Type 27 Vs Type 28 Grinding Wheels . .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than grinding wheels (1/4”) and pipeline wheels (1/8”). Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. Our article on angle grinders explains why. Operators that use a type 27 wheel. Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. Maximize the safe and effective use of type 27 depressed center grinding wheels by following these do's and don'ts from our safety experts. The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed.

from www.farmacologiaactual.com

Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. Our article on angle grinders explains why. The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed. Maximize the safe and effective use of type 27 depressed center grinding wheels by following these do's and don'ts from our safety experts. Operators that use a type 27 wheel. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than grinding wheels (1/4”) and pipeline wheels (1/8”).

United Abrasives SAIT A24RBF 41/2" Type 27 Grinding Wheel 7/8 Arbor

Type 27 Vs Type 28 Grinding Wheels There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than grinding wheels (1/4”) and pipeline wheels (1/8”). In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. Our article on angle grinders explains why. Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. Maximize the safe and effective use of type 27 depressed center grinding wheels by following these do's and don'ts from our safety experts. Operators that use a type 27 wheel. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed. Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains.

From www.amazon.com

United AbrasivesSAIT 20063 A24R General Purpose/Long Life Type 27 Vs Type 28 Grinding Wheels .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than grinding wheels (1/4”) and pipeline wheels (1/8”). Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. Operators that use a type 27 wheel. Maximize the safe and effective use. Type 27 Vs Type 28 Grinding Wheels.

From dansdiscounttools.com

Barnes BD3059 Type 27 Grinding Wheel 4" x 1/4" x 5/8" 5 Pack Type 27 Vs Type 28 Grinding Wheels Operators that use a type 27 wheel. .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than grinding wheels (1/4”) and pipeline wheels (1/8”). Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. Maximize the safe and effective use. Type 27 Vs Type 28 Grinding Wheels.

From www.walmart.com

DeWalt® Type 27 Grinding Wheel Type 27 Vs Type 28 Grinding Wheels Operators that use a type 27 wheel. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. The key advantage to using a cutting wheel and angle grinder is. Type 27 Vs Type 28 Grinding Wheels.

From www.unitedabrasives.com

Saitech Ultimate Performance™ TYPE 28 United Abrasives Type 27 Vs Type 28 Grinding Wheels Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. Our article on angle grinders explains why. Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. In most cases (particularly within maintenance, repair and operations) you would typically use. Type 27 Vs Type 28 Grinding Wheels.

From ronixtools.com

A Beginner’s Guide to Angle Grinder Wheels Ronix Mag Type 27 Vs Type 28 Grinding Wheels Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than grinding wheels (1/4”) and pipeline wheels (1/8”). Operators that use a type 27 wheel. The key advantage to using a. Type 27 Vs Type 28 Grinding Wheels.

From www.homedepot.com

Forney 5 in. x 1/4 in. x 7/8 in. Metal Type 27 A24RBF Grinding Wheel Type 27 Vs Type 28 Grinding Wheels There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed. Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum. Type 27 Vs Type 28 Grinding Wheels.

From www.forturetools.com

How to read a grinding wheel's specification Forture Tools Type 27 Vs Type 28 Grinding Wheels Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than. Type 27 Vs Type 28 Grinding Wheels.

From www.farmacologiaactual.com

United Abrasives SAIT A24RBF 41/2" Type 27 Grinding Wheel 7/8 Arbor Type 27 Vs Type 28 Grinding Wheels The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed. In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses. Type 27 Vs Type 28 Grinding Wheels.

From www.ddtexasoutfitters.com

Type 27 Metal Grinding Wheel, 41/2" by 1/8" Type 27 Vs Type 28 Grinding Wheels There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Our article on angle grinders explains why. In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. Grit range is from 36, 46 and 60 grit and can be found. Type 27 Vs Type 28 Grinding Wheels.

From www.mmsonline.com

7 Key Factors in Choosing a Grinding Wheel Modern Machine Shop Type 27 Vs Type 28 Grinding Wheels Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed. Maximize the safe and effective use of type 27 depressed center grinding wheels by following these do's and. Type 27 Vs Type 28 Grinding Wheels.

From www.finepowertools.com

Angle Grinder for Metal Cutting. (StepbyStep Guide) Type 27 Vs Type 28 Grinding Wheels Our article on angle grinders explains why. Operators that use a type 27 wheel. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. .045 cutting wheels are designed specifically. Type 27 Vs Type 28 Grinding Wheels.

From www.empireabrasives.com

41/2" x .045" x 7/8" Aluminum Grinding Wheel Type 27 Disc Type 27 Vs Type 28 Grinding Wheels In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed. Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees.. Type 27 Vs Type 28 Grinding Wheels.

From www.shopjfi.com

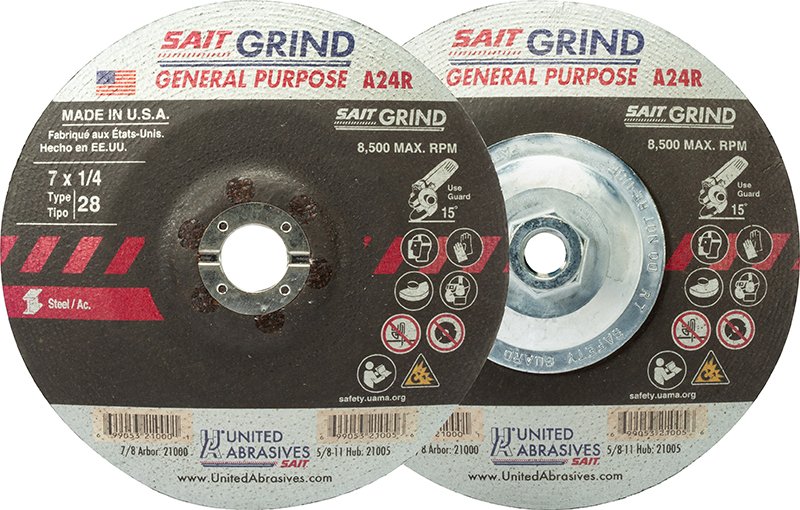

Sait 21005 7" x 1/4" x 5/8"11 A24R Type 28 Grinding Wheel Type 27 Vs Type 28 Grinding Wheels Maximize the safe and effective use of type 27 depressed center grinding wheels by following these do's and don'ts from our safety experts. Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”). Type 27 Vs Type 28 Grinding Wheels.

From www.tornillospr.com

SaitType 27 A24R Depressed Center Grinding Wheel Long Life Type 27 Vs Type 28 Grinding Wheels There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. Our article on angle grinders explains why. Type 27 wheels have a flat profile with a depressed center that performs. Type 27 Vs Type 28 Grinding Wheels.

From www.forneyind.com

Grinding Wheel, Masonry, Type 27, 41/2 in x 1/4 in x 5/8 in11 Type 27 Vs Type 28 Grinding Wheels Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —.. Type 27 Vs Type 28 Grinding Wheels.

From finemetalworking.com

Surface Grinding Wheels Types and Specification Type 27 Vs Type 28 Grinding Wheels The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed. In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. Maximize the safe and effective use of type 27 depressed center grinding wheels by following these do's and don'ts. Type 27 Vs Type 28 Grinding Wheels.

From www.extremeabrasives.com

Cutting and Grinding Wheels Application Guide Archives Extreme Type 27 Vs Type 28 Grinding Wheels Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed. Maximize the safe and effective use of type 27 depressed center grinding wheels by following these do's and. Type 27 Vs Type 28 Grinding Wheels.

From www.weilerabrasives.com

How to Choose a Grinding Wheel for Different Types of Metal Weiler Type 27 Vs Type 28 Grinding Wheels Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. Operators that use a type 27 wheel. .045 cutting wheels are designed specifically for cutting metal and have a much. Type 27 Vs Type 28 Grinding Wheels.

From www.toolsource.com

Depressed Center Grinding Wheel (Type 27 w/o Hub) 41/2†x 1/4†x 7 Type 27 Vs Type 28 Grinding Wheels Our article on angle grinders explains why. In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. Maximize the safe and effective use of type 27 depressed center grinding wheels by following these do's and don'ts from our safety experts. Type 27 wheels have a flat profile with a depressed. Type 27 Vs Type 28 Grinding Wheels.

From www.amazon.com

United Abrasives SAIT 21010 9x1/4x7/8 A24R Long Life No Hub Type 27 Vs Type 28 Grinding Wheels .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than grinding wheels (1/4”) and pipeline wheels (1/8”). Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. Our article on angle grinders explains why. In most cases (particularly within maintenance,. Type 27 Vs Type 28 Grinding Wheels.

From www.rexcut.com

Cotton Fiber Type 27 Grinding & Blending Wheels Type 27 Vs Type 28 Grinding Wheels Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. Our article on angle grinders explains why. .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than grinding wheels (1/4”) and pipeline wheels (1/8”). The key advantage to using a. Type 27 Vs Type 28 Grinding Wheels.

From www.forneyind.com

Grinding Wheel, Masonry, Type 27, 4 in x 1/4 in x 5/8 in Type 27 Vs Type 28 Grinding Wheels Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when. Type 27 Vs Type 28 Grinding Wheels.

From www.johnplylerhomecenter.com

Dewalt DW4542 Type 27 Depressed Center Fast Cutting Grinding Wheel, 41 Type 27 Vs Type 28 Grinding Wheels In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. Maximize the safe and effective use of type 27 depressed center grinding wheels by following these do's and don'ts from our safety experts. Type 27 wheels have a flat profile with a depressed center that performs best between 25 and. Type 27 Vs Type 28 Grinding Wheels.

From www.shopjfi.com

Sait 20080 7" x 1/4" x 7/8" A24R Type 27 Grinding Wheel Type 27 Vs Type 28 Grinding Wheels Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than grinding. Type 27 Vs Type 28 Grinding Wheels.

From www.dewalt.com

HP Metal Grinding Wheels Type 27 DEWALT Type 27 Vs Type 28 Grinding Wheels There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than. Type 27 Vs Type 28 Grinding Wheels.

From www.youtube.com

Grinding Wheel Selection Grinding Methods Types of Grinding Type 27 Vs Type 28 Grinding Wheels Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. Operators that use a type 27 wheel. The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed. There are three main types of grinding wheels, where various numbers differentiate between. Type 27 Vs Type 28 Grinding Wheels.

From www.forneyind.com

Type 27 Grinding Wheels Type 27 Vs Type 28 Grinding Wheels Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. Our article on angle grinders explains why. Maximize the safe and effective use of type 27 depressed center grinding wheels. Type 27 Vs Type 28 Grinding Wheels.

From www.orientcraft-abra.com

China Type 27 Fibreglass Reinforced Depressed Center Grinding Wheels Type 27 Vs Type 28 Grinding Wheels Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than grinding wheels (1/4”) and pipeline wheels (1/8”). Maximize the safe and effective use of type 27 depressed center grinding wheels. Type 27 Vs Type 28 Grinding Wheels.

From ostartools.en.made-in-china.com

Type 27 Grinding Wheels for Metal and Masonry Cutting & Grinding Disc Type 27 Vs Type 28 Grinding Wheels The key advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed. Maximize the safe and effective use of type 27 depressed center grinding wheels by following these do's and don'ts from our safety experts. Operators that use a type 27 wheel. Grit range is from 36, 46 and 60 grit. Type 27 Vs Type 28 Grinding Wheels.

From www.auweld.com

Stainless Steel Grinding Wheel Type 27 Auweld Type 27 Vs Type 28 Grinding Wheels Our article on angle grinders explains why. Operators that use a type 27 wheel. Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. .045 cutting wheels are designed specifically. Type 27 Vs Type 28 Grinding Wheels.

From learnmechanical.com

Grinding WheelDefinition, Material, Grit, Grades, Structure, Types Type 27 Vs Type 28 Grinding Wheels There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. Operators that use a type 27 wheel. In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. Type 27 wheels have a flat profile with a depressed center that performs. Type 27 Vs Type 28 Grinding Wheels.

From www.shakedeal.com

How to choose the right grinding wheel? Type 27 Vs Type 28 Grinding Wheels .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than grinding wheels (1/4”) and pipeline wheels (1/8”). Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. Type 27 wheels have a flat profile with a depressed center that performs. Type 27 Vs Type 28 Grinding Wheels.

From www.cgwabrasives.com

Depressed Center Grinding Wheels Type 27 and 28 Grinding Wheels CGW Type 27 Vs Type 28 Grinding Wheels Grit range is from 36, 46 and 60 grit and can be found in ceramic, zirconia and treated aluminum oxide grains. Our article on angle grinders explains why. Maximize the safe and effective use of type 27 depressed center grinding wheels by following these do's and don'ts from our safety experts. Operators that use a type 27 wheel. In most. Type 27 Vs Type 28 Grinding Wheels.

From ropesoapndope.com

RopeSoapNDope. 9"x 1/4", TIGER ZIRC Type 28 Grinding Wheel, Z24T, 7/8 Type 27 Vs Type 28 Grinding Wheels Type 27 wheels have a flat profile with a depressed center that performs best between 25 and 35 degrees. In most cases (particularly within maintenance, repair and operations) you would typically use a grinding wheel on an angle grinder. .045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as “kerf”) than grinding wheels. Type 27 Vs Type 28 Grinding Wheels.

From www.shopjfi.com

Sait 22414 41/2" x 1/4" x 7/8" Ultimate Grind Type 27 Grinding Wheel Type 27 Vs Type 28 Grinding Wheels Maximize the safe and effective use of type 27 depressed center grinding wheels by following these do's and don'ts from our safety experts. There are three main types of grinding wheels, where various numbers differentiate between wheels with specific properties and uses —. The key advantage to using a cutting wheel and angle grinder is that they are easily configured. Type 27 Vs Type 28 Grinding Wheels.