Types Of Rolling In Piping . Rolling is the most important metal forming process. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. What are the different types of pipeline drawings? In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. It stands as a metalworking technique employing a sequence of rollers to intricately shape a metal. Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Roll bending is also known as angle bending or plate rolling.

from republicbap.weebly.com

Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. Rolling is the most important metal forming process. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. What are the different types of pipeline drawings? It stands as a metalworking technique employing a sequence of rollers to intricately shape a metal. Roll bending is also known as angle bending or plate rolling. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane.

Isometric drawing piping rolling republicbap

Types Of Rolling In Piping Rolling is the most important metal forming process. It stands as a metalworking technique employing a sequence of rollers to intricately shape a metal. Roll bending is also known as angle bending or plate rolling. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. What are the different types of pipeline drawings? Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. Rolling is the most important metal forming process.

From fittertraining.com

rolling pipe elbow degree and travel pipe length calculation formula Types Of Rolling In Piping Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. It stands as a metalworking technique employing a sequence of rollers to intricately shape a metal. Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Roll bending is also known as. Types Of Rolling In Piping.

From drawingmebleg.netlify.app

Piping Isometric Drawings Examples Automatic Piping Isometrics From 3d Types Of Rolling In Piping Rolling is the most important metal forming process. Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. It stands as a metalworking technique employing a sequence of rollers. Types Of Rolling In Piping.

From www.studypool.com

SOLUTION How to draw isometric of different types of Rollings in Types Of Rolling In Piping Roll bending is also known as angle bending or plate rolling. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. What are the different types of pipeline drawings? Rolling is the most important metal forming process. Tube rolling refers to the reduction and extension of the perforated hollow bloom through. Types Of Rolling In Piping.

From www.titanmf.com

Piping Piping Fabricators Types Of Rolling In Piping Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. It stands as a metalworking technique employing a sequence of rollers to intricately shape a metal. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. In piping isometric drawings, “rolling” refers. Types Of Rolling In Piping.

From neloauthentic.weebly.com

Isometric drawing piping rolling neloauthentic Types Of Rolling In Piping Rolling is the most important metal forming process. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. Roll bending is also known as angle bending or plate rolling. Tube rolling refers. Types Of Rolling In Piping.

From www.studypool.com

SOLUTION How to draw isometric of different types of rollings in Types Of Rolling In Piping In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. What are the different types of pipeline drawings? Roll bending is also known as angle bending or plate rolling. Pipe bending and. Types Of Rolling In Piping.

From www.youtube.com

PIPING STANDARD Rolling offset and Simple offset YouTube Types Of Rolling In Piping Rolling is the most important metal forming process. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. Pipe bending and rolling are two important types of metal forming processes used to. Types Of Rolling In Piping.

From www.youtube.com

PipingHow to Read Pipe Rolling/Offset in Isometric Drawing? YouTube Types Of Rolling In Piping Rolling is the most important metal forming process. Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. It stands as a metalworking technique employing a sequence of rollers to intricately shape a metal. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than. Types Of Rolling In Piping.

From republicbap.weebly.com

Isometric drawing piping rolling republicbap Types Of Rolling In Piping Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Roll bending is also known as angle bending or plate rolling. Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. It stands as a metalworking technique employing a. Types Of Rolling In Piping.

From nomeye.weebly.com

Rolling in piping isometric drawing nomeye Types Of Rolling In Piping Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Roll bending is also known as angle bending or plate rolling. It stands as a metalworking technique employing a sequence of rollers to intricately shape a metal. Rolling can be classified into various types according to the temperature of the rolling. Types Of Rolling In Piping.

From dadver.weebly.com

How to read isometric drawing piping dadver Types Of Rolling In Piping In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. Roll bending is also known as angle bending or plate rolling. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. Tube rolling refers to the reduction and extension of the perforated. Types Of Rolling In Piping.

From www.youtube.com

Piping Isometric Double Rolling Horizontal and Vertical Drawing Types Of Rolling In Piping Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. Rolling is the most important metal forming process. Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Pipe bending and rolling are two important types of metal forming processes used to. Types Of Rolling In Piping.

From extrudesign.com

What are the Different Types of Rolling Mills? ExtruDesign Types Of Rolling In Piping Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. What are the different types of pipeline drawings? Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Pipe bending and rolling are two important types of metal forming processes used to. Types Of Rolling In Piping.

From www.baseconstructionca.com

Process Piping Explained Base Construction, Inc. Types Of Rolling In Piping In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. What are the different types of pipeline drawings? Rolling is the most important metal forming process. Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Rolling can be classified into various. Types Of Rolling In Piping.

From www.youtube.com

Piping Isometric Drawing, Basic piping tutorial YouTube Types Of Rolling In Piping What are the different types of pipeline drawings? Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. Roll bending is also known as angle bending or plate rolling. Rolling is the most important metal forming process. It stands as a metalworking technique employing a sequence of rollers. Types Of Rolling In Piping.

From www.allaboutpiping.com

What is Piping Isometric drawing? How to Read Piping Drawing? ALL Types Of Rolling In Piping Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to.. Types Of Rolling In Piping.

From www.youtube.com

ROLLING OFFSET piping 45 degree (example question) YouTube Types Of Rolling In Piping It stands as a metalworking technique employing a sequence of rollers to intricately shape a metal. Roll bending is also known as angle bending or plate rolling. Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. Tube rolling refers to the reduction and extension of the perforated. Types Of Rolling In Piping.

From www.studypool.com

SOLUTION How to draw isometric of different types of rollings in Types Of Rolling In Piping Roll bending is also known as angle bending or plate rolling. What are the different types of pipeline drawings? Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. Rolling is the most important metal forming process. Rolling can be classified into various types according to the temperature. Types Of Rolling In Piping.

From extrudesign.com

What is the Rolling process? ExtruDesign Types Of Rolling In Piping In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. Roll bending is also known as angle bending or plate rolling. Rolling is the most important metal forming process. Tube rolling refers. Types Of Rolling In Piping.

From www.youtube.com

DIFFERENT PIPING FIT UP TECHNIQUES TUTORIAL YouTube Types Of Rolling In Piping Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. What are the different types of pipeline drawings? In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. Pipe bending and rolling are two important types of metal forming processes used to. Types Of Rolling In Piping.

From www.mech4study.com

Rolling Process Types, Working, Terminology and Application mech4study Types Of Rolling In Piping Rolling is the most important metal forming process. Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. What are the different types of pipeline drawings? Roll bending is also known as. Types Of Rolling In Piping.

From learnmech.com

Metal Forming Basic, Types , Diagram , Classification Types Of Rolling In Piping What are the different types of pipeline drawings? Roll bending is also known as angle bending or plate rolling. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications.. Types Of Rolling In Piping.

From www.studypool.com

SOLUTION How to draw isometric of different types of Rollings in Types Of Rolling In Piping What are the different types of pipeline drawings? Rolling is the most important metal forming process. Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. It stands as a metalworking technique. Types Of Rolling In Piping.

From www.youtube.com

rolling process and types of rolling rolling process YouTube Types Of Rolling In Piping Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Roll bending is also known as angle bending or plate rolling. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. Rolling is the most important metal forming process. In piping isometric. Types Of Rolling In Piping.

From www.studypool.com

SOLUTION How to draw isometric of different types of rollings in Types Of Rolling In Piping Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. Rolling is the most important metal forming process. Roll bending is also known as angle bending or plate rolling.. Types Of Rolling In Piping.

From www.youtube.com

Pipe Double Rolling Offset Calculation YouTube Types Of Rolling In Piping What are the different types of pipeline drawings? Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. Rolling can be classified into various types according to the temperature of the rolling. Types Of Rolling In Piping.

From barclaymechanical.com

Discover 9 Types Of Process Piping And What A Process Piping Types Of Rolling In Piping Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. What are the different types of pipeline drawings? It stands as a metalworking technique employing a sequence of rollers to intricately shape a metal. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than. Types Of Rolling In Piping.

From www.youtube.com

Piping Material Selection Piping Training Course Video1 YouTube Types Of Rolling In Piping What are the different types of pipeline drawings? In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. Rolling is the most important metal forming process. Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. Tube rolling refers. Types Of Rolling In Piping.

From www.youtube.com

Types of rolling mills Rolling process metal forming application Types Of Rolling In Piping What are the different types of pipeline drawings? Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Roll bending is also known as angle bending or plate rolling. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. Rolling is the. Types Of Rolling In Piping.

From getdrawings.com

Piping Isometric Drawing Exercises Pdf at GetDrawings Free download Types Of Rolling In Piping Rolling is the most important metal forming process. Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. In piping isometric drawings, “rolling” refers to the change in direction of a pipe. Types Of Rolling In Piping.

From www.ppsphx.com

Material Rolling Professional Piping Systems Phoenix, AZ Types Of Rolling In Piping Roll bending is also known as angle bending or plate rolling. What are the different types of pipeline drawings? Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. Pipe bending and. Types Of Rolling In Piping.

From www.youtube.com

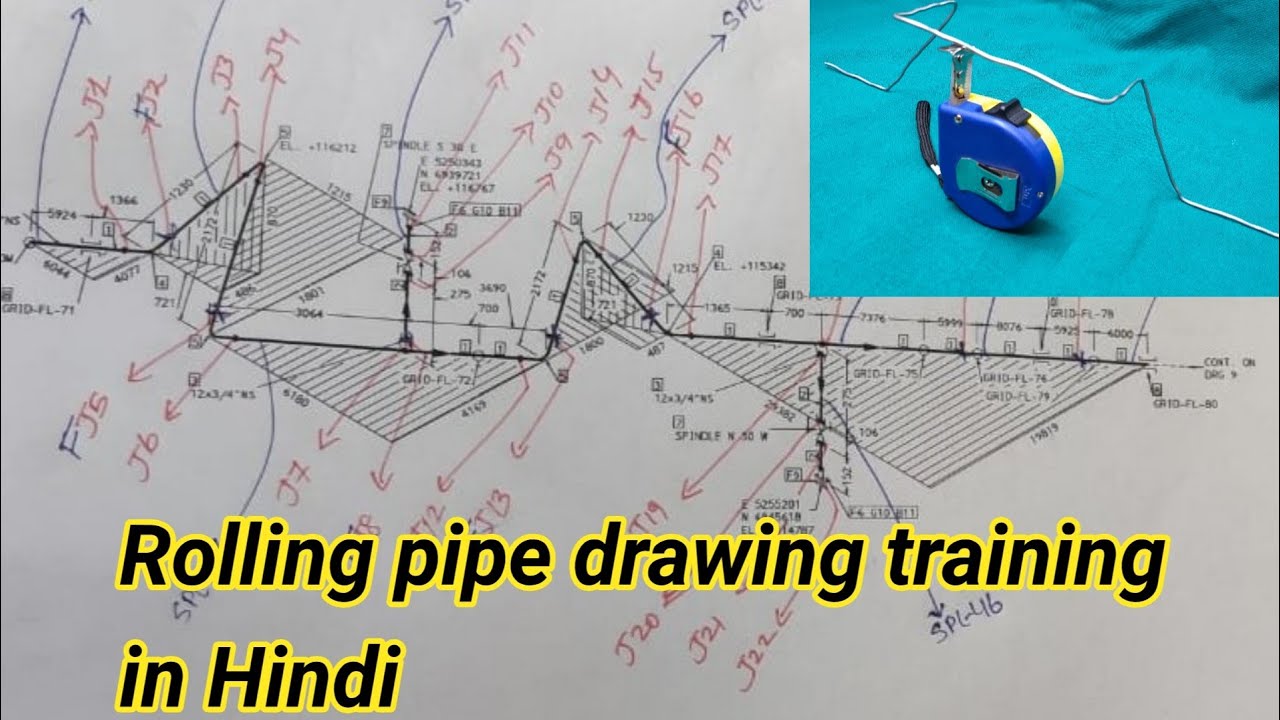

ROLLING IN PIPING DRAWING रोलिंग किसे कहा जाता है isometricrolling Types Of Rolling In Piping Rolling is the most important metal forming process. Roll bending is also known as angle bending or plate rolling. In piping isometric drawings, “rolling” refers to the change in direction of a pipe in more than one plane. What are the different types of pipeline drawings? Rolling can be classified into various types according to the temperature of the rolling. Types Of Rolling In Piping.

From www.studypool.com

SOLUTION How to draw isometric of different types of Rollings in Types Of Rolling In Piping Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. It stands as a metalworking technique employing a sequence of rollers to intricately shape a metal. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. Roll bending is. Types Of Rolling In Piping.

From www.youtube.com

How to read piping isometric drawing, Pipe fitter training, Watch the Types Of Rolling In Piping It stands as a metalworking technique employing a sequence of rollers to intricately shape a metal. Pipe bending and rolling are two important types of metal forming processes used to deform pipes or tubes permanently for various applications. Rolling is the most important metal forming process. Rolling can be classified into various types according to the temperature of the rolling. Types Of Rolling In Piping.

From www.youtube.com

Piping, Vertical and Horizontal Rolling YouTube Types Of Rolling In Piping Tube rolling refers to the reduction and extension of the perforated hollow bloom through the tube rolling mill to. It stands as a metalworking technique employing a sequence of rollers to intricately shape a metal. Rolling can be classified into various types according to the temperature of the rolling process, roller characteristics, product types,. In piping isometric drawings, “rolling” refers. Types Of Rolling In Piping.