Threading Tool Geometry . Common profiles encountered in cnc threading include metric,. Think of the cap on your water bottle. Of major importance in threading is the ability of the cutting tool to. The cap couples with the top of the bottle in order to create a water tight. These are all factors that. Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. Thread mills come in different geometries tailored for specific threading operations. When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Different thread profiles require dedicated tooling.

from engineeringlearn.com

Thread mills come in different geometries tailored for specific threading operations. Different thread profiles require dedicated tooling. Of major importance in threading is the ability of the cutting tool to. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. These are all factors that. The cap couples with the top of the bottle in order to create a water tight. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Think of the cap on your water bottle. Common profiles encountered in cnc threading include metric,. Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining.

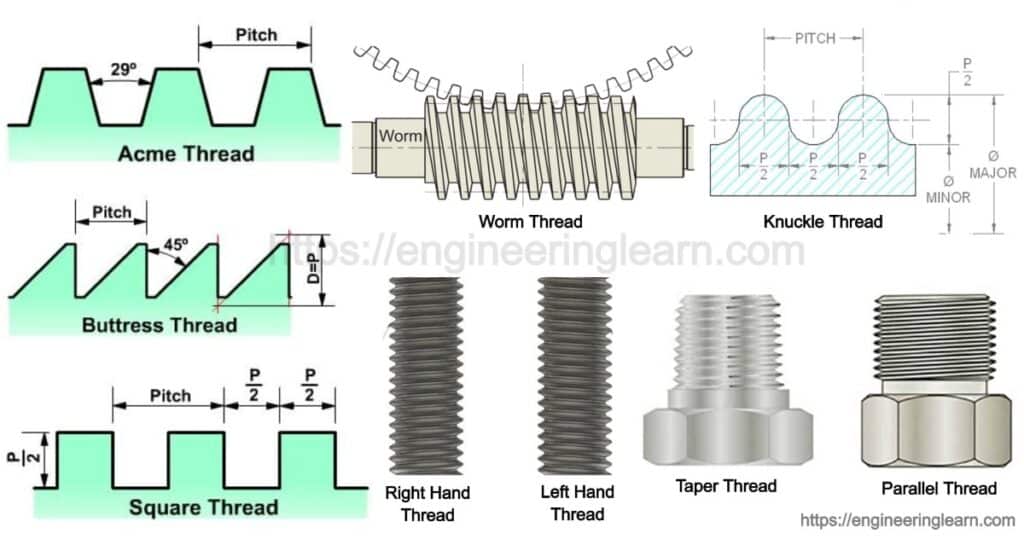

13 Types of Threads Definition, Parts and Thread Identifying Tools

Threading Tool Geometry Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Different thread profiles require dedicated tooling. The cap couples with the top of the bottle in order to create a water tight. Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. Thread mills come in different geometries tailored for specific threading operations. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Think of the cap on your water bottle. Common profiles encountered in cnc threading include metric,. These are all factors that. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. Of major importance in threading is the ability of the cutting tool to.

From www.shapemastertool.com

PCD Cutting Tools & Inserts for Threading Shape Master Tool Threading Tool Geometry Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Think of the cap on your water bottle. Of major importance in threading is the ability of the cutting tool to. These are all factors that. The cap couples with the top of the bottle in order to create a water tight. From. Threading Tool Geometry.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Tool Geometry Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. Common profiles encountered in cnc threading include metric,. Of major importance in threading is the ability of the cutting tool to. Different thread profiles require dedicated tooling. These are all factors that. Think of the cap on your water bottle. From point a to b, the. Threading Tool Geometry.

From www.canadianmetalworking.com

Geometry Adds Volume to Thread Mill Work Threading Tool Geometry Different thread profiles require dedicated tooling. When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. Think of the cap on your water bottle. Of major importance in threading is the ability of the cutting tool to. The cap couples with the top of the bottle in. Threading Tool Geometry.

From www.linquip.com

9 Types of Threading Tools + Table with Characteristics and Usage Linquip Threading Tool Geometry When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. Common profiles encountered in cnc threading include metric,. Thread mills come in different geometries tailored for specific threading operations. Different thread profiles require dedicated tooling. Think of the cap on your water bottle. Of major importance in. Threading Tool Geometry.

From www.gaugestools.com

UNIFIED SCREW THREADS gaugestools Threading Tool Geometry Common profiles encountered in cnc threading include metric,. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Of major importance in threading is the ability of the cutting tool to. The cap couples with the top of the bottle in order to create a water tight. When. Threading Tool Geometry.

From www.scribd.com

METRIC THREAD EXTENDED THREAD SIZE RANGE.pdf Tools Crafts Threading Tool Geometry The cap couples with the top of the bottle in order to create a water tight. Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Different thread profiles require dedicated tooling. Common profiles encountered in cnc threading include. Threading Tool Geometry.

From bestontool.blogspot.com

Tools For Making Threads best tools Threading Tool Geometry Different thread profiles require dedicated tooling. Think of the cap on your water bottle. These are all factors that. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Thread mills come in different geometries tailored for specific threading operations. Common profiles encountered in cnc threading include metric,. Of major importance in threading. Threading Tool Geometry.

From engineeringlearn.com

13 Types of Threads Definition, Parts and Thread Identifying Tools Threading Tool Geometry These are all factors that. Different thread profiles require dedicated tooling. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Think of the cap on your water bottle. When choosing. Threading Tool Geometry.

From www.pinterest.com

Basic Thread Concepts Metal working tools, Metal lathe tools, Screws Threading Tool Geometry Think of the cap on your water bottle. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Of major importance in threading is the ability of the cutting tool to. Common profiles encountered in cnc threading include metric,. These are all factors that. Threading involves many short. Threading Tool Geometry.

From www.rapiddirect.com

The Ultimate Guide to Machining Thread RapidDirect Blog Threading Tool Geometry Thread mills come in different geometries tailored for specific threading operations. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Common profiles encountered in cnc threading include metric,. Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. Thread machining is a precise. Threading Tool Geometry.

From www.scribd.com

UNC UNF BSW BSF Screw Thread Chart PDF Joining Cutting Tools Threading Tool Geometry Different thread profiles require dedicated tooling. Common profiles encountered in cnc threading include metric,. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. Of major importance in threading is the ability of the cutting tool to. When choosing. Threading Tool Geometry.

From www.pinterest.ca

Metric Thread Dimensions Chart ISO and UTS Thread Dimensions (sk).svg Threading Tool Geometry When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Different thread profiles require dedicated tooling. Of major importance in threading is the ability of. Threading Tool Geometry.

From www.sharpeninghandbook.info

Sharpening Handbook Threading Tool Geometry When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. The. Threading Tool Geometry.

From learnmech.com

Nomenclature of Mechanical Threads Diagram Of Threads Threading Tool Geometry Thread mills come in different geometries tailored for specific threading operations. Common profiles encountered in cnc threading include metric,. Of major importance in threading is the ability of the cutting tool to. Think of the cap on your water bottle. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Different thread profiles. Threading Tool Geometry.

From www.youtube.com

Square Thread Or Profile Of Square Screw Thread In Machine Drawing Threading Tool Geometry From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Different thread profiles require dedicated tooling. The cap couples with the top of the bottle in order to create a water tight. Thread mills come in different geometries tailored for specific threading operations. Think of the cap on. Threading Tool Geometry.

From www.youtube.com

CNC Threading insert Nomenclature. INSERT NOMENCLATURE THREADING Threading Tool Geometry Think of the cap on your water bottle. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Of major importance in threading is the ability of the cutting tool to. The cap couples with the top of the bottle in order to create a water tight. Different. Threading Tool Geometry.

From www.gdandtbasics.com

Common Thread Information Diameters, Pitch, and Threads per Inch GD Threading Tool Geometry Different thread profiles require dedicated tooling. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Thread mills come in different geometries tailored for specific threading operations. When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. Threading involves many. Threading Tool Geometry.

From www.canadianmetalworking.com

Geometry Adds Volume to Thread Mill Work Canadian Metalworking Threading Tool Geometry These are all factors that. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Common profiles encountered in cnc threading include metric,. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Of major importance in threading is the ability. Threading Tool Geometry.

From www.youtube.com

How I do single point internal threading YouTube Threading Tool Geometry Different thread profiles require dedicated tooling. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. Think of the cap on your water bottle. The cap couples with the top. Threading Tool Geometry.

From www.youtube.com

Understanding Cutting Tool Geometry YouTube Threading Tool Geometry Thread mills come in different geometries tailored for specific threading operations. Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Different thread profiles require dedicated tooling. The cap couples with the top of the bottle in order to. Threading Tool Geometry.

From www.slideserve.com

PPT ME311 Machine Design PowerPoint Presentation ID468279 Threading Tool Geometry From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Thread mills come in different geometries tailored for specific threading operations. Different thread profiles require dedicated tooling. These are all factors that. Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. Common profiles. Threading Tool Geometry.

From www.youtube.com

HSS V Shape Threading Tool Grinding (B.S.W 55° & Metric 60°) ITI Threading Tool Geometry The cap couples with the top of the bottle in order to create a water tight. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. These are all factors that.. Threading Tool Geometry.

From toolnotes.com

Thread Forms ToolNotes Threading Tool Geometry When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. These are all factors that. Common profiles encountered in cnc threading include metric,. Different thread profiles require dedicated tooling. Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. Of major importance in. Threading Tool Geometry.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Threading Tool Geometry Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. Common profiles encountered in cnc threading include metric,. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Different thread profiles require dedicated tooling. The cap couples with the top of the bottle in order to create a water. Threading Tool Geometry.

From www.apollointernational.in

British Standard Fine Thread BSF Thread Chart Apollo International Threading Tool Geometry The cap couples with the top of the bottle in order to create a water tight. These are all factors that. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z.. Threading Tool Geometry.

From www.slideserve.com

PPT BOLTS PowerPoint Presentation, free download ID2315285 Threading Tool Geometry From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Think of the cap on your water bottle. Common profiles encountered in cnc threading include metric,. The cap couples with the top of the bottle in order to create a water tight. When choosing the most suitable thread. Threading Tool Geometry.

From www.researchgate.net

Schematic diagram of the thread milling geometry model (D = 16 mm Threading Tool Geometry Thread mills come in different geometries tailored for specific threading operations. These are all factors that. The cap couples with the top of the bottle in order to create a water tight. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Threading involves many short cutting sequences and often relatively low cutting. Threading Tool Geometry.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools Threading Tool Geometry When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. These are all factors that. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. The. Threading Tool Geometry.

From www.emastercam.com

Lathe Threading tool parameters Industrial Forum Threading Tool Geometry When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. The cap couples with the top of the bottle in order to create a water tight. Thread mills come in different geometries tailored for specific threading operations. Common profiles encountered in cnc threading include metric,. Thread machining. Threading Tool Geometry.

From www.canadianmetalworking.com

Geometry Adds Volume to Thread Mill Work Canadian Metalworking Threading Tool Geometry Thread mills come in different geometries tailored for specific threading operations. When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. Threading involves many short cutting sequences and often relatively low cutting speeds throughout machining. The cap couples with the top of the bottle in order to. Threading Tool Geometry.

From toolnotes.com

Lathe Operations ToolNotes Threading Tool Geometry Thread mills come in different geometries tailored for specific threading operations. When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Different thread profiles require dedicated tooling. From point a. Threading Tool Geometry.

From woodworkingset.com

Threading Lathe Tool A Beginner's Guide to Perfect Thread Cuts. Threading Tool Geometry Thread mills come in different geometries tailored for specific threading operations. The cap couples with the top of the bottle in order to create a water tight. Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. These are all factors that. Common profiles encountered in cnc threading include metric,. When choosing the. Threading Tool Geometry.

From toolnotes.com

Thread Terminology ToolNotes Threading Tool Geometry Of major importance in threading is the ability of the cutting tool to. Different thread profiles require dedicated tooling. From point a to b, the cutter moves 360 ° in a circular motion while simultaneously moving the pitch in the z. Think of the cap on your water bottle. The cap couples with the top of the bottle in order. Threading Tool Geometry.

From forums.autodesk.com

Better Thread Mill Tool Geometry Autodesk Community Threading Tool Geometry Thread mills come in different geometries tailored for specific threading operations. The cap couples with the top of the bottle in order to create a water tight. When choosing the most suitable thread turning insert for your application, you need to consider the insert type, flank/radial clearance, and insert geometry. Different thread profiles require dedicated tooling. From point a to. Threading Tool Geometry.

From www.youtube.com

THREADING STAINLESS STEEL MODEL ENGINEERING FOR BEGINNERS PART 20 Threading Tool Geometry Thread machining is a precise manufacturing operation used to create helical or spiral grooves on a workpiece. Thread mills come in different geometries tailored for specific threading operations. Think of the cap on your water bottle. Different thread profiles require dedicated tooling. Of major importance in threading is the ability of the cutting tool to. Common profiles encountered in cnc. Threading Tool Geometry.