Continuous Casting Machine Steel . Continuous casting transforms liquid steel into solid on a continuous basis. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. Continuous casting is the important linking process between steelmaking and rolling. The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. As early as 1856, henry bessemer suggested a. As early as 1856, henry bessemer suggested a. Continuous casting is the important linking process between steelmaking and rolling.

from www.comsol.com

Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. Continuous casting transforms liquid steel into solid on a continuous basis. As early as 1856, henry bessemer suggested a. Continuous casting is the important linking process between steelmaking and rolling. The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. As early as 1856, henry bessemer suggested a. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. Continuous casting is the important linking process between steelmaking and rolling.

Optimizing the Continuous Casting Process with Simulation COMSOL Blog

Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. As early as 1856, henry bessemer suggested a. Continuous casting transforms liquid steel into solid on a continuous basis. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. As early as 1856, henry bessemer suggested a. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting is the important linking process between steelmaking and rolling.

From www.ccmrolling.com

China Professional China Ccm Continuous Casting Machine Continuous Continuous Casting Machine Steel Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. As early as 1856, henry bessemer suggested a. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. Continuous casting is the important linking process between steelmaking and rolling.. Continuous Casting Machine Steel.

From www.cdoinduction.com

Steel Billet Continuous Casting MachineCooldo Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. Continuous casting transforms liquid steel into solid on a continuous basis. As early as 1856, henry bessemer suggested a. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s,. Continuous Casting Machine Steel.

From www.ccmrolling.com

Horizontal Continuous Casting Machine Continuous Casting Machine Steel Continuous casting is the important linking process between steelmaking and rolling. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. Continuous casting practices for steelmaking have been constantly. Continuous Casting Machine Steel.

From www.reddit.com

Radial type Continuous Casting Machine (CCM) at Vizag Steel in India Continuous Casting Machine Steel Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. As early as 1856, henry bessemer suggested a. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. Continuous casting transforms liquid steel into solid on a continuous basis.. Continuous Casting Machine Steel.

From www.syalons.com

Continuous Steel Casting with Syalon Break Rings Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. As early as 1856, henry bessemer suggested a. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting transforms liquid steel into solid on a continuous basis. Continuous casting, an. Continuous Casting Machine Steel.

From www.ccmrolling.com

China Manufacturer for Horizontal Casting Machine Continuous Casting Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. As early as 1856, henry bessemer suggested a. Continuous casting transforms liquid steel into solid on a continuous basis. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting is a method in metallurgy where molten metal is. Continuous Casting Machine Steel.

From cartoondealer.com

Continuous Casting Machine For Slabs RoyaltyFree Stock Photo Continuous Casting Machine Steel Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting transforms liquid steel into. Continuous Casting Machine Steel.

From www.danieli.com

Products › Long › Billet casters Continuous Casting Machine solutions Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. Continuous casting transforms liquid steel into solid on a continuous basis. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was. Continuous Casting Machine Steel.

From www.ccmrolling.com

China CCM Steel Making with Continuous Casting Machine factory and Continuous Casting Machine Steel Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. As early as 1856, henry bessemer suggested a. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. Continuous casting practices for steelmaking have been constantly evolving ever since. Continuous Casting Machine Steel.

From www.danieli.com

Products › Long › Bloom Casters Continuous Casting Machine solutions Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. Continuous casting is the important linking process between steelmaking and rolling. As early as 1856, henry bessemer suggested a. Continuous casting is the important. Continuous Casting Machine Steel.

From megatherm.com

CONTINUOUS CASTING MACHINE MEGATHERM Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. Continuous casting is the important linking process between steelmaking and rolling. The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. As early as 1856,. Continuous Casting Machine Steel.

From www.primetals.com

Tata Steel IJmuiden orders new continuous slab caster from Primetals Continuous Casting Machine Steel Continuous casting transforms liquid steel into solid on a continuous basis. Continuous casting is the important linking process between steelmaking and rolling. The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. As early as 1856, henry bessemer suggested a. Continuous casting, an innovative method in steel production, has reshaped the. Continuous Casting Machine Steel.

From nkmz-ce.com

Billet continuous casting machine NKMZ CE Continuous Casting Machine Steel Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. As early as 1856, henry bessemer suggested a. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions.. Continuous Casting Machine Steel.

From asmt-sales.en.made-in-china.com

Electric Continuous Casting Machine CCM for Steel Billet Producing Continuous Casting Machine Steel Continuous casting is the important linking process between steelmaking and rolling. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and. Continuous Casting Machine Steel.

From www.linkedin.com

Introduction of Continuous Casting Machine Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. The process is the most efficient way to solidify large. Continuous Casting Machine Steel.

From www.luoyangsndl.com

Steel Billets Continuous Casting Machine Luoyang Shennai Power Continuous Casting Machine Steel Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. As early as 1856, henry bessemer suggested a. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. As early as 1856, henry bessemer. Continuous Casting Machine Steel.

From www.comsol.com

Optimizing the Continuous Casting Process with Simulation COMSOL Blog Continuous Casting Machine Steel The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. Continuous casting. Continuous Casting Machine Steel.

From www.zbmetaltech.com

China Types of CCM Continuous Casting Machine Manufacturer/Supplier Continuous Casting Machine Steel The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. Continuous casting transforms liquid steel into solid on a continuous basis. As early as 1856, henry bessemer. Continuous Casting Machine Steel.

From www.mdpi.com

Materials Free FullText Optimization of Continuous Casting for Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. Continuous casting practices for steelmaking have been constantly evolving ever since. Continuous Casting Machine Steel.

From www.researchgate.net

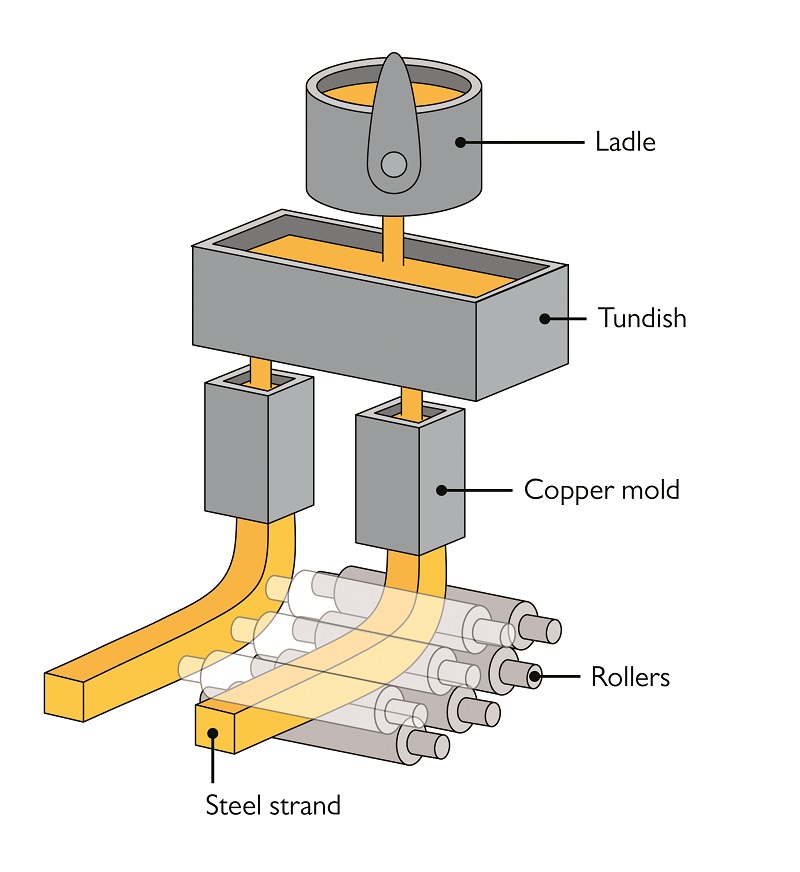

Show Illustration of Continuous Casting Process [6]. Download Continuous Casting Machine Steel Continuous casting transforms liquid steel into solid on a continuous basis. Continuous casting is the important linking process between steelmaking and rolling. As early as 1856, henry bessemer suggested a. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. Continuous casting, an innovative method in steel production, has reshaped the industry’s. Continuous Casting Machine Steel.

From shengli2019.en.made-in-china.com

Continuous Casting Machine (CCM) for Foundry and Steel Making China Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. Continuous casting transforms liquid steel into solid on a continuous basis. As early as 1856, henry bessemer suggested a. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. The process is the most. Continuous Casting Machine Steel.

From ac-dc-motor-furnace.en.made-in-china.com

Electric Continuous Casting Machine for Steel Billet Producing China Continuous Casting Machine Steel Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting transforms liquid steel into solid on a continuous basis. As early as 1856, henry bessemer suggested a. Continuous casting, an innovative method in steel production, has reshaped the industry’s. Continuous Casting Machine Steel.

From www.ccmrolling.com

China CCM Steel Making with Continuous Casting Machine factory and Continuous Casting Machine Steel Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. As early as 1856, henry bessemer suggested a. The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. As early as 1856, henry. Continuous Casting Machine Steel.

From www.youtube.com

CONTINUOUS CASTING MACHINE YouTube Continuous Casting Machine Steel Continuous casting is the important linking process between steelmaking and rolling. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. As early as 1856, henry bessemer suggested a. As early as 1856, henry bessemer suggested a. Continuous casting. Continuous Casting Machine Steel.

From www.shengchonggroup.com

Continuous casting machine shengchong Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. Continuous casting is the important linking process between steelmaking and rolling. As early as 1856, henry bessemer suggested a. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting is a method in metallurgy where molten. Continuous Casting Machine Steel.

From www.luoyangsndl.com

Steel Billets Continuous Casting Machine Luoyang Shennai Power Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. As early as 1856, henry bessemer suggested a. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. The process. Continuous Casting Machine Steel.

From www.alamy.com

Steel billets in a continuous casting machine in a steel mill Stock Continuous Casting Machine Steel The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. Continuous casting transforms liquid steel into solid on a continuous basis. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting is a method in. Continuous Casting Machine Steel.

From www.ccmrolling.com

China Continuous Casting Machine Steel Billet CCM factory and Continuous Casting Machine Steel Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. The process is the most efficient way to solidify large volumes of liquid steel. Continuous Casting Machine Steel.

From www.danieli.com

Products › Long › Billet casters Continuous Casting Machine solutions Continuous Casting Machine Steel Continuous casting is the important linking process between steelmaking and rolling. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting transforms liquid steel into solid on a continuous basis. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. Continuous casting is a method in metallurgy where molten. Continuous Casting Machine Steel.

From www.ccmrolling.com

China Continuous Casting Machine ( CCM ) for steel billet 100 X 100 mm Continuous Casting Machine Steel The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. As early as 1856, henry bessemer suggested a. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. Continuous casting. Continuous Casting Machine Steel.

From www.researchgate.net

Types of continuous casting machines Download Scientific Diagram Continuous Casting Machine Steel Continuous casting transforms liquid steel into solid on a continuous basis. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. Continuous casting is the important linking process between steelmaking and rolling. The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. Continuous. Continuous Casting Machine Steel.

From asmt-sales.en.made-in-china.com

Continuous Casting Machine CCM for Steel Billet Brass China Continuous Casting Machine Steel Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. As early as 1856, henry bessemer suggested a. Continuous casting is the important linking. Continuous Casting Machine Steel.

From www.syalons.com

Continuous Steel Casting with Syalon Break Rings Continuous Casting Machine Steel Continuous casting is the important linking process between steelmaking and rolling. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. Continuous casting practices for steelmaking have been constantly evolving ever since the early 1930s, when junghans was first. Continuous casting transforms liquid steel into solid on a continuous basis. As early as 1856, henry bessemer suggested. Continuous Casting Machine Steel.

From www.ccmrolling.com

China Continuous Casting Machine ( CCM ) for Steel Plant factory and Continuous Casting Machine Steel Continuous casting is the important linking process between steelmaking and rolling. The process is the most efficient way to solidify large volumes of liquid steel into simple shapes for subsequent. Continuous casting is a method in metallurgy where molten metal is poured into a continuous casting machine and solidifies into a continuous strand of desired shape and dimensions. Continuous casting. Continuous Casting Machine Steel.

From aisusteel.org

Continuous Cast Technology Arab Iron and Steel Union Continuous Casting Machine Steel As early as 1856, henry bessemer suggested a. Continuous casting transforms liquid steel into solid on a continuous basis. Continuous casting, an innovative method in steel production, has reshaped the industry’s landscape. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting is the important linking process between steelmaking and rolling. Continuous casting is a method in. Continuous Casting Machine Steel.