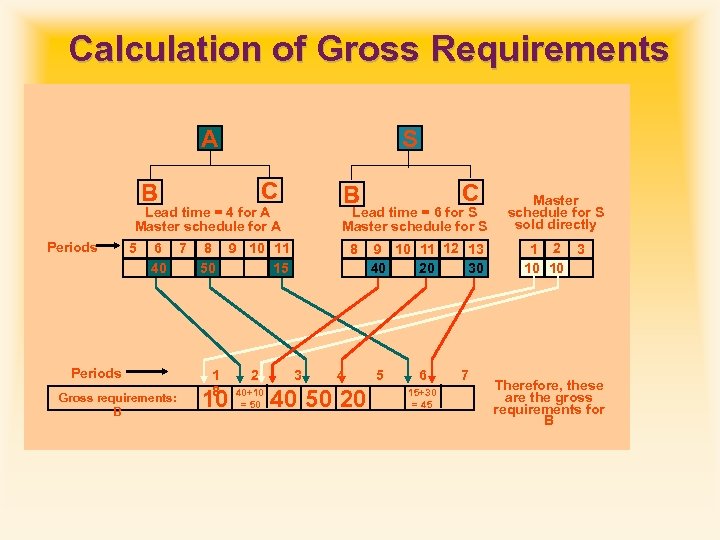

Explain Gross Requirements . The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. It consists of three primary steps: Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for production is required. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp converts the master schedule of production into a detailed. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product.

from present5.com

The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Mrp converts the master schedule of production into a detailed. It consists of three primary steps: Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for production is required. Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product.

Materials Requirements Planning Collins Industries ØLargest manufacturer

Explain Gross Requirements Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Mrp converts the master schedule of production into a detailed. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. It consists of three primary steps: Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for production is required.

From www.asprova.jp

Calculating Gross Requirements Material Planning MRP glossary of Explain Gross Requirements Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling.. Explain Gross Requirements.

From www.youtube.com

Gross requirements plan Part 1 YouTube Explain Gross Requirements Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for production is required. Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. The mrp system takes the master schedule for end items and determines the gross quantities of. Explain Gross Requirements.

From www.erp-information.com

What are Net Requirements? (Formula, Planning, Calculations, and Example) Explain Gross Requirements Mrp converts the master schedule of production into a detailed. The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. Material requirements planning. Explain Gross Requirements.

From www.chegg.com

Solved The gross requirements for items A and H are Explain Gross Requirements Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. It consists of three primary steps: Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for production is required. Mrp converts the master schedule of production into a detailed. Gross requirements refer to the. Explain Gross Requirements.

From www.chegg.com

Solved The gross requirements of a given part or component Explain Gross Requirements The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp converts the master schedule of production into a detailed. Learn how to use mrp (material requirement planning) to plan production and procurement. Explain Gross Requirements.

From www.youtube.com

MRP Gross Requirements Plan YouTube Explain Gross Requirements The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Mrp converts the master schedule of production into a detailed. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Learn the basic idea, assumptions, and steps of mrp, a method to determine. Explain Gross Requirements.

From www.scribd.com

Gross Requirement Planning PDF Explain Gross Requirements Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. The mrp. Explain Gross Requirements.

From www.erp-information.com

What are Gross Requirements 3 main Characteristics Explain Gross Requirements Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for production is required. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. It consists of three primary steps: The mrp system takes the master schedule for end items and determines the gross quantities of components. Explain Gross Requirements.

From www.youtube.com

Calculate Gross Requirement YouTube Explain Gross Requirements Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for production is required. The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished. Explain Gross Requirements.

From www.erp-information.com

What are Gross Requirements? (Characteristics, Formula & Plan) Explain Gross Requirements Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure.. Explain Gross Requirements.

From www.chegg.com

Solved Using the gross requirements schedule below*, prepare Explain Gross Requirements Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. It consists of three primary steps: Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. Learn how to use mrp (material requirement planning) to plan production. Explain Gross Requirements.

From www.slideserve.com

PPT Chapter 6 Material Requirements Planning PowerPoint Presentation Explain Gross Requirements Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure.. Explain Gross Requirements.

From www.erp-information.com

What are Gross Requirements? (Characteristics, Formula & Plan) Explain Gross Requirements The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or. Explain Gross Requirements.

From www.slideserve.com

PPT Manufacturing Planning and Control PowerPoint Presentation, free Explain Gross Requirements The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product.. Explain Gross Requirements.

From efinancemanagement.com

Methods for Estimating Working Capital Requirement Explain Gross Requirements Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. It consists of three primary steps: Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Learn the basic idea, assumptions, and steps of mrp,. Explain Gross Requirements.

From www.slideserve.com

PPT Material Requirements Planning (MRP) and ERP PowerPoint Explain Gross Requirements Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Mrp converts the master schedule of production into a detailed. It consists of. Explain Gross Requirements.

From www.slideserve.com

PPT Material Requirements Planning (MRP) PowerPoint Presentation Explain Gross Requirements Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. It consists of three primary steps: Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for production is required. Learn how to use mrp (material requirement planning) to plan. Explain Gross Requirements.

From www.chegg.com

Solved Using the gross requirements schedule below*, prepare Chegg Explain Gross Requirements Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. It consists of three primary steps: Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Mrp. Explain Gross Requirements.

From www.chegg.com

Solved The gross requirements for items A and B are Explain Gross Requirements Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. Mrp converts the master schedule of production into a detailed. The mrp system takes the master schedule. Explain Gross Requirements.

From www.financestrategists.com

Material Requirements Planning (MRP) Definition & Process Explain Gross Requirements Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Mrp converts the. Explain Gross Requirements.

From www.chegg.com

Solved The product structure tree for product A and the data Explain Gross Requirements Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for production is required. It consists of three primary steps: Mrp converts the master schedule of production into a detailed.. Explain Gross Requirements.

From www.chegg.com

Solved Using the gross requirements schedule below*, prepare Explain Gross Requirements The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Material requirements planning. Explain Gross Requirements.

From www.slideserve.com

PPT Material Requirements Planning (MRP) and ERP PowerPoint Explain Gross Requirements Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. It consists of three primary steps: Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Material requirements planning (mrp) is a planning and control system for. Explain Gross Requirements.

From www.chegg.com

Solved Using the gross requirements schedule below*, prepare Explain Gross Requirements Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. Mrp converts the master schedule of production into a detailed. Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. The mrp system takes the master schedule. Explain Gross Requirements.

From www.chegg.com

Solved The MRP gross requirements for Item X are shown here Explain Gross Requirements Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Mrp converts the master schedule of production into a detailed. It consists of three primary. Explain Gross Requirements.

From www.chegg.com

Solved Using gross requirements schedule below*, prepare an Explain Gross Requirements Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. It consists of three primary steps: Mrp converts the master schedule of production into a detailed. Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Material requirements planning (mrp). Explain Gross Requirements.

From www.slideserve.com

PPT Material Requirements Planning (MRP) and ERP PowerPoint Explain Gross Requirements Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture a product. It consists of three primary steps: Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for. Explain Gross Requirements.

From www.slideserve.com

PPT MRP PowerPoint Presentation, free download ID5644234 Explain Gross Requirements Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Gross requirements refer to the total quantity of an item or component that is needed to meet production. Explain Gross Requirements.

From www.asprova.jp

Calculating Gross Requirements Material Planning MRP glossary of Explain Gross Requirements Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. Gross requirements refer to the total quantity of an item or component that is needed to meet production. Explain Gross Requirements.

From www.chegg.com

Solved Using the gross requirements schedule below*, prepare Explain Gross Requirements Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. It consists of three primary steps: Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for production is required. Material requirements planning (mrp) is a system for calculating the. Explain Gross Requirements.

From www.erp-information.com

What are net requirements calculations and 1 example Explain Gross Requirements It consists of three primary steps: Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for production is required. Material requirements planning (mrp) is a planning and control system. Explain Gross Requirements.

From www.slideserve.com

PPT ISEN 315 Spring 2011 Dr. Gary Gaukler PowerPoint Presentation Explain Gross Requirements Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific.. Explain Gross Requirements.

From en.ppt-online.org

Material requirements planning (MRP). Chapter 14 online presentation Explain Gross Requirements The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. It consists of three primary steps: Material requirements planning (mrp) is a planning and control system for inventory, production, and scheduling. Mrp converts the master schedule of production into a detailed. Learn how to use mrp (material requirement. Explain Gross Requirements.

From present5.com

Materials Requirements Planning Collins Industries ØLargest manufacturer Explain Gross Requirements Learn the basic idea, assumptions, and steps of mrp, a method to determine when material for production is required. Gross requirements refer to the total quantity of an item or component that is needed to meet production schedules or customer demand over a specific. Material requirements planning (mrp) is a system for calculating the materials and components needed to manufacture. Explain Gross Requirements.

From www.erp-information.com

What are Gross Requirements? (Characteristics, Formula & Plan) Explain Gross Requirements The mrp system takes the master schedule for end items and determines the gross quantities of components required from the product structure. It consists of three primary steps: Learn how to use mrp (material requirement planning) to plan production and procurement orders based on demand for finished products. Mrp converts the master schedule of production into a detailed. Learn the. Explain Gross Requirements.