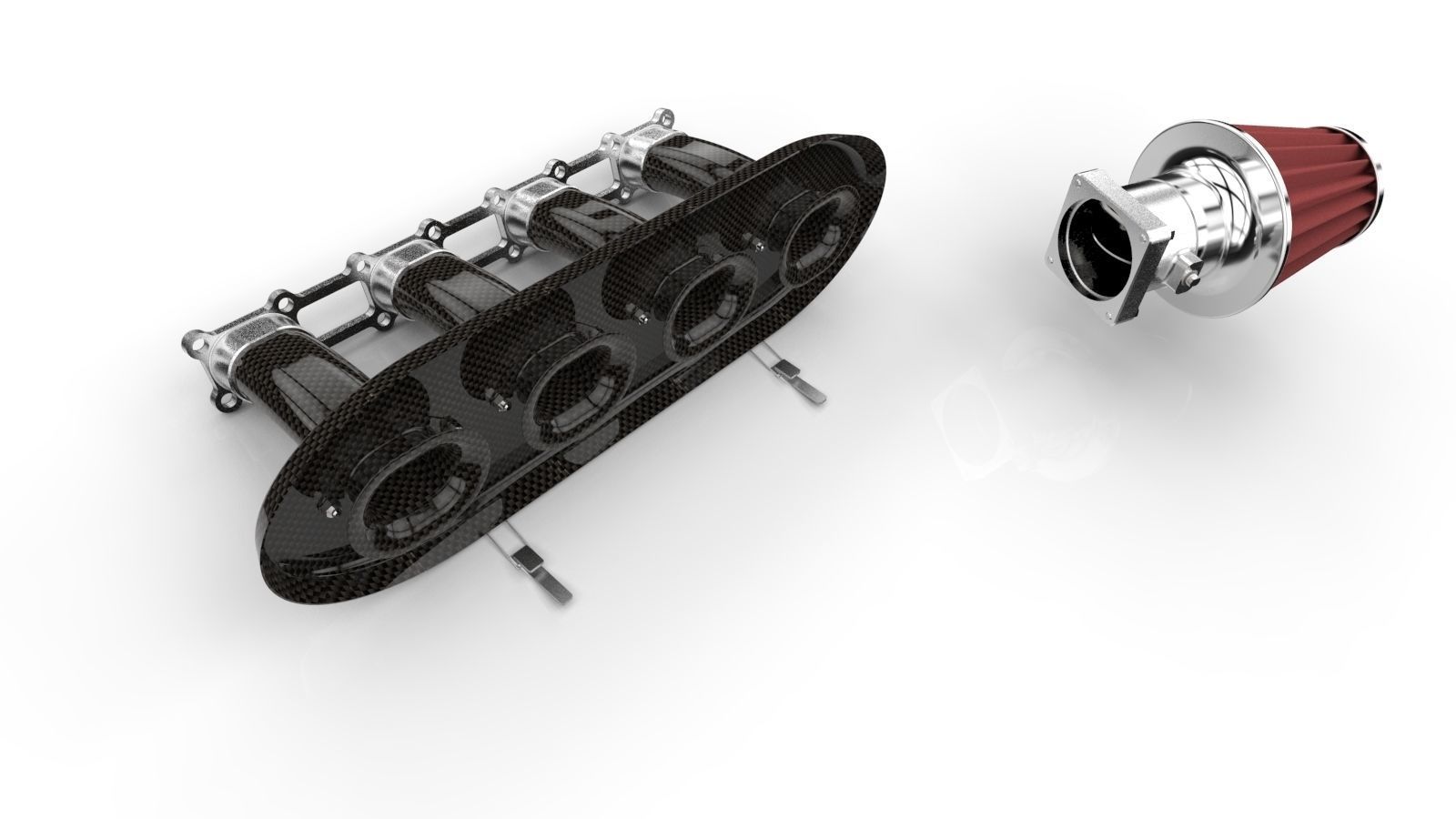

Carbon Fiber 3D Printed Intake Manifold . My plan is to 3d print the intake in carbon fiber nylon, which has a temperature rating just above engine temperatures (240f. The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing process. If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. Produced in windform sp the intake manifold is mounted directly to engine. You can also 3d print bucks for mold making or even molds depending on the geometry and use them to form carbon fiber fairly easily. Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. The deltawing intake manifold is 3d printed on crp usa’s additive manufacturing sls technology. Deltawing racing cars have run 4 copies of the intake since july 2013. Polycarbonate /10% long fiber carbon fiber. 8mm is a pretty length for a fiber and we get get alignment in the printing. Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was created.

from www.cgtrader.com

Polycarbonate /10% long fiber carbon fiber. My plan is to 3d print the intake in carbon fiber nylon, which has a temperature rating just above engine temperatures (240f. Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was created. 8mm is a pretty length for a fiber and we get get alignment in the printing. The deltawing intake manifold is 3d printed on crp usa’s additive manufacturing sls technology. Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. Deltawing racing cars have run 4 copies of the intake since july 2013. Produced in windform sp the intake manifold is mounted directly to engine. The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing process. If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds.

Carbon intake manifold 3D Model .ige .igs .iges .stp

Carbon Fiber 3D Printed Intake Manifold Produced in windform sp the intake manifold is mounted directly to engine. 8mm is a pretty length for a fiber and we get get alignment in the printing. The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing process. If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. Deltawing racing cars have run 4 copies of the intake since july 2013. Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. My plan is to 3d print the intake in carbon fiber nylon, which has a temperature rating just above engine temperatures (240f. Produced in windform sp the intake manifold is mounted directly to engine. You can also 3d print bucks for mold making or even molds depending on the geometry and use them to form carbon fiber fairly easily. The deltawing intake manifold is 3d printed on crp usa’s additive manufacturing sls technology. Polycarbonate /10% long fiber carbon fiber. Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was created.

From www.fabbaloo.com

Continuous Carbon Fiber 3D Prints For Space Applications? « Fabbaloo Carbon Fiber 3D Printed Intake Manifold You can also 3d print bucks for mold making or even molds depending on the geometry and use them to form carbon fiber fairly easily. If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing. Carbon Fiber 3D Printed Intake Manifold.

From www.thedetroitbureau.com

Ford, Other Automakers Betting Big on 3D Printing Carbon Fiber 3D Printed Intake Manifold Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. Deltawing racing cars have run 4 copies of the intake since july 2013. Polycarbonate /10% long fiber carbon fiber. The deltawing intake manifold is 3d printed on crp usa’s additive manufacturing sls. Carbon Fiber 3D Printed Intake Manifold.

From 3dprintings.com.au

Top 3 Uses For Carbon Fibre 3D Printing In Manufacturing Carbon Fiber 3D Printed Intake Manifold My plan is to 3d print the intake in carbon fiber nylon, which has a temperature rating just above engine temperatures (240f. Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. Produced in windform sp the intake manifold is mounted directly. Carbon Fiber 3D Printed Intake Manifold.

From 3dcentroamerica.com

3D printed intake manifold Carbon Fiber 3D Printed Intake Manifold My plan is to 3d print the intake in carbon fiber nylon, which has a temperature rating just above engine temperatures (240f. You can also 3d print bucks for mold making or even molds depending on the geometry and use them to form carbon fiber fairly easily. If you have a need for speed, learn how vehicle performance is being. Carbon Fiber 3D Printed Intake Manifold.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Carbon Fiber 3D Printed Intake Manifold Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was created. Deltawing racing cars have run 4 copies of the intake since july 2013. If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. The deltawing. Carbon Fiber 3D Printed Intake Manifold.

From dragcartel.com

PRACWORKS KSERIES CARBON FIBER INTAKE MANIFOLD 20° PLENUM DRAG CARTEL IND. Carbon Fiber 3D Printed Intake Manifold My plan is to 3d print the intake in carbon fiber nylon, which has a temperature rating just above engine temperatures (240f. Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. The deltawing intake manifold is 3d printed on crp usa’s. Carbon Fiber 3D Printed Intake Manifold.

From formlabs.com

3D Printing in Manufacturing Carbon Fiber 3D Printed Intake Manifold The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing process. Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was created. Produced in windform sp the intake manifold is mounted directly to engine. 8mm is a pretty length. Carbon Fiber 3D Printed Intake Manifold.

From www.youtube.com

10 How to reinforce your 3D prints with carbon fiber. Basics of composites. YouTube Carbon Fiber 3D Printed Intake Manifold My plan is to 3d print the intake in carbon fiber nylon, which has a temperature rating just above engine temperatures (240f. Polycarbonate /10% long fiber carbon fiber. The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing process. Deltawing racing cars have run 4 copies of the intake since july 2013. The deltawing. Carbon Fiber 3D Printed Intake Manifold.

From www.pinterest.com

Hydrographic dipped Red Carbon Fiber Honda Intake Manifold Cover By Voyles Performance Cool Carbon Fiber 3D Printed Intake Manifold Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. Deltawing racing cars have run 4 copies of the intake since july 2013. The deltawing intake manifold is 3d printed on crp usa’s additive manufacturing sls technology. Polycarbonate /10% long fiber carbon. Carbon Fiber 3D Printed Intake Manifold.

From www.practicalmachinist.com

Printing an intake manifold? Carbon Fiber 3D Printed Intake Manifold Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was created. If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. Deltawing racing cars have run 4 copies of the intake since july 2013. 8mm is. Carbon Fiber 3D Printed Intake Manifold.

From www.windform.com

3D printed intake manifold for testing turbo diesel engine Carbon Fiber 3D Printed Intake Manifold 8mm is a pretty length for a fiber and we get get alignment in the printing. Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was created. Produced in windform sp the intake manifold is mounted directly to engine. If you have a need for. Carbon Fiber 3D Printed Intake Manifold.

From 3dcentroamerica.com

3D printed intake manifold Carbon Fiber 3D Printed Intake Manifold Deltawing racing cars have run 4 copies of the intake since july 2013. My plan is to 3d print the intake in carbon fiber nylon, which has a temperature rating just above engine temperatures (240f. Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was. Carbon Fiber 3D Printed Intake Manifold.

From www.cgtrader.com

Carbon intake manifold vehicle 3D CGTrader Carbon Fiber 3D Printed Intake Manifold Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. Produced in windform sp the intake manifold is mounted directly to engine. If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. The. Carbon Fiber 3D Printed Intake Manifold.

From www.3dprintingtoday.com

3D Printed Aluminum Intake Manifold Laser Melting Process 3D Printing Today 3D Printing Carbon Fiber 3D Printed Intake Manifold If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. 8mm is a pretty length for a fiber and we get get alignment. Carbon Fiber 3D Printed Intake Manifold.

From www.cgtrader.com

Carbon intake manifold 3D Model .ige .igs .iges .stp Carbon Fiber 3D Printed Intake Manifold The deltawing intake manifold is 3d printed on crp usa’s additive manufacturing sls technology. Deltawing racing cars have run 4 copies of the intake since july 2013. You can also 3d print bucks for mold making or even molds depending on the geometry and use them to form carbon fiber fairly easily. Finally, by working with carbon to develop a. Carbon Fiber 3D Printed Intake Manifold.

From www.reddit.com

Carbon Fiber Polycarbonate 3d printing Intake Manifold Test (more to come) r/3Dprinting Carbon Fiber 3D Printed Intake Manifold The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing process. Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. If you have a need for speed, learn how vehicle performance is being enhanced through. Carbon Fiber 3D Printed Intake Manifold.

From www.my4dsc.com

Custom Intake Manifold With Carbon Fiber Plenum VQ35DE Carbon Fiber 3D Printed Intake Manifold Polycarbonate /10% long fiber carbon fiber. Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing process. Produced in windform sp the intake manifold is mounted. Carbon Fiber 3D Printed Intake Manifold.

From www.pinterest.com

Here’s How Ford Performance 3DPrinted the Intake Manifold for Ken Block’s Hoonitruck Ken Carbon Fiber 3D Printed Intake Manifold 8mm is a pretty length for a fiber and we get get alignment in the printing. The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing process. Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was created. Produced. Carbon Fiber 3D Printed Intake Manifold.

From www.aniwaa.com

Carbon fiber 3D printers 2023 guide to continuous fiber printing Carbon Fiber 3D Printed Intake Manifold Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was created. You can also 3d print bucks for mold making or even molds depending on the geometry and use them to form carbon fiber fairly easily. Deltawing racing cars have run 4 copies of the. Carbon Fiber 3D Printed Intake Manifold.

From 3dcentroamerica.com

3D printing intake manifold Carbon Fiber 3D Printed Intake Manifold The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing process. If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold. Carbon Fiber 3D Printed Intake Manifold.

From dragcartel.com

PRACWORKS KSERIES CARBON FIBER INTAKE MANIFOLD 20° PLENUM DRAG CARTEL IND. Carbon Fiber 3D Printed Intake Manifold Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was created. My plan is to 3d print the intake in carbon fiber nylon, which has a temperature rating just above engine temperatures (240f. 8mm is a pretty length for a fiber and we get get. Carbon Fiber 3D Printed Intake Manifold.

From dddrop.com

Exploring Carbon Fiber 3D Printing Strength Meets Lightweight Precision dddrop Professional Carbon Fiber 3D Printed Intake Manifold Produced in windform sp the intake manifold is mounted directly to engine. Deltawing racing cars have run 4 copies of the intake since july 2013. Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. My plan is to 3d print the. Carbon Fiber 3D Printed Intake Manifold.

From all3dp.com

Incredible Prints Can You 3D Print an Intake Manifold? All3DP Carbon Fiber 3D Printed Intake Manifold 8mm is a pretty length for a fiber and we get get alignment in the printing. Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was created. You can also 3d print bucks for mold making or even molds depending on the geometry and use. Carbon Fiber 3D Printed Intake Manifold.

From www.youtube.com

CR125 3d printed intake manifold for vforce reeds YouTube Carbon Fiber 3D Printed Intake Manifold Produced in windform sp the intake manifold is mounted directly to engine. The deltawing intake manifold is 3d printed on crp usa’s additive manufacturing sls technology. The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing process. You can also 3d print bucks for mold making or even molds depending on the geometry and. Carbon Fiber 3D Printed Intake Manifold.

From dragcartel.com

PRACWORKS KSERIES CARBON FIBER INTAKE MANIFOLD 20° PLENUM DRAG CARTEL IND. Carbon Fiber 3D Printed Intake Manifold Deltawing racing cars have run 4 copies of the intake since july 2013. 8mm is a pretty length for a fiber and we get get alignment in the printing. You can also 3d print bucks for mold making or even molds depending on the geometry and use them to form carbon fiber fairly easily. Employing the most advanced intake yet. Carbon Fiber 3D Printed Intake Manifold.

From www.mustang6g.com

3D Printed Manifold of the new Gen 5 3.8L Whipple Supercharger kit 2015+ S550 Mustang Forum Carbon Fiber 3D Printed Intake Manifold The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing process. Produced in windform sp the intake manifold is mounted directly to engine. 8mm is a pretty length for a fiber and we get get alignment in the printing. Polycarbonate /10% long fiber carbon fiber. Employing the most advanced intake yet printed, in combination. Carbon Fiber 3D Printed Intake Manifold.

From www.youtube.com

3D Printed Carbon Fiber YouTube Carbon Fiber 3D Printed Intake Manifold If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a strong, reliable and lightweight intake manifold was created. Polycarbonate /10% long fiber carbon fiber. Finally, by working with carbon to develop a more. Carbon Fiber 3D Printed Intake Manifold.

From www.wenext.com

The Ultimate Guide The Best Carbon Fiber 3D Printers of 2023 Wenext Carbon Fiber 3D Printed Intake Manifold If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. You can also 3d print bucks for mold making or even molds depending on the geometry and use them to form carbon fiber fairly easily. The long carbon fibers increases the stiffness by about 350% and hugely benefits the 3d printing. Carbon Fiber 3D Printed Intake Manifold.

From www.pinterest.com

Air Intake Manifold — Formlabs 3d printing, 3d printing technology, Engineering tools Carbon Fiber 3D Printed Intake Manifold Polycarbonate /10% long fiber carbon fiber. Deltawing racing cars have run 4 copies of the intake since july 2013. Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. The long carbon fibers increases the stiffness by about 350% and hugely benefits. Carbon Fiber 3D Printed Intake Manifold.

From www.reddit.com

3D printed velocity stacks/intake in carbon fiber nylon. r/functionalprint Carbon Fiber 3D Printed Intake Manifold Produced in windform sp the intake manifold is mounted directly to engine. The deltawing intake manifold is 3d printed on crp usa’s additive manufacturing sls technology. Deltawing racing cars have run 4 copies of the intake since july 2013. If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. 8mm is. Carbon Fiber 3D Printed Intake Manifold.

From blog.3dprinters-shop.com

3D Printing With Carbon Fiber Filament Carbon Fiber 3D Printed Intake Manifold Polycarbonate /10% long fiber carbon fiber. Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. You can also 3d print bucks for mold making or even molds depending on the geometry and use them to form carbon fiber fairly easily. The. Carbon Fiber 3D Printed Intake Manifold.

From www.cosineadditive.com

Composite Intake Manifold — Large Scale 3D Printing Cosine Carbon Fiber 3D Printed Intake Manifold Polycarbonate /10% long fiber carbon fiber. 8mm is a pretty length for a fiber and we get get alignment in the printing. If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. The deltawing intake manifold is 3d printed on crp usa’s additive manufacturing sls technology. My plan is to 3d. Carbon Fiber 3D Printed Intake Manifold.

From 3dprintingindustry.com

DeltaWing's 3D Printed Engine Manifold 3D Printing Industry Carbon Fiber 3D Printed Intake Manifold You can also 3d print bucks for mold making or even molds depending on the geometry and use them to form carbon fiber fairly easily. My plan is to 3d print the intake in carbon fiber nylon, which has a temperature rating just above engine temperatures (240f. Employing the most advanced intake yet printed, in combination with carbon fiber intake. Carbon Fiber 3D Printed Intake Manifold.

From formlabs.com

How to Manufacture Carbon Fiber Parts Formlabs Carbon Fiber 3D Printed Intake Manifold You can also 3d print bucks for mold making or even molds depending on the geometry and use them to form carbon fiber fairly easily. Deltawing racing cars have run 4 copies of the intake since july 2013. If you have a need for speed, learn how vehicle performance is being enhanced through 3d printed intake manifolds. Employing the most. Carbon Fiber 3D Printed Intake Manifold.

From www.reddit.com

After 25 hours of printing, the intake manifold is complete for my 3d printed LS3 model Corvette Carbon Fiber 3D Printed Intake Manifold Finally, by working with carbon to develop a more compact and simple design, and using its rpu material, the 3d printed intake manifold has achieved a 50% weight. The deltawing intake manifold is 3d printed on crp usa’s additive manufacturing sls technology. Employing the most advanced intake yet printed, in combination with carbon fiber intake plenums developed by multimatic, a. Carbon Fiber 3D Printed Intake Manifold.