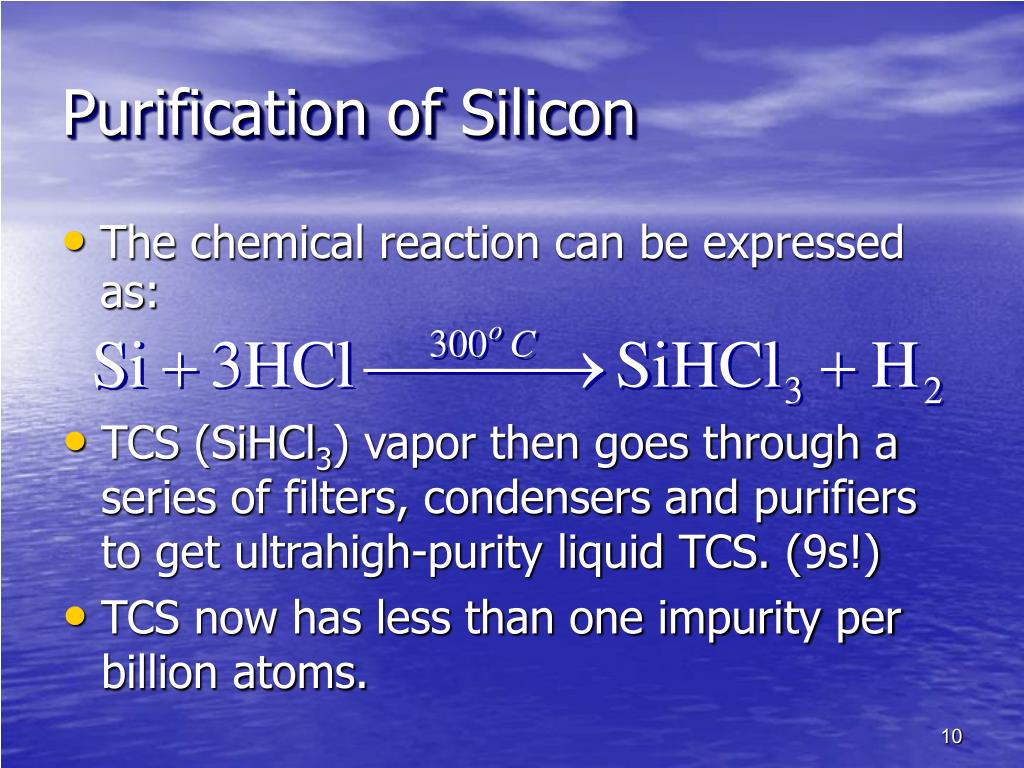

Silicon Purification Process . The web page explains the chemical. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. Review of existing processes to produce solar grade silicon. A process for producing semiconductor grade silicon. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Chemical purification route with auxiliary steps to recycle the.

from www.slideserve.com

It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. Chemical purification route with auxiliary steps to recycle the. The web page explains the chemical. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. A process for producing semiconductor grade silicon. Review of existing processes to produce solar grade silicon. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,.

PPT Wafer Manufacturing PowerPoint Presentation, free download ID

Silicon Purification Process It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. Review of existing processes to produce solar grade silicon. A process for producing semiconductor grade silicon. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. Chemical purification route with auxiliary steps to recycle the. The web page explains the chemical. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically.

From www.researchgate.net

Binding of DNA to silica matrix and mini columns.(a) The purification Silicon Purification Process Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Chemical purification route with auxiliary steps to recycle the. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. A process for producing. Silicon Purification Process.

From www.slideserve.com

PPT Wafer Manufacturing PowerPoint Presentation, free download ID Silicon Purification Process Chemical purification route with auxiliary steps to recycle the. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. A process for producing semiconductor grade silicon. Metallurgical grade silicon, silicon dioxide, and silicon. Silicon Purification Process.

From www.lcicorp.com

Silicone Purification Silicon Purification Process Chemical purification route with auxiliary steps to recycle the. Review of existing processes to produce solar grade silicon. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. The web page explains the chemical. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. A process. Silicon Purification Process.

From www.youtube.com

SILICON PURIFICATION ANALOG ELECTRONICS LECTURE 3 UPRVUNL 2021 Silicon Purification Process Chemical purification route with auxiliary steps to recycle the. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. Review of existing processes to produce solar grade silicon. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. A process for producing semiconductor. Silicon Purification Process.

From www.researchgate.net

7 The traditional chemical route for silicon purification. Sketch Silicon Purification Process The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. A process for. Silicon Purification Process.

From www.mdpi.com

Processes Free FullText Integration of Kazakhstan Technologies for Silicon Purification Process A process for producing semiconductor grade silicon. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. The web page explains the chemical. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. It can produce very high purities, including. Silicon Purification Process.

From www.youtube.com

Overview of doping and purification of silicon (Dr. M. Aslam Revision Silicon Purification Process Chemical purification route with auxiliary steps to recycle the. The web page explains the chemical. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. A process for producing semiconductor grade silicon. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Silicon,. Silicon Purification Process.

From www.youtube.com

Zone Refining Technique Purification of Silicon YouTube Silicon Purification Process Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Review of existing processes to produce solar grade silicon. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. A process for producing semiconductor grade silicon. It can produce very. Silicon Purification Process.

From www.powerelectronicsnews.com

Improving the SiC Wafer Process Power Electronics News Silicon Purification Process Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Chemical purification route with auxiliary steps to recycle the. The. Silicon Purification Process.

From www.semanticscholar.org

Figure 4.6 from Production and Purification of Silicon by Silicon Purification Process The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. A process for producing semiconductor grade silicon. The web page explains the chemical. Silicon, with its great abundance and mature infrastructure, is a foundational material for. Silicon Purification Process.

From www.google.com

Patent US6368568 Method for improving the efficiency of a silicon Silicon Purification Process A process for producing semiconductor grade silicon. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from. Silicon Purification Process.

From www2.mdpi.com

Metals Free FullText Purification of Organosilicon Waste Silicon Silicon Purification Process The web page explains the chemical. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits.. Silicon Purification Process.

From www.dsnsolar.com

Production de plaquettes de silicium Connaissances DS New Energy Silicon Purification Process Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. A process for producing semiconductor grade silicon. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. Chemical purification route with auxiliary steps to recycle the. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits.. Silicon Purification Process.

From www.slideserve.com

PPT Wafer Manufacturing PowerPoint Presentation, free download ID Silicon Purification Process Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. A process for producing semiconductor grade silicon. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. Learn how silicon dioxide is reduced. Silicon Purification Process.

From pubs.rsc.org

Purification of metallurgicalgrade silicon combining SnSi solvent Silicon Purification Process The web page explains the chemical. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. A process for producing semiconductor grade silicon. Chemical purification route with auxiliary steps to recycle the. Metallurgical. Silicon Purification Process.

From www.lcicorp.com

Silicone Purification Silicon Purification Process Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Chemical purification route with auxiliary steps to recycle the. The web page explains the chemical. A process for producing semiconductor grade silicon. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such. Silicon Purification Process.

From hackaday.com

Mining And Refining Pure Silicon And The Incredible Effort It Takes To Silicon Purification Process Review of existing processes to produce solar grade silicon. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. Chemical purification route with auxiliary steps to recycle the. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. The siemens method uses temperatures. Silicon Purification Process.

From www.slideserve.com

PPT Chapter 2 Semiconductor Materials and Process Chemicals Silicon Purification Process Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. Chemical purification route with auxiliary steps to recycle the. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. Review of existing processes to produce solar grade silicon. Metallurgical grade silicon, silicon dioxide,. Silicon Purification Process.

From www.mdpi.com

Metals Free FullText Purification of Organosilicon Waste Silicon Silicon Purification Process It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. The web page explains the chemical. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications,. Silicon Purification Process.

From www.mianfeiwendang.com

SILICON PURIFICATION METHOD_word文档在线阅读与下载_免费文档 Silicon Purification Process Chemical purification route with auxiliary steps to recycle the. A process for producing semiconductor grade silicon. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. Review of existing processes to produce solar grade silicon. The web page explains the chemical. Learn how. Silicon Purification Process.

From www.mdpi.com

Applied Sciences Free FullText Fabrication of Silicon Carbide from Silicon Purification Process Review of existing processes to produce solar grade silicon. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. It can produce very high purities, including the 99.9999999 percent pure. Silicon Purification Process.

From canonica.ai

Silicon purification Silicon Purification Process It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. Review of existing processes to produce. Silicon Purification Process.

From interfacegroup.ch

Purification of metallurgical grade silicon by a solar process The Silicon Purification Process Review of existing processes to produce solar grade silicon. The web page explains the chemical. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. It can produce very high purities, including the. Silicon Purification Process.

From www.slideserve.com

PPT Wafer Manufacturing PowerPoint Presentation, free download ID Silicon Purification Process Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Review of existing processes to produce solar grade silicon. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. The web page explains the chemical. Silicon, with its great abundance and mature infrastructure,. Silicon Purification Process.

From pubs.rsc.org

Purification of metallurgicalgrade silicon combining SnSi solvent Silicon Purification Process Chemical purification route with auxiliary steps to recycle the. Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. The web page explains the chemical. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. Silicon,. Silicon Purification Process.

From www.marefa.org

ملفSilicon purification processes.svg المعرفة Silicon Purification Process Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. Chemical purification route with auxiliary steps to recycle the. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. A process for producing. Silicon Purification Process.

From www.marefa.org

ملفSilicon purification processes.svg المعرفة Silicon Purification Process Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. It can produce very high purities, including the 99.9999999 percent. Silicon Purification Process.

From www.degruyter.com

Study of the Boron Distribution and Microstructure of Solidified AlSi Silicon Purification Process The web page explains the chemical. A process for producing semiconductor grade silicon. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. It can produce very high purities, including. Silicon Purification Process.

From www.slideserve.com

PPT Wafer Manufacturing PowerPoint Presentation, free download ID Silicon Purification Process Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Review of existing processes to produce solar grade silicon. Chemical purification route with auxiliary steps to recycle the. Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. It can. Silicon Purification Process.

From www.semanticscholar.org

Figure 1 from Preparation of 6N grade silicon ingot by combined Silicon Purification Process Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. A process for producing semiconductor grade silicon. Learn how silicon dioxide is reduced. Silicon Purification Process.

From www.researchgate.net

7 The traditional chemical route for silicon purification. Sketch Silicon Purification Process Silicon, with its great abundance and mature infrastructure, is a foundational material for a range of applications, such as electronics,. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. The web page. Silicon Purification Process.

From www.researchgate.net

(PDF) New Insights into Silicon Purification by Alloying−Leaching Silicon Purification Process Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. The web page explains the chemical. Chemical purification route with auxiliary steps to recycle the. It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. The siemens method uses temperatures of over 1000°. Silicon Purification Process.

From www.degruyter.com

Study of the Boron Distribution and Microstructure of Solidified AlSi Silicon Purification Process Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. The web page explains the chemical. Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. It can produce very high purities, including. Silicon Purification Process.

From www.scientific.net

Purification of Metallurgical Grade Silicon by Slag and Acid Leaching Silicon Purification Process It can produce very high purities, including the 99.9999999 percent pure silicon needed for today’s integrated circuits. Review of existing processes to produce solar grade silicon. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. A process for producing semiconductor grade silicon. Metallurgical grade silicon, silicon dioxide, and silicon. Silicon Purification Process.

From studiousguy.com

15 Crystallization Examples in Everyday Life StudiousGuy Silicon Purification Process The web page explains the chemical. The siemens method uses temperatures of over 1000° c, to purify and deposit pure silicon from gases. Learn how silicon dioxide is reduced to metallurgical grade silicon and further refined to semiconductor grade silicon for solar cells. Metallurgical grade silicon, silicon dioxide, and silicon tetrafluoride are chemically. A process for producing semiconductor grade silicon.. Silicon Purification Process.