Pulley Belt Tension Formula . How to calculate pulley belt length and distance between wheels. Belt tensions, pretensions, torques, power and configurations. This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). Calculation for the tension in a pulley and belt system. First, the effective belt tension (te) must be calculated. To calculate the tension in a pulley system driven by a belt, we use the. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. Additional tension required to prevent slippage. This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective tension, te, and slack side tension, t2. V and flat belt design guide, equations, and information. In this article we’re going to be looking at some pulley belt calculations with worked examples. Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. Total tension to move belt and load horizontally: E 2 = e+e 1.

from www.tec-science.com

To calculate the tension in a pulley system driven by a belt, we use the. Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. Total tension to move belt and load horizontally: Belt tensions, pretensions, torques, power and configurations. First, the effective belt tension (te) must be calculated. Additional tension required to prevent slippage. V and flat belt design guide, equations, and information. In this article we’re going to be looking at some pulley belt calculations with worked examples. E 2 = e+e 1. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter.

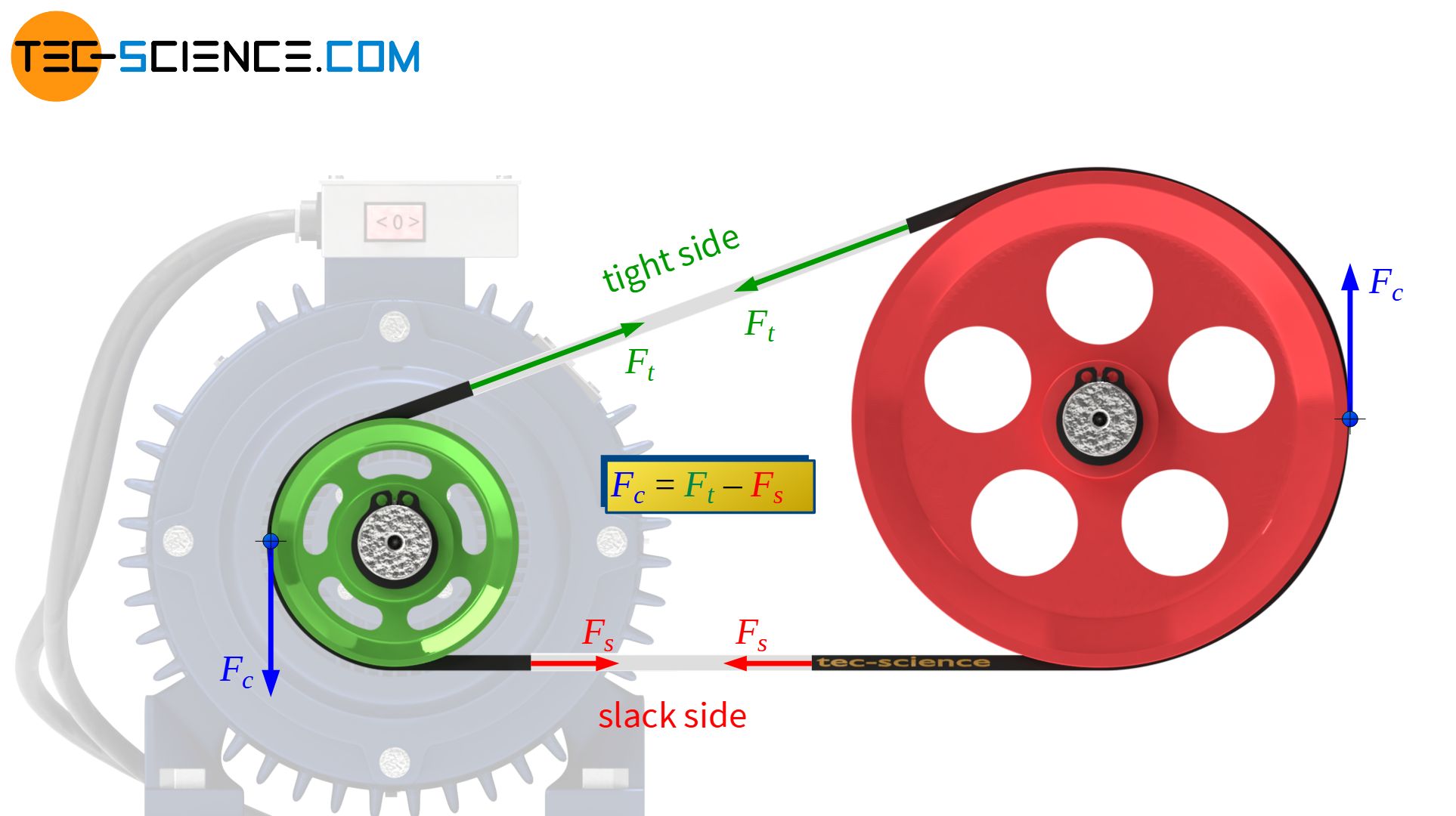

Slippage of the belt in belt drives tecscience

Pulley Belt Tension Formula First, the effective belt tension (te) must be calculated. V and flat belt design guide, equations, and information. E 2 = e+e 1. Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. Belt tensions, pretensions, torques, power and configurations. This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective tension, te, and slack side tension, t2. First, the effective belt tension (te) must be calculated. Total tension to move belt and load horizontally: This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. Additional tension required to prevent slippage. In this article we’re going to be looking at some pulley belt calculations with worked examples. To calculate the tension in a pulley system driven by a belt, we use the. Calculation for the tension in a pulley and belt system. How to calculate pulley belt length and distance between wheels.

From www.doubtnut.com

What is Vbelt. Drive the expression of Ratio in belt tension for Pulley Belt Tension Formula Belt tensions, pretensions, torques, power and configurations. How to calculate pulley belt length and distance between wheels. Calculation for the tension in a pulley and belt system. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. Total tension to move belt and load horizontally: First, the effective belt tension (te) must be calculated.. Pulley Belt Tension Formula.

From www.youtube.com

How to calculate tension in a multiple pulley system YouTube Pulley Belt Tension Formula Additional tension required to prevent slippage. Calculation for the tension in a pulley and belt system. This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). V and flat belt design guide, equations, and information. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter.. Pulley Belt Tension Formula.

From www.linearmotiontips.com

How to calculate motor drive torque for belt and pulley systems Pulley Belt Tension Formula To calculate the tension in a pulley system driven by a belt, we use the. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. Additional tension required to prevent slippage. Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. In this. Pulley Belt Tension Formula.

From www.youtube.com

Belt Drive Pulley Diameter and Belt Speed Calculation Belt Drive Basics Types of Belt Drives Pulley Belt Tension Formula Belt tensions, pretensions, torques, power and configurations. Additional tension required to prevent slippage. Total tension to move belt and load horizontally: You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. To calculate the tension in a pulley system driven by a belt, we use the. E 2 = e+e 1. Calculation for the. Pulley Belt Tension Formula.

From www.youtube.com

Belt Drive (ratio of tension for flat belt) YouTube Pulley Belt Tension Formula First, the effective belt tension (te) must be calculated. E 2 = e+e 1. Belt tensions, pretensions, torques, power and configurations. To calculate the tension in a pulley system driven by a belt, we use the. This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective tension, te, and slack side tension,. Pulley Belt Tension Formula.

From engineeringdiscoveries.com

Types Of Pulleys Systems Engineering Discoveries Pulley Belt Tension Formula How to calculate pulley belt length and distance between wheels. Belt tensions, pretensions, torques, power and configurations. Total tension to move belt and load horizontally: First, the effective belt tension (te) must be calculated. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. V and flat belt design guide, equations, and information. In. Pulley Belt Tension Formula.

From www.tec-science.com

Slippage of the belt in belt drives tecscience Pulley Belt Tension Formula E 2 = e+e 1. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. To calculate the tension in a pulley system driven by a belt, we use the. Additional tension required to prevent slippage. This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective. Pulley Belt Tension Formula.

From physics.stackexchange.com

newtonian mechanics What is the "pulley formula" and how to use it? Physics Stack Exchange Pulley Belt Tension Formula This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). Calculation for the tension in a pulley and belt system. In this article we’re going to be looking at some pulley belt calculations with worked examples. V and flat belt design guide, equations, and information. You can use it to calculate. Pulley Belt Tension Formula.

From www.youtube.com

How to calculate tension in a multiple pulley system on a slope YouTube Pulley Belt Tension Formula V and flat belt design guide, equations, and information. Belt tensions, pretensions, torques, power and configurations. Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. E 2 = e+e 1. This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective. Pulley Belt Tension Formula.

From www.brecoflex.com

Timing Belt Drive Definitions & Formulas Pulley Belt Tension Formula E 2 = e+e 1. First, the effective belt tension (te) must be calculated. This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). How to calculate pulley belt length and distance between wheels. Additional tension required to prevent slippage. Belt tensions, pretensions, torques, power and configurations. You can use it. Pulley Belt Tension Formula.

From www.tec-science.com

Slippage of the belt in belt drives tecscience Pulley Belt Tension Formula Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). Total tension to move belt and load horizontally: First, the effective belt tension (te) must be calculated. How to calculate. Pulley Belt Tension Formula.

From maztezsenior.blogspot.com

Free Body Diagram Tension Pulley Maztezsenior Pulley Belt Tension Formula In this article we’re going to be looking at some pulley belt calculations with worked examples. How to calculate pulley belt length and distance between wheels. First, the effective belt tension (te) must be calculated. This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective tension, te, and slack side tension, t2.. Pulley Belt Tension Formula.

From www.numerade.com

SOLVED A countershaft carrying two Vbelt pulleys is shown in the figure. Pulley A receives Pulley Belt Tension Formula In this article we’re going to be looking at some pulley belt calculations with worked examples. This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). First, the effective belt tension (te) must be calculated. To calculate the tension in a pulley system driven by a belt, we use the. V. Pulley Belt Tension Formula.

From www.tec-science.com

Calculation of the bearing force for belt drives tecscience Pulley Belt Tension Formula Additional tension required to prevent slippage. V and flat belt design guide, equations, and information. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. In this article we’re going to be looking at some pulley belt calculations with worked examples. First, the effective belt tension (te) must be calculated. This pulley calculator analyzes. Pulley Belt Tension Formula.

From www.youtube.com

Pulley Physics Problem Finding Acceleration and Tension Force YouTube Pulley Belt Tension Formula Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. Belt tensions, pretensions, torques, power and configurations. First, the effective belt tension (te) must be calculated. To calculate the tension in a pulley system driven by a belt, we use the. This pulley calculator analyzes a system of two. Pulley Belt Tension Formula.

From www.youtube.com

How to Solve a Problem with Multiple Pulleys Finding the Tension YouTube Pulley Belt Tension Formula E 2 = e+e 1. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. How to calculate pulley belt length and distance between wheels. Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. Total tension to move belt and load horizontally:. Pulley Belt Tension Formula.

From www.youtube.com

Initial Tension in the belt YouTube Pulley Belt Tension Formula Belt tensions, pretensions, torques, power and configurations. To calculate the tension in a pulley system driven by a belt, we use the. Calculation for the tension in a pulley and belt system. This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective tension, te, and slack side tension, t2. V and flat. Pulley Belt Tension Formula.

From www.youtube.com

Pulley Problem using Work Energy Theorem YouTube Pulley Belt Tension Formula Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. In this article we’re going to be looking at some pulley belt calculations with worked examples. E 2 = e+e 1. First, the effective belt tension (te) must be calculated. This pulley calculator analyzes a system of two pulleys. Pulley Belt Tension Formula.

From www.youtube.com

Compound Gears, Pulley & Belt Systems, and Sprockets Examples YouTube Pulley Belt Tension Formula To calculate the tension in a pulley system driven by a belt, we use the. Calculation for the tension in a pulley and belt system. Total tension to move belt and load horizontally: This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective tension, te, and slack side tension, t2. Te is. Pulley Belt Tension Formula.

From www.hvacrschool.com

Some Belt Tensioning Thoughts HVAC School Pulley Belt Tension Formula Belt tensions, pretensions, torques, power and configurations. V and flat belt design guide, equations, and information. Calculation for the tension in a pulley and belt system. Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. This video explains how to calculate conveyor belt tensions in bulk materials handling. Pulley Belt Tension Formula.

From www.youtube.com

How to solve for tension in pulley problems physics YouTube Pulley Belt Tension Formula To calculate the tension in a pulley system driven by a belt, we use the. Calculation for the tension in a pulley and belt system. Belt tensions, pretensions, torques, power and configurations. E 2 = e+e 1. Additional tension required to prevent slippage. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. This. Pulley Belt Tension Formula.

From www.pinterest.ca

Belt Length Calculator Distance Between Pulleys Calculator Pulley, Electrical projects Pulley Belt Tension Formula You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. To calculate the tension in a pulley system driven by a belt, we use the. This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). Calculation for the tension in a pulley and belt system.. Pulley Belt Tension Formula.

From chart.conaresvirtual.edu.sv

V Belt Tensioning Chart Pulley Belt Tension Formula In this article we’re going to be looking at some pulley belt calculations with worked examples. Total tension to move belt and load horizontally: First, the effective belt tension (te) must be calculated. To calculate the tension in a pulley system driven by a belt, we use the. V and flat belt design guide, equations, and information. This pulley calculator. Pulley Belt Tension Formula.

From www.youtube.com

How to Calculate Belt Tensions in Bulk Handling Belt Conveyors YouTube Pulley Belt Tension Formula You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. To calculate the tension in a pulley system driven by a belt, we use the. Calculation for the tension in a pulley and belt system. This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive).. Pulley Belt Tension Formula.

From www.youtube.com

Belt Drive Speed Calculation How to Select Pulley size For Belt Drive Belt Drive YouTube Pulley Belt Tension Formula Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. To calculate the tension in a pulley system driven by a belt, we use the. First, the effective belt tension (te) must be calculated. Total tension to move belt and load horizontally: This video explains how to calculate conveyor. Pulley Belt Tension Formula.

From www.linearmotiontips.com

How to measue synchronous (toothed) belt tension Pulley Belt Tension Formula How to calculate pulley belt length and distance between wheels. Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. This pulley calculator analyzes a system of two pulleys joined by a conveyor. Pulley Belt Tension Formula.

From www.youtube.com

Ratio of Tension on tight and Slack side of Flat belt YouTube Pulley Belt Tension Formula V and flat belt design guide, equations, and information. First, the effective belt tension (te) must be calculated. How to calculate pulley belt length and distance between wheels. This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective tension, te, and slack side tension, t2. To calculate the tension in a pulley. Pulley Belt Tension Formula.

From www.youtube.com

Calculating Initial Tension Requirements for Vee Belts YouTube Pulley Belt Tension Formula First, the effective belt tension (te) must be calculated. Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective tension, te, and slack side tension, t2. How to calculate pulley belt. Pulley Belt Tension Formula.

From www.pfeiferindustries.com

Timing Belt Pulley Diameter Charts Pfeifer Industries Pulley Belt Tension Formula E 2 = e+e 1. How to calculate pulley belt length and distance between wheels. To calculate the tension in a pulley system driven by a belt, we use the. Belt tensions, pretensions, torques, power and configurations. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. Total tension to move belt and load. Pulley Belt Tension Formula.

From www.youtube.com

HOW TO FIND BELT DRIVE PULLEY RPM AND DIAMETER BY CALCULATION Rotating & Static Equipments Pulley Belt Tension Formula Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. Total tension to move belt and load horizontally: Calculation for the tension in a pulley and belt system. This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective tension, te, and. Pulley Belt Tension Formula.

From www.tec-science.com

Maximum belt stress in belt drives tecscience Pulley Belt Tension Formula Additional tension required to prevent slippage. In this article we’re going to be looking at some pulley belt calculations with worked examples. This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective tension, te, and slack side tension, t2. How to calculate pulley belt length and distance between wheels. To calculate the. Pulley Belt Tension Formula.

From www.youtube.com

Tension & Pulley Example 3 YouTube Pulley Belt Tension Formula This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). V and flat belt design guide, equations, and information. You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. Calculation for the tension in a pulley and belt system. This video explains how to calculate. Pulley Belt Tension Formula.

From monica-well-dudley.blogspot.com

Is Tension the Same on Both Sides of a Pulley MonicawellDudley Pulley Belt Tension Formula Additional tension required to prevent slippage. Te is the sum of the tension required to move the empty belt (tc), the tension required to move the load. Belt tensions, pretensions, torques, power and configurations. In this article we’re going to be looking at some pulley belt calculations with worked examples. V and flat belt design guide, equations, and information. First,. Pulley Belt Tension Formula.

From www.youtube.com

Tension & Pulley Example 2 YouTube Pulley Belt Tension Formula To calculate the tension in a pulley system driven by a belt, we use the. This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). You can use it to calculate the pulley rpm (revolutions per minute), but also its diameter. Belt tensions, pretensions, torques, power and configurations. Total tension to. Pulley Belt Tension Formula.

From www.youtube.com

Initial tension in the belt drive YouTube Pulley Belt Tension Formula V and flat belt design guide, equations, and information. How to calculate pulley belt length and distance between wheels. Total tension to move belt and load horizontally: Calculation for the tension in a pulley and belt system. This video explains how to calculate conveyor belt tensions in bulk materials handling conveyors, with emphasis on effective tension, te, and slack side. Pulley Belt Tension Formula.