Boring Bar Vs End Mill . In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. Boring holes on a milling machine requires the use of an. What’s different is the method of holding the boring tool. Most definitely an end mill in the tool post is a great way to bore on the lathe. It might spell trouble later if/when you revert to. Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. The boring bar allows the cutting insert to cut the walls of the hole. Unlike the boring bar for a lathe, the tool used on a mill must be adjustable to achieve the correct size. The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right side.

from www.marox.com.tw

Boring holes on a milling machine requires the use of an. What’s different is the method of holding the boring tool. In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. It might spell trouble later if/when you revert to. If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. Most definitely an end mill in the tool post is a great way to bore on the lathe. The boring bar allows the cutting insert to cut the walls of the hole. The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right side. Unlike the boring bar for a lathe, the tool used on a mill must be adjustable to achieve the correct size.

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer

Boring Bar Vs End Mill Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. Boring holes on a milling machine requires the use of an. It might spell trouble later if/when you revert to. Most definitely an end mill in the tool post is a great way to bore on the lathe. In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. The boring bar allows the cutting insert to cut the walls of the hole. The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right side. Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. Unlike the boring bar for a lathe, the tool used on a mill must be adjustable to achieve the correct size. What’s different is the method of holding the boring tool.

From www.ebay.com.au

9Pcs Alloy 12mm Shank Boring Bars Set for 2 inch 50mm Boring Head Lathe Boring Bar Vs End Mill Boring holes on a milling machine requires the use of an. The boring bar allows the cutting insert to cut the walls of the hole. Unlike the boring bar for a lathe, the tool used on a mill must be adjustable to achieve the correct size. If using a mill, the workpiece is fixed while the boring bar rotates to. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill Boring holes on a milling machine requires the use of an. The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right side. If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. The boring bar allows the cutting insert to cut. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill The boring bar allows the cutting insert to cut the walls of the hole. Boring holes on a milling machine requires the use of an. It might spell trouble later if/when you revert to. If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. In a lathe, the boring bar is stationary and. Boring Bar Vs End Mill.

From www.ctemag.com

Boring with a milling machine Cutting Tool Engineering Boring Bar Vs End Mill If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. Boring holes on a milling machine requires the use of an. It might spell trouble later if/when you revert to. In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. The. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill Most definitely an end mill in the tool post is a great way to bore on the lathe. Unlike the boring bar for a lathe, the tool used on a mill must be adjustable to achieve the correct size. In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill Boring holes on a milling machine requires the use of an. The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right side. The boring bar allows the cutting insert to cut the walls of the hole. In a lathe, the boring bar is stationary and gripped in a. Boring Bar Vs End Mill.

From www.kodiakcuttingtools.com

Double Insert Mini Boring Bars Dorian Mini Boring Bars Boring Bar Vs End Mill The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right side. Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. In a lathe, the boring bar is stationary and gripped in. Boring Bar Vs End Mill.

From www.youtube.com

Milling with a Boring Head And Boring Bar YouTube Boring Bar Vs End Mill Unlike the boring bar for a lathe, the tool used on a mill must be adjustable to achieve the correct size. If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right side. In a lathe, the boring bar is stationary and gripped in. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right side. Most definitely an end mill in the tool post is a great way to bore on the lathe. Boring holes on a milling machine requires the use of an. In a lathe, the boring bar is stationary. Boring Bar Vs End Mill.

From www.zlytool.com

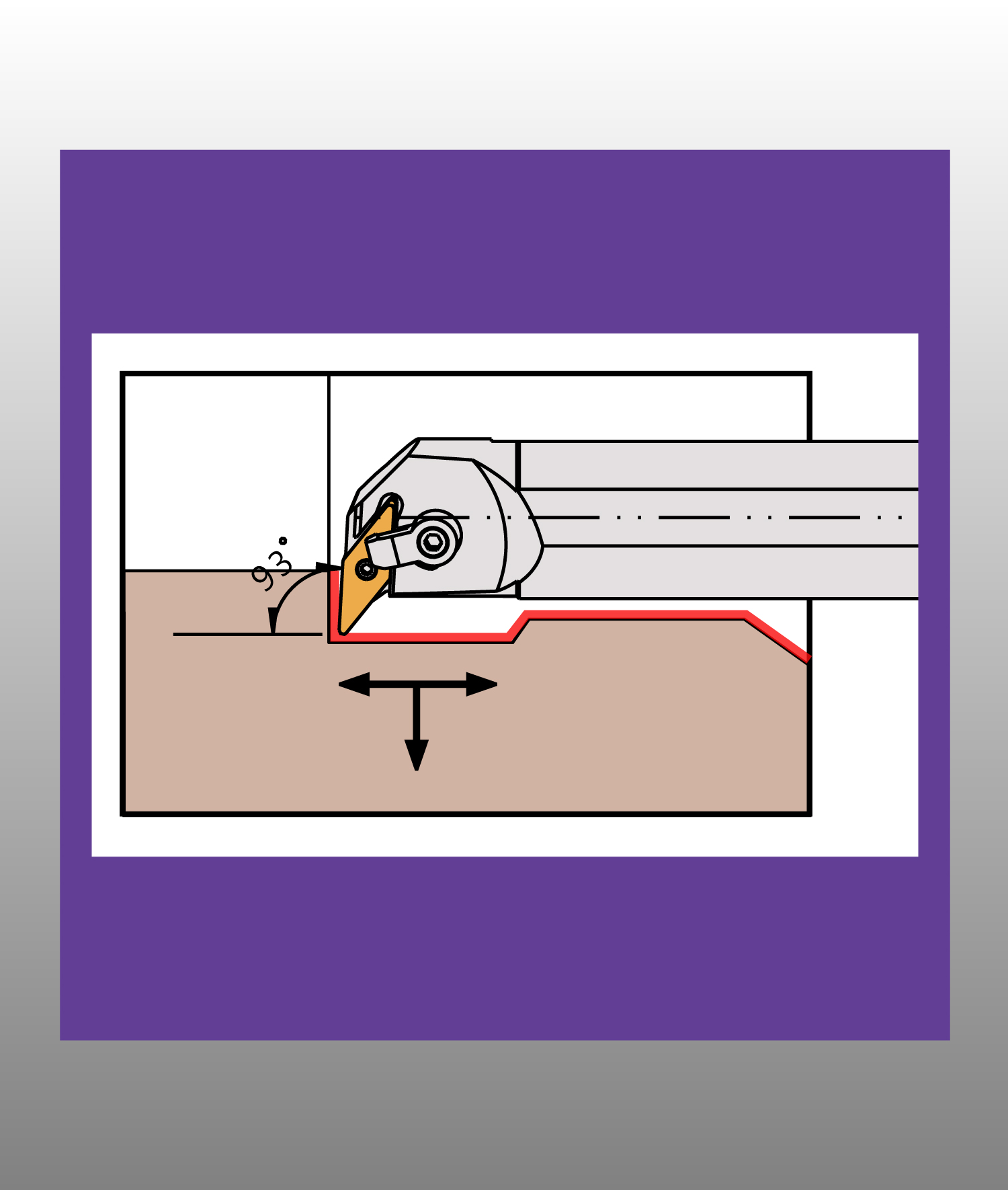

Solid Carbide Boring Bar for profile turningZLY tools_Carbide milling Boring Bar Vs End Mill If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. The boring bars are the actual cutting tools and go in one of the 3 holes pictured. Boring Bar Vs End Mill.

From www.slideserve.com

PPT Boring Bars PowerPoint Presentation, free download ID1425827 Boring Bar Vs End Mill In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. Boring holes on a milling machine requires the use of an. If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. Explore the different types of boring tools used for metalworking,. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill Most definitely an end mill in the tool post is a great way to bore on the lathe. It might spell trouble later if/when you revert to. If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. Boring holes on a milling machine requires the use of an. Unlike the boring bar for. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill It might spell trouble later if/when you revert to. Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. Boring holes on a milling machine requires the use of an. Unlike the boring bar for a lathe, the tool used on a mill must. Boring Bar Vs End Mill.

From www.youtube.com

Difference between Drilling Boring and Reaming operation YouTube Boring Bar Vs End Mill Boring holes on a milling machine requires the use of an. In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. It might spell trouble later if/when you revert to. Most definitely an end mill in the tool post is a great way to bore on the lathe.. Boring Bar Vs End Mill.

From www.unitymechanics.com

Services Unity Mechanics Boring Bar Vs End Mill In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. The boring bar allows the cutting insert to cut the walls of the hole. It might spell trouble later if/when you revert to. What’s different is the method of holding the boring tool. Most definitely an end mill. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. The boring bar allows the cutting insert to cut the walls of the hole. If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. The boring bars. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill Boring holes on a milling machine requires the use of an. The boring bar allows the cutting insert to cut the walls of the hole. The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right side. Explore the different types of boring tools used for metalworking, including boring. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill Most definitely an end mill in the tool post is a great way to bore on the lathe. Boring holes on a milling machine requires the use of an. If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. The boring bars are the actual cutting tools and go in one of the. Boring Bar Vs End Mill.

From news.thomasnet.com

MD Adjustable Boring Bars Offer Flexibility Boring Bar Vs End Mill It might spell trouble later if/when you revert to. Unlike the boring bar for a lathe, the tool used on a mill must be adjustable to achieve the correct size. Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. The boring bar allows. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill Unlike the boring bar for a lathe, the tool used on a mill must be adjustable to achieve the correct size. Boring holes on a milling machine requires the use of an. If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. What’s different is the method of holding the boring tool. The. Boring Bar Vs End Mill.

From www.indiamart.com

Carbide Tipped Fine Boring Bars with Micro Bore Units, ID 22631784773 Boring Bar Vs End Mill Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. It might spell trouble later if/when you revert to. Boring holes on a milling machine requires the use of an. In a lathe, the boring bar is stationary and gripped in a tool block. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill Boring holes on a milling machine requires the use of an. Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. Most definitely an end mill in the tool post is a great way to bore on the lathe. What’s different is the method. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right side. In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. If using a mill, the workpiece is fixed while the boring bar rotates to cut. Boring Bar Vs End Mill.

From www.youtube.com

Drilling,Boring & Reaming(Difference) YouTube Boring Bar Vs End Mill In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. It might spell trouble later if/when you revert to. The boring bar allows the cutting insert to cut the walls of the hole. Most definitely an end mill in the tool post is a great way to bore. Boring Bar Vs End Mill.

From lihuacarbide.en.made-in-china.com

High Hardness Exchangeable Carbide End Mills Cutters with Anti Boring Bar Vs End Mill What’s different is the method of holding the boring tool. Unlike the boring bar for a lathe, the tool used on a mill must be adjustable to achieve the correct size. Boring holes on a milling machine requires the use of an. Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. It might spell trouble later if/when you revert to. In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. The boring bar allows the cutting insert to cut the walls of. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. If using a mill, the workpiece is fixed while the boring bar. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. Unlike the boring bar for a lathe, the tool used on a mill must be adjustable to achieve the correct size. The boring bar allows the cutting insert to cut the walls of the hole. What’s different is the method of holding the. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right side. What’s different is the method of holding the boring tool. The boring bar allows the cutting insert to cut the walls of the hole. Most definitely an end mill in the tool post is a great way. Boring Bar Vs End Mill.

From www.ebay.com

2" boring head + 9pcs 1/2" carbide boring bars with MT3 M12 Bridgeport Boring Bar Vs End Mill If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. Boring holes on a milling machine requires the use of an. It might spell trouble later if/when. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. Boring holes on a milling machine requires the use of an. Most definitely an end mill in the tool post is. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill Explore the different types of boring tools used for metalworking, including boring bars, damping bars, boring heads, and starter drills, and their unique applications and benefits. If using a mill, the workpiece is fixed while the boring bar rotates to cut the part. Most definitely an end mill in the tool post is a great way to bore on the. Boring Bar Vs End Mill.

From www.marox.com.tw

Boring Bars, Turning Tool, Threading Tools|MAROX End Mills Manufacturer Boring Bar Vs End Mill The boring bars are the actual cutting tools and go in one of the 3 holes pictured on the top and right side. Boring holes on a milling machine requires the use of an. Unlike the boring bar for a lathe, the tool used on a mill must be adjustable to achieve the correct size. The boring bar allows the. Boring Bar Vs End Mill.

From www.smlease.com

Drilling vs Boring vs Reaming What is the Difference SMLease Design Boring Bar Vs End Mill In a lathe, the boring bar is stationary and gripped in a tool block the same as any other round shank tool. What’s different is the method of holding the boring tool. Boring holes on a milling machine requires the use of an. Most definitely an end mill in the tool post is a great way to bore on the. Boring Bar Vs End Mill.