Ignition Timing Advance Cylinder . Initial timing, mechanical advance, and vacuum advance. Together, they form the overall spark curve the engine uses over its entire rpm. We’ll look at three critical ignition timing areas: The way we do it is to set the timing at 30 degrees total advanced on the no. 1 cylinder, with the engine at a predetermined rpm. The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). Spark plugs need to fire at the right time, which can be achieved by advancing or. Find all the details inside circle track magazine. This is when the piston. Ignition timing is measured in degrees of a crankshaft rotation before top dead center (btdc). The best way to set ignition timing on a load type dynamometer is to slowly advance the timing until peak torque output is reached. The idea is to light the charge in the cylinder with enough lead time (advance) to create maximum cylinder pressure at the ideal point. A tech article on tuning your ignition timing for each cylinder to improve power output of your engine.

from www.slideserve.com

Find all the details inside circle track magazine. A tech article on tuning your ignition timing for each cylinder to improve power output of your engine. Together, they form the overall spark curve the engine uses over its entire rpm. Ignition timing is measured in degrees of a crankshaft rotation before top dead center (btdc). The way we do it is to set the timing at 30 degrees total advanced on the no. Initial timing, mechanical advance, and vacuum advance. 1 cylinder, with the engine at a predetermined rpm. Spark plugs need to fire at the right time, which can be achieved by advancing or. This is when the piston. The idea is to light the charge in the cylinder with enough lead time (advance) to create maximum cylinder pressure at the ideal point.

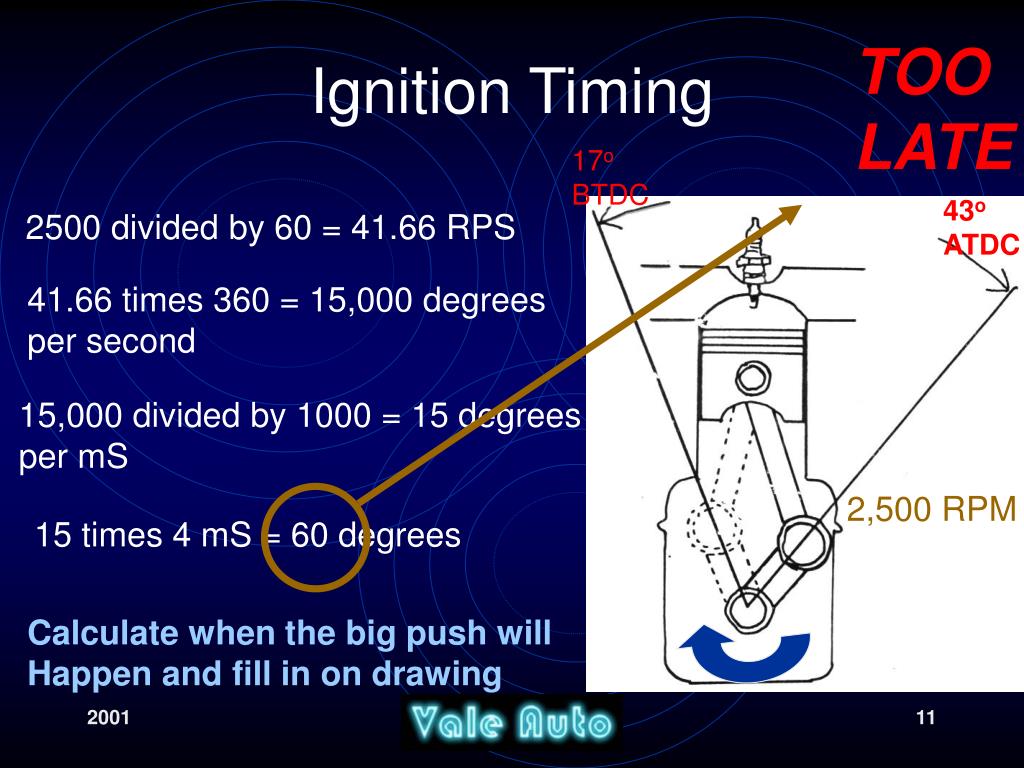

PPT IGNITION TIMING PowerPoint Presentation, free download ID975809

Ignition Timing Advance Cylinder This is when the piston. Together, they form the overall spark curve the engine uses over its entire rpm. The best way to set ignition timing on a load type dynamometer is to slowly advance the timing until peak torque output is reached. The idea is to light the charge in the cylinder with enough lead time (advance) to create maximum cylinder pressure at the ideal point. The way we do it is to set the timing at 30 degrees total advanced on the no. Find all the details inside circle track magazine. Initial timing, mechanical advance, and vacuum advance. 1 cylinder, with the engine at a predetermined rpm. Ignition timing is measured in degrees of a crankshaft rotation before top dead center (btdc). The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). This is when the piston. Spark plugs need to fire at the right time, which can be achieved by advancing or. We’ll look at three critical ignition timing areas: A tech article on tuning your ignition timing for each cylinder to improve power output of your engine.

From dxomwoeqn.blob.core.windows.net

Ignition Advance Timing at Anita Brooks blog Ignition Timing Advance Cylinder The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). 1 cylinder, with the engine at a predetermined rpm. A tech article on tuning your ignition timing for each cylinder to improve power output of your engine. Ignition timing is measured in degrees of. Ignition Timing Advance Cylinder.

From www.heritagepartscentre.com

Understanding Aircooled VW Ignition Timing Ignition Timing Advance Cylinder This is when the piston. The idea is to light the charge in the cylinder with enough lead time (advance) to create maximum cylinder pressure at the ideal point. Find all the details inside circle track magazine. Spark plugs need to fire at the right time, which can be achieved by advancing or. 1 cylinder, with the engine at a. Ignition Timing Advance Cylinder.

From klahrtnfa.blob.core.windows.net

Ignition Timing For Distributor at Andrew Powers blog Ignition Timing Advance Cylinder Initial timing, mechanical advance, and vacuum advance. A tech article on tuning your ignition timing for each cylinder to improve power output of your engine. The way we do it is to set the timing at 30 degrees total advanced on the no. The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly. Ignition Timing Advance Cylinder.

From en.wikipedia.org

Ignition timing Wikipedia Ignition Timing Advance Cylinder This is when the piston. Ignition timing is measured in degrees of a crankshaft rotation before top dead center (btdc). We’ll look at three critical ignition timing areas: The best way to set ignition timing on a load type dynamometer is to slowly advance the timing until peak torque output is reached. 1 cylinder, with the engine at a predetermined. Ignition Timing Advance Cylinder.

From www.wdbsa.nl

Ignition timing Ignition Timing Advance Cylinder Spark plugs need to fire at the right time, which can be achieved by advancing or. Ignition timing is measured in degrees of a crankshaft rotation before top dead center (btdc). The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). We’ll look at. Ignition Timing Advance Cylinder.

From www.2040-parts.com

HotSpark electronic ignition conversion kit for 4cylinder Ford/Mercury Motorcraft distributors Ignition Timing Advance Cylinder Spark plugs need to fire at the right time, which can be achieved by advancing or. The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). A tech article on tuning your ignition timing for each cylinder to improve power output of your engine.. Ignition Timing Advance Cylinder.

From www.partsplaceinc.com

VW Mechanical Advance Ignition Distributor Free Tech Help Ignition Timing Advance Cylinder Ignition timing is measured in degrees of a crankshaft rotation before top dead center (btdc). Together, they form the overall spark curve the engine uses over its entire rpm. We’ll look at three critical ignition timing areas: Spark plugs need to fire at the right time, which can be achieved by advancing or. The ideal ignition timing occurs (at any. Ignition Timing Advance Cylinder.

From klahrtnfa.blob.core.windows.net

Ignition Timing For Distributor at Andrew Powers blog Ignition Timing Advance Cylinder Spark plugs need to fire at the right time, which can be achieved by advancing or. Ignition timing is measured in degrees of a crankshaft rotation before top dead center (btdc). The idea is to light the charge in the cylinder with enough lead time (advance) to create maximum cylinder pressure at the ideal point. The best way to set. Ignition Timing Advance Cylinder.

From www.motortrend.com

Cylinder & Ignition Timing Tuning Timing Advance Circle Track Ignition Timing Advance Cylinder This is when the piston. 1 cylinder, with the engine at a predetermined rpm. We’ll look at three critical ignition timing areas: Together, they form the overall spark curve the engine uses over its entire rpm. Find all the details inside circle track magazine. Initial timing, mechanical advance, and vacuum advance. Spark plugs need to fire at the right time,. Ignition Timing Advance Cylinder.

From classicautoadvisors.com

Understanding Ignition Timing Advance Classic Auto Advisors Ignition Timing Advance Cylinder A tech article on tuning your ignition timing for each cylinder to improve power output of your engine. This is when the piston. The idea is to light the charge in the cylinder with enough lead time (advance) to create maximum cylinder pressure at the ideal point. Spark plugs need to fire at the right time, which can be achieved. Ignition Timing Advance Cylinder.

From www.autozone.com

Repair Guides Ignition Timing Timing Ignition Timing Advance Cylinder The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). Spark plugs need to fire at the right time, which can be achieved by advancing or. The best way to set ignition timing on a load type dynamometer is to slowly advance the timing. Ignition Timing Advance Cylinder.

From classicautoadvisors.com

Proper Engine Ignition Timing is Important Classic Auto Advisors Ignition Timing Advance Cylinder Initial timing, mechanical advance, and vacuum advance. A tech article on tuning your ignition timing for each cylinder to improve power output of your engine. The idea is to light the charge in the cylinder with enough lead time (advance) to create maximum cylinder pressure at the ideal point. Together, they form the overall spark curve the engine uses over. Ignition Timing Advance Cylinder.

From www.motortrend.com

Cylinder & Ignition Timing Tuning Timing Advance Circle Track Ignition Timing Advance Cylinder The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). The best way to set ignition timing on a load type dynamometer is to slowly advance the timing until peak torque output is reached. Initial timing, mechanical advance, and vacuum advance. The idea is. Ignition Timing Advance Cylinder.

From www.onallcylinders.com

How to Install a Distributor and Set Initial Timing Ignition Timing Advance Cylinder Spark plugs need to fire at the right time, which can be achieved by advancing or. The way we do it is to set the timing at 30 degrees total advanced on the no. Find all the details inside circle track magazine. A tech article on tuning your ignition timing for each cylinder to improve power output of your engine.. Ignition Timing Advance Cylinder.

From www.carthrottle.com

How To Advance Your Ignition Timing For Great Performance Gains News CarThrottle Ignition Timing Advance Cylinder This is when the piston. The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). A tech article on tuning your ignition timing for each cylinder to improve power output of your engine. 1 cylinder, with the engine at a predetermined rpm. Together, they. Ignition Timing Advance Cylinder.

From cepsncvf.blob.core.windows.net

How To Set Distributor Timing On Golf 1 at Jason Huntington blog Ignition Timing Advance Cylinder Find all the details inside circle track magazine. The best way to set ignition timing on a load type dynamometer is to slowly advance the timing until peak torque output is reached. The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). The way. Ignition Timing Advance Cylinder.

From www.onallcylinders.com

Ask Away with Jeff Smith A Basic Guide to Ignition Advance OnAllCylinders Ignition Timing Advance Cylinder The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). This is when the piston. The idea is to light the charge in the cylinder with enough lead time (advance) to create maximum cylinder pressure at the ideal point. The way we do it. Ignition Timing Advance Cylinder.

From www.researchgate.net

Injection timing on valve timing diagram. Download Scientific Diagram Ignition Timing Advance Cylinder This is when the piston. Ignition timing is measured in degrees of a crankshaft rotation before top dead center (btdc). The way we do it is to set the timing at 30 degrees total advanced on the no. Spark plugs need to fire at the right time, which can be achieved by advancing or. The best way to set ignition. Ignition Timing Advance Cylinder.

From www.haltech.com

Ignition Timing VS Air to Fuel Ratio Haltech Ignition Timing Advance Cylinder The way we do it is to set the timing at 30 degrees total advanced on the no. 1 cylinder, with the engine at a predetermined rpm. Ignition timing is measured in degrees of a crankshaft rotation before top dead center (btdc). Together, they form the overall spark curve the engine uses over its entire rpm. The ideal ignition timing. Ignition Timing Advance Cylinder.

From www.youtube.com

How to set ignition timing YouTube Ignition Timing Advance Cylinder We’ll look at three critical ignition timing areas: The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). 1 cylinder, with the engine at a predetermined rpm. Together, they form the overall spark curve the engine uses over its entire rpm. The way we. Ignition Timing Advance Cylinder.

From www.hotrod.com

Everything You Wanted to Know About Vacuum Advance and Ignition Timing Hot Rod Network Ignition Timing Advance Cylinder Find all the details inside circle track magazine. 1 cylinder, with the engine at a predetermined rpm. Spark plugs need to fire at the right time, which can be achieved by advancing or. We’ll look at three critical ignition timing areas: The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to. Ignition Timing Advance Cylinder.

From www.youtube.com

How To Set Ignition Timing with a Timing Light / Ignition Timing Explained Tech Tip 04 YouTube Ignition Timing Advance Cylinder Find all the details inside circle track magazine. The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). Together, they form the overall spark curve the engine uses over its entire rpm. This is when the piston. Initial timing, mechanical advance, and vacuum advance.. Ignition Timing Advance Cylinder.

From www.onallcylinders.com

How to Install a Distributor and Set Initial Timing Ignition Timing Advance Cylinder A tech article on tuning your ignition timing for each cylinder to improve power output of your engine. We’ll look at three critical ignition timing areas: The way we do it is to set the timing at 30 degrees total advanced on the no. Find all the details inside circle track magazine. Spark plugs need to fire at the right. Ignition Timing Advance Cylinder.

From www.motortrend.com

Cylinder & Ignition Timing Tuning Timing Advance Circle Track Ignition Timing Advance Cylinder Initial timing, mechanical advance, and vacuum advance. The idea is to light the charge in the cylinder with enough lead time (advance) to create maximum cylinder pressure at the ideal point. 1 cylinder, with the engine at a predetermined rpm. The best way to set ignition timing on a load type dynamometer is to slowly advance the timing until peak. Ignition Timing Advance Cylinder.

From www.youtube.com

Ignition Timing Explained & Tested HowTo Advance & Retard Timing With The MVT Digital Direct Ignition Timing Advance Cylinder We’ll look at three critical ignition timing areas: Together, they form the overall spark curve the engine uses over its entire rpm. The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). Ignition timing is measured in degrees of a crankshaft rotation before top. Ignition Timing Advance Cylinder.

From dxomwoeqn.blob.core.windows.net

Ignition Advance Timing at Anita Brooks blog Ignition Timing Advance Cylinder A tech article on tuning your ignition timing for each cylinder to improve power output of your engine. Together, they form the overall spark curve the engine uses over its entire rpm. We’ll look at three critical ignition timing areas: Ignition timing is measured in degrees of a crankshaft rotation before top dead center (btdc). The way we do it. Ignition Timing Advance Cylinder.

From www.hotrod.com

How to Set Ignition Curves and Create Optimal Performance Hot Rod Network Ignition Timing Advance Cylinder The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). Find all the details inside circle track magazine. The way we do it is to set the timing at 30 degrees total advanced on the no. 1 cylinder, with the engine at a predetermined. Ignition Timing Advance Cylinder.

From www.researchgate.net

The effect of spark timing on (a) cylinder pressure, (b) cylinder... Download Scientific Diagram Ignition Timing Advance Cylinder The idea is to light the charge in the cylinder with enough lead time (advance) to create maximum cylinder pressure at the ideal point. Together, they form the overall spark curve the engine uses over its entire rpm. The way we do it is to set the timing at 30 degrees total advanced on the no. Find all the details. Ignition Timing Advance Cylinder.

From www.slideserve.com

PPT IGNITION TIMING PowerPoint Presentation, free download ID975809 Ignition Timing Advance Cylinder Ignition timing is measured in degrees of a crankshaft rotation before top dead center (btdc). Initial timing, mechanical advance, and vacuum advance. The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). This is when the piston. Together, they form the overall spark curve. Ignition Timing Advance Cylinder.

From www.coolairvw.co.uk

Setting Your Valves and Timing an Engine Cool Air VW Ignition Timing Advance Cylinder A tech article on tuning your ignition timing for each cylinder to improve power output of your engine. The best way to set ignition timing on a load type dynamometer is to slowly advance the timing until peak torque output is reached. The way we do it is to set the timing at 30 degrees total advanced on the no.. Ignition Timing Advance Cylinder.

From www.onallcylinders.com

How to Install a Distributor and Set Initial Timing Ignition Timing Advance Cylinder Initial timing, mechanical advance, and vacuum advance. The way we do it is to set the timing at 30 degrees total advanced on the no. The ideal ignition timing occurs (at any given rpm) when maximum cylinder pressure is achieved at roughly 15 to 20 degrees after top dead center (atdc). A tech article on tuning your ignition timing for. Ignition Timing Advance Cylinder.

From dxoojvuzd.blob.core.windows.net

How To Adjust Vacuum Advance On Distributor at Carrie Tuma blog Ignition Timing Advance Cylinder This is when the piston. Initial timing, mechanical advance, and vacuum advance. Spark plugs need to fire at the right time, which can be achieved by advancing or. Find all the details inside circle track magazine. The idea is to light the charge in the cylinder with enough lead time (advance) to create maximum cylinder pressure at the ideal point.. Ignition Timing Advance Cylinder.

From theautoinsiderblog.com

What Happens If Ignition Timing Is Too Advanced? Problems To Consider Ignition Timing Advance Cylinder The way we do it is to set the timing at 30 degrees total advanced on the no. Find all the details inside circle track magazine. Spark plugs need to fire at the right time, which can be achieved by advancing or. This is when the piston. The idea is to light the charge in the cylinder with enough lead. Ignition Timing Advance Cylinder.

From www.heritagepartscentre.com

Understanding Aircooled VW Ignition Timing Ignition Timing Advance Cylinder A tech article on tuning your ignition timing for each cylinder to improve power output of your engine. Spark plugs need to fire at the right time, which can be achieved by advancing or. 1 cylinder, with the engine at a predetermined rpm. Initial timing, mechanical advance, and vacuum advance. The ideal ignition timing occurs (at any given rpm) when. Ignition Timing Advance Cylinder.

From www.youtube.com

Spark Timing & Dwell Control Training Module Trailer YouTube Ignition Timing Advance Cylinder Ignition timing is measured in degrees of a crankshaft rotation before top dead center (btdc). Find all the details inside circle track magazine. A tech article on tuning your ignition timing for each cylinder to improve power output of your engine. We’ll look at three critical ignition timing areas: Spark plugs need to fire at the right time, which can. Ignition Timing Advance Cylinder.