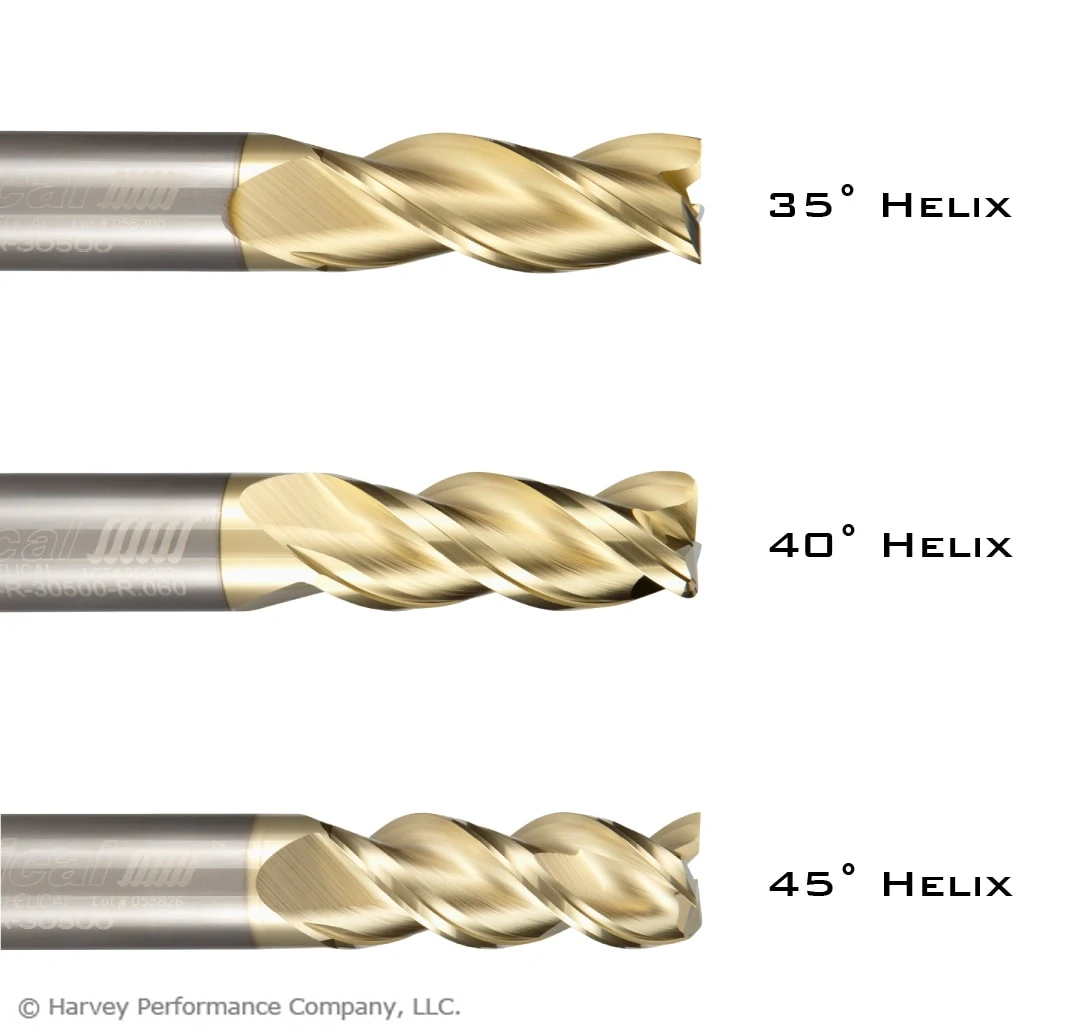

End Mill Helix Angle For Aluminum . Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. The helix angle of an end mill refers to the angle formed between the centerline of the tool and the edge of the rake face. Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently select the end mill that best meets your. In most cases, the specialized helix angles for aluminum. The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. Small variations in this angle can change the performance of a cutting tool. This range offers a good balance between all factors involved. End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. For instance, a larger helix angle might be preferred for softer materials like aluminum to aid in chip evacuation, whereas a smaller angle might be more suitable. End mills designed specifically for cutting aluminum often have helix angles that are steeper than those seen on regular end mills.

from www.harveyperformance.com

In most cases, the specialized helix angles for aluminum. The helix angle of an end mill refers to the angle formed between the centerline of the tool and the edge of the rake face. Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently select the end mill that best meets your. Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. Small variations in this angle can change the performance of a cutting tool. For instance, a larger helix angle might be preferred for softer materials like aluminum to aid in chip evacuation, whereas a smaller angle might be more suitable. This range offers a good balance between all factors involved. End mills designed specifically for cutting aluminum often have helix angles that are steeper than those seen on regular end mills. End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from.

Attacking Aluminum a Machining Guide In The Loupe

End Mill Helix Angle For Aluminum Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently select the end mill that best meets your. End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. Small variations in this angle can change the performance of a cutting tool. This range offers a good balance between all factors involved. The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. The helix angle of an end mill refers to the angle formed between the centerline of the tool and the edge of the rake face. End mills designed specifically for cutting aluminum often have helix angles that are steeper than those seen on regular end mills. For instance, a larger helix angle might be preferred for softer materials like aluminum to aid in chip evacuation, whereas a smaller angle might be more suitable. In most cases, the specialized helix angles for aluminum. Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently select the end mill that best meets your.

From www.maritool.com

Tool Holders, Collets and Machine Accessories Aluminum Specific End End Mill Helix Angle For Aluminum Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. This range offers a good balance between all factors involved. For instance, a. End Mill Helix Angle For Aluminum.

From www.buyustools.com

1/2" X 3" 3FLUTE SOLID CARBIDE SQUARE END MILL ALUMINUM buyustools End Mill Helix Angle For Aluminum Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. End mills designed specifically for cutting aluminum often have helix angles that are. End Mill Helix Angle For Aluminum.

From createalloy.en.made-in-china.com

U Groove Unequal Helix Angle End Mill for Roughing Machining China U End Mill Helix Angle For Aluminum Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. End mills designed specifically for cutting aluminum often have helix angles that are steeper than those seen on regular end mills. End mills with high helix angles ensure better chip evacuation as. End Mill Helix Angle For Aluminum.

From www.hobby-machinist.com

What end mill for brass? Copper? Page 2 The HobbyMachinist End Mill Helix Angle For Aluminum Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. End mills designed specifically for cutting aluminum often have helix angles. End Mill Helix Angle For Aluminum.

From mungfali.com

Helix Angle End Mill End Mill Helix Angle For Aluminum End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. This range offers a good balance between all factors involved. For instance, a larger helix angle might be preferred for softer materials like aluminum to aid in chip evacuation, whereas a smaller angle might be more suitable. In most. End Mill Helix Angle For Aluminum.

From www.densotools.com

end mill helix anglesave 50 cost Can nonstandard End Mill Helix Angle For Aluminum End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. The helix angle of an end mill refers to the angle formed between the centerline of the tool and the edge of the rake face. For instance, a larger helix angle might be preferred for softer materials like aluminum. End Mill Helix Angle For Aluminum.

From www.indiamart.com

Hagg 10x75 MM Aluminium End Mill, Helix Angle 35 Deg, Number Of Flutes End Mill Helix Angle For Aluminum End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. This range offers a good balance between all factors involved. For instance, a larger helix angle might be preferred for softer materials like aluminum to aid in chip evacuation, whereas a smaller angle might be more suitable. The higher. End Mill Helix Angle For Aluminum.

From www.indiamart.com

1/8inch Solid Carbide End Mill, Helix Angle 30Degree, Number Of Flutes End Mill Helix Angle For Aluminum Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. For instance, a larger helix angle might be preferred for softer materials like aluminum to aid in chip evacuation, whereas a smaller angle might be more suitable. End mills with high helix. End Mill Helix Angle For Aluminum.

From www.carbideend-mill.com

ODM Support Helix Angle Long Neck End Mill With Customized Cutting Edge End Mill Helix Angle For Aluminum Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. This range offers a good balance between all factors involved. Download our fundamentals. End Mill Helix Angle For Aluminum.

From huanatools.com

Helix Angle 45 Degree Carbide End Mill for Stainless Steel Huana Tools End Mill Helix Angle For Aluminum In most cases, the specialized helix angles for aluminum. End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently select the end mill. End Mill Helix Angle For Aluminum.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe End Mill Helix Angle For Aluminum End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. In most cases, the specialized helix angles for aluminum. The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. End mills designed specifically for cutting aluminum often have helix angles. End Mill Helix Angle For Aluminum.

From chinayinlk.en.made-in-china.com

HighQuality Tungsten Carbide 4 Flutes Flat End Mill Helix Degree End Mill Helix Angle For Aluminum Small variations in this angle can change the performance of a cutting tool. Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently select the end mill that best meets your. In most cases, the specialized helix angles for aluminum. End mills designed specifically. End Mill Helix Angle For Aluminum.

From www.cnccarbideinserts.com

Aluminum Alloy Solid Carbide End Mills With Sharp Cutting Edge / Large End Mill Helix Angle For Aluminum The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. Small variations in this angle can change the performance of a cutting tool. For instance, a larger helix angle might be preferred for softer materials like aluminum to aid in chip evacuation, whereas a smaller angle might be more suitable. In. End Mill Helix Angle For Aluminum.

From www.harveyperformance.com

Attacking Aluminum a Machining Guide In The Loupe End Mill Helix Angle For Aluminum The helix angle of an end mill refers to the angle formed between the centerline of the tool and the edge of the rake face. Small variations in this angle can change the performance of a cutting tool. For instance, a larger helix angle might be preferred for softer materials like aluminum to aid in chip evacuation, whereas a smaller. End Mill Helix Angle For Aluminum.

From www.shop-apt.co.uk

2mm Diameter Variable Helix Carbide End Mill for Aluminium DLC Coated End Mill Helix Angle For Aluminum This range offers a good balance between all factors involved. Small variations in this angle can change the performance of a cutting tool. The helix angle of an end mill refers to the angle formed between the centerline of the tool and the edge of the rake face. End mills designed specifically for cutting aluminum often have helix angles that. End Mill Helix Angle For Aluminum.

From www.shop-apt.co.uk

10mm Diameter Variable Helix Carbide End Mill for Aluminium DLC Coated End Mill Helix Angle For Aluminum The helix angle of an end mill refers to the angle formed between the centerline of the tool and the edge of the rake face. The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. In most cases, the specialized helix angles for aluminum. End mills with high helix angles ensure. End Mill Helix Angle For Aluminum.

From www.amanatool.com

51830 CNC Solid Carbide Aluminum and Acrylic Cutting 55º Helix End Mill End Mill Helix Angle For Aluminum Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. In most cases, the specialized helix angles for aluminum. Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so. End Mill Helix Angle For Aluminum.

From www.indiamart.com

Guhring 3 Flute Metric Aluminum Performance General Purpose End Mill End Mill Helix Angle For Aluminum This range offers a good balance between all factors involved. End mills designed specifically for cutting aluminum often have helix angles that are steeper than those seen on regular end mills. In most cases, the specialized helix angles for aluminum. The helix angle of an end mill refers to the angle formed between the centerline of the tool and the. End Mill Helix Angle For Aluminum.

From www.shop-apt.co.uk

3mm Diameter Variable Helix Carbide End Mill for Aluminium Uncoated End Mill Helix Angle For Aluminum Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. The helix angle of an end mill refers to the angle formed between the centerline of the tool and the edge of the rake face. In most cases, the specialized helix angles. End Mill Helix Angle For Aluminum.

From www.shop-apt.co.uk

4mm Dia 0.2mm Corner Chamfer 4 Flute Variable Helix Angle High End Mill Helix Angle For Aluminum End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. Small variations in this angle can change the performance of a cutting tool. Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently. End Mill Helix Angle For Aluminum.

From www.shop-apt.co.uk

8mm Diameter Variable Helix Carbide End Mill for Aluminium DLC Coated End Mill Helix Angle For Aluminum End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently select the end mill that best meets your. Small variations in this angle. End Mill Helix Angle For Aluminum.

From endszd.blogspot.com

End Mill Helix Angle ENDSZD End Mill Helix Angle For Aluminum The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. In most cases, the specialized helix angles for aluminum. For instance, a larger helix angle might be preferred for softer. End Mill Helix Angle For Aluminum.

From huanatools.com

Variable Helix End Mill for Stainless Steel Huana Tools End Mill Helix Angle For Aluminum In most cases, the specialized helix angles for aluminum. Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently select the end mill that best meets your. Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen. End Mill Helix Angle For Aluminum.

From www.alibaba.com

Carbide End Mill Helix Angle 35 Degree Cutter Buy Professional End Mill Helix Angle For Aluminum Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. End mills designed specifically for cutting aluminum often have helix angles that are steeper than those seen on regular end mills. The higher helix angle also results in a finer finish on. End Mill Helix Angle For Aluminum.

From www.end-milling.com

Tungsten Carbide End Mills , Micro End Mill for Steel with Helix Angle End Mill Helix Angle For Aluminum The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. This range offers a good balance between all factors involved. Small variations in this angle can change the performance of a cutting tool. Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings,. End Mill Helix Angle For Aluminum.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe End Mill Helix Angle For Aluminum Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently select the end mill that best meets your. This range offers a good balance between all factors involved. Small variations in this angle can change the performance of a cutting tool. The higher helix. End Mill Helix Angle For Aluminum.

From www.kenturn.com.tw

Milling Tools Supplier Provides Helix Angle End Mill KENTURN End Mill Helix Angle For Aluminum The helix angle of an end mill refers to the angle formed between the centerline of the tool and the edge of the rake face. End mills designed specifically for cutting aluminum often have helix angles that are steeper than those seen on regular end mills. Small variations in this angle can change the performance of a cutting tool. In. End Mill Helix Angle For Aluminum.

From www.shop-apt.co.uk

3 Flute Carbide End Mill for Aluminium 10mm Diameter 45° Helix End Mill Helix Angle For Aluminum This range offers a good balance between all factors involved. Small variations in this angle can change the performance of a cutting tool. For instance, a larger helix angle might be preferred for softer materials like aluminum to aid in chip evacuation, whereas a smaller angle might be more suitable. Therefore, a large helix angle end mill, such as those. End Mill Helix Angle For Aluminum.

From www.cnccarbideinserts.com

Aluminum Alloy Solid Carbide End Mills With Sharp Cutting Edge / Large End Mill Helix Angle For Aluminum Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently select the end mill that best meets your. The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. Small variations in this angle can change. End Mill Helix Angle For Aluminum.

From kovestool888.en.made-in-china.com

Koves 2 Flute CNC Tool Solid Carbide Aluminum End Mill Helix Angle 55 End Mill Helix Angle For Aluminum Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently select the end mill that best meets your. The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. This range offers a good balance between. End Mill Helix Angle For Aluminum.

From www.researchgate.net

(PDF) Influence of End Mill Helix Angle on Surface Quality of Aluminium End Mill Helix Angle For Aluminum Small variations in this angle can change the performance of a cutting tool. Download our fundamentals of end mills guide and learn the pros and cons of varying helix angles, coatings, tool materials and more, so you can confidently select the end mill that best meets your. The helix angle of an end mill refers to the angle formed between. End Mill Helix Angle For Aluminum.

From www.universalsawblade.com

5/16 8mm High Helix End Mill Aluminum Helix Corner Radius Milling End Mill Helix Angle For Aluminum In most cases, the specialized helix angles for aluminum. For instance, a larger helix angle might be preferred for softer materials like aluminum to aid in chip evacuation, whereas a smaller angle might be more suitable. Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation. End Mill Helix Angle For Aluminum.

From samhotool.com

Unlock the Secrets to Choosing the Right End Mill Helix Angle for End Mill Helix Angle For Aluminum Therefore, a large helix angle end mill, such as those with a 45° helix, is often chosen for aluminum to ensure smooth chip evacuation and reduce heat buildup. In most cases, the specialized helix angles for aluminum. The higher helix angle also results in a finer finish on the workpiece surface, crucial for many aluminum projects. Small variations in this. End Mill Helix Angle For Aluminum.

From www.icarbide.com

1/2"X4" 3FLUTE CARBIDE END MILL CC ALUSPEED COATED FOR ALUMINUM END MIL End Mill Helix Angle For Aluminum End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. In most cases, the specialized helix angles for aluminum. This range offers a good balance between all factors involved. For instance, a larger helix angle might be preferred for softer materials like aluminum to aid in chip evacuation, whereas. End Mill Helix Angle For Aluminum.

From gxtools.en.made-in-china.com

Tungsten Carbide Variable Helix Angle End Mill 4flutes Milling Cutter End Mill Helix Angle For Aluminum Small variations in this angle can change the performance of a cutting tool. End mills designed specifically for cutting aluminum often have helix angles that are steeper than those seen on regular end mills. End mills with high helix angles ensure better chip evacuation as they have steep flute angles that quickly remove material from. In most cases, the specialized. End Mill Helix Angle For Aluminum.