Back Pressure Valve In Injection Moulding Machine . Back pressure in injection molding refers to the resistance or force that the molten plastic exerts against the forward motion of the screw as it pushes the material into the. Normally, the highest pressure and fastest fill rate are the. How this is done depends on the machine type. Back pressure is the pressure applied to the screw during the injection molding process. A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking action on the back of the screw. Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. The back pressure is generated by the metering section of the mixing. The material is pushing back against the injection screw as the material is mixed and pushed forward. This is the primary pressure for injecting 95 percent of the molten plastic into the closed mould. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. It is controlled by adjusting the return throttle of the injection cylinder.

from predictabledesigns.com

The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. How this is done depends on the machine type. Back pressure in injection molding refers to the resistance or force that the molten plastic exerts against the forward motion of the screw as it pushes the material into the. Normally, the highest pressure and fastest fill rate are the. Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. The back pressure is generated by the metering section of the mixing. Back pressure is the pressure applied to the screw during the injection molding process. This is the primary pressure for injecting 95 percent of the molten plastic into the closed mould. The material is pushing back against the injection screw as the material is mixed and pushed forward. A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking action on the back of the screw.

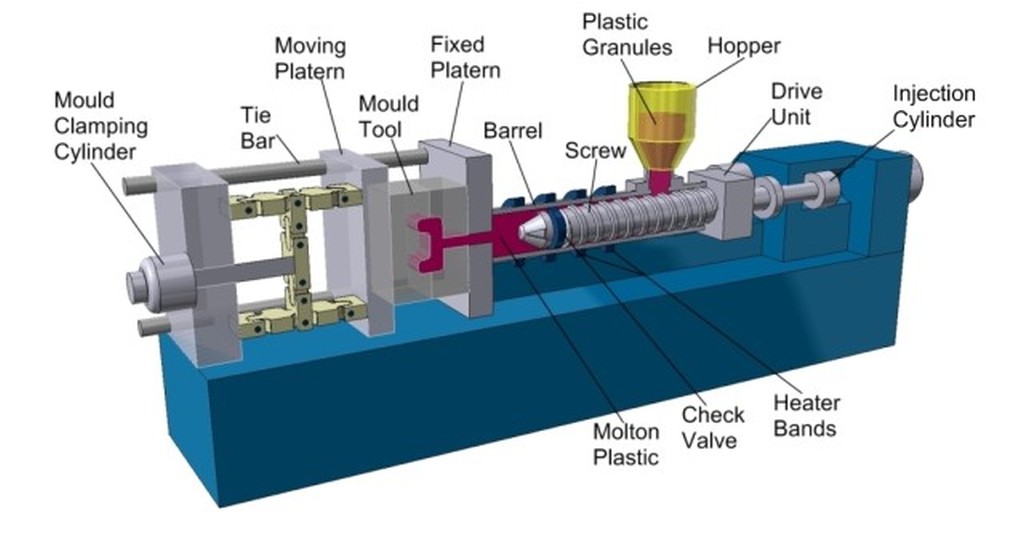

Introduction to Injection Molding for Mass Production of Custom Plastic

Back Pressure Valve In Injection Moulding Machine The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. It is controlled by adjusting the return throttle of the injection cylinder. Normally, the highest pressure and fastest fill rate are the. How this is done depends on the machine type. Back pressure is the pressure applied to the screw during the injection molding process. The material is pushing back against the injection screw as the material is mixed and pushed forward. A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking action on the back of the screw. The back pressure is generated by the metering section of the mixing. This is the primary pressure for injecting 95 percent of the molten plastic into the closed mould. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. Back pressure in injection molding refers to the resistance or force that the molten plastic exerts against the forward motion of the screw as it pushes the material into the.

From exozbdaug.blob.core.windows.net

Injection Molding Machine For Small Parts at Amanda Colton blog Back Pressure Valve In Injection Moulding Machine Back pressure is the pressure applied to the screw during the injection molding process. The back pressure is generated by the metering section of the mixing. A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking action on the back of the screw. How this is done depends on the machine type. Back. Back Pressure Valve In Injection Moulding Machine.

From toolingmagazine.com

Injection Molding Basics TOOLING MAGAZINE Back Pressure Valve In Injection Moulding Machine A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking action on the back of the screw. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. The material is pushing back against the injection screw as the material is. Back Pressure Valve In Injection Moulding Machine.

From mgs-mfg-group-ireland-ltd.hirehive.com

Toolmaker MGS Leixlip Back Pressure Valve In Injection Moulding Machine The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. Back pressure is the pressure applied to the screw during the injection molding process. The material is pushing back against the injection screw as the material is mixed and pushed forward. Back pressure in injection molding refers. Back Pressure Valve In Injection Moulding Machine.

From www.cavitymold.com

Introduction to Injection Molding Plastic Injection Molding and Mold Back Pressure Valve In Injection Moulding Machine A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking action on the back of the screw. Back pressure is the pressure applied to the screw during the injection molding process. Back pressure in injection molding refers to the resistance or force that the molten plastic exerts against the forward motion of the. Back Pressure Valve In Injection Moulding Machine.

From www.rutlandplastics.co.uk

How does injection moulding work Rutland Plastics Back Pressure Valve In Injection Moulding Machine This is the primary pressure for injecting 95 percent of the molten plastic into the closed mould. How this is done depends on the machine type. The back pressure is generated by the metering section of the mixing. It is controlled by adjusting the return throttle of the injection cylinder. Normally, the highest pressure and fastest fill rate are the.. Back Pressure Valve In Injection Moulding Machine.

From www.dymold.com

China Professinal injection mold and die casting Back Pressure Valve In Injection Moulding Machine Normally, the highest pressure and fastest fill rate are the. It is controlled by adjusting the return throttle of the injection cylinder. Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. The adjustment of injection molding back pressure should depend on the performance,. Back Pressure Valve In Injection Moulding Machine.

From www.myplasticmold.com

injection molding machine operation PIM plastic mold company Back Pressure Valve In Injection Moulding Machine Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. Back pressure is the pressure applied to the screw during the injection molding process. It is controlled by adjusting the return throttle of the injection cylinder. The material is pushing back against the injection. Back Pressure Valve In Injection Moulding Machine.

From predictabledesigns.com

Introduction to Injection Molding for Mass Production of Custom Plastic Back Pressure Valve In Injection Moulding Machine The material is pushing back against the injection screw as the material is mixed and pushed forward. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. Back pressure is the pressure applied to the screw during the injection molding process. Back pressure in injection molding refers. Back Pressure Valve In Injection Moulding Machine.

From www.injectionmoldingmaster.com

HighEfficiency, CostEffective PET Injection Molding Machines for Back Pressure Valve In Injection Moulding Machine It is controlled by adjusting the return throttle of the injection cylinder. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. The back pressure is generated by the metering section of the mixing. Back pressure in injection molding refers to the resistance or force that the. Back Pressure Valve In Injection Moulding Machine.

From www.injectionmoldingmaster.com

HighEfficiency, CostEffective PET Injection Molding Machines for Back Pressure Valve In Injection Moulding Machine Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. Back pressure in injection molding refers to the resistance or force that the molten plastic exerts against the forward motion of the screw as it pushes the material into the. It is controlled by. Back Pressure Valve In Injection Moulding Machine.

From www.injectionmoldingmaster.com

HighEfficiency, CostEffective PET Injection Molding Machines for Back Pressure Valve In Injection Moulding Machine The material is pushing back against the injection screw as the material is mixed and pushed forward. The back pressure is generated by the metering section of the mixing. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. Back pressure in injection molding refers to the. Back Pressure Valve In Injection Moulding Machine.

From www.pinterest.com

US6499987B1 Positive control nonreturn valve for an injection Back Pressure Valve In Injection Moulding Machine Back pressure in injection molding refers to the resistance or force that the molten plastic exerts against the forward motion of the screw as it pushes the material into the. Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. How this is done. Back Pressure Valve In Injection Moulding Machine.

From malaki-well-manning.blogspot.com

Injection Moulding Theory Back Pressure Valve In Injection Moulding Machine Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking action on the back of the screw. This is the primary pressure for injecting 95 percent of. Back Pressure Valve In Injection Moulding Machine.

From www.magneticplaten.com

Injection Molding Basics What Is It and How Does It Work HVR MAG Back Pressure Valve In Injection Moulding Machine It is controlled by adjusting the return throttle of the injection cylinder. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. Back pressure is the pressure applied to the screw during the injection molding process. Back pressure in injection molding refers to the resistance or force. Back Pressure Valve In Injection Moulding Machine.

From www.youtube.com

Plastic Injection Moulding Machine Process Animation Construction and Back Pressure Valve In Injection Moulding Machine This is the primary pressure for injecting 95 percent of the molten plastic into the closed mould. Back pressure in injection molding refers to the resistance or force that the molten plastic exerts against the forward motion of the screw as it pushes the material into the. Back pressure is the pressure applied to the screw during the injection molding. Back Pressure Valve In Injection Moulding Machine.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation Back Pressure Valve In Injection Moulding Machine Back pressure in injection molding refers to the resistance or force that the molten plastic exerts against the forward motion of the screw as it pushes the material into the. How this is done depends on the machine type. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic. Back Pressure Valve In Injection Moulding Machine.

From blog.asaclean.com

Injection Molding FAQ What is Cushion & why do I need to hold it? Back Pressure Valve In Injection Moulding Machine Back pressure is the pressure applied to the screw during the injection molding process. How this is done depends on the machine type. A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking action on the back of the screw. It is controlled by adjusting the return throttle of the injection cylinder. Back. Back Pressure Valve In Injection Moulding Machine.

From mavink.com

Injection Molding Cycle Back Pressure Valve In Injection Moulding Machine Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. The back pressure is generated by the metering section of the mixing. Back pressure in injection molding refers to the resistance or force that the molten plastic exerts against the forward motion of the. Back Pressure Valve In Injection Moulding Machine.

From www.fastercouplings.com

Faster Injection moulding is a manufacturing process for producing Back Pressure Valve In Injection Moulding Machine The material is pushing back against the injection screw as the material is mixed and pushed forward. A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking action on the back of the screw. The back pressure is generated by the metering section of the mixing. Back pressure in an injection molding process. Back Pressure Valve In Injection Moulding Machine.

From 3dwithus.com

Manual Injection Molding Hand Operated Machine Back Pressure Valve In Injection Moulding Machine The material is pushing back against the injection screw as the material is mixed and pushed forward. The back pressure is generated by the metering section of the mixing. Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. How this is done depends. Back Pressure Valve In Injection Moulding Machine.

From www.log-imm.com

LOG Injection Molding Machine S8300T Servo Injection Molding Machine Back Pressure Valve In Injection Moulding Machine The material is pushing back against the injection screw as the material is mixed and pushed forward. The back pressure is generated by the metering section of the mixing. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. Back pressure in injection molding refers to the. Back Pressure Valve In Injection Moulding Machine.

From www.rdray.com

Types of Injection Molding Valves R. DRAY MFG. Back Pressure Valve In Injection Moulding Machine The material is pushing back against the injection screw as the material is mixed and pushed forward. Normally, the highest pressure and fastest fill rate are the. Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. This is the primary pressure for injecting. Back Pressure Valve In Injection Moulding Machine.

From www.youtube.com

What is rubber injection molding? YouTube Back Pressure Valve In Injection Moulding Machine How this is done depends on the machine type. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. Back pressure is the pressure applied to the screw during the injection molding process. The material is pushing back against the injection screw as the material is mixed. Back Pressure Valve In Injection Moulding Machine.

From www.pinterest.com

Image result for valves in injection molding machine Plastic Moulding Back Pressure Valve In Injection Moulding Machine The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. How this is done depends on the machine type. A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking action on the back of the screw. The back pressure is. Back Pressure Valve In Injection Moulding Machine.

From www.pinterest.com

Injection moulding explained Mould design, Injection moulding process Back Pressure Valve In Injection Moulding Machine How this is done depends on the machine type. The back pressure is generated by the metering section of the mixing. Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. The adjustment of injection molding back pressure should depend on the performance, drying. Back Pressure Valve In Injection Moulding Machine.

From www.jazzmold.com

Back Pressure Control of Injection Molding Machine Plastic Injection Back Pressure Valve In Injection Moulding Machine A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking action on the back of the screw. It is controlled by adjusting the return throttle of the injection cylinder. The material is pushing back against the injection screw as the material is mixed and pushed forward. Back pressure is the pressure applied to. Back Pressure Valve In Injection Moulding Machine.

From www.rdray.com

Types of Injection Molding Valves R. DRAY MFG. Back Pressure Valve In Injection Moulding Machine How this is done depends on the machine type. Back pressure in injection molding refers to the resistance or force that the molten plastic exerts against the forward motion of the screw as it pushes the material into the. The back pressure is generated by the metering section of the mixing. Back pressure is the pressure applied to the screw. Back Pressure Valve In Injection Moulding Machine.

From chenchanghong.en.made-in-china.com

PVC UPVC Water Ball Valves Valve Stainless Steel Injection Molding Back Pressure Valve In Injection Moulding Machine Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps molten plastic through. This is the primary pressure for injecting 95 percent of the molten plastic into the closed mould. A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking. Back Pressure Valve In Injection Moulding Machine.

From www.youtube.com

Energy Saving Twoplatens injection molding machine YouTube Back Pressure Valve In Injection Moulding Machine The back pressure is generated by the metering section of the mixing. How this is done depends on the machine type. Normally, the highest pressure and fastest fill rate are the. Back pressure is the pressure applied to the screw during the injection molding process. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product. Back Pressure Valve In Injection Moulding Machine.

From www.injectionmoldingmaster.com

HighEfficiency, CostEffective PET Injection Molding Machines for Back Pressure Valve In Injection Moulding Machine This is the primary pressure for injecting 95 percent of the molten plastic into the closed mould. A hydraulic machine restricts the oil flow as the cylinder, whereas a servo electric provides a breaking action on the back of the screw. Back pressure is the pressure applied to the screw during the injection molding process. Back pressure in injection molding. Back Pressure Valve In Injection Moulding Machine.

From exoiisphe.blob.core.windows.net

How Many Types Of Nozzle In Injection Moulding Machine at Larry Wicker blog Back Pressure Valve In Injection Moulding Machine Back pressure in injection molding refers to the resistance or force that the molten plastic exerts against the forward motion of the screw as it pushes the material into the. How this is done depends on the machine type. It is controlled by adjusting the return throttle of the injection cylinder. Normally, the highest pressure and fastest fill rate are. Back Pressure Valve In Injection Moulding Machine.

From mavink.com

Injection Molding Machine Schematic Back Pressure Valve In Injection Moulding Machine Back pressure is the pressure applied to the screw during the injection molding process. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps. Back Pressure Valve In Injection Moulding Machine.

From knowledge.ulprospector.com

Injection moulding the role of backpressure Prospector Back Pressure Valve In Injection Moulding Machine Back pressure is the pressure applied to the screw during the injection molding process. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic raw materials. Back pressure in an injection molding process is often defined as “the resistance of the screw to recover as the metering section pumps. Back Pressure Valve In Injection Moulding Machine.

From www.lsr-molding.com

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding Back Pressure Valve In Injection Moulding Machine How this is done depends on the machine type. Back pressure in injection molding refers to the resistance or force that the molten plastic exerts against the forward motion of the screw as it pushes the material into the. The adjustment of injection molding back pressure should depend on the performance, drying conditions, product structure, and quality of the plastic. Back Pressure Valve In Injection Moulding Machine.