Electrochemical Etching Aluminum . For etching you will need: Sometimes we find ourselves with the need of making marks on metal, perhaps somewhat intricate marks or patterns for. Then add as much salt as the water will hold, don't worry if. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. But how does this process compare with other marking methods? Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. First fill the jar with enough water to cover your piece. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad subject spanning several chapters. There are no hazardous chemicals (except dihydrogen monoxide and salts of sodium and chlorine), no dangerous voltages, and no toxic chemicals to dispose of. Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids.

from www.precisionmicro.com

First fill the jar with enough water to cover your piece. Sometimes we find ourselves with the need of making marks on metal, perhaps somewhat intricate marks or patterns for. For etching you will need: Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). There are no hazardous chemicals (except dihydrogen monoxide and salts of sodium and chlorine), no dangerous voltages, and no toxic chemicals to dispose of. A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad subject spanning several chapters. Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. But how does this process compare with other marking methods?

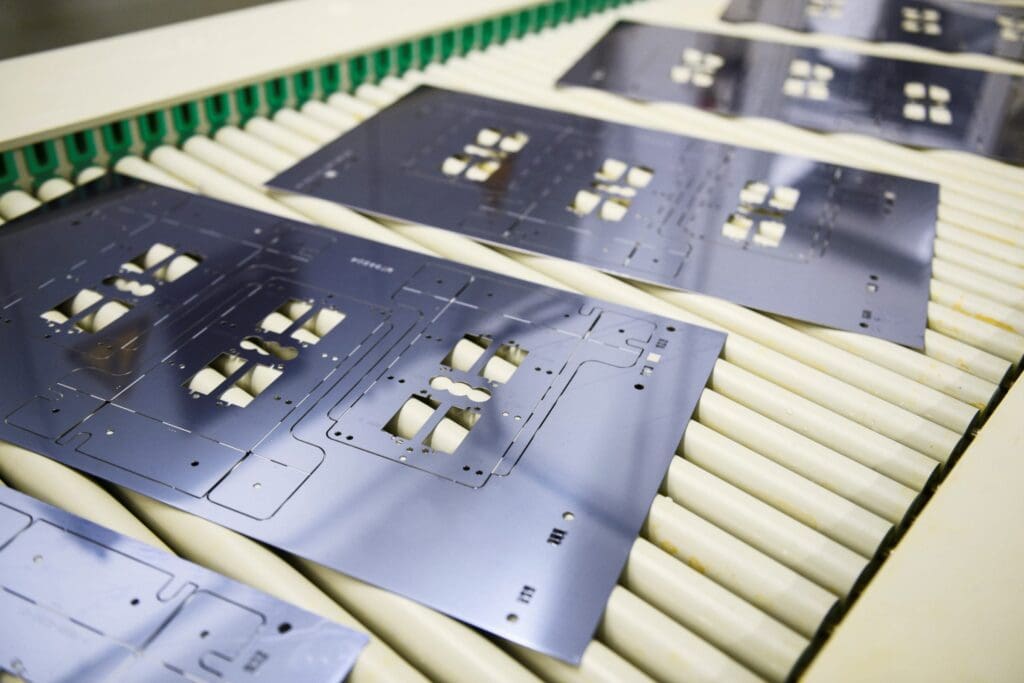

Aluminum Etching Aluminium Etching Process Precision Micro

Electrochemical Etching Aluminum Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. For etching you will need: There are no hazardous chemicals (except dihydrogen monoxide and salts of sodium and chlorine), no dangerous voltages, and no toxic chemicals to dispose of. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. Then add as much salt as the water will hold, don't worry if. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. But how does this process compare with other marking methods? Sometimes we find ourselves with the need of making marks on metal, perhaps somewhat intricate marks or patterns for. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad subject spanning several chapters. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. First fill the jar with enough water to cover your piece.

From katalemwacheshire.org

The Photo Etching ProcessA StepbyStep Guide / UWE Guides Online Electrochemical Etching Aluminum There are no hazardous chemicals (except dihydrogen monoxide and salts of sodium and chlorine), no dangerous voltages, and no toxic chemicals to dispose of. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Then add as much salt as the water will hold, don't worry if. Achieving dark marking and white etching results involves switching between. Electrochemical Etching Aluminum.

From metal-etch.com

Electrochemical Etching Service Supplier and Manufacturer BeCu Etch Electrochemical Etching Aluminum Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. A look through wernick, pinner, and. Electrochemical Etching Aluminum.

From www.youtube.com

How To Etch Aluminium YouTube Electrochemical Etching Aluminum Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. There are no hazardous chemicals (except dihydrogen monoxide and salts of sodium and chlorine), no dangerous voltages, and no toxic chemicals to dispose of. Then add as much salt as the water will hold, don't worry if. Electrochemical marking. Electrochemical Etching Aluminum.

From www.researchgate.net

Basic schematic of electrochemical etching method Download Scientific Diagram Electrochemical Etching Aluminum First fill the jar with enough water to cover your piece. But how does this process compare with other marking methods? There are no hazardous chemicals (except dihydrogen monoxide and salts of sodium and chlorine), no dangerous voltages, and no toxic chemicals to dispose of. Then add as much salt as the water will hold, don't worry if. A look. Electrochemical Etching Aluminum.

From www.researchgate.net

Schematic representation of the setup for electrochemical etching of... Download Scientific Electrochemical Etching Aluminum For etching you will need: Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). Sometimes we find ourselves with the need of making marks on metal, perhaps somewhat intricate marks or patterns for. First fill the jar with enough water to cover your piece. Electrochemical marking is a process by which conductive. Electrochemical Etching Aluminum.

From www.youtube.com

Marking Methods, Inc. shows you how to ElectroChemically Deep Etch on Aluminum. YouTube Electrochemical Etching Aluminum Then add as much salt as the water will hold, don't worry if. But how does this process compare with other marking methods? Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. For etching you will need: Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current. Electrochemical Etching Aluminum.

From www.jove.com

Electrochemical Etching and Characterization of Sharp Field Emission Points for Electron Impact Electrochemical Etching Aluminum For etching you will need: First fill the jar with enough water to cover your piece. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. Then add as much salt as the water will hold, don't worry if. Sometimes we find ourselves with the need. Electrochemical Etching Aluminum.

From www.metaletching.org

Stainless Steel Etching Companies Services Electrochemical Etching Aluminum Then add as much salt as the water will hold, don't worry if. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching. Electrochemical Etching Aluminum.

From www.researchgate.net

(a) Scheme of electrochemical etching method. (b) Surface morphologies... Download Scientific Electrochemical Etching Aluminum Sometimes we find ourselves with the need of making marks on metal, perhaps somewhat intricate marks or patterns for. Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. Then add as much salt as the water will hold, don't worry if. There are no hazardous chemicals (except dihydrogen. Electrochemical Etching Aluminum.

From www.researchgate.net

3 Diagram of the electrochemical cell used for etching metal tips. Download Scientific Diagram Electrochemical Etching Aluminum For etching you will need: Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). First fill the jar with enough water to cover your piece. But how does this process compare with other marking methods? There are no hazardous chemicals (except dihydrogen monoxide and salts of sodium and chlorine), no dangerous voltages,. Electrochemical Etching Aluminum.

From sites.utexas.edu

MetalAssisted Chemical Etching (MacEtch) Electrochemical Etching Aluminum Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. First fill the jar with enough water to cover your piece. But how does this process compare with other marking methods? A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Achieving dark marking and white. Electrochemical Etching Aluminum.

From www.youtube.com

Electrochemical Marking & Etching Fast and Easy Method to mark metal surfaces YouTube Electrochemical Etching Aluminum But how does this process compare with other marking methods? Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. Sometimes we find ourselves with. Electrochemical Etching Aluminum.

From www.cambridge.org

Photoelectrochemical etch enables damagefree device fabrication process for GaN Electrochemical Etching Aluminum Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. For etching you will need: Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). But how does this process compare with other marking methods? A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad. Electrochemical Etching Aluminum.

From pubs.acs.org

Replacing Metals with Oxides in MetalAssisted Chemical Etching Enables Direct Fabrication of Electrochemical Etching Aluminum Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. First fill the jar with enough water to cover your piece. For etching you will need: A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad subject spanning several chapters.. Electrochemical Etching Aluminum.

From www.youtube.com

Electro Etching Aluminium Disks YouTube Electrochemical Etching Aluminum Then add as much salt as the water will hold, don't worry if. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad subject spanning several chapters. Electrochemical marking is a process by which conductive metal surfaces. Electrochemical Etching Aluminum.

From www.etch-tech.co.uk

EtchTech Experts in Precision Aluminium Etching Electrochemical Etching Aluminum Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad subject spanning several chapters. But how does this process compare with other marking methods? There are no hazardous chemicals (except. Electrochemical Etching Aluminum.

From www.researchgate.net

SEM images of the aluminum surface after etching in acid solution for... Download Scientific Electrochemical Etching Aluminum A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad subject spanning several chapters. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. First fill the jar with enough water to cover your piece. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current. Electrochemical Etching Aluminum.

From www.youtube.com

How To ElectroEtch with Salt Water and Aluminium YouTube Electrochemical Etching Aluminum A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Sometimes we find ourselves with the need of making marks on metal, perhaps somewhat intricate marks or patterns for. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. Then add as much salt as the water will hold, don't worry if. A look through. Electrochemical Etching Aluminum.

From universalmarking.com

Electro Chemical Etching / Electro Etching / Electrolytic Etching Universal Marking Inc. Electrochemical Etching Aluminum A marking head is used with a marking stencil/mask soaked in electrolyte fluid. First fill the jar with enough water to cover your piece. But how does this process compare with other marking methods? Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. Monode's electrochemical etching power units provide a low voltage secondary power supply that can. Electrochemical Etching Aluminum.

From www.researchgate.net

Schematic of the DCetching process of aluminum foil Download Scientific Diagram Electrochemical Etching Aluminum Sometimes we find ourselves with the need of making marks on metal, perhaps somewhat intricate marks or patterns for. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). For etching you will need: Then add as much salt as the water will hold, don't worry if. But how does this process compare. Electrochemical Etching Aluminum.

From www.metaletching.org

Chemical Etching Companies Chemical Etching Services Electrochemical Etching Aluminum There are no hazardous chemicals (except dihydrogen monoxide and salts of sodium and chlorine), no dangerous voltages, and no toxic chemicals to dispose of. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to. Electrochemical Etching Aluminum.

From www.etch-tech.co.uk

EtchTech Experts in Precision Aluminium Etching Electrochemical Etching Aluminum A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). For etching you will need: A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad subject spanning several chapters. Electrochemical marking is a process. Electrochemical Etching Aluminum.

From www.youtube.com

Electro Etch Metal at Home Easy Electrolysis & Etching YouTube Electrochemical Etching Aluminum A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. Then add as much salt as the water will hold, don't worry if. Achieving dark marking and white etching results involves switching between alternating current (ac). Electrochemical Etching Aluminum.

From www.researchgate.net

The electrochemical etching process (A) and obtaining the electrical... Download Scientific Electrochemical Etching Aluminum A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad subject spanning several chapters. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched. Electrochemical Etching Aluminum.

From www.researchgate.net

DC electrochemical etching of the anodized aluminum foils as depicted... Download Scientific Electrochemical Etching Aluminum There are no hazardous chemicals (except dihydrogen monoxide and salts of sodium and chlorine), no dangerous voltages, and no toxic chemicals to dispose of. Then add as much salt as the water will hold, don't worry if. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. A look through wernick, pinner, and sheasby ⇨ shows electrochemical. Electrochemical Etching Aluminum.

From www.researchgate.net

Electrochemical etching process. (a) At a beginning step. (b) At an... Download Scientific Diagram Electrochemical Etching Aluminum Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad subject spanning several chapters. Achieving dark marking and white etching. Electrochemical Etching Aluminum.

From www.researchgate.net

The electrochemical etching system. Download Scientific Diagram Electrochemical Etching Aluminum But how does this process compare with other marking methods? Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help. Electrochemical Etching Aluminum.

From www.researchgate.net

(PDF) Electrochemical AC Etching of Aluminum Foils in Hydrochloric Acid Electrolytes Electrochemical Etching Aluminum Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Sometimes we. Electrochemical Etching Aluminum.

From www.precisionmicro.com

Aluminum Etching Aluminium Etching Process Precision Micro Electrochemical Etching Aluminum There are no hazardous chemicals (except dihydrogen monoxide and salts of sodium and chlorine), no dangerous voltages, and no toxic chemicals to dispose of. Then add as much salt as the water will hold, don't worry if. Sometimes we find ourselves with the need of making marks on metal, perhaps somewhat intricate marks or patterns for. A look through wernick,. Electrochemical Etching Aluminum.

From www.researchgate.net

Schematic of the DCetching process of aluminum foil Download Scientific Diagram Electrochemical Etching Aluminum Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Electrochemical marking is a process by which conductive metal. Electrochemical Etching Aluminum.

From www.heatsign.com

Metal Etching ProcessChoosing a Right Metal Etching Machine Electrochemical Etching Aluminum Then add as much salt as the water will hold, don't worry if. There are no hazardous chemicals (except dihydrogen monoxide and salts of sodium and chlorine), no dangerous voltages, and no toxic chemicals to dispose of. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Electrochemical marking is a process by which conductive metal surfaces. Electrochemical Etching Aluminum.

From ace-uk.net

What Is Aluminium Etching? Our Aluminium Etching Process At ACE Electrochemical Etching Aluminum Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. But how does this process compare with other marking methods? A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad subject spanning several chapters. Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac. Electrochemical Etching Aluminum.

From www.researchgate.net

Schematic diagrams illustrating the progressive alkaline etching... Download Scientific Diagram Electrochemical Etching Aluminum For etching you will need: Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. First fill the jar. Electrochemical Etching Aluminum.

From www.researchgate.net

Electrochemical etching setup Download Scientific Diagram Electrochemical Etching Aluminum Monode's electrochemical etching power units provide a low voltage secondary power supply that can be switched between ac and dc output. Then add as much salt as the water will hold, don't worry if. First fill the jar with enough water to cover your piece. Sometimes we find ourselves with the need of making marks on metal, perhaps somewhat intricate. Electrochemical Etching Aluminum.

From www.researchgate.net

Anodic etching of bulk Ti 3 AlC 2 in a binary aqueous electrolyte. a)... Download Scientific Electrochemical Etching Aluminum A look through wernick, pinner, and sheasby ⇨ shows electrochemical etching to be a very broad subject spanning several chapters. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic. Electrochemical Etching Aluminum.