Eddy Current Testing Coating Thickness . The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. The eddy currents create their. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under.

from www.theseverngroup.com

In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. The eddy currents create their. The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance.

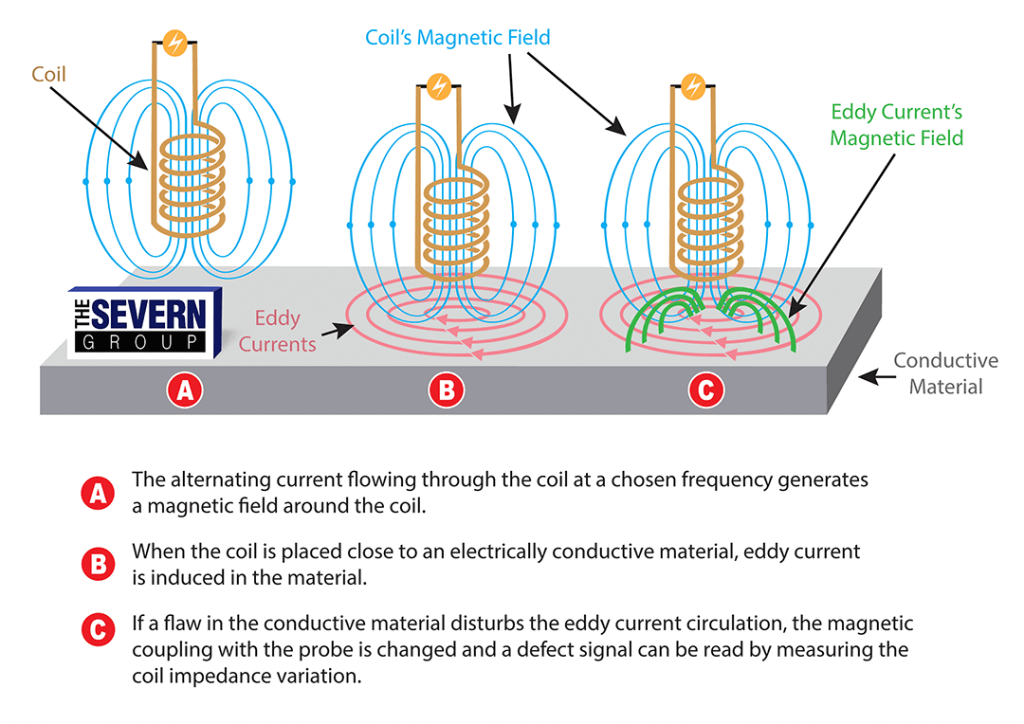

Eddy Current Testing 101 The Severn Group

Eddy Current Testing Coating Thickness ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. The eddy currents create their. The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance.

From meterflowmeters.com

Kett LH200J Eddycurrent Coating Thickness Tester Eddy Current Testing Coating Thickness In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. The eddy currents create their. ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. The substrate characteristics and the distance of the probe. Eddy Current Testing Coating Thickness.

From www.sumico.com.pk

Eddy Current Testing Service Eddy Current Testing Coating Thickness The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. The eddy currents create their. In addition to crack detection in metal sheets and tubing, eddy current testing. Eddy Current Testing Coating Thickness.

From www.ndttester.com

Good stability Eddy current 0.1um / 1um Coating Thickness Tester Eddy Current Testing Coating Thickness The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive. Eddy Current Testing Coating Thickness.

From www.sciensoria.fr

Advantages of the eddy current technique for thickness measurement Eddy Current Testing Coating Thickness The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. The eddy currents create their. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. High frequency eddy current testing (hf ect). Eddy Current Testing Coating Thickness.

From anthropology.iresearchnet.com

DR3000 03000um Coating Thickness Gauge for Metal Material Surface Eddy Current Testing Coating Thickness The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic.. Eddy Current Testing Coating Thickness.

From www.aliexpress.com

Cm8823 Portable Eddy Current N Probe Coating Thickness Gauge Meter Eddy Current Testing Coating Thickness High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy. Eddy Current Testing Coating Thickness.

From www.huatecgroup.com

Portable Eddy Current Micro Coating Thickness Tester Gauge Bluetooth Eddy Current Testing Coating Thickness The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal. Eddy Current Testing Coating Thickness.

From www.directindustry.com

Portable thickness gauge 456 series coating / digital Eddy Current Testing Coating Thickness The eddy currents create their. ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde). Eddy Current Testing Coating Thickness.

From www.huatecgroup.com

Portable Eddy Current Coating Thickness Tester Gauge Bluetooth / USB Data Eddy Current Testing Coating Thickness Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness. Eddy Current Testing Coating Thickness.

From dgmengtai.en.made-in-china.com

Eddy Current DualUse Coating Thickness Gauge/Thickness Meter Eddy Current Testing Coating Thickness High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. In addition. Eddy Current Testing Coating Thickness.

From www.tmteck-ndt.com

Digital Portable Eddy Current Flaw Detector Filter Coating Thickness Eddy Current Testing Coating Thickness The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for. Eddy Current Testing Coating Thickness.

From www.globalinstrumentsg.com

EddyCurrent Coating Thickness Tester Model LH200J Eddy Current Testing Coating Thickness ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. The eddy currents create their. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. In addition to crack detection in metal sheets and tubing, eddy current testing can be. Eddy Current Testing Coating Thickness.

From www.mikrometry.com

Mikrometry Etg15fn Eddy Current Digital Coating Thickness Gauge/mater Eddy Current Testing Coating Thickness Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. The eddy currents create their. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of. Eddy Current Testing Coating Thickness.

From www.sanko-denshi.co.jp

EDDY CURRENT COATING THICKNESS METERS | 株式会社サンコウ電子研究所 Eddy Current Testing Coating Thickness In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. The eddy currents create their. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. The substrate characteristics and the distance of the probe. Eddy Current Testing Coating Thickness.

From nanbei-china.en.made-in-china.com

Eddy Current Method (NFe) Coating Thickness Gauge Thickness Gauge and Eddy Current Testing Coating Thickness ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents.. Eddy Current Testing Coating Thickness.

From www.theseverngroup.com

Eddy Current Testing 101 The Severn Group Eddy Current Testing Coating Thickness Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. The eddy currents. Eddy Current Testing Coating Thickness.

From www.tec-science.com

Eddy current testing (ECT) tecscience Eddy Current Testing Coating Thickness High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. The thickness. Eddy Current Testing Coating Thickness.

From tiat.nl

Eddy Current Testing Tiat Europe B.V. Eddy Current Testing Coating Thickness High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. The eddy currents create their. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. In addition to crack detection in metal sheets and tubing, eddy current testing can be used. Eddy Current Testing Coating Thickness.

From present5.com

EDDY CURRENT TESTING Introduction l l This Eddy Current Testing Coating Thickness The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal. Eddy Current Testing Coating Thickness.

From ndtblog-us.fujifilm.com

Complete Guide to Eddy Current Testing Fujifilm NDT Eddy Current Testing Coating Thickness Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other. Eddy Current Testing Coating Thickness.

From www.tekcoplus.com

TMTK760 Coating Thickness Meter 01000um/040mil + F & FN Eddy Current Testing Coating Thickness Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. In addition. Eddy Current Testing Coating Thickness.

From www.elcometer.com

Electronic Coating Thickness Gauges Eddy Current Testing Coating Thickness The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. The thickness of nonmetallic coatings on metal substrates can be determined simply. Eddy Current Testing Coating Thickness.

From es.innerspec.com

Eddy Current Technology Eddy Current Testing Coating Thickness The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. The eddy currents. Eddy Current Testing Coating Thickness.

From www.aliexpress.com

ED400 Eddy current testing equipment with aluminum coating thickness Eddy Current Testing Coating Thickness In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect. Eddy Current Testing Coating Thickness.

From www.huatecgroup.com

Eddy Current Good Stability 0.1um / 1um Coating Thickness Gauge TG8830N Eddy Current Testing Coating Thickness The eddy currents create their. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings. Eddy Current Testing Coating Thickness.

From prideinstrument.en.made-in-china.com

Coating Thickness Gauge Using and Eddy Current Two Thickness Eddy Current Testing Coating Thickness High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. The eddy currents create their. ‒ standard test method for measurement of thickness of. Eddy Current Testing Coating Thickness.

From www.phynix.com

Application notes PHYNIX Eddy Current Testing Coating Thickness High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements. Eddy Current Testing Coating Thickness.

From www.tec-science.com

Eddy current testing (ECT) tecscience Eddy Current Testing Coating Thickness ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements. Eddy Current Testing Coating Thickness.

From joicmatbn.blob.core.windows.net

Thickness Measurement Using Eddy Current at Michael Bjorklund blog Eddy Current Testing Coating Thickness In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. The eddy currents create their. The substrate characteristics and the distance of the probe. Eddy Current Testing Coating Thickness.

From www.twi-global.com

Eddy Current Testing A Definitive Guide (Includes Eddy Current Array Eddy Current Testing Coating Thickness ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. The thickness of nonmetallic coatings on metal substrates can be determined simply from the. Eddy Current Testing Coating Thickness.

From www.aliexpress.com

Portable Coating Thickness Gauge Leeb252 induction Eddy Eddy Current Testing Coating Thickness ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements.. Eddy Current Testing Coating Thickness.

From www.huatecgroup.com

Eddy Current Good Stability 0.1um / 1um Coating Thickness Gauge TG8830N Eddy Current Testing Coating Thickness The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect the magnitude of the eddy currents. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. The eddy currents create their. ‒ standard test method for measurement of thickness of anodic coatings on aluminum. Eddy Current Testing Coating Thickness.

From www.instrumentstrade.com

DR370 Handheld Eddy current coating thickness gauge Eddy Current Testing Coating Thickness ‒ standard test method for measurement of thickness of anodic coatings on aluminum and of other nonconductive coatings on nonmagnetic. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. The eddy currents create their. The substrate characteristics and the distance of the probe from the substrate (the coating thickness) affect. Eddy Current Testing Coating Thickness.

From www.ndtcorner.com

NDT Corner Eddy Current Testing Coating Thickness In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under. High frequency eddy current testing (hf ect) is considered as an efficient technique for nondestructive evaluation (nde) of the tbc. The thickness of nonmetallic coatings on metal substrates can be determined simply from the. Eddy Current Testing Coating Thickness.

From globalinstrumentsg.com

Eddycurrent Coating Thickness Tester Model LH373 Eddy Current Testing Coating Thickness The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on impedance. Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as. Eddy Current Testing Coating Thickness.