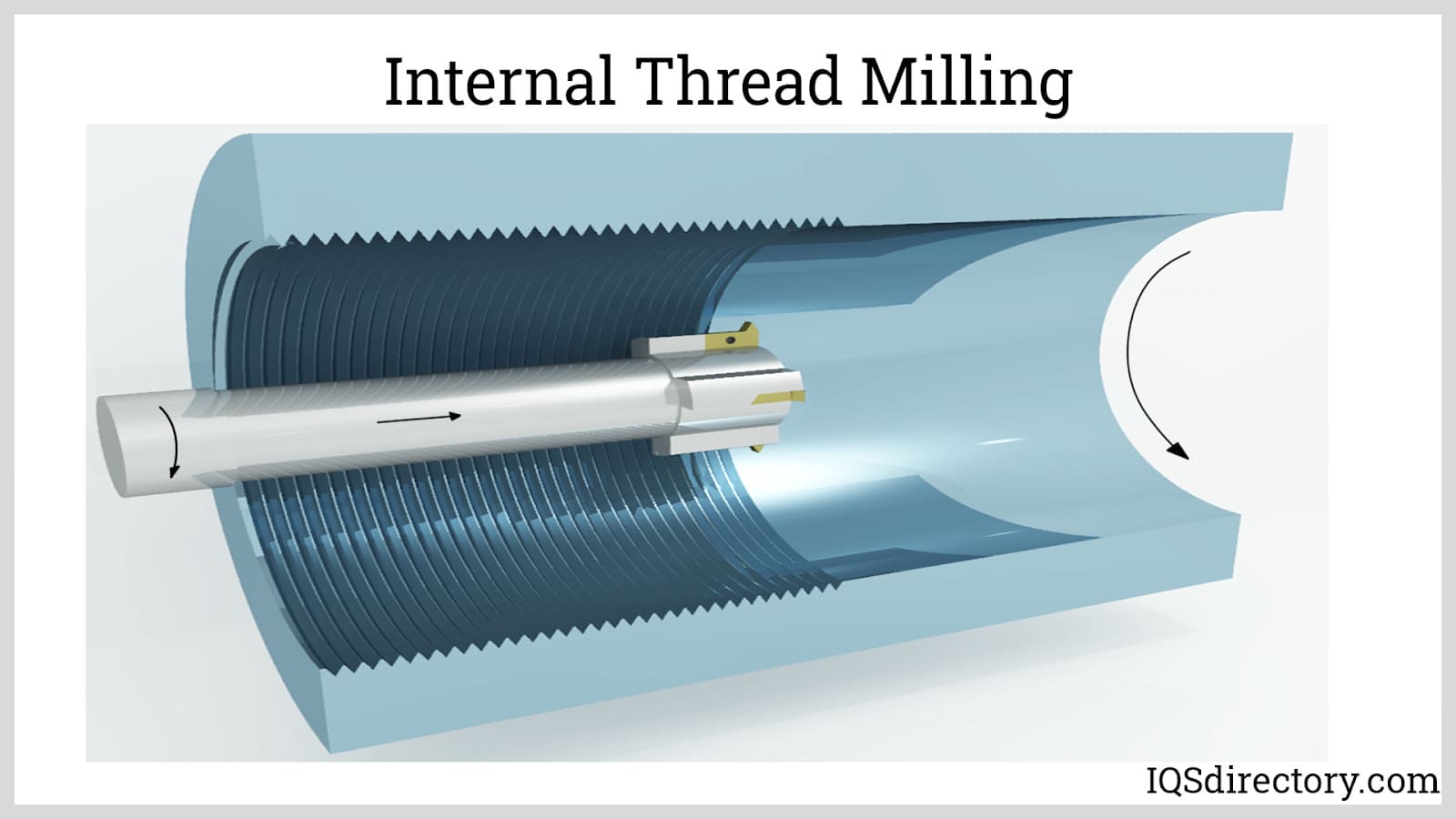

from www.iqsdirectory.com

Always engage and retract the thread mill in a smooth path i.e. Roll in and out of cut. This is performed by taking successive cuts with a threading toolbit the same shape. Many machinists consider milling more effective than threading on a lathe. Always program climb milling for better surface finish and improved tool life. Climb milling generates less heat and less tool deflection,. The lateral movement of the tool in one revolution creates the thread pitch. Although not as widely used as. Thread milling produces threads with the circular ramping movement of a rotating tool. Milling is the most efficient method of parts like lead screws.

Thread Rolling What Is It? How Does It Work? Process, Types

Thread Milling Lathe Thread milling produces threads with the circular ramping movement of a rotating tool. Thread milling produces threads with the circular ramping movement of a rotating tool. Climb milling generates less heat and less tool deflection,. This is performed by taking successive cuts with a threading toolbit the same shape. Thread milling is a metalworking process to cut threads at different sizes through the circular ramping movement of a rotating tool, the thread pitch is. This is because of the fast production and high accuracy. Milling is the most efficient method of parts like lead screws. Although not as widely used as. Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. Always program climb milling for better surface finish and improved tool life. Thread mills provide superior chip control over tapping applications. Roll in and out of cut. Always engage and retract the thread mill in a smooth path i.e. Many machinists consider milling more effective than threading on a lathe. The lateral movement of the tool in one revolution creates the thread pitch.

From www.secotools.fr

Thread Milling Thread Milling Lathe This is performed by taking successive cuts with a threading toolbit the same shape. Milling is the most efficient method of parts like lead screws. Thread mills provide superior chip control over tapping applications. Thread milling produces threads with the circular ramping movement of a rotating tool. This is because of the fast production and high accuracy. The lateral movement. Thread Milling Lathe.

From jointcnc.en.made-in-china.com

Qk1322 CNC Pipe Thread Milling Machine Turning Center Automatic Pipe Thread Milling Lathe The lateral movement of the tool in one revolution creates the thread pitch. This is performed by taking successive cuts with a threading toolbit the same shape. Although not as widely used as. Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. Thread milling is a metalworking process. Thread Milling Lathe.

From pelatools.com

Buy Metal lathe / mill Combo CQ6128 at PELA Tools Thread Milling Lathe Always engage and retract the thread mill in a smooth path i.e. Climb milling generates less heat and less tool deflection,. Always program climb milling for better surface finish and improved tool life. Thread milling produces threads with the circular ramping movement of a rotating tool. This is because of the fast production and high accuracy. Many machinists consider milling. Thread Milling Lathe.

From www.e-lathe.com

CW6636 Universal Horizontal Pipe Thread Lathe Machine Buy pipe thread Thread Milling Lathe Thread milling produces threads with the circular ramping movement of a rotating tool. Always engage and retract the thread mill in a smooth path i.e. Always program climb milling for better surface finish and improved tool life. Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. Milling is. Thread Milling Lathe.

From clynteasterwood21.blogspot.com

Milling Machine Attachments Thread Milling Lathe Thread mills provide superior chip control over tapping applications. Many machinists consider milling more effective than threading on a lathe. Always program climb milling for better surface finish and improved tool life. Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. Thread milling is a metalworking process to. Thread Milling Lathe.

From www.practicalmachinist.com

Pratt & Whitney Thread Milling Lathe Thread Milling Lathe The lateral movement of the tool in one revolution creates the thread pitch. Many machinists consider milling more effective than threading on a lathe. Milling is the most efficient method of parts like lead screws. Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. Although not as widely. Thread Milling Lathe.

From www.youtube.com

Proto Trak CNC Lathe Cutting Double Lead Acme Thread YouTube Thread Milling Lathe Thread mills provide superior chip control over tapping applications. Climb milling generates less heat and less tool deflection,. This is because of the fast production and high accuracy. Always engage and retract the thread mill in a smooth path i.e. Although not as widely used as. Always program climb milling for better surface finish and improved tool life. Thread milling. Thread Milling Lathe.

From www.desertcart.ae

Buy 1/2" Lathe Threading Tool SER1212H11 with 10pcs 11ER AG60 Threading Thread Milling Lathe The lateral movement of the tool in one revolution creates the thread pitch. Thread mills provide superior chip control over tapping applications. This is performed by taking successive cuts with a threading toolbit the same shape. Thread milling produces threads with the circular ramping movement of a rotating tool. Always program climb milling for better surface finish and improved tool. Thread Milling Lathe.

From www.lathes.co.uk

For Sale Craftsman 6inch Lathe Thread Milling Lathe Thread mills provide superior chip control over tapping applications. Many machinists consider milling more effective than threading on a lathe. The lateral movement of the tool in one revolution creates the thread pitch. Milling is the most efficient method of parts like lead screws. Thread milling produces threads with the circular ramping movement of a rotating tool. Always program climb. Thread Milling Lathe.

From pelatools.com

Buy 3 jaw lathe chuck with flange, self centering at Pela Tools Thread Milling Lathe Roll in and out of cut. This is because of the fast production and high accuracy. This is performed by taking successive cuts with a threading toolbit the same shape. Always program climb milling for better surface finish and improved tool life. The lateral movement of the tool in one revolution creates the thread pitch. Many machinists consider milling more. Thread Milling Lathe.

From www.youtube.com

THREAD MILLING LATHE MACHINES YouTube Thread Milling Lathe Thread milling is a metalworking process to cut threads at different sizes through the circular ramping movement of a rotating tool, the thread pitch is. Always engage and retract the thread mill in a smooth path i.e. This is because of the fast production and high accuracy. The lateral movement of the tool in one revolution creates the thread pitch.. Thread Milling Lathe.

From www.shop-apt.co.uk

Internal Single Tooth Carbide Thread Mill 6 TPI ACME Associated Thread Milling Lathe Thread milling produces threads with the circular ramping movement of a rotating tool. Thread mills provide superior chip control over tapping applications. This is because of the fast production and high accuracy. Climb milling generates less heat and less tool deflection,. Although not as widely used as. Lathe threading thread cutting on the lathe is a process that produces a. Thread Milling Lathe.

From www.youtube.com

Thread Milling on a Small Lathe Making a Camera Mount YouTube Thread Milling Lathe Thread milling is a metalworking process to cut threads at different sizes through the circular ramping movement of a rotating tool, the thread pitch is. The lateral movement of the tool in one revolution creates the thread pitch. Climb milling generates less heat and less tool deflection,. Lathe threading thread cutting on the lathe is a process that produces a. Thread Milling Lathe.

From www.galleon.ph

Galleon Mophorn Metal Lathe Precision Mini Lathe Variable Speed 2500 Thread Milling Lathe Thread milling produces threads with the circular ramping movement of a rotating tool. Many machinists consider milling more effective than threading on a lathe. This is performed by taking successive cuts with a threading toolbit the same shape. Although not as widely used as. This is because of the fast production and high accuracy. Thread milling is a metalworking process. Thread Milling Lathe.

From www.mccrone.com

An Adjustable Threading Feed Attachment for a Lathe Without Metric Thread Milling Lathe Climb milling generates less heat and less tool deflection,. Many machinists consider milling more effective than threading on a lathe. Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. Thread mills provide superior chip control over tapping applications. Milling is the most efficient method of parts like lead. Thread Milling Lathe.

From www.practicalmachinist.com

Pratt & Whitney Thread Milling Lathe Thread Milling Lathe Thread mills provide superior chip control over tapping applications. This is performed by taking successive cuts with a threading toolbit the same shape. Thread milling produces threads with the circular ramping movement of a rotating tool. Although not as widely used as. Thread milling is a metalworking process to cut threads at different sizes through the circular ramping movement of. Thread Milling Lathe.

From www.youtube.com

Making Lathe MILLING Attachment YouTube Thread Milling Lathe Thread milling is a metalworking process to cut threads at different sizes through the circular ramping movement of a rotating tool, the thread pitch is. Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. Always engage and retract the thread mill in a smooth path i.e. Roll in. Thread Milling Lathe.

From www.kingcanada.com

16 x 20 Combo Lathe Mill KING Canada Power Tools, Woodworking and Thread Milling Lathe This is performed by taking successive cuts with a threading toolbit the same shape. Many machinists consider milling more effective than threading on a lathe. Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. Always engage and retract the thread mill in a smooth path i.e. The lateral. Thread Milling Lathe.

From www.desertcart.in

VEVOR Metal Lathe, 210x800 Mini Lathe Machine, 2500 RPM Variable Speed Thread Milling Lathe This is performed by taking successive cuts with a threading toolbit the same shape. Always program climb milling for better surface finish and improved tool life. Climb milling generates less heat and less tool deflection,. Although not as widely used as. Thread milling produces threads with the circular ramping movement of a rotating tool. Roll in and out of cut.. Thread Milling Lathe.

From www.practicalmachinist.com

Pratt & Whitney Thread Milling Lathe Thread Milling Lathe Always program climb milling for better surface finish and improved tool life. Always engage and retract the thread mill in a smooth path i.e. This is because of the fast production and high accuracy. Milling is the most efficient method of parts like lead screws. Thread milling is a metalworking process to cut threads at different sizes through the circular. Thread Milling Lathe.

From www.ebay.fr

Set of 8 SCT Solid HSS Lathe Turning Tools 16 mm Square eBay Thread Milling Lathe Thread mills provide superior chip control over tapping applications. Climb milling generates less heat and less tool deflection,. Thread milling produces threads with the circular ramping movement of a rotating tool. This is because of the fast production and high accuracy. Many machinists consider milling more effective than threading on a lathe. Lathe threading thread cutting on the lathe is. Thread Milling Lathe.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Milling Lathe Thread milling is a metalworking process to cut threads at different sizes through the circular ramping movement of a rotating tool, the thread pitch is. Always engage and retract the thread mill in a smooth path i.e. This is performed by taking successive cuts with a threading toolbit the same shape. Although not as widely used as. Many machinists consider. Thread Milling Lathe.

From www.youtube.com

HOW TO THREAD ON LATHE MACHINE. EXTERNAL AND INTERNAL THREADS YouTube Thread Milling Lathe Although not as widely used as. The lateral movement of the tool in one revolution creates the thread pitch. Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. Many machinists consider milling more effective than threading on a lathe. Thread milling produces threads with the circular ramping movement. Thread Milling Lathe.

From www.ebay.com.au

Keyless Drill Chuck 013mm METEX MT1,MT2,MT3,MT4,R8,ISO30,ISO40 Lathe Thread Milling Lathe The lateral movement of the tool in one revolution creates the thread pitch. Thread milling produces threads with the circular ramping movement of a rotating tool. Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. Many machinists consider milling more effective than threading on a lathe. Climb milling. Thread Milling Lathe.

From www.alibaba.com

At520 Mini 3 In 1 Combo Lathe Drill Mill Multi Purpose Machine With Ce Thread Milling Lathe Many machinists consider milling more effective than threading on a lathe. Thread milling is a metalworking process to cut threads at different sizes through the circular ramping movement of a rotating tool, the thread pitch is. Although not as widely used as. Climb milling generates less heat and less tool deflection,. Always program climb milling for better surface finish and. Thread Milling Lathe.

From golpmachine.en.made-in-china.com

Whirlwind Milling ThreadCutting Lathe for Stainless Steel NineHeaded Thread Milling Lathe Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. The lateral movement of the tool in one revolution creates the thread pitch. Although not as widely used as. Thread milling produces threads with the circular ramping movement of a rotating tool. Milling is the most efficient method of. Thread Milling Lathe.

From joiqxchsp.blob.core.windows.net

Ideas For Metal Lathe at Maria Alexander blog Thread Milling Lathe Thread milling is a metalworking process to cut threads at different sizes through the circular ramping movement of a rotating tool, the thread pitch is. Milling is the most efficient method of parts like lead screws. Many machinists consider milling more effective than threading on a lathe. Thread milling produces threads with the circular ramping movement of a rotating tool.. Thread Milling Lathe.

From www.youtube.com

Thread milling with Lathe Threading Tool YouTube Thread Milling Lathe Many machinists consider milling more effective than threading on a lathe. Thread milling produces threads with the circular ramping movement of a rotating tool. The lateral movement of the tool in one revolution creates the thread pitch. Thread mills provide superior chip control over tapping applications. Lathe threading thread cutting on the lathe is a process that produces a helical. Thread Milling Lathe.

From www.desertcart.co.ke

Buy Lathe Turning Tool, 1/2" Shank 7 Pieces Carbide Lathe Threading Thread Milling Lathe This is performed by taking successive cuts with a threading toolbit the same shape. The lateral movement of the tool in one revolution creates the thread pitch. Although not as widely used as. Always program climb milling for better surface finish and improved tool life. Roll in and out of cut. Lathe threading thread cutting on the lathe is a. Thread Milling Lathe.

From www.gskequipment.com

Q1343 Pipe Thread Lathe Manufacturer China Thread Milling Lathe Always engage and retract the thread mill in a smooth path i.e. Many machinists consider milling more effective than threading on a lathe. Thread milling produces threads with the circular ramping movement of a rotating tool. Climb milling generates less heat and less tool deflection,. Thread mills provide superior chip control over tapping applications. Although not as widely used as.. Thread Milling Lathe.

From engineeringlearn.com

14 Types of Lathe Cutting Tools and Their Uses Guide Thread Milling Lathe Roll in and out of cut. This is performed by taking successive cuts with a threading toolbit the same shape. Many machinists consider milling more effective than threading on a lathe. Lathe threading thread cutting on the lathe is a process that produces a helical ridge of uniform section on the workpiece. Thread milling produces threads with the circular ramping. Thread Milling Lathe.

From www.banggood.com

Snr0010k11 internal lathe threading boring turning tool with 11ir ag60 Thread Milling Lathe Thread mills provide superior chip control over tapping applications. The lateral movement of the tool in one revolution creates the thread pitch. This is because of the fast production and high accuracy. Milling is the most efficient method of parts like lead screws. Thread milling produces threads with the circular ramping movement of a rotating tool. Roll in and out. Thread Milling Lathe.

From www.youtube.com

Threading on a lathe YouTube Thread Milling Lathe Milling is the most efficient method of parts like lead screws. This is performed by taking successive cuts with a threading toolbit the same shape. Although not as widely used as. Many machinists consider milling more effective than threading on a lathe. Thread milling is a metalworking process to cut threads at different sizes through the circular ramping movement of. Thread Milling Lathe.

From jbcmachine.com

Threading Services JBC Machine, Inc. Thread Milling Lathe Thread milling is a metalworking process to cut threads at different sizes through the circular ramping movement of a rotating tool, the thread pitch is. The lateral movement of the tool in one revolution creates the thread pitch. Roll in and out of cut. Milling is the most efficient method of parts like lead screws. This is because of the. Thread Milling Lathe.

From joihjfths.blob.core.windows.net

Mini Lathe Mill Drill Combo at Milton Elizondo blog Thread Milling Lathe Milling is the most efficient method of parts like lead screws. Thread mills provide superior chip control over tapping applications. The lateral movement of the tool in one revolution creates the thread pitch. Thread milling produces threads with the circular ramping movement of a rotating tool. Lathe threading thread cutting on the lathe is a process that produces a helical. Thread Milling Lathe.