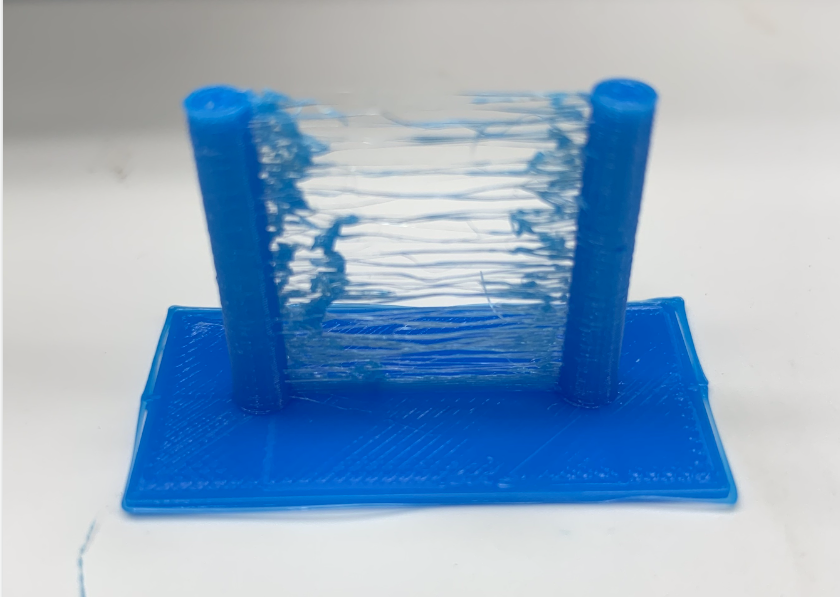

Filament Stringing Pla . This issue is caused by very high printing temperatures and/or using incorrect retraction settings. But they’re problems which can usually be resolved, with a little troubleshooting. Some of the major causes behind the stringing and oozing problem include: Overcome this issue with these five simple. Simple test to check your filament for moisture. Poor bed adhesion, layer splitting, blobs of filament, oozing, and stringing will be problems familiar to any 3d printing enthusiast. 3d printer stringing is a common problem, especially with flexible materials. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. This can be solved by. Try bumping your retraction length to 2m and leave the speed at 40mm/s. Retraction settings not being used; You can see this as a marginal line of filament left between the objects.

from forums.gratkit.com

But they’re problems which can usually be resolved, with a little troubleshooting. Retraction settings not being used; Overcome this issue with these five simple. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. Some of the major causes behind the stringing and oozing problem include: Simple test to check your filament for moisture. Try bumping your retraction length to 2m and leave the speed at 40mm/s. This issue is caused by very high printing temperatures and/or using incorrect retraction settings. You can see this as a marginal line of filament left between the objects. This can be solved by.

【Filament Solutions】How to fix PLA filament brittle? Gratkit

Filament Stringing Pla Some of the major causes behind the stringing and oozing problem include: This can be solved by. Try bumping your retraction length to 2m and leave the speed at 40mm/s. Simple test to check your filament for moisture. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. Poor bed adhesion, layer splitting, blobs of filament, oozing, and stringing will be problems familiar to any 3d printing enthusiast. Some of the major causes behind the stringing and oozing problem include: This issue is caused by very high printing temperatures and/or using incorrect retraction settings. You can see this as a marginal line of filament left between the objects. Overcome this issue with these five simple. 3d printer stringing is a common problem, especially with flexible materials. But they’re problems which can usually be resolved, with a little troubleshooting. Retraction settings not being used;

From the3dprinterbee.com

Best Methods & Settings to Prevent Stringing in 3D Printing Filament Stringing Pla Simple test to check your filament for moisture. Overcome this issue with these five simple. 3d printer stringing is a common problem, especially with flexible materials. This can be solved by. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. This issue is caused by very high printing temperatures. Filament Stringing Pla.

From makemeamaker.de

Geeetech Transparent PLA Filament im Test Filament Stringing Pla But they’re problems which can usually be resolved, with a little troubleshooting. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. Simple test to check your filament for moisture. Retraction settings not being used; Overcome this issue with these five simple. Try bumping your retraction length to 2m and. Filament Stringing Pla.

From americanfilament.us

How to fix stringing and oozing American Filament Filament Stringing Pla This issue is caused by very high printing temperatures and/or using incorrect retraction settings. Retraction settings not being used; Simple test to check your filament for moisture. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. But they’re problems which can usually be resolved, with a little troubleshooting. Overcome. Filament Stringing Pla.

From www.amazon.de

eSUN Light Weight PLA Filament 1.75 mm, 3D Printer Filament PLALW Filament Stringing Pla Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. This issue is caused by very high printing temperatures and/or using incorrect retraction settings. This can be solved by. Overcome this issue with these five simple. But they’re problems which can usually be resolved, with a little troubleshooting. Poor bed. Filament Stringing Pla.

From forums.gratkit.com

【Filament Solutions】How to fix PLA filament brittle? Gratkit Filament Stringing Pla You can see this as a marginal line of filament left between the objects. 3d printer stringing is a common problem, especially with flexible materials. Try bumping your retraction length to 2m and leave the speed at 40mm/s. Some of the major causes behind the stringing and oozing problem include: Stringing or oozing in 3d printing is when thin strings. Filament Stringing Pla.

From makemendel.com

How to Prevent and Fix PLA Stringing 4 Effective Tips 3D Printing Filament Stringing Pla Poor bed adhesion, layer splitting, blobs of filament, oozing, and stringing will be problems familiar to any 3d printing enthusiast. But they’re problems which can usually be resolved, with a little troubleshooting. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. This issue is caused by very high printing. Filament Stringing Pla.

From of3lia.com

【Filamento PLA】 Qué es y Cómo imprimirlo. Mi filamento favorito. Filament Stringing Pla This can be solved by. Retraction settings not being used; This issue is caused by very high printing temperatures and/or using incorrect retraction settings. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. Overcome this issue with these five simple. But they’re problems which can usually be resolved, with. Filament Stringing Pla.

From 3dprintmentor.com

PETG Stringing (8 Easy Solutions to Prevent Them) Filament Stringing Pla Try bumping your retraction length to 2m and leave the speed at 40mm/s. Retraction settings not being used; Overcome this issue with these five simple. Simple test to check your filament for moisture. 3d printer stringing is a common problem, especially with flexible materials. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts. Filament Stringing Pla.

From www.reddit.com

How can I fix this stringing issue? Seems like it's only when I'm using Filament Stringing Pla Simple test to check your filament for moisture. Overcome this issue with these five simple. Poor bed adhesion, layer splitting, blobs of filament, oozing, and stringing will be problems familiar to any 3d printing enthusiast. This issue is caused by very high printing temperatures and/or using incorrect retraction settings. This can be solved by. Stringing or oozing in 3d printing. Filament Stringing Pla.

From 3dprintbeginner.com

How To Dry Your Filament 3D Print Beginner Filament Stringing Pla You can see this as a marginal line of filament left between the objects. 3d printer stringing is a common problem, especially with flexible materials. Some of the major causes behind the stringing and oozing problem include: Retraction settings not being used; Simple test to check your filament for moisture. Try bumping your retraction length to 2m and leave the. Filament Stringing Pla.

From printingit3d.com

How To Clean Up Stringing on a 3D Print Printing It 3D Filament Stringing Pla Simple test to check your filament for moisture. But they’re problems which can usually be resolved, with a little troubleshooting. Some of the major causes behind the stringing and oozing problem include: This issue is caused by very high printing temperatures and/or using incorrect retraction settings. Retraction settings not being used; Poor bed adhesion, layer splitting, blobs of filament, oozing,. Filament Stringing Pla.

From www.reddit.com

First time using Fiber Wood filament. Any advice on stringing? Basic Filament Stringing Pla Some of the major causes behind the stringing and oozing problem include: You can see this as a marginal line of filament left between the objects. But they’re problems which can usually be resolved, with a little troubleshooting. Overcome this issue with these five simple. Simple test to check your filament for moisture. Poor bed adhesion, layer splitting, blobs of. Filament Stringing Pla.

From makemeamaker.de

Geeetech Transparent PLA Filament im Test Filament Stringing Pla But they’re problems which can usually be resolved, with a little troubleshooting. Try bumping your retraction length to 2m and leave the speed at 40mm/s. You can see this as a marginal line of filament left between the objects. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. Some. Filament Stringing Pla.

From www.reddit.com

eSun Filament Stringing (Black PLA+) FixMyPrint Filament Stringing Pla Some of the major causes behind the stringing and oozing problem include: Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. 3d printer stringing is a common problem, especially with flexible materials. You can see this as a marginal line of filament left between the objects. Try bumping your. Filament Stringing Pla.

From www.reddit.com

Linear advance stringing? Or stringy filament? r/ender3 Filament Stringing Pla This can be solved by. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. Simple test to check your filament for moisture. But they’re problems which can usually be resolved, with a little troubleshooting. Try bumping your retraction length to 2m and leave the speed at 40mm/s. Overcome this. Filament Stringing Pla.

From www.reddit.com

Stringing different pla filaments at 190c. Any ideas how to fix? r Filament Stringing Pla This can be solved by. This issue is caused by very high printing temperatures and/or using incorrect retraction settings. Simple test to check your filament for moisture. Try bumping your retraction length to 2m and leave the speed at 40mm/s. But they’re problems which can usually be resolved, with a little troubleshooting. Overcome this issue with these five simple. Retraction. Filament Stringing Pla.

From www.reddit.com

Stringing with Prusa supplied filament and Prusa PLA in Prusa slicer Filament Stringing Pla Some of the major causes behind the stringing and oozing problem include: You can see this as a marginal line of filament left between the objects. Simple test to check your filament for moisture. Retraction settings not being used; 3d printer stringing is a common problem, especially with flexible materials. Try bumping your retraction length to 2m and leave the. Filament Stringing Pla.

From www.reddit.com

PLA wood filament stringing more in commebts r/FixMyPrint Filament Stringing Pla Overcome this issue with these five simple. But they’re problems which can usually be resolved, with a little troubleshooting. This issue is caused by very high printing temperatures and/or using incorrect retraction settings. Try bumping your retraction length to 2m and leave the speed at 40mm/s. 3d printer stringing is a common problem, especially with flexible materials. Some of the. Filament Stringing Pla.

From forum.duet3d.com

Stringing with PLA Duet3D Forum Filament Stringing Pla Overcome this issue with these five simple. This can be solved by. You can see this as a marginal line of filament left between the objects. But they’re problems which can usually be resolved, with a little troubleshooting. Retraction settings not being used; Simple test to check your filament for moisture. Some of the major causes behind the stringing and. Filament Stringing Pla.

From www.reddit.com

New Filament Stringing ( r/3Dprinting Filament Stringing Pla Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. Poor bed adhesion, layer splitting, blobs of filament, oozing, and stringing will be problems familiar to any 3d printing enthusiast. This issue is caused by very high printing temperatures and/or using incorrect retraction settings. This can be solved by. Simple. Filament Stringing Pla.

From zonetuto.fr

Filament PLA vs PETG quelle différence ? Qui est le meilleur Filament Stringing Pla 3d printer stringing is a common problem, especially with flexible materials. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. You can see this as a marginal line of filament left between the objects. Poor bed adhesion, layer splitting, blobs of filament, oozing, and stringing will be problems familiar. Filament Stringing Pla.

From makemeamaker.de

Geeetech Transparent PLA Filament im Test Filament Stringing Pla Simple test to check your filament for moisture. Overcome this issue with these five simple. This issue is caused by very high printing temperatures and/or using incorrect retraction settings. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. Retraction settings not being used; This can be solved by. Try. Filament Stringing Pla.

From support.makerbot.com

How to fix stringing Filament Stringing Pla But they’re problems which can usually be resolved, with a little troubleshooting. This issue is caused by very high printing temperatures and/or using incorrect retraction settings. This can be solved by. Some of the major causes behind the stringing and oozing problem include: Retraction settings not being used; Simple test to check your filament for moisture. You can see this. Filament Stringing Pla.

From forum.prusa3d.com

Filament comes out at 200° Nozzle collects PLA stringing on prints Filament Stringing Pla Retraction settings not being used; Overcome this issue with these five simple. But they’re problems which can usually be resolved, with a little troubleshooting. You can see this as a marginal line of filament left between the objects. Some of the major causes behind the stringing and oozing problem include: Simple test to check your filament for moisture. Stringing or. Filament Stringing Pla.

From storables.com

How To Store Pla Filament Storables Filament Stringing Pla 3d printer stringing is a common problem, especially with flexible materials. Overcome this issue with these five simple. Try bumping your retraction length to 2m and leave the speed at 40mm/s. But they’re problems which can usually be resolved, with a little troubleshooting. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of. Filament Stringing Pla.

From eurekafilaments.ca

Temperature & Filament Stringing Eureka Filaments Filament Stringing Pla But they’re problems which can usually be resolved, with a little troubleshooting. Overcome this issue with these five simple. Some of the major causes behind the stringing and oozing problem include: Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. Simple test to check your filament for moisture. 3d. Filament Stringing Pla.

From www.reddit.com

PLA wood filament stringing more in commebts r/FixMyPrint Filament Stringing Pla This can be solved by. Overcome this issue with these five simple. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. Poor bed adhesion, layer splitting, blobs of filament, oozing, and stringing will be problems familiar to any 3d printing enthusiast. Retraction settings not being used; This issue is. Filament Stringing Pla.

From www.reddit.com

PLA wood filament stringing more in commebts r/FixMyPrint Filament Stringing Pla But they’re problems which can usually be resolved, with a little troubleshooting. Retraction settings not being used; You can see this as a marginal line of filament left between the objects. Some of the major causes behind the stringing and oozing problem include: Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of. Filament Stringing Pla.

From www.wevolver.com

How to diagnose, and fix, PLA stringing in 3D printing Filament Stringing Pla But they’re problems which can usually be resolved, with a little troubleshooting. 3d printer stringing is a common problem, especially with flexible materials. You can see this as a marginal line of filament left between the objects. Some of the major causes behind the stringing and oozing problem include: Simple test to check your filament for moisture. Poor bed adhesion,. Filament Stringing Pla.

From plasticranger.com

3D Printing Stringing Easy Solutions PlasticRanger Filament Stringing Pla Poor bed adhesion, layer splitting, blobs of filament, oozing, and stringing will be problems familiar to any 3d printing enthusiast. This can be solved by. Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. Overcome this issue with these five simple. Some of the major causes behind the stringing. Filament Stringing Pla.

From www.youtube.com

Change This Setting To Removed PLA Stringing YouTube Filament Stringing Pla Stringing or oozing in 3d printing is when thin strings of filament appear between different parts of your design, compromising. Retraction settings not being used; This can be solved by. But they’re problems which can usually be resolved, with a little troubleshooting. You can see this as a marginal line of filament left between the objects. Poor bed adhesion, layer. Filament Stringing Pla.

From www.lesimprimantes3d.fr

Stringing avec les filaments PLA GEEETECH Entraide Questions Filament Stringing Pla But they’re problems which can usually be resolved, with a little troubleshooting. Retraction settings not being used; Some of the major causes behind the stringing and oozing problem include: This can be solved by. Simple test to check your filament for moisture. Poor bed adhesion, layer splitting, blobs of filament, oozing, and stringing will be problems familiar to any 3d. Filament Stringing Pla.

From www.reddit.com

Getting significant stringing. Filament SUNLU White PLA. Bed 66 Filament Stringing Pla Simple test to check your filament for moisture. Poor bed adhesion, layer splitting, blobs of filament, oozing, and stringing will be problems familiar to any 3d printing enthusiast. This can be solved by. This issue is caused by very high printing temperatures and/or using incorrect retraction settings. You can see this as a marginal line of filament left between the. Filament Stringing Pla.

From makemeamaker.de

Geeetech Transparent PLA Filament im Test Filament Stringing Pla Simple test to check your filament for moisture. This issue is caused by very high printing temperatures and/or using incorrect retraction settings. 3d printer stringing is a common problem, especially with flexible materials. You can see this as a marginal line of filament left between the objects. Poor bed adhesion, layer splitting, blobs of filament, oozing, and stringing will be. Filament Stringing Pla.

From www.reddit.com

PLA wood filament stringing more in commebts r/FixMyPrint Filament Stringing Pla You can see this as a marginal line of filament left between the objects. Some of the major causes behind the stringing and oozing problem include: Poor bed adhesion, layer splitting, blobs of filament, oozing, and stringing will be problems familiar to any 3d printing enthusiast. 3d printer stringing is a common problem, especially with flexible materials. Try bumping your. Filament Stringing Pla.