Threaded Hole Fatigue . There are two main reasons why the root of the thread is rounded. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. 2.2.2 improving thread fatigue performance. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. For rolled threads, he suggests an average stress concentration factor of 2.2 for sae grades 0 to 2 and a factor of 3.0 for sae grades 4 to 8. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. Any changes that can be made to produce a more even load distribution in the. Firstly, the rounding reduces the stress concentration and hence facilitates. Fatigue failures in fasteners occur in the thread just under the nut.

from boneandjoint.org.uk

There are two main reasons why the root of the thread is rounded. For rolled threads, he suggests an average stress concentration factor of 2.2 for sae grades 0 to 2 and a factor of 3.0 for sae grades 4 to 8. Firstly, the rounding reduces the stress concentration and hence facilitates. 2.2.2 improving thread fatigue performance. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. Any changes that can be made to produce a more even load distribution in the. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. Fatigue failures in fasteners occur in the thread just under the nut.

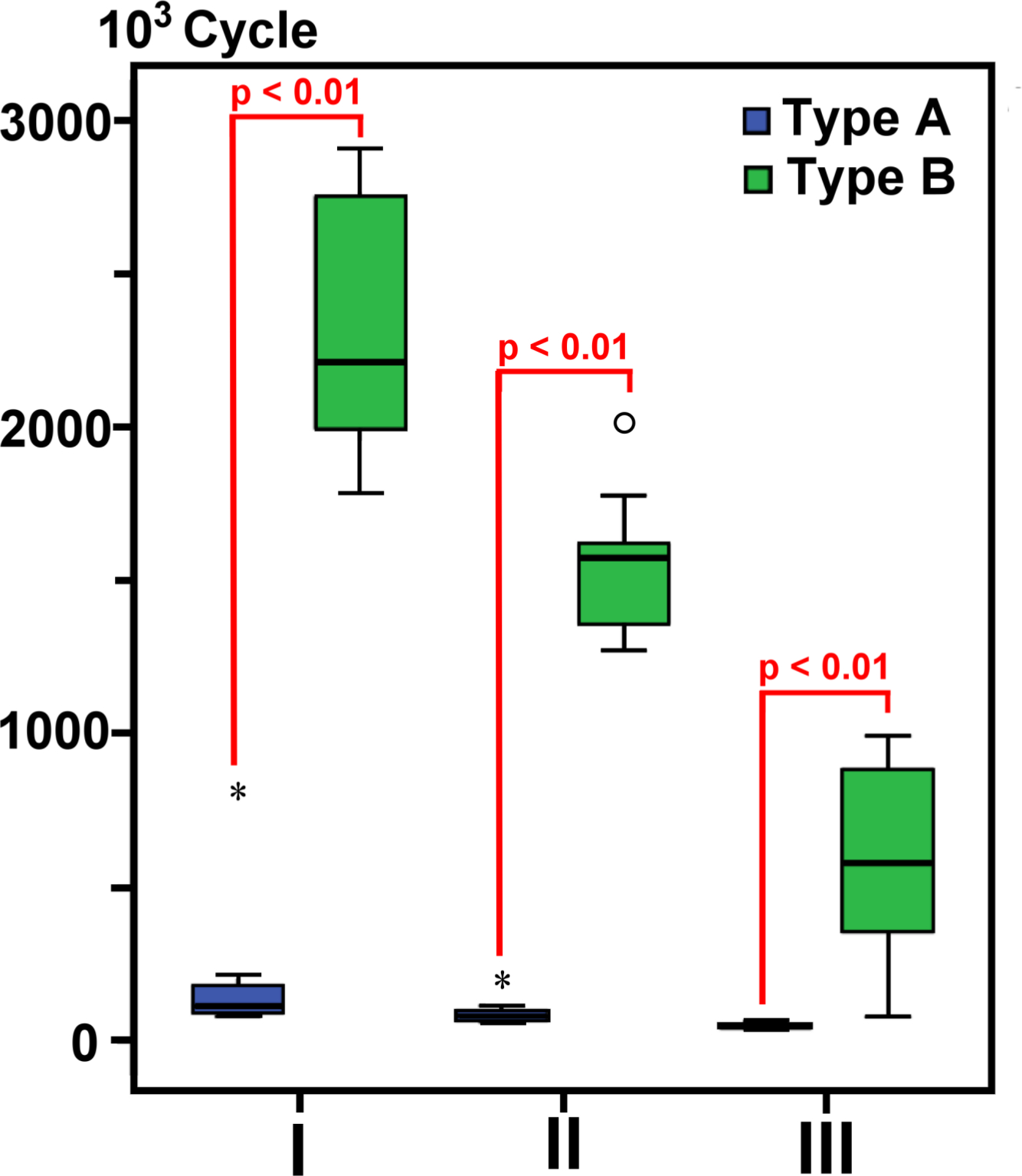

Halfthreaded holes markedly increase the fatigue life of locking

Threaded Hole Fatigue Any changes that can be made to produce a more even load distribution in the. There are two main reasons why the root of the thread is rounded. Firstly, the rounding reduces the stress concentration and hence facilitates. 2.2.2 improving thread fatigue performance. Any changes that can be made to produce a more even load distribution in the. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. Fatigue failures in fasteners occur in the thread just under the nut. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. For rolled threads, he suggests an average stress concentration factor of 2.2 for sae grades 0 to 2 and a factor of 3.0 for sae grades 4 to 8. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the.

From www.eng-tips.com

GD&T for Threaded holes Drafting Standards, GD&T & Tolerance Analysis Threaded Hole Fatigue There are two main reasons why the root of the thread is rounded. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. Fatigue failures in fasteners occur in the thread just under the nut. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware,. Threaded Hole Fatigue.

From www.xometry.com

What Are Blind Holes in Engineering and Machining? Xometry Threaded Hole Fatigue Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. Fatigue failures in fasteners occur in the thread just under the nut. Firstly, the rounding reduces the stress concentration. Threaded Hole Fatigue.

From www.teamrapidtooling.com

Threaded Holes Types, Methods, and Precautions Threaded Hole Fatigue Firstly, the rounding reduces the stress concentration and hence facilitates. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. 2.2.2 improving. Threaded Hole Fatigue.

From fgg-web.fgg.uni-lj.si

ESDEP LECTURE NOTE [WG12] Threaded Hole Fatigue Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. Fatigue failures in fasteners occur in the thread just under the nut. For rolled threads, he suggests an average. Threaded Hole Fatigue.

From cad.onshape.com

Hole/Thread Callout Threaded Hole Fatigue There are two main reasons why the root of the thread is rounded. 2.2.2 improving thread fatigue performance. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. For. Threaded Hole Fatigue.

From www.scribd.com

Fatigue Analysis of Threaded Holes PDF Linear Elasticity Threaded Hole Fatigue Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. Any changes that can be made to produce a more even load distribution in the. By using the thread rolling process, due to the effects of cold work hardening, there is residual. Threaded Hole Fatigue.

From brazilmetalparts.com

Threading Standard Holes Threaded Hole Fatigue Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. Any changes that can be made to produce a more even load. Threaded Hole Fatigue.

From www.yamawa.eu

Cored holes Direct tapping with no tool breakage Yamawa Threaded Hole Fatigue Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. There are two main reasons why the root of the thread is. Threaded Hole Fatigue.

From www.madearia.com

What are the different types of holes in engineering? Threaded Hole Fatigue Any changes that can be made to produce a more even load distribution in the. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. Fatigue failures in fasteners occur in the thread just under the nut. Firstly, the rounding reduces the stress concentration and hence facilitates. For rolled threads,. Threaded Hole Fatigue.

From www.madearia.com

What are the different types of holes in engineering? Threaded Hole Fatigue By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. For rolled threads, he suggests an average stress concentration factor of 2.2 for sae grades 0 to 2 and a factor of 3.0 for sae grades 4 to 8. 2.2.2 improving thread fatigue performance. Firstly, the rounding reduces the. Threaded Hole Fatigue.

From www.teamrapidtooling.com

Threaded Holes Types, Methods, and Precautions Threaded Hole Fatigue Fatigue failures in fasteners occur in the thread just under the nut. There are two main reasons why the root of the thread is rounded. For rolled threads, he suggests an average stress concentration factor of 2.2 for sae grades 0 to 2 and a factor of 3.0 for sae grades 4 to 8. Firstly, the rounding reduces the stress. Threaded Hole Fatigue.

From sendcutsend.com

Threaded Vs Tapped Holes for Laser Cutting Threaded Hole Fatigue There are two main reasons why the root of the thread is rounded. Firstly, the rounding reduces the stress concentration and hence facilitates. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. By using the thread rolling process, due to the. Threaded Hole Fatigue.

From www.youtube.com

Onshape How To Make A Threaded Hole YouTube Threaded Hole Fatigue Any changes that can be made to produce a more even load distribution in the. There are two main reasons why the root of the thread is rounded. For rolled threads, he suggests an average stress concentration factor of 2.2 for sae grades 0 to 2 and a factor of 3.0 for sae grades 4 to 8. Firstly, the rounding. Threaded Hole Fatigue.

From www.scribd.com

Bolt Thread and Head Fillet Stress Concentration Factors Screw Threaded Hole Fatigue 2.2.2 improving thread fatigue performance. For rolled threads, he suggests an average stress concentration factor of 2.2 for sae grades 0 to 2 and a factor of 3.0 for sae grades 4 to 8. Fatigue failures in fasteners occur in the thread just under the nut. There are two main reasons why the root of the thread is rounded. Firstly,. Threaded Hole Fatigue.

From boneandjoint.org.uk

Halfthreaded holes markedly increase the fatigue life of locking Threaded Hole Fatigue Firstly, the rounding reduces the stress concentration and hence facilitates. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. Fatigue failures. Threaded Hole Fatigue.

From www.eng-tips.com

GD&T for Threaded holes Drafting Standards, GD&T & Tolerance Analysis Threaded Hole Fatigue There are two main reasons why the root of the thread is rounded. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3). Threaded Hole Fatigue.

From www.villageinframe.com

Threaded Hole Callout Standard A Pictures Of Hole 2018 Threaded Hole Fatigue Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. 2.2.2 improving thread fatigue performance. For rolled threads, he suggests an average stress concentration factor of 2.2 for sae grades 0 to 2 and a factor of 3.0 for sae grades 4 to 8. By using the thread rolling process,. Threaded Hole Fatigue.

From home-building.wonderhowto.com

How to Remove a threaded stud from a threaded hole « Construction Threaded Hole Fatigue There are two main reasons why the root of the thread is rounded. Fatigue failures in fasteners occur in the thread just under the nut. Firstly, the rounding reduces the stress concentration and hence facilitates. Any changes that can be made to produce a more even load distribution in the. By using the thread rolling process, due to the effects. Threaded Hole Fatigue.

From www.cnclathing.com

Tapped Holes vs. Threaded Holes Process, Cost, Size, Material, Speed Threaded Hole Fatigue Any changes that can be made to produce a more even load distribution in the. There are two main reasons why the root of the thread is rounded. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. Firstly, the rounding reduces the stress concentration and hence facilitates. Hydrogen. Threaded Hole Fatigue.

From smrp.kellenams.com

Bolt Failures Why Learn to Recognize Mechanical Failure Modes Threaded Hole Fatigue Fatigue failures in fasteners occur in the thread just under the nut. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on. Threaded Hole Fatigue.

From www.valuedes.co.uk

What is Stress Concentration in FEA Analysis? Value Design Ltd Threaded Hole Fatigue Any changes that can be made to produce a more even load distribution in the. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. Firstly, the rounding reduces the stress concentration and hence facilitates. Bolts can fail by due to several reasons including (1) the bolt had not been. Threaded Hole Fatigue.

From engineerexcel.com

Thread Stripping Explained EngineerExcel Threaded Hole Fatigue There are two main reasons why the root of the thread is rounded. Fatigue failures in fasteners occur in the thread just under the nut. For rolled threads, he suggests an average stress concentration factor of 2.2 for sae grades 0 to 2 and a factor of 3.0 for sae grades 4 to 8. By using the thread rolling process,. Threaded Hole Fatigue.

From fineartamerica.com

Threaded Hole by Gary Chapple Threaded Hole Fatigue Fatigue failures in fasteners occur in the thread just under the nut. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. For rolled threads, he suggests an average stress concentration factor of 2.2 for sae grades 0 to 2 and a factor of 3.0 for sae grades 4. Threaded Hole Fatigue.

From www.solidsolutions.ie

How to Thread a Hole in SOLIDWORKS Threaded Hole Fatigue Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. Any changes that can be made to produce a more even load distribution in the. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. 2.2.2 improving thread fatigue. Threaded Hole Fatigue.

From www.ifixit.com

How to Fix a Cross Threaded or Stripped Hole in Aluminum iFixit Threaded Hole Fatigue Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. There are two main reasons why the root of the thread is. Threaded Hole Fatigue.

From www.clinbiomech.com

Effects of merged holes, partial thread removal, and offset holes on Threaded Hole Fatigue Firstly, the rounding reduces the stress concentration and hence facilitates. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. Hydrogen. Threaded Hole Fatigue.

From www.protolabs.com

Threading Coil Inserts Threaded Hole Fatigue 2.2.2 improving thread fatigue performance. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. There are two main reasons why the root of the thread is rounded. Any changes that can be made to produce a more even load distribution in the. Fatigue failures in fasteners occur in the. Threaded Hole Fatigue.

From www.nord-lock.com

How Much Thread Engagement Is Needed in a Tapped Hole? NordLock Group Threaded Hole Fatigue Firstly, the rounding reduces the stress concentration and hence facilitates. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. There are two main reasons why the root of the thread is rounded. 2.2.2 improving thread fatigue performance. Any changes that can be made to produce a more even. Threaded Hole Fatigue.

From motormission.com

Damged and Stripped Bolt Hole Threads Machining, Repair and Insert Threaded Hole Fatigue For rolled threads, he suggests an average stress concentration factor of 2.2 for sae grades 0 to 2 and a factor of 3.0 for sae grades 4 to 8. Fatigue failures in fasteners occur in the thread just under the nut. 2.2.2 improving thread fatigue performance. Bolts can fail by due to several reasons including (1) the bolt had not. Threaded Hole Fatigue.

From www.slideserve.com

PPT ME 350 Lecture 5 Chapter 22 PowerPoint Presentation, free Threaded Hole Fatigue Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. Firstly, the rounding reduces the stress concentration and hence facilitates. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. By using. Threaded Hole Fatigue.

From www.assemblymag.com

Why Threaded Fasteners Fail 20180406 Assembly Magazine Threaded Hole Fatigue Firstly, the rounding reduces the stress concentration and hence facilitates. There are two main reasons why the root of the thread is rounded. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. For rolled threads, he suggests an average stress concentration. Threaded Hole Fatigue.

From www.dreamstime.com

Threaded Hole And Counter Bore Holes On Stainless Steel Plate Stock Threaded Hole Fatigue Any changes that can be made to produce a more even load distribution in the. For rolled threads, he suggests an average stress concentration factor of 2.2 for sae grades 0 to 2 and a factor of 3.0 for sae grades 4 to 8. 2.2.2 improving thread fatigue performance. There are two main reasons why the root of the thread. Threaded Hole Fatigue.

From www.researchgate.net

(PDF) Halfthreaded holes markedly increase the fatigue life of locking Threaded Hole Fatigue There are two main reasons why the root of the thread is rounded. Firstly, the rounding reduces the stress concentration and hence facilitates. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently preloaded/tension during installation, (2) had lost its preload during service, (3) the. 2.2.2 improving thread fatigue performance. By using the thread. Threaded Hole Fatigue.

From www.kemalmfg.com

How to Make Difference Between Threaded Holes and Tapped Holes for CNC Threaded Hole Fatigue Firstly, the rounding reduces the stress concentration and hence facilitates. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. There are two main reasons why the root of the thread is rounded. Bolts can fail by due to several reasons including (1) the bolt had not been sufficiently. Threaded Hole Fatigue.

From smicut.com

ThreadBurr Solid Carbide Thread Mills from SmiCut Threaded Hole Fatigue Any changes that can be made to produce a more even load distribution in the. By using the thread rolling process, due to the effects of cold work hardening, there is residual compressive stress on the. Hydrogen embrittlement, stress corrosion cracking, mismatched hardware, fatigue and mechanical failure are the five ways that bolts and screws fail. For rolled threads, he. Threaded Hole Fatigue.