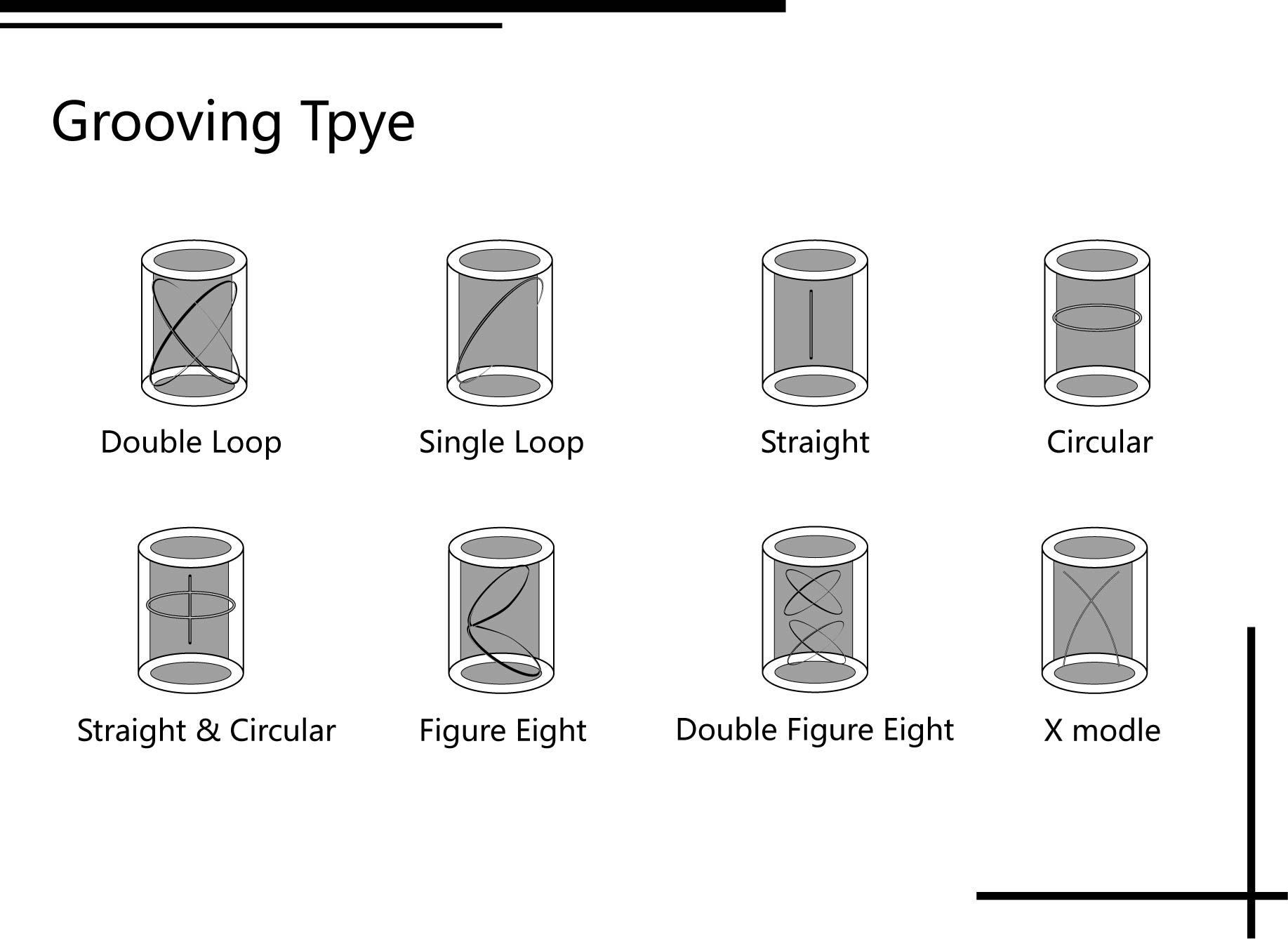

Bushing Grease Groove Design . The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Our oil and grease groove bronze bushings are. On this basis, a bearing design can be accepted. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and.

from www.bronzelube.com

The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. On this basis, a bearing design can be accepted. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. Our oil and grease groove bronze bushings are.

Groove Bushings Flanged Bearing Bronze Lube Parts

Bushing Grease Groove Design The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. On this basis, a bearing design can be accepted. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Our oil and grease groove bronze bushings are. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing.

From bronzeoilless.com

Oil Groove Bushing Types of Grooves, Grease the Groove Bushing Grease Groove Design Our oil and grease groove bronze bushings are. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding. Bushing Grease Groove Design.

From bronzeoilless.com

Oil Groove Bushing Types of Grooves, Grease the Groove Bushing Grease Groove Design Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. The design of grease grooves in bushings is essential for optimal lubrication distribution within. Bushing Grease Groove Design.

From www.nationalbronze.com

Oil Grooves for Bronze Bushings National Bronze Manufacturing Bushing Grease Groove Design Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. Our oil and grease groove bronze bushings are. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. The design of grease grooves in bushings is essential for optimal lubrication distribution. Bushing Grease Groove Design.

From www.bearingface.com

Bushing Grease Groove Design Choose Bushing Grease Groove Design On this basis, a bearing design can be accepted. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing. Our oil and grease groove bronze bushings are. Sufficient engineering. Bushing Grease Groove Design.

From irontime-sales.com

5" FLANGED BRONZE SHEAVE BUSHING WITH GREASE GROOVES IRONTIME SALES INC. Bushing Grease Groove Design Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing.. Bushing Grease Groove Design.

From www.viiplus.com

MaintenanceFree HeavyDuty Bearings Grease the Groove Bushing Grease Groove Design The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing. On this basis, a bearing design. Bushing Grease Groove Design.

From www.youtube.com

Cutting Grease grooves in bush on Modification machines lathe YouTube Bushing Grease Groove Design The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. Our oil and grease groove bronze bushings are. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and. Bushing Grease Groove Design.

From bronzeoilless.com

Oil Groove Bushing Types of Grooves, Grease the Groove Bushing Grease Groove Design Our oil and grease groove bronze bushings are. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding. Bushing Grease Groove Design.

From www.bearingface.com

Bushing Grease Groove Design Choose Bushing Grease Groove Design Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Our oil and grease groove bronze bushings are. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and. Bushing Grease Groove Design.

From www.aaxisdistributors.com

7199002999 Sintered Bronze Bushing OD 1.628 in, ID 1.254 in, W 1.125 in Bushing Grease Groove Design Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. On. Bushing Grease Groove Design.

From www.bronzelube.com

Lubrication Groove Bronze Bushing? Custom A Part! Bushing Grease Groove Design Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. On this basis, a bearing design can be accepted. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. The design of grease grooves in bushings is essential for optimal lubrication. Bushing Grease Groove Design.

From www.bronzelube.com

Groove Bushings Flanged Bearing Bronze Lube Parts Bushing Grease Groove Design Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Grease. Bushing Grease Groove Design.

From tehcoparts.en.made-in-china.com

Harden Steel Bushing Sleeve with Grease Groove China steel bushing Bushing Grease Groove Design The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. Our oil and grease groove bronze bushings are. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. Grease grooves in bushings are. Bushing Grease Groove Design.

From bronzeoilless.com

Casting Bronze Buhsing Cast Bearing Manufacturer Bushing Grease Groove Design Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and. Bushing Grease Groove Design.

From www.reddit.com

Grease grooves in bronze bushing. r/Machinists Bushing Grease Groove Design On this basis, a bearing design can be accepted. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing. The design of these grooves can vary significantly based on the application requirements, such as load, speed,. Bushing Grease Groove Design.

From www.bearingface.com

Bushing Grease Groove Design Choose Bushing Grease Groove Design Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. Grease grooves in bushings are essential. Bushing Grease Groove Design.

From www.youtube.com

Machining Oil Groove Bushing Cara Membuat Alur Oli Pada Bushing YouTube Bushing Grease Groove Design Our oil and grease groove bronze bushings are. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. The design of these grooves can vary significantly based on the application requirements,. Bushing Grease Groove Design.

From bronzeoilless.com

Oil Groove Bushing Types of Grooves, Grease the Groove Bushing Grease Groove Design The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings.. Bushing Grease Groove Design.

From www.bearingface.com

Bushing Grease Groove Design Choose Bushing Grease Groove Design On this basis, a bearing design can be accepted. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. Sufficient engineering data to permit design and performance prediction of. Bushing Grease Groove Design.

From www.youtube.com

Bronze Bushings Grease Grooves CNC LATHE YouTube Bushing Grease Groove Design Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing.. Bushing Grease Groove Design.

From bronzeoilless.com

Oil Groove Bushing Types of Grooves, Grease the Groove Bushing Grease Groove Design The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. On this basis, a bearing design. Bushing Grease Groove Design.

From www.bronzegleitlager.com

Double Loop Grease Groove Cast Bronze Bushings CuZn25AL6Fe3Mn3 Bushing Grease Groove Design Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. On this basis, a bearing design can be accepted. Our oil and grease. Bushing Grease Groove Design.

From www.viiplus.com

MaintenanceFree HeavyDuty Bearings Grease the Groove Bushing Grease Groove Design On this basis, a bearing design can be accepted. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. Sufficient engineering data to. Bushing Grease Groove Design.

From www.oilitebronze.com

Double Loop Grease Groove Cast Bronze Bushings CuZn25AL6Fe3Mn3 Bushing Grease Groove Design On this basis, a bearing design can be accepted. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Our oil and grease groove bronze bushings are. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. Grease grooves in bushings are essential for ensuring proper lubrication,. Bushing Grease Groove Design.

From www.bronzelube.com

Bronze Bushings With Oil Grooves Bushing Grease Groove Design Our oil and grease groove bronze bushings are. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction. Bushing Grease Groove Design.

From bronzeoilless.com

Oil Groove Bushing Types of Grooves, Grease the Groove Bushing Grease Groove Design Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. On this basis, a bearing design can be accepted. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. The design of these grooves can vary significantly based on the application. Bushing Grease Groove Design.

From www.bronzelube.com

Groove Bushings Flanged Bearing Bronze Lube Parts Bushing Grease Groove Design The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. On this basis, a bearing design can be accepted. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. Grease grooves in bushings are essential for ensuring proper lubrication,. Bushing Grease Groove Design.

From www.viiplus.com

MaintenanceFree HeavyDuty Bearings Grease the Groove Bushing Grease Groove Design Our oil and grease groove bronze bushings are. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical. Bushing Grease Groove Design.

From www.concretepumpsupply.com

Bearing Bushing w/Grease Groove Bushing Grease Groove Design Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical. Bushing Grease Groove Design.

From bronzeoilless.com

Oil Groove Bushing Types of Grooves, Grease the Groove Bushing Grease Groove Design Sufficient engineering data to permit design and performance prediction of bronze sleeve bearings. On this basis, a bearing design can be accepted. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. Our oil and grease groove bronze bushings are. The design of these. Bushing Grease Groove Design.

From bronzeoilless.com

Oil Groove Bushing Types of Grooves, Grease the Groove Bushing Grease Groove Design The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding. Bushing Grease Groove Design.

From www.viiplus.com

MaintenanceFree HeavyDuty Bearings Grease the Groove Bushing Grease Groove Design The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. Our oil and grease groove bronze bushings are. Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. Grease grooves in bushings are. Bushing Grease Groove Design.

From www.viiplus.com

Bushing Oil Groove Design, Bronze Bearing Design Bushing Grease Groove Design On this basis, a bearing design can be accepted. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. The design of these grooves can vary significantly based on the application requirements, such as load, speed, and environmental conditions. Solid bronze bushings can be lubricated with oil or grease,. Bushing Grease Groove Design.

From www.youtube.com

cutting grease grooves in bushings x y z cnc, machining internal oil Bushing Grease Groove Design Solid bronze bushings can be lubricated with oil or grease, whereas the lubricant not only improves the sliding properties, but also reduces wear and prevents corrosion. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. Our oil and grease groove bronze bushings are. Sufficient engineering data to permit. Bushing Grease Groove Design.

From bronzeoilless.com

Oil Groove Bushing Types of Grooves, Grease the Groove Bushing Grease Groove Design Our oil and grease groove bronze bushings are. The design of grease grooves in bushings is essential for optimal lubrication distribution within the bearing, reducing friction and wear, and. Grease grooves in bushings are essential for ensuring proper lubrication, which is critical for the performance and longevity of the bushing. The design of these grooves can vary significantly based on. Bushing Grease Groove Design.