Pneumatic Problems And Solutions . The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. How fast do you need. How much force do you need? With pneumatic systems, a little guessing is okay, but be sure to understand the application. There are 8 reasons pneumatic systems fail. They include contaminants clogging compressed air or cylinders needing repairing.

from tm.smkn1bawang.sch.id

How fast do you need. They include contaminants clogging compressed air or cylinders needing repairing. How much force do you need? With pneumatic systems, a little guessing is okay, but be sure to understand the application. There are 8 reasons pneumatic systems fail. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment.

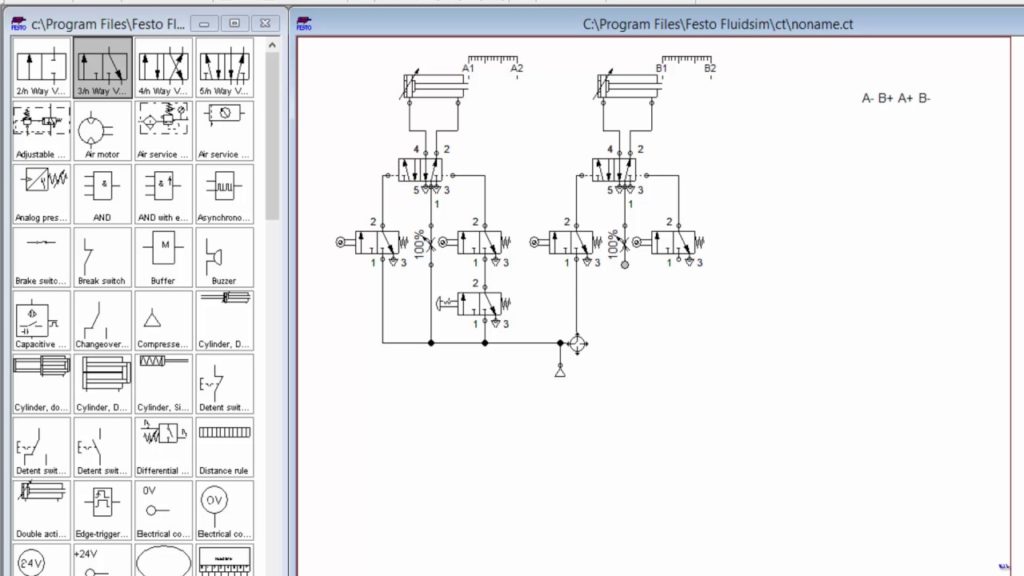

pneumatic A B+ A+ B sequence TEKNIK MEKATRONIKA

Pneumatic Problems And Solutions There are 8 reasons pneumatic systems fail. There are 8 reasons pneumatic systems fail. How fast do you need. How much force do you need? They include contaminants clogging compressed air or cylinders needing repairing. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. With pneumatic systems, a little guessing is okay, but be sure to understand the application. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment.

From mechdiploma.com

ElectroPneumatic circuits Mechanical Engg Simple Notes ,Solved Pneumatic Problems And Solutions With pneumatic systems, a little guessing is okay, but be sure to understand the application. How fast do you need. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. There are 8 reasons pneumatic systems fail. How much force do you need? The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination,. Pneumatic Problems And Solutions.

From www.numerade.com

SOLVED Please explain the following problem Problem 4 Determine the Pneumatic Problems And Solutions The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. There are 8 reasons pneumatic systems fail. How much force do you need? With pneumatic systems, a little guessing is okay, but be sure to understand the application. How fast do. Pneumatic Problems And Solutions.

From www.youtube.com

Cascade Method A+B+BA(Pneumatic) YouTube Pneumatic Problems And Solutions They include contaminants clogging compressed air or cylinders needing repairing. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. How fast do you need. There are 8 reasons pneumatic systems fail. How much force do you need? With pneumatic systems,. Pneumatic Problems And Solutions.

From www.youtube.com

Tutorial FluidSIM pneumatic A+ B+ A B YouTube Pneumatic Problems And Solutions The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. How fast do you need. How much force do you need? They include contaminants clogging compressed air or cylinders needing repairing. With pneumatic systems, a little guessing is okay, but be sure to understand the application. The following troubleshooting charts cover common problems with. Pneumatic Problems And Solutions.

From www.chiefdelphi.com

pneumatic problem Pneumatics Chief Delphi Pneumatic Problems And Solutions The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. With pneumatic systems, a little guessing is okay, but be sure to understand the application. They include contaminants clogging compressed air or cylinders needing repairing. How much force do you need? There are 8 reasons pneumatic systems fail. How fast do you need. The 5 common issues. Pneumatic Problems And Solutions.

From www.chegg.com

Solved Problem 1 Draw the sequence chart for this pneumatic Pneumatic Problems And Solutions How fast do you need. How much force do you need? There are 8 reasons pneumatic systems fail. They include contaminants clogging compressed air or cylinders needing repairing. With pneumatic systems, a little guessing is okay, but be sure to understand the application. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. The. Pneumatic Problems And Solutions.

From gesrepair.com

How Can You Diagnose Pneumatic System Failure? Global Electronic Services Pneumatic Problems And Solutions How much force do you need? They include contaminants clogging compressed air or cylinders needing repairing. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. With pneumatic systems, a little guessing is okay, but be sure to understand the application. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment.. Pneumatic Problems And Solutions.

From www.rowse.co.uk

11 Steps Troubleshooting Pneumatic Systems Rowse Pneumatic Problems And Solutions The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. They include contaminants clogging compressed air or cylinders needing repairing. How much force do you need? The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. With pneumatic systems, a little guessing is okay, but be sure to understand the application.. Pneumatic Problems And Solutions.

From www.docsity.com

ELECTROPNEUMATICS EXERCISES Cheat Sheet Pneumatics Docsity Pneumatic Problems And Solutions The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. They include contaminants clogging compressed air or cylinders needing repairing. How fast do you need. With pneumatic systems, a little guessing is okay, but be sure to understand the application. How. Pneumatic Problems And Solutions.

From www.slideshare.net

Pneumatic System Pneumatic Problems And Solutions How fast do you need. With pneumatic systems, a little guessing is okay, but be sure to understand the application. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. There are 8 reasons pneumatic systems fail. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. How much force do. Pneumatic Problems And Solutions.

From www.chegg.com

Solved 1. Analyze the pneumatic problem and design direct Pneumatic Problems And Solutions With pneumatic systems, a little guessing is okay, but be sure to understand the application. There are 8 reasons pneumatic systems fail. How fast do you need. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. How much force do. Pneumatic Problems And Solutions.

From www.youtube.com

Advantages And Disadvantages of Pneumatic System YouTube Pneumatic Problems And Solutions How much force do you need? The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. With pneumatic systems, a little guessing is okay, but be sure to understand the application. There are 8 reasons pneumatic systems fail. How fast do you need. They include contaminants clogging compressed air or cylinders needing repairing. The. Pneumatic Problems And Solutions.

From www.chegg.com

3. For the pneumatic circuit given below, following Pneumatic Problems And Solutions How much force do you need? The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. They include contaminants clogging compressed air or cylinders needing repairing. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. With pneumatic systems, a little guessing is okay, but be sure to understand the application.. Pneumatic Problems And Solutions.

From www.studocu.com

Pneumatic Circuits Development with solution problesm 1 9 2022 Pneumatic Problems And Solutions With pneumatic systems, a little guessing is okay, but be sure to understand the application. How much force do you need? There are 8 reasons pneumatic systems fail. They include contaminants clogging compressed air or cylinders needing repairing. How fast do you need. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. The. Pneumatic Problems And Solutions.

From www.chegg.com

Solved Design a pneumatic circuit to do a sequence of A+ B+ Pneumatic Problems And Solutions There are 8 reasons pneumatic systems fail. With pneumatic systems, a little guessing is okay, but be sure to understand the application. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. How fast do you need. How much force do. Pneumatic Problems And Solutions.

From www.slideserve.com

PPT Science 8 PowerPoint Presentation, free download ID2195366 Pneumatic Problems And Solutions With pneumatic systems, a little guessing is okay, but be sure to understand the application. How much force do you need? They include contaminants clogging compressed air or cylinders needing repairing. There are 8 reasons pneumatic systems fail. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. The following troubleshooting charts cover common. Pneumatic Problems And Solutions.

From www.chegg.com

Solved Problem 2 For the shown pneumatic circuit, what is Pneumatic Problems And Solutions There are 8 reasons pneumatic systems fail. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. With pneumatic systems, a little guessing is okay, but be sure to understand the application. How fast do you need. They include contaminants clogging. Pneumatic Problems And Solutions.

From www.rowse.co.uk

What Is Pneumatics? Answered by Our Experts Rowse Pneumatic Problems And Solutions There are 8 reasons pneumatic systems fail. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. They include contaminants clogging compressed air or cylinders needing repairing. How fast do you need. With pneumatic systems, a little guessing is okay, but be sure to understand the application. How much force do you need? The 5 common issues. Pneumatic Problems And Solutions.

From exougvbtk.blob.core.windows.net

Pneumatic System Problems And Solutions at Lydia Day blog Pneumatic Problems And Solutions With pneumatic systems, a little guessing is okay, but be sure to understand the application. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. There are 8 reasons pneumatic systems fail. How fast do you need. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. How much force do. Pneumatic Problems And Solutions.

From www.chegg.com

Solved FIGURE 1 shows a pneumatic circuit diagram used to Pneumatic Problems And Solutions There are 8 reasons pneumatic systems fail. They include contaminants clogging compressed air or cylinders needing repairing. With pneumatic systems, a little guessing is okay, but be sure to understand the application. How fast do you need. How much force do you need? The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. The. Pneumatic Problems And Solutions.

From www.pneumatictoolz.com

Tips for Troubleshooting Common Pneumatic Tool Problems Pneumatic Tools Pneumatic Problems And Solutions With pneumatic systems, a little guessing is okay, but be sure to understand the application. How much force do you need? The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. How fast do you need. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. They include contaminants clogging compressed. Pneumatic Problems And Solutions.

From www.chegg.com

Solved Analyze the pneumatic problem and design direct and Pneumatic Problems And Solutions The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. How fast do you need. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. How much force do you need? There are 8 reasons pneumatic systems fail. With pneumatic systems, a little guessing is okay, but be sure to understand. Pneumatic Problems And Solutions.

From www.chegg.com

Solved Problem 1 Draw the sequence chart for this pneumatic Pneumatic Problems And Solutions The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. How fast do you need. There are 8 reasons pneumatic systems fail. How much force do you need? With pneumatic systems, a little guessing is okay, but be sure to understand the application. They include contaminants clogging compressed air or cylinders needing repairing. The 5 common issues. Pneumatic Problems And Solutions.

From amatrol.com

Pneumatic System Troubleshooting Maintenance Training Pneumatic Problems And Solutions How much force do you need? The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. With pneumatic systems, a little guessing is okay, but be sure to understand the application. They include contaminants clogging compressed air or cylinders needing repairing.. Pneumatic Problems And Solutions.

From www.mchhydraulics.co.uk

Top 5 Common Pneumatic Problems & Solutions MCH Hydraulics Pneumatic Problems And Solutions The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. They include contaminants clogging compressed air or cylinders needing repairing. How fast do you need. There are 8 reasons pneumatic systems fail. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. With pneumatic systems, a little guessing is okay, but. Pneumatic Problems And Solutions.

From www.chegg.com

Solved QUIZ 5 (ELECTROPNEUMATICS) Figure 1 shows a drilling Pneumatic Problems And Solutions There are 8 reasons pneumatic systems fail. How much force do you need? They include contaminants clogging compressed air or cylinders needing repairing. How fast do you need. With pneumatic systems, a little guessing is okay, but be sure to understand the application. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. The. Pneumatic Problems And Solutions.

From amatrol.com

Pneumatic System Troubleshooting Maintenance Training Pneumatic Problems And Solutions The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. How much force do you need? With pneumatic systems, a little guessing is okay, but be sure to understand the application. How fast do you need. They include contaminants clogging compressed air or cylinders needing repairing. The following troubleshooting charts cover common problems with. Pneumatic Problems And Solutions.

From www.chegg.com

Solved Problem 3 The diagram below shows a pneumatic lemon Pneumatic Problems And Solutions There are 8 reasons pneumatic systems fail. How fast do you need. How much force do you need? The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. They include contaminants clogging compressed air or cylinders needing repairing. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. With pneumatic systems,. Pneumatic Problems And Solutions.

From www.chegg.com

Solved Problem 1 Figure 7.3 shows a pneumatic system, in Pneumatic Problems And Solutions The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. There are 8 reasons pneumatic systems fail. With pneumatic systems, a little guessing is okay, but be sure to understand the application. How much force do you need? How fast do. Pneumatic Problems And Solutions.

From www.chegg.com

Solved Problem 1 For the below pneumatic circuit, what is Pneumatic Problems And Solutions How fast do you need. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. They include contaminants clogging compressed air or cylinders needing repairing. How much force do you need? With pneumatic systems, a little guessing is okay, but be. Pneumatic Problems And Solutions.

From www.youtube.com

How to Solve Control Valve Pneumatic System Instrumentation Problems Pneumatic Problems And Solutions The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. How much force do you need? They include contaminants clogging compressed air or cylinders needing repairing. There are 8 reasons pneumatic systems fail. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. With pneumatic systems, a little guessing is okay,. Pneumatic Problems And Solutions.

From exougvbtk.blob.core.windows.net

Pneumatic System Problems And Solutions at Lydia Day blog Pneumatic Problems And Solutions The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. With pneumatic systems, a little guessing is okay, but be sure to understand the application. How much force do you need? They include contaminants clogging compressed air or cylinders needing repairing.. Pneumatic Problems And Solutions.

From www.chegg.com

Solved Figure 2 shows a sketch of a pneumatic system. You Pneumatic Problems And Solutions How fast do you need. How much force do you need? The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. They include contaminants clogging compressed air or cylinders needing repairing. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. There are 8 reasons pneumatic systems fail. With pneumatic systems,. Pneumatic Problems And Solutions.

From answerhappy.com

1. Analyze the pneumatic problem and design direct and indirect Pneumatic Problems And Solutions The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. They include contaminants clogging compressed air or cylinders needing repairing. The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. How fast do you need. How much force do you need? With pneumatic systems, a little guessing is okay, but be. Pneumatic Problems And Solutions.

From tm.smkn1bawang.sch.id

pneumatic A B+ A+ B sequence TEKNIK MEKATRONIKA Pneumatic Problems And Solutions How much force do you need? The 5 common issues with pneumatic cylinders are leakage, poor performance, seal failure, contamination, and misalignment. They include contaminants clogging compressed air or cylinders needing repairing. The following troubleshooting charts cover common problems with pneumatic equipment including actuators, filters,. With pneumatic systems, a little guessing is okay, but be sure to understand the application.. Pneumatic Problems And Solutions.