What Does An Ball Burnisher Do . This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish.

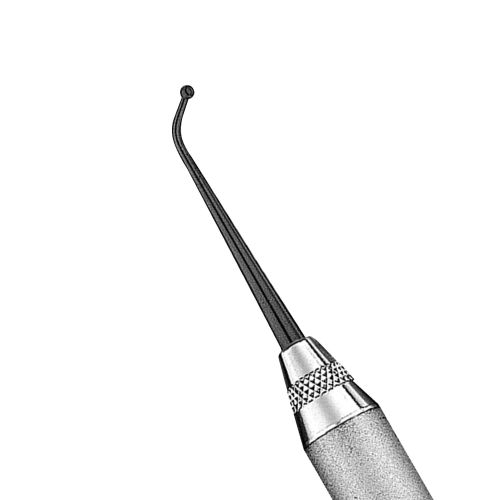

from www.hufriedygroup.com

In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color.

Small/Medium Ball Burnisher XTS™ Composite Instrument TNBBS/M

What Does An Ball Burnisher Do This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal.

From shipshapeins.com

Dental Ball Burnisher 1.8mm/3mm Restoration Procedure Amalgam Filling What Does An Ball Burnisher Do Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is an. What Does An Ball Burnisher Do.

From dentalstall.com

Buy API+ Ball Burnisher at Lowest Price Dentalstall What Does An Ball Burnisher Do This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow.. What Does An Ball Burnisher Do.

From zoeowyn.blogspot.com

Pithy Art Blog The Ball Burnisher, Love this tool What Does An Ball Burnisher Do In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is an essential. What Does An Ball Burnisher Do.

From www.ridleydental.com

Ball Burnisher What Does An Ball Burnisher Do In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is an essential. What Does An Ball Burnisher Do.

From cennlksn.blob.core.windows.net

What Is A Ball Burnisher Used For at Daniel Byers blog What Does An Ball Burnisher Do This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering.. What Does An Ball Burnisher Do.

From www.healthcareessentials.nz

ME47518T BALL BURNISHER 18T GOLD COMPOSITE Health Care Essentials What Does An Ball Burnisher Do This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. Burnishing is an essential. What Does An Ball Burnisher Do.

From www.ebay.com

Ball Burnisher 27/29 Eggshape Composite Dental Amalgam Filling What Does An Ball Burnisher Do Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. Burnishing is an essential surface treatment technique in many areas of metallurgy and. What Does An Ball Burnisher Do.

From surgicalmart.com

6 Ball Burnisher 27/29 De Dental Amalgam Surgical Mart What Does An Ball Burnisher Do Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This process involves. What Does An Ball Burnisher Do.

From useliteinc.com

Burnishers Dental US Elite INC. What Does An Ball Burnisher Do Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This process involves. What Does An Ball Burnisher Do.

From ayushidensity.com

GDC Ball Burnisher (BB22/23) 3 Ayushi Density What Does An Ball Burnisher Do In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. Burnishing is a method of polishing the. What Does An Ball Burnisher Do.

From sdt1988.com

26/27 S Ball Burnisher SDT What Does An Ball Burnisher Do This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. In the metal burnishing process, a hard roller or balls. What Does An Ball Burnisher Do.

From surgicalmart.com

Ball Burnisher 27/30 Dental Surgical Mart What Does An Ball Burnisher Do Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. This process involves applying a chemical or electrochemical. What Does An Ball Burnisher Do.

From hiteckmedical.com

18 Ball Burnisher, 1.6MM 2.4MM HiTeck Medical Instruments What Does An Ball Burnisher Do Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. This can be accomplished before transfer to a plating cycle or after plating. What Does An Ball Burnisher Do.

From jamesrsutera.blob.core.windows.net

What Does A Ball Burnisher Do at jamesrsutera blog What Does An Ball Burnisher Do This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This puts stress on the metal being. What Does An Ball Burnisher Do.

From orangeinstruments.com

PFI 18 Ball Burnisher Orange Instruments What Does An Ball Burnisher Do This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black. What Does An Ball Burnisher Do.

From cennlksn.blob.core.windows.net

What Is A Ball Burnisher Used For at Daniel Byers blog What Does An Ball Burnisher Do In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. Burnishing is a method of polishing the. What Does An Ball Burnisher Do.

From surgicalmart.com

Ball Burnisher 28/29 Dental Amalgam Surgical Mart What Does An Ball Burnisher Do This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. This can be accomplished before transfer to a plating cycle or after plating to improve the final. What Does An Ball Burnisher Do.

From unitedkingdom.mddiglobal.com

Ball Burnisher DE SM156ST1 MDDI UK What Does An Ball Burnisher Do Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. This can be accomplished before transfer to a plating cycle or. What Does An Ball Burnisher Do.

From www.hufriedygroup.com

Small/Medium Ball Burnisher XTS™ Composite Instrument TNBBS/M What Does An Ball Burnisher Do Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a. What Does An Ball Burnisher Do.

From cennlksn.blob.core.windows.net

What Is A Ball Burnisher Used For at Daniel Byers blog What Does An Ball Burnisher Do This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives. What Does An Ball Burnisher Do.

From surgicalmart.com

3 Ball Burnisher 27/30 Dental Surgical Mart What Does An Ball Burnisher Do This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. This puts stress on the metal being burnished and initiates. What Does An Ball Burnisher Do.

From www.singleusedentalinstruments.com

BB56 Ball Burnisher Single Use Dental Instruments What Does An Ball Burnisher Do This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. Burnishing is a method of polishing the surface of a component, through compression as opposed to material. What Does An Ball Burnisher Do.

From www.amazon.com

3× Dental Ball Burnisher 75127/29 Composite Amalgam What Does An Ball Burnisher Do In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. This puts stress on the metal being. What Does An Ball Burnisher Do.

From jamesrsutera.blob.core.windows.net

What Does A Ball Burnisher Do at jamesrsutera blog What Does An Ball Burnisher Do In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. This process involves applying a chemical or electrochemical coating to. What Does An Ball Burnisher Do.

From surgicalmart.com

Ball Burnisher 34 Se Dental Amalgam Surgical Mart What Does An Ball Burnisher Do This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This process involves applying a chemical or. What Does An Ball Burnisher Do.

From www.tristatedental.com

HuFriedy Ball Burnisher Small/Medium TriState Dental What Does An Ball Burnisher Do This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. This can be accomplished before transfer to a plating cycle or after plating to improve the final. What Does An Ball Burnisher Do.

From jamesrsutera.blob.core.windows.net

What Does A Ball Burnisher Do at jamesrsutera blog What Does An Ball Burnisher Do In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. This process involves applying a chemical or electrochemical coating to. What Does An Ball Burnisher Do.

From prodentusa.com

26/27S Ball Burnisher ProDentUSA What Does An Ball Burnisher Do Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. Burnishing is a method of polishing the surface of a component, through compression as opposed to material. What Does An Ball Burnisher Do.

From shipshapeins.com

Ball Burnisher 1mm/1.2mm Composite, Restorative Dental Instruments What Does An Ball Burnisher Do In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. Burnishing is a method. What Does An Ball Burnisher Do.

From www.hufriedygroup.com

Small/Medium Ball Burnisher XTS™ Composite Instrument TNBBS/M What Does An Ball Burnisher Do In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. This process involves applying a chemical or. What Does An Ball Burnisher Do.

From jamesrsutera.blob.core.windows.net

What Does A Ball Burnisher Do at jamesrsutera blog What Does An Ball Burnisher Do Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black. What Does An Ball Burnisher Do.

From surgicalmart.com

6 Ball Burnisher 27/29 De Dental Amalgam Surgical Mart What Does An Ball Burnisher Do In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. This puts stress on the metal being burnished and initiates a process called “cold flow.” cold flow. Burnishing is an essential. What Does An Ball Burnisher Do.

From surgicalmart.com

6 Ball Burnisher 1 De Dental Amalgam Surgical Mart What Does An Ball Burnisher Do This process involves applying a chemical or electrochemical coating to the surface of the metal, producing an oxide layer that gives the material a black or dark brown color. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. This can be accomplished before transfer to a plating cycle or after plating. What Does An Ball Burnisher Do.

From www.hufriedygroup.com

XTS 18 DE Ball Burnisher TNBB18 HuFriedy Group What Does An Ball Burnisher Do Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. In the metal burnishing process, a hard roller or balls rub against or press on the softer workpiece. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. This puts stress on the metal being. What Does An Ball Burnisher Do.

From jamesrsutera.blob.core.windows.net

What Does A Ball Burnisher Do at jamesrsutera blog What Does An Ball Burnisher Do Burnishing is an essential surface treatment technique in many areas of metallurgy and engineering. Burnishing is a method of polishing the surface of a component, through compression as opposed to material removal. This can be accomplished before transfer to a plating cycle or after plating to improve the final luster of the finish. In the metal burnishing process, a hard. What Does An Ball Burnisher Do.