Manufacturing Process Of Etching . At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. an overview of damage resulting from ion etching and ion implantation. chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving. An etch system is used in manufacturing lines for semiconductors and other electronic devices.

from www.slideserve.com

chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. An etch system is used in manufacturing lines for semiconductors and other electronic devices. chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving. an overview of damage resulting from ion etching and ion implantation. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid.

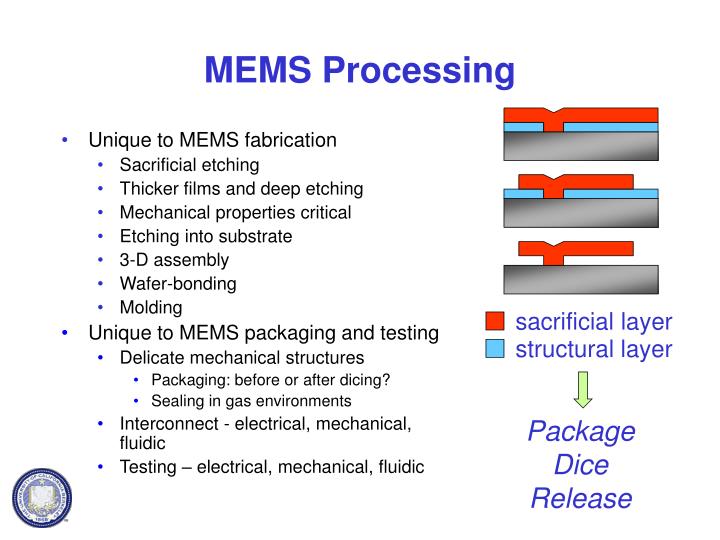

PPT MEMS Fabrication Process Flows and Bulk Silicon Etching

Manufacturing Process Of Etching an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. an overview of damage resulting from ion etching and ion implantation. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. An etch system is used in manufacturing lines for semiconductors and other electronic devices. chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving.

From www.researchgate.net

Schematic illustrating the manufacturing steps in the photochemical Manufacturing Process Of Etching An etch system is used in manufacturing lines for semiconductors and other electronic devices. chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. an etch system shapes the thin film into a desired patterns. Manufacturing Process Of Etching.

From www.researchgate.net

Main patterning and metallization steps in the PCB fabrication (a) A Manufacturing Process Of Etching chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. An etch system is used in manufacturing lines for semiconductors and other electronic devices. chemical etching is a process that uses. Manufacturing Process Of Etching.

From www.youtube.com

Etching Process in semiconductor manufacturing! YouTube Manufacturing Process Of Etching An etch system is used in manufacturing lines for semiconductors and other electronic devices. chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. an overview of damage resulting from ion etching and ion implantation. chemical etching is a complex process that relies on chemical reactions, material properties, and process control. Manufacturing Process Of Etching.

From www.slideserve.com

PPT MEMS Fabrication Process Flows and Bulk Silicon Etching Manufacturing Process Of Etching At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. an overview of damage resulting from ion etching and ion implantation. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. chemical etching, also known as. Manufacturing Process Of Etching.

From www.iqsdirectory.com

Acid Etching Acid Types, Metal Types, Applications, and Benefits Manufacturing Process Of Etching chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and. Manufacturing Process Of Etching.

From www.researchgate.net

Schema of the fabrication process followed for the etching of thin Manufacturing Process Of Etching an overview of damage resulting from ion etching and ion implantation. chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. chemical etching is a process that uses a. Manufacturing Process Of Etching.

From djeizfuweco.blob.core.windows.net

Etching Manufacturing Process at Arthur Sutton blog Manufacturing Process Of Etching At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. an overview of damage resulting from ion etching and ion implantation. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. chemical etching, also known as. Manufacturing Process Of Etching.

From ace-uk.net

What is Titanium Etching? Our Titanium Etching Process Manufacturing Process Of Etching chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results.. Manufacturing Process Of Etching.

From ace-uk.net

What Is Aluminium Etching? Our Aluminium Etching Process At ACE Manufacturing Process Of Etching an overview of damage resulting from ion etching and ion implantation. chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. an etch system shapes the thin film into. Manufacturing Process Of Etching.

From www.researchgate.net

Six typical glass microstructure fabrication techniques. (a) Wet Manufacturing Process Of Etching an overview of damage resulting from ion etching and ion implantation. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving. At its core, chemical etching involves the selective. Manufacturing Process Of Etching.

From www.uweinc.com

Photo Etching Process A StepbyStep Guide UWE Manufacturing Process Of Etching At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. an overview of damage resulting from ion etching and ion implantation. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving. An etch system is. Manufacturing Process Of Etching.

From www.youtube.com

Chemical Etching Process Masteretch YouTube Manufacturing Process Of Etching an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving. chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in. Manufacturing Process Of Etching.

From djeizfuweco.blob.core.windows.net

Etching Manufacturing Process at Arthur Sutton blog Manufacturing Process Of Etching chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. chemical etching is a complex process that relies on chemical reactions, material properties, and process. Manufacturing Process Of Etching.

From djeizfuweco.blob.core.windows.net

Etching Manufacturing Process at Arthur Sutton blog Manufacturing Process Of Etching chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. An etch system is used in manufacturing lines for semiconductors and other electronic devices. chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. At its core, chemical etching involves the. Manufacturing Process Of Etching.

From news.skhynix.com

Etching, Process to Complete Semiconductor Patterning 2 SK hynix Manufacturing Process Of Etching an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. . Manufacturing Process Of Etching.

From www.metaletching.org

Stainless Steel Etching Companies Services Manufacturing Process Of Etching chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. At its core, chemical. Manufacturing Process Of Etching.

From www.uweinc.com

Photo Etching Process A StepbyStep Guide UWE Manufacturing Process Of Etching chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. An etch system is used in manufacturing lines for semiconductors and other electronic devices. chemical etching is a process that. Manufacturing Process Of Etching.

From www.researchgate.net

Photolithography, the etching process of the silicon wafer. Download Manufacturing Process Of Etching chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction.. Manufacturing Process Of Etching.

From pv-manufacturing.org

Manufacturing Process Of Etching At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. An etch system is used in manufacturing lines for semiconductors and other electronic devices. chemical etching is. Manufacturing Process Of Etching.

From www.youtube.com

Chemical Etching Process A StepbyStep Guide to Chemical Etching Manufacturing Process Of Etching At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. An etch system is used in manufacturing lines for semiconductors and other electronic devices. chemical etching, also. Manufacturing Process Of Etching.

From www.ceramicmanufacturing.net

Louisiana Ceramic Manufacturing Companies Manufacturing Process Of Etching an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted. Manufacturing Process Of Etching.

From exommwdsl.blob.core.windows.net

Photo Etching Process at Tammy Rawlings blog Manufacturing Process Of Etching chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted. Manufacturing Process Of Etching.

From www.tecforddesign.com

Tecford Design Inc. What is PCM? Manufacturing Process Of Etching An etch system is used in manufacturing lines for semiconductors and other electronic devices. chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving. an overview of damage resulting. Manufacturing Process Of Etching.

From www.youtube.com

Etching Multilayer PCB Manufacturing Process 09 YouTube Manufacturing Process Of Etching An etch system is used in manufacturing lines for semiconductors and other electronic devices. chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. chemical etching, also known as “industrial. Manufacturing Process Of Etching.

From www.youtube.com

ETCHING PROCESS METALLIZATION PROCESS IN IC FABRICATION VLSI Manufacturing Process Of Etching chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving. an overview. Manufacturing Process Of Etching.

From www.ctemag.com

Photochemical etching process pushes metal fabrication boundaries Manufacturing Process Of Etching chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results.. Manufacturing Process Of Etching.

From dokumen.tips

(DOCX) · viewChemical Milling or Industrial etching is the Manufacturing Process Of Etching An etch system is used in manufacturing lines for semiconductors and other electronic devices. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. an overview of damage resulting from ion. Manufacturing Process Of Etching.

From www.masteretching.com

Chemical Etching Process What is Chemical Etching? Manufacturing Process Of Etching At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving. an overview of damage resulting from ion etching and ion implantation. chemical etching, also. Manufacturing Process Of Etching.

From www.metaletching.org

Chemical Etching Companies Chemical Etching Services Manufacturing Process Of Etching chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. an overview of damage resulting from ion etching and ion implantation. an etch system shapes the thin film into a desired patterns using liquid. Manufacturing Process Of Etching.

From www.researchgate.net

Fabrication process for the proposed wetetching method. Download Manufacturing Process Of Etching an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. chemical etching is a complex process that relies on chemical reactions, material properties, and process control to achieve the desired results.. Manufacturing Process Of Etching.

From www.masteretching.com

Chemical Etching Process What is Chemical Etching? Manufacturing Process Of Etching chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. At its core, chemical etching. Manufacturing Process Of Etching.

From www.youtube.com

Etching process PCB manufacturing chemical process YouTube Manufacturing Process Of Etching chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving. An etch system is used in manufacturing lines for semiconductors and other electronic devices. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. chemical. Manufacturing Process Of Etching.

From www.infographicbee.com

Precision In The Photochemical Etching Process Manufacturing Process Of Etching chemical etching, also known as “industrial etching” or “chemical milling”, is a subtractive process in manufacturing. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. An. Manufacturing Process Of Etching.

From www.horiba.com

Semiconductor Processing Etch Manufacturing Process Of Etching chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet,. Manufacturing Process Of Etching.

From www.uweinc.com

Unveiling the Process How Photo Etching Transforms Metal Manufacturing Manufacturing Process Of Etching At its core, chemical etching involves the selective removal of material from a substrate using a chemical solution, typically an acid. chemical etching is commonly used in the manufacturing of electronic components, decorative items, and precision tools. an etch system shapes the thin film into a desired patterns using liquid chemicals, reaction gases or ion chemical reaction. . Manufacturing Process Of Etching.