Crankshaft And Cam Sensor . Testing a crankshaft position sensor is simple. A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position sensor used to detect the position of the crankshaft and piston that is located near the crankshaft of engine. Camshaft and crankshaft sensors keep ignition timing, engine speed and cylinder firing times synchronized, allowing the engine to run smoothly. If the sensor can detect a value of 200 to 1000 ohms, then your sensor is. These two types of sensor help the electrical. This article is a primer that will help you to learn and understand the essentials of testing the crankshaft position sensor (camshaft position sensors too). That means they serve unrelated purposes in the engine. Connect the two multimeter leads to the two metal prongs on the sensor. The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. Difference between camshaft and crankshaft sensor. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and camshaft position (cmp) sensor waveforms and features. Understanding the key differences between a crankshaft sensor and a camshaft sensor is crucial for proper engine diagnosis and maintenance.

from www.picoauto.com

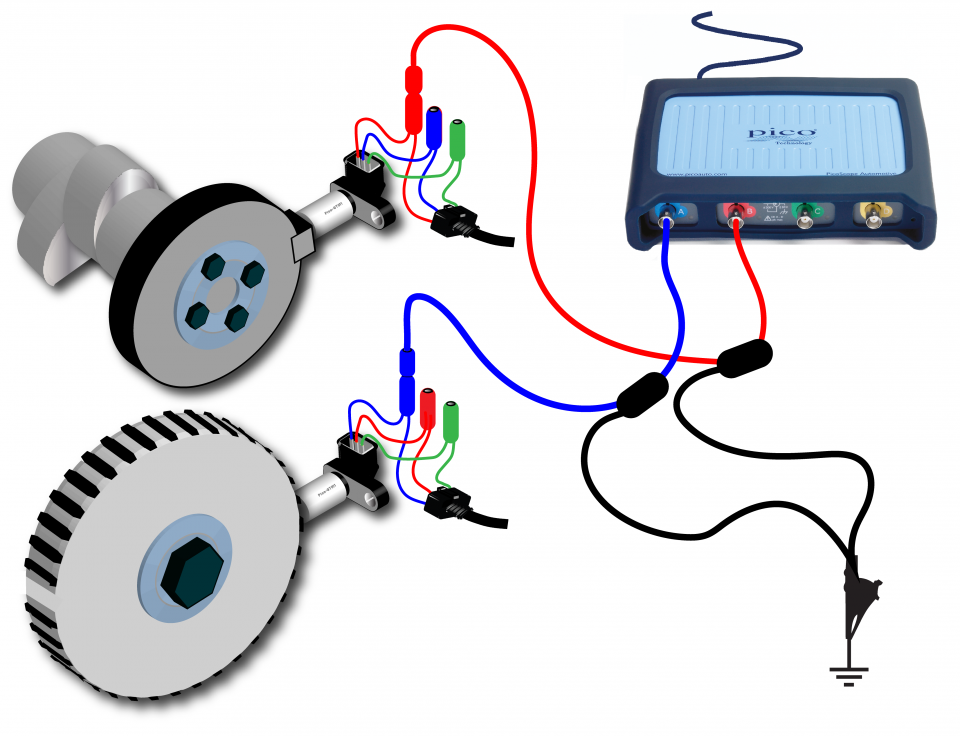

Testing a crankshaft position sensor is simple. This article is a primer that will help you to learn and understand the essentials of testing the crankshaft position sensor (camshaft position sensors too). The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and camshaft position (cmp) sensor waveforms and features. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. Understanding the key differences between a crankshaft sensor and a camshaft sensor is crucial for proper engine diagnosis and maintenance. Difference between camshaft and crankshaft sensor. A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position sensor used to detect the position of the crankshaft and piston that is located near the crankshaft of engine. Connect the two multimeter leads to the two metal prongs on the sensor. The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. These two types of sensor help the electrical.

Crankshaft and camshaft position sensor comparison

Crankshaft And Cam Sensor That means they serve unrelated purposes in the engine. The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. This article is a primer that will help you to learn and understand the essentials of testing the crankshaft position sensor (camshaft position sensors too). Understanding the key differences between a crankshaft sensor and a camshaft sensor is crucial for proper engine diagnosis and maintenance. Testing a crankshaft position sensor is simple. A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position sensor used to detect the position of the crankshaft and piston that is located near the crankshaft of engine. These two types of sensor help the electrical. Difference between camshaft and crankshaft sensor. That means they serve unrelated purposes in the engine. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and camshaft position (cmp) sensor waveforms and features. If the sensor can detect a value of 200 to 1000 ohms, then your sensor is. Connect the two multimeter leads to the two metal prongs on the sensor. Camshaft and crankshaft sensors keep ignition timing, engine speed and cylinder firing times synchronized, allowing the engine to run smoothly.

From www.youtube.com

Crankshaft & camshaft position sensor explained YouTube Crankshaft And Cam Sensor A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. Difference between camshaft and crankshaft sensor. If the sensor can detect a value of 200 to 1000 ohms, then your sensor is. Connect the two multimeter leads to the two metal prongs on the sensor. A key difference is that the camshaft position. Crankshaft And Cam Sensor.

From pmfmag.co.uk

Camshaft and crankshaft sensors Professional Motor Factor Crankshaft And Cam Sensor A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position sensor used to detect the position of the crankshaft and piston that is located near the crankshaft of engine. That means they serve unrelated purposes in the engine. Understanding the key differences between a crankshaft. Crankshaft And Cam Sensor.

From www.aliexpress.com

PC166 For Dodge Chrysler Plymouth Crankshaft Crank Cam Position Sensor Crankshaft And Cam Sensor Difference between camshaft and crankshaft sensor. These two types of sensor help the electrical. The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position. Crankshaft And Cam Sensor.

From www.familyhandyman.com

Camshaft vs. Crankshaft What's the Difference? Crankshaft And Cam Sensor Understanding the key differences between a crankshaft sensor and a camshaft sensor is crucial for proper engine diagnosis and maintenance. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. Testing a. Crankshaft And Cam Sensor.

From www.garagelube.com

Camshaft and Crankshaft Sensor Signal Output Test Crankshaft And Cam Sensor Camshaft and crankshaft sensors keep ignition timing, engine speed and cylinder firing times synchronized, allowing the engine to run smoothly. These two types of sensor help the electrical. That means they serve unrelated purposes in the engine. Testing a crankshaft position sensor is simple. The purpose of this test is to directly compare the relative positions of the crankshaft position. Crankshaft And Cam Sensor.

From www.picoauto.com

Crankshaft and camshaft position sensor comparison Crankshaft And Cam Sensor The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. That means they serve unrelated purposes in the engine. If the sensor can detect a value of 200 to 1000 ohms, then your sensor is. A key difference is that the camshaft position sensor finds the position of the. Crankshaft And Cam Sensor.

From www.aliexpress.com

New 2pcs Crank Crankshaft & Cam Camshaft Position Sensor for Nissan Crankshaft And Cam Sensor A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. Testing a crankshaft position sensor is simple. The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. If the sensor can detect a value of 200 to 1000 ohms, then your sensor. Crankshaft And Cam Sensor.

From www.aliexpress.com

Cam Crank Camshaft Crankshaft Position Sensor For Ford 7.3 L 7.3L E 350 Crankshaft And Cam Sensor The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and camshaft position (cmp) sensor waveforms and features. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. Testing a crankshaft position sensor is simple. A key difference is that the camshaft position sensor finds the. Crankshaft And Cam Sensor.

From www.counterman.com

Camshaft and Crankshaft Sensors Crankshaft And Cam Sensor Camshaft and crankshaft sensors keep ignition timing, engine speed and cylinder firing times synchronized, allowing the engine to run smoothly. That means they serve unrelated purposes in the engine. The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. This article is a primer that will help you to. Crankshaft And Cam Sensor.

From www.ebay.com

New 237316N21A Crank Crankshaft & Cam Camshaft Position Sensor For Crankshaft And Cam Sensor A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position sensor used to detect the position of the crankshaft and piston that is located near the crankshaft of engine. Difference between camshaft and crankshaft sensor. If the sensor can detect a value of 200 to. Crankshaft And Cam Sensor.

From shop.advanceautoparts.com

How to Replace the Crank and Camshaft Position Sensors Crankshaft And Cam Sensor Connect the two multimeter leads to the two metal prongs on the sensor. That means they serve unrelated purposes in the engine. Understanding the key differences between a crankshaft sensor and a camshaft sensor is crucial for proper engine diagnosis and maintenance. Testing a crankshaft position sensor is simple. A key difference is that the camshaft position sensor finds the. Crankshaft And Cam Sensor.

From www.aliexpress.com

3pcs/Set Car Intake Exhaust Cam Camshaft Crankshaft Position Sensor Crankshaft And Cam Sensor Difference between camshaft and crankshaft sensor. That means they serve unrelated purposes in the engine. These two types of sensor help the electrical. This article is a primer that will help you to learn and understand the essentials of testing the crankshaft position sensor (camshaft position sensors too). Camshaft and crankshaft sensors keep ignition timing, engine speed and cylinder firing. Crankshaft And Cam Sensor.

From goss.com.au

Goss Cam & Crank Sensors Crankshaft And Cam Sensor Testing a crankshaft position sensor is simple. This article is a primer that will help you to learn and understand the essentials of testing the crankshaft position sensor (camshaft position sensors too). That means they serve unrelated purposes in the engine. Camshaft and crankshaft sensors keep ignition timing, engine speed and cylinder firing times synchronized, allowing the engine to run. Crankshaft And Cam Sensor.

From www.aliexpress.com

Crankshaft Camshaft Crank Cam Position Sensor For Dodge Ram 2500 3500 Crankshaft And Cam Sensor The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position sensor used to detect the position of the crankshaft and piston that is located. Crankshaft And Cam Sensor.

From www.ebay.com

New 237316N21A Crank Crankshaft & Cam Camshaft Position Sensor For Crankshaft And Cam Sensor That means they serve unrelated purposes in the engine. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. Difference between camshaft and crankshaft sensor. The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. Camshaft and crankshaft sensors keep ignition timing,. Crankshaft And Cam Sensor.

From carfromjapan.com

How To Test Camshaft And Crankshaft Position Sensors Crankshaft And Cam Sensor These two types of sensor help the electrical. If the sensor can detect a value of 200 to 1000 ohms, then your sensor is. A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position sensor used to detect the position of the crankshaft and piston. Crankshaft And Cam Sensor.

From www.denso-am.eu

How camshaft & crankshaft sensors work DENSO Crankshaft And Cam Sensor This article is a primer that will help you to learn and understand the essentials of testing the crankshaft position sensor (camshaft position sensors too). If the sensor can detect a value of 200 to 1000 ohms, then your sensor is. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. The cam. Crankshaft And Cam Sensor.

From www.ebay.com

New 237316N21A Crank Crankshaft & Cam Camshaft Position Sensor For Crankshaft And Cam Sensor Understanding the key differences between a crankshaft sensor and a camshaft sensor is crucial for proper engine diagnosis and maintenance. Camshaft and crankshaft sensors keep ignition timing, engine speed and cylinder firing times synchronized, allowing the engine to run smoothly. This article is a primer that will help you to learn and understand the essentials of testing the crankshaft position. Crankshaft And Cam Sensor.

From eltaeurope.com

Crankshaft Sensors Camshaft Sensors Position Sensors ELTA Automotive Crankshaft And Cam Sensor Connect the two multimeter leads to the two metal prongs on the sensor. The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. Camshaft and crankshaft sensors keep ignition timing, engine speed and cylinder firing times synchronized, allowing the engine to run smoothly. These two types of sensor help. Crankshaft And Cam Sensor.

From www.aliexpress.com

Original Crankshaft Camshaft Crank Cam Position Sensor 4921686 For Crankshaft And Cam Sensor A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position sensor used to detect the position of the crankshaft and piston that is located near the crankshaft of engine. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms. Crankshaft And Cam Sensor.

From www.garagelube.com

Camshaft and Crankshaft Sensor Signal Output Test Crankshaft And Cam Sensor The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and camshaft position (cmp) sensor waveforms and features. A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position sensor used to detect the position of the crankshaft and. Crankshaft And Cam Sensor.

From www.aliexpress.com

Crankshaft Camshaft Crank Cam Position Sensor For Mitsubishi Challenger Crankshaft And Cam Sensor That means they serve unrelated purposes in the engine. A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position sensor used to detect the position of the crankshaft and piston that is located near the crankshaft of engine. These two types of sensor help the. Crankshaft And Cam Sensor.

From www.youtube.com

How to Test Crankshaft and Camshaft Position Sensors in car and truck Crankshaft And Cam Sensor This article is a primer that will help you to learn and understand the essentials of testing the crankshaft position sensor (camshaft position sensors too). A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position sensor used to detect the position of the crankshaft and. Crankshaft And Cam Sensor.

From www.denso-am.eu

How camshaft & crankshaft sensors work DENSO Crankshaft And Cam Sensor Difference between camshaft and crankshaft sensor. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and camshaft position (cmp) sensor waveforms and features. That means they serve unrelated purposes in the engine. Testing a crankshaft position sensor is simple. Camshaft and crankshaft sensors keep ignition timing, engine speed and cylinder firing times. Crankshaft And Cam Sensor.

From www.aliexpress.com

Engine Crankshaft Camshaft Crank Cam Position Sensor For CUMMINS Crankshaft And Cam Sensor The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and camshaft position (cmp) sensor waveforms and features. Connect the two multimeter leads to the two metal prongs on the sensor. Understanding. Crankshaft And Cam Sensor.

From www.diyautotune.com

Adding a camshaft and crankshaft position sensor to an older engine Crankshaft And Cam Sensor A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and camshaft position (cmp) sensor waveforms and features. If the sensor can detect a value of 200 to 1000 ohms, then your sensor is. This article. Crankshaft And Cam Sensor.

From www.youtube.com

Camshaft and Crankshaft Position Sensor Waveform Analysis YouTube Crankshaft And Cam Sensor A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position sensor used to detect the position of the crankshaft and piston that is located near the crankshaft of engine. The purpose of this test is to directly compare the relative positions of the crankshaft position. Crankshaft And Cam Sensor.

From www.ebay.com

New 237316N21A Crank Crankshaft & Cam Camshaft Position Sensor For Crankshaft And Cam Sensor This article is a primer that will help you to learn and understand the essentials of testing the crankshaft position sensor (camshaft position sensors too). Difference between camshaft and crankshaft sensor. Camshaft and crankshaft sensors keep ignition timing, engine speed and cylinder firing times synchronized, allowing the engine to run smoothly. Understanding the key differences between a crankshaft sensor and. Crankshaft And Cam Sensor.

From autopartsu.com

Camshaft and Crankshaft Sensor Locations and Functions Auto Parts Crankshaft And Cam Sensor A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. These two types of sensor help the electrical. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and camshaft position (cmp) sensor waveforms and features. If the sensor can detect a value of 200 to. Crankshaft And Cam Sensor.

From www.samarins.com

Crankshaft position sensor how it works, symptoms, problems, testing Crankshaft And Cam Sensor The cam sensor monitors the camshaft position and rotation, while the crank sensor monitors the crankshaft angle and speed of spin. A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. This article is a primer that will help you to learn and understand the essentials of testing the crankshaft position sensor (camshaft. Crankshaft And Cam Sensor.

From voltautoelectrics.com

CAM & CRANKSHAFT SENSORS VOLT Auto Electrics Crankshaft And Cam Sensor If the sensor can detect a value of 200 to 1000 ohms, then your sensor is. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and camshaft position (cmp) sensor waveforms and features. This article is a primer that will help you to learn and understand the essentials of testing the crankshaft. Crankshaft And Cam Sensor.

From aftermarket.hitachiastemo.com

Automotive products Cam&Crank Shaft Sensors Hitachi Astemo Americas Crankshaft And Cam Sensor These two types of sensor help the electrical. Testing a crankshaft position sensor is simple. Understanding the key differences between a crankshaft sensor and a camshaft sensor is crucial for proper engine diagnosis and maintenance. A key difference is that the camshaft position sensor finds the position of the camshaft and hence located near the camshaft, while the crankshaft position. Crankshaft And Cam Sensor.

From www.ebay.com

New 237316N21A Crank Crankshaft & Cam Camshaft Position Sensor For Crankshaft And Cam Sensor The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and camshaft position (cmp) sensor waveforms and features. This article is a primer that will help you to learn and understand the essentials of testing the crankshaft position sensor (camshaft position sensors too). Camshaft and crankshaft sensors keep ignition timing, engine speed and. Crankshaft And Cam Sensor.

From eltaeurope.com

Crankshaft Sensors Camshaft Sensors Position Sensors ELTA Automotive Crankshaft And Cam Sensor Camshaft and crankshaft sensors keep ignition timing, engine speed and cylinder firing times synchronized, allowing the engine to run smoothly. Understanding the key differences between a crankshaft sensor and a camshaft sensor is crucial for proper engine diagnosis and maintenance. Difference between camshaft and crankshaft sensor. That means they serve unrelated purposes in the engine. Connect the two multimeter leads. Crankshaft And Cam Sensor.

From www.garageandmot.com

camshaft & crankshaft sensors The Garage and MOT Magazine Crankshaft And Cam Sensor A crankshaft position sensor test involves getting a multimeter and setting it to the 20,000 ohms setting. Difference between camshaft and crankshaft sensor. The purpose of this test is to directly compare the relative positions of the crankshaft position (ckp) and camshaft position (cmp) sensor waveforms and features. Testing a crankshaft position sensor is simple. Camshaft and crankshaft sensors keep. Crankshaft And Cam Sensor.