Distillation Heat Exchanger . Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at.

from www.semanticscholar.org

The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost.

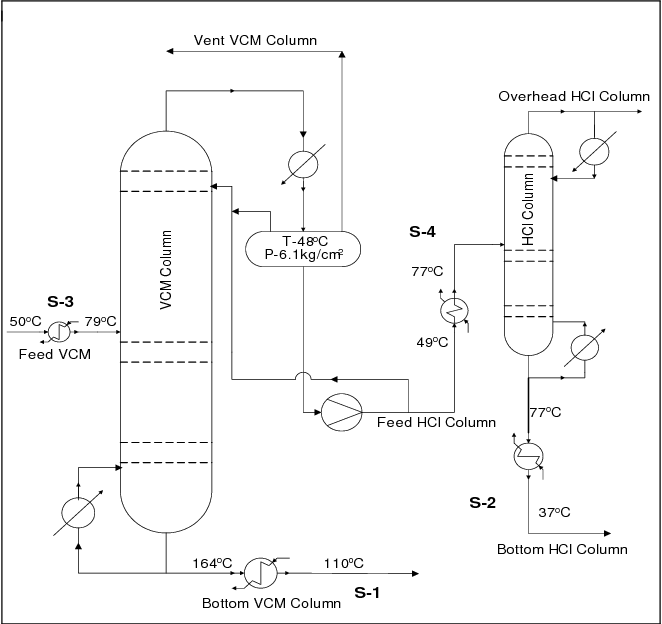

Figure 1 from Design of Heat Exchanger Network for VCM Distillation

Distillation Heat Exchanger For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat.

From savree.com

Shell and Tube Heat Exchanger Explained saVRee saVRee Distillation Heat Exchanger For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute. Distillation Heat Exchanger.

From www.dreamstime.com

Large Iron Heat Exchanger, Tank, Reactor, Distillation Column in Distillation Heat Exchanger For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. A distillation column is a series of equilibrium. Distillation Heat Exchanger.

From www.aac-autoclave.com

ASME high durability Water Distillation Plant Tubular Heat Exchanger Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. A distillation column is a series of equilibrium. Distillation Heat Exchanger.

From www.semanticscholar.org

Figure 1 from Analysis of Heat Exchanger Network of Distillation Unit Distillation Heat Exchanger For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. For the case study under consideration, however, heat transfer. Distillation Heat Exchanger.

From www.alaquainc.com

EVAPORATORS SYSTEM IN HEAT EXCHANGE Alaquainc Distillation Heat Exchanger A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. The results show that. Distillation Heat Exchanger.

From www.alamy.com

Heat exchanger and distillation tower (refinery column) on oil refinery Distillation Heat Exchanger The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. A distillation column is a series of equilibrium. Distillation Heat Exchanger.

From www.heatexchangerjm.com

Best Shell Tube Heat Exchanger in Distillation Tower Column Manufacturer Distillation Heat Exchanger The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. For the case study under consideration, however, heat transfer. Distillation Heat Exchanger.

From www.slideserve.com

PPT Heat Exchanger Network Synthesis, Part III PowerPoint Distillation Heat Exchanger The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. Heat integration in a multicomponent separation can be industrialized. Distillation Heat Exchanger.

From www.freepik.com

Premium Photo The appearance of the distillation column and the main Distillation Heat Exchanger The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. A distillation column is a series of equilibrium. Distillation Heat Exchanger.

From www.eresson.com

Vacuum Distillation Plant with tube heat exchanger Distillation Heat Exchanger For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. Heat integration in. Distillation Heat Exchanger.

From www.alamy.com

Heat exchanger and pipelines on distillation tower and blue sky Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can. Distillation Heat Exchanger.

From www.freepik.com

Premium Photo Appearance of the distillation column and heat Distillation Heat Exchanger A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. For heat integrated distillation columns, the rectifying and stripping. Distillation Heat Exchanger.

From www.eresson.com

Vacuum Distillation Plant with tube heat exchanger Distillation Heat Exchanger The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. For heat integrated distillation columns, the rectifying and. Distillation Heat Exchanger.

From www.slideserve.com

PPT Heat Exchanger Network Synthesis, Part III PowerPoint Distillation Heat Exchanger For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. The results show that an improved heat exchange. Distillation Heat Exchanger.

From www.indiamart.com

Distillation Plant Equipment Heat Exchanger for Distilleries Plant Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute. Distillation Heat Exchanger.

From e3-tec.com

Heat Integrated Distillation E³Tec Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can. Distillation Heat Exchanger.

From www.freepik.com

Premium Photo The appearance of the distillation column and the main Distillation Heat Exchanger The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. Heat integration in a multicomponent separation can be. Distillation Heat Exchanger.

From mungfali.com

Heat Pump Distillation Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute. Distillation Heat Exchanger.

From bangwin.en.made-in-china.com

Pharmaceutical Shell and Tube Heat Exchanger for Reactor Distillation Distillation Heat Exchanger The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. For heat integrated distillation columns, the rectifying and stripping. Distillation Heat Exchanger.

From vitechgroupindia.com

Heat Exchanger Vitech Group Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. A distillation column is a series of equilibrium. Distillation Heat Exchanger.

From qlkj2012.en.made-in-china.com

Industrial Heat Exchanger Shell and Tube Condenser for Pharmaceutical Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. A distillation column is a series of equilibrium. Distillation Heat Exchanger.

From www.alamy.com

Large iron heat exchanger, tank, reactor, distillation column in Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. Heat integration in. Distillation Heat Exchanger.

From www.dreamstime.com

Large Iron Heat Exchanger, Tank, Reactor, Distillation Column in Distillation Heat Exchanger A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. Heat integration in. Distillation Heat Exchanger.

From www.torq-n-seal.com

The Uses Of Heat Exchangers In Oil Refineries Torq N' Seal® Distillation Heat Exchanger For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. Heat integration in a multicomponent separation can be industrialized by saving considerable energy. Distillation Heat Exchanger.

From www.slideserve.com

PPT Heat Exchanger Network Synthesis, Part III PowerPoint Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. Heat integration in a multicomponent separation can be. Distillation Heat Exchanger.

From vrcoolertech.en.made-in-china.com

Polished Shell Tube Heat Exchanger for Reactor Distillation Reflux Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute. Distillation Heat Exchanger.

From www.heatexchangerjm.com

Best Shell Tube Heat Exchanger in Distillation Tower Column Manufacturer Distillation Heat Exchanger The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. Heat integration in a multicomponent separation can be. Distillation Heat Exchanger.

From www.slideserve.com

PPT Heat Exchanger Network Synthesis, Part III PowerPoint Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. The results show. Distillation Heat Exchanger.

From www.researchgate.net

General Structure of an Internally Heat Integrated Distillation Column Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. Heat integration in a multicomponent separation can be industrialized by saving considerable energy and cost. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. The results show that an improved heat exchange. Distillation Heat Exchanger.

From www.exportersindia.com

D1C1 SA 240 TP 304 SS304 Heat Exchangers, for distillation, Outer Distillation Heat Exchanger A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. The results show. Distillation Heat Exchanger.

From www.dreamstime.com

Large Iron Heat Exchanger, Tank, Reactor, Distillation Column in Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation. Distillation Heat Exchanger.

From encyclopedia.pub

Applications of Heat Exchanger in Solar Desalination Encyclopedia MDPI Distillation Heat Exchanger The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. For heat integrated distillation columns, the rectifying and. Distillation Heat Exchanger.

From www.chemicals.co.uk

Distillation Of A Product From A Reaction The Chemistry Blog Distillation Heat Exchanger For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. Heat integration in a multicomponent separation can be industrialized by saving considerable energy. Distillation Heat Exchanger.

From www.alamy.com

Large iron heat exchanger, tank, reactor, distillation column in Distillation Heat Exchanger For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. A distillation column is a series of equilibrium flashes with two feeds and two product streams exiting liquid is at. For heat integrated distillation columns, the rectifying and stripping sections are internally coupled through heat exchangers. The results show. Distillation Heat Exchanger.

From www.semanticscholar.org

Figure 1 from Design of Heat Exchanger Network for VCM Distillation Distillation Heat Exchanger The results show that an improved heat exchange reduces the energy demand up to 64% compared to classic distillation columns, and thus can contribute to the reduction of carbon dioxide emissions. For the case study under consideration, however, heat transfer across very small temperature differences is required, which result in additional heat. A distillation column is a series of equilibrium. Distillation Heat Exchanger.