Pipeline Marker Requirements . Pipe marking standard for ammonia. Key elements of ansi/asme pipe marking standard. Here are our top product recommendations to get you started. (1) mains and transmission lines located offshore, or at. marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. Adjacent to all changes of direction. markers are required at the following locations: Under the asme a13.1 approach to pipe marking, there are five key elements to an. Information to include on pipe marker. what is the osha standard for pipe marking? proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. line markers are not required for the following pipelines: asme a13.1 pipe label requirements & components. Adjacent to all valves and flanges. Pipe marker color code system.

from piedgas.com

markers are required at the following locations: Adjacent to all changes of direction. Pipe marking standard for ammonia. asme a13.1 pipe label requirements & components. marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. Pipe marker color code system. (1) mains and transmission lines located offshore, or at. proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. Information to include on pipe marker. Under the asme a13.1 approach to pipe marking, there are five key elements to an.

How to Recognize the Location of a Pipeline Piedmont Gas Co.

Pipeline Marker Requirements marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. mark pipes every 25 to 50 foot intervals on straight runs. Adjacent to all changes of direction. Information to include on pipe marker. Under the asme a13.1 approach to pipe marking, there are five key elements to an. marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. line markers are not required for the following pipelines: markers are required at the following locations: asme a13.1 pipe label requirements & components. Pipe marker color code system. Key elements of ansi/asme pipe marking standard. proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. Adjacent to all valves and flanges. (1) mains and transmission lines located offshore, or at. Here are our top product recommendations to get you started. what is the osha standard for pipe marking?

From firstresponder.domsafety.com

Transmission pipeline markers Dominion Energy Pipeline Marker Requirements line markers are not required for the following pipelines: Pipe marking standard for ammonia. Key elements of ansi/asme pipe marking standard. Pipe marker color code system. markers are required at the following locations: (1) mains and transmission lines located offshore, or at. proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. Information. Pipeline Marker Requirements.

From www.youtube.com

Safety Minute Monday Pipeline Markers YouTube Pipeline Marker Requirements (1) mains and transmission lines located offshore, or at. Adjacent to all valves and flanges. line markers are not required for the following pipelines: proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. Key elements of ansi/asme pipe marking standard. mark pipes every 25 to 50 foot intervals on straight runs. Pipe. Pipeline Marker Requirements.

From www.sciencephoto.com

Underground pipeline markers, Texas, USA Stock Image C038/1816 Pipeline Marker Requirements Key elements of ansi/asme pipe marking standard. mark pipes every 25 to 50 foot intervals on straight runs. marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. Information to include on pipe marker. Pipe marker color code system. Adjacent to all changes of direction. Adjacent to all valves and flanges.. Pipeline Marker Requirements.

From elmetal.pl

Pipe marking. Pipe labeling Elmetal Pipeline Marker Requirements Information to include on pipe marker. mark pipes every 25 to 50 foot intervals on straight runs. asme a13.1 pipe label requirements & components. markers are required at the following locations: what is the osha standard for pipe marking? Adjacent to all changes of direction. Here are our top product recommendations to get you started. Pipe. Pipeline Marker Requirements.

From www.tdwilliamson.com

T.D. Williamson Three Steps of Pipeline Identification Pipeline Marker Requirements Adjacent to all changes of direction. Pipe marking standard for ammonia. (1) mains and transmission lines located offshore, or at. asme a13.1 pipe label requirements & components. what is the osha standard for pipe marking? Pipe marker color code system. Adjacent to all valves and flanges. Under the asme a13.1 approach to pipe marking, there are five key. Pipeline Marker Requirements.

From www.kansasgasservice.com

Kansas Gas Service RightofWay Pipeline Marker Requirements markers are required at the following locations: Key elements of ansi/asme pipe marking standard. (1) mains and transmission lines located offshore, or at. Adjacent to all valves and flanges. Here are our top product recommendations to get you started. Pipe marking standard for ammonia. mark pipes every 25 to 50 foot intervals on straight runs. what is. Pipeline Marker Requirements.

From www.kristechwire.com

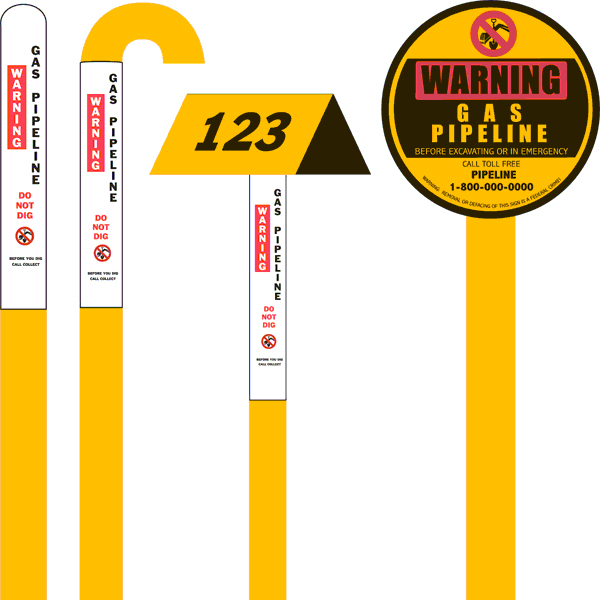

Pipeline Markers, Utility Markers, Cathodic Protection Test Stations Pipeline Marker Requirements Under the asme a13.1 approach to pipe marking, there are five key elements to an. proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. Pipe marking standard for ammonia. Information to include on pipe marker. Adjacent to all changes of direction. Adjacent to all valves and flanges. (1) mains and transmission lines located offshore,. Pipeline Marker Requirements.

From trialame.com

MEP Identification Labels, Pipe Marking Labels UAE Pipeline Marker Requirements Adjacent to all changes of direction. what is the osha standard for pipe marking? markers are required at the following locations: proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. Pipe marking standard for ammonia. (1) mains and transmission lines located offshore, or at. Adjacent to all valves and flanges. Here are. Pipeline Marker Requirements.

From www.sgn.co.uk

Where are our pipelines? SGN Your gas. Our network. Pipeline Marker Requirements Adjacent to all changes of direction. line markers are not required for the following pipelines: Information to include on pipe marker. Adjacent to all valves and flanges. Pipe marker color code system. (1) mains and transmission lines located offshore, or at. markers are required at the following locations: proper pipe marking can lead to better safety incident. Pipeline Marker Requirements.

From www.montana-dakota.com

mdu pipeline marker MontanaDakota Utilities Company Pipeline Marker Requirements proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. Adjacent to all changes of direction. Adjacent to all valves and flanges. (1) mains and transmission lines located offshore, or at. what is the osha standard for pipe marking? Key elements of ansi/asme pipe marking standard. line markers are not required for the. Pipeline Marker Requirements.

From www.oklahomanaturalgas.com

Oklahoma Natural Gas RightofWay Pipeline Marker Requirements what is the osha standard for pipe marking? marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. line markers are not required for the following pipelines: markers are required at the following locations: Information to include on pipe marker. Adjacent to all changes of direction. mark pipes. Pipeline Marker Requirements.

From firstresponder.domsafety.com

Transmission pipeline markers Dominion Energy Pipeline Marker Requirements what is the osha standard for pipe marking? asme a13.1 pipe label requirements & components. Here are our top product recommendations to get you started. Information to include on pipe marker. Adjacent to all valves and flanges. line markers are not required for the following pipelines: Pipe marker color code system. (1) mains and transmission lines located. Pipeline Marker Requirements.

From www.securitysafetyproducts.co.uk

Pipeline Markers Safety Poster Safety Signs Security Safety Products Pipeline Marker Requirements what is the osha standard for pipe marking? line markers are not required for the following pipelines: Information to include on pipe marker. Pipe marker color code system. Adjacent to all changes of direction. Pipe marking standard for ammonia. Under the asme a13.1 approach to pipe marking, there are five key elements to an. mark pipes every. Pipeline Marker Requirements.

From dxopvamlg.blob.core.windows.net

Flexible Pipeline Markers at Mitchell Colon blog Pipeline Marker Requirements line markers are not required for the following pipelines: Pipe marker color code system. proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. what is the osha standard for pipe marking? Adjacent to all valves and flanges. (1) mains and transmission lines located offshore, or at. Here are our top product recommendations. Pipeline Marker Requirements.

From www.unigas-tx.com

Pipelines in your community Pipeline Marker Requirements (1) mains and transmission lines located offshore, or at. Information to include on pipe marker. Key elements of ansi/asme pipe marking standard. Under the asme a13.1 approach to pipe marking, there are five key elements to an. Adjacent to all valves and flanges. mark pipes every 25 to 50 foot intervals on straight runs. Pipe marking standard for ammonia.. Pipeline Marker Requirements.

From www.scribd.com

Specifications for Installing Pipeline Markers Along an Underground Pipeline Marker Requirements Pipe marking standard for ammonia. Adjacent to all valves and flanges. proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. line markers are not required for the following pipelines: Information to include on pipe marker. Here are our top product recommendations to get you started. Adjacent to all changes of direction. asme. Pipeline Marker Requirements.

From piedgas.com

How to Recognize the Location of a Pipeline Piedmont Gas Co. Pipeline Marker Requirements mark pipes every 25 to 50 foot intervals on straight runs. proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. Adjacent to all changes of direction. what is the osha standard for pipe marking? Key elements of ansi/asme pipe marking standard. Information to include on pipe marker. Adjacent to all valves and. Pipeline Marker Requirements.

From megadepot.com

Pipe Marking Guide Mega Depot Pipeline Marker Requirements line markers are not required for the following pipelines: mark pipes every 25 to 50 foot intervals on straight runs. Key elements of ansi/asme pipe marking standard. Under the asme a13.1 approach to pipe marking, there are five key elements to an. Information to include on pipe marker. asme a13.1 pipe label requirements & components. (1) mains. Pipeline Marker Requirements.

From www.seawardsafety.com

Pipe Marking Seaward Safety Pipeline Marker Requirements line markers are not required for the following pipelines: Here are our top product recommendations to get you started. Pipe marker color code system. proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. markers are required at the following locations: what is the osha standard for pipe marking? Adjacent to all. Pipeline Marker Requirements.

From medium.com

Pipe Marking bengeck48 Medium Pipeline Marker Requirements markers are required at the following locations: Information to include on pipe marker. Here are our top product recommendations to get you started. what is the osha standard for pipe marking? Key elements of ansi/asme pipe marking standard. marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. mark. Pipeline Marker Requirements.

From trialame.com

MEP Identification Labels, Pipe Marking Labels UAE Pipeline Marker Requirements what is the osha standard for pipe marking? Adjacent to all valves and flanges. Pipe marking standard for ammonia. asme a13.1 pipe label requirements & components. marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. Here are our top product recommendations to get you started. mark pipes every. Pipeline Marker Requirements.

From dxonhpfqd.blob.core.windows.net

Gas Pipeline Marking System at Dora Dean blog Pipeline Marker Requirements Pipe marker color code system. Under the asme a13.1 approach to pipe marking, there are five key elements to an. line markers are not required for the following pipelines: Pipe marking standard for ammonia. markers are required at the following locations: proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. marking. Pipeline Marker Requirements.

From slideplayer.com

Locating Gas Structures ppt download Pipeline Marker Requirements markers are required at the following locations: what is the osha standard for pipe marking? Pipe marking standard for ammonia. marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. Under the asme a13.1 approach to pipe marking, there are five key elements to an. mark pipes every 25. Pipeline Marker Requirements.

From www.mplx.com

Gathering and Processing Pipeline Safety Pipeline Marker Requirements marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. Here are our top product recommendations to get you started. what is the osha standard for pipe marking? mark pipes every 25 to 50 foot intervals on straight runs. proper pipe marking can lead to better safety incident management,. Pipeline Marker Requirements.

From parisnaturalgas.com

Pipeline Markers Paris Natural Gas Pipeline Marker Requirements Pipe marking standard for ammonia. (1) mains and transmission lines located offshore, or at. Here are our top product recommendations to get you started. asme a13.1 pipe label requirements & components. markers are required at the following locations: Key elements of ansi/asme pipe marking standard. what is the osha standard for pipe marking? Adjacent to all changes. Pipeline Marker Requirements.

From www.emedco.com

Pipe Labeling & Marking Guidelines Emedco Pipeline Marker Requirements markers are required at the following locations: proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. what is the osha standard for pipe marking? Pipe marking standard for ammonia. Here are our top product recommendations to get you started. line markers are not required for the following pipelines: Adjacent to all. Pipeline Marker Requirements.

From signsmart.com.au

Shop Pipeline Markers at Signsmart Workplace Signs Australia Pipeline Marker Requirements Adjacent to all changes of direction. Adjacent to all valves and flanges. what is the osha standard for pipe marking? (1) mains and transmission lines located offshore, or at. line markers are not required for the following pipelines: Key elements of ansi/asme pipe marking standard. asme a13.1 pipe label requirements & components. proper pipe marking can. Pipeline Marker Requirements.

From nelsonjameson.com

Pipe Marker Standards & Material NelsonJameson Learning Center Pipeline Marker Requirements line markers are not required for the following pipelines: markers are required at the following locations: Under the asme a13.1 approach to pipe marking, there are five key elements to an. marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. Here are our top product recommendations to get you. Pipeline Marker Requirements.

From firstenergy.e-smartresponders.com

Pipeline Markers FirstEnergy First Responder Utility Training Pipeline Marker Requirements Pipe marker color code system. Key elements of ansi/asme pipe marking standard. Here are our top product recommendations to get you started. Adjacent to all valves and flanges. mark pipes every 25 to 50 foot intervals on straight runs. Information to include on pipe marker. what is the osha standard for pipe marking? Pipe marking standard for ammonia.. Pipeline Marker Requirements.

From www.pinterest.com

Pin on Pipe markings save lives Do you know your standards and color Pipeline Marker Requirements Pipe marking standard for ammonia. what is the osha standard for pipe marking? asme a13.1 pipe label requirements & components. Under the asme a13.1 approach to pipe marking, there are five key elements to an. Key elements of ansi/asme pipe marking standard. Pipe marker color code system. marking promotes greater safety, lessens the chances of error and. Pipeline Marker Requirements.

From signsmart.com.au

Shop Pipeline Markers at Signsmart Workplace Signs Australia Pipeline Marker Requirements marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. mark pipes every 25 to 50 foot intervals on straight runs. Under the asme a13.1 approach to pipe marking, there are five key elements to an. Pipe marker color code system. Information to include on pipe marker. asme a13.1 pipe. Pipeline Marker Requirements.

From massachusetts.libertyutilities.com

Natural Gas Pipeline Safety Residential Massachusetts Gas Liberty Pipeline Marker Requirements Under the asme a13.1 approach to pipe marking, there are five key elements to an. asme a13.1 pipe label requirements & components. Pipe marking standard for ammonia. mark pipes every 25 to 50 foot intervals on straight runs. markers are required at the following locations: Key elements of ansi/asme pipe marking standard. Pipe marker color code system.. Pipeline Marker Requirements.

From joyce-road.blogspot.com

The Joyce Road Neighborhood Pipeline Construction Pipeline Marker Requirements Pipe marking standard for ammonia. what is the osha standard for pipe marking? line markers are not required for the following pipelines: Here are our top product recommendations to get you started. markers are required at the following locations: proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. Information to include. Pipeline Marker Requirements.

From www.seton.ca

Pipe Labeling & Marking Guidelines Pipeline Marker Requirements Adjacent to all valves and flanges. mark pipes every 25 to 50 foot intervals on straight runs. Adjacent to all changes of direction. asme a13.1 pipe label requirements & components. Under the asme a13.1 approach to pipe marking, there are five key elements to an. Pipe marker color code system. markers are required at the following locations:. Pipeline Marker Requirements.

From t-iss.com

Pipe Marking / Regulations / TISS Safety Suppliers Pipeline Marker Requirements marking promotes greater safety, lessens the chances of error and reduces hazards involved in the handling of. Pipe marker color code system. markers are required at the following locations: Adjacent to all valves and flanges. proper pipe marking can lead to better safety incident management, streamlined routine maintenance, and. asme a13.1 pipe label requirements & components.. Pipeline Marker Requirements.