Tungsten Carbide Vs Silicon Carbide Hardness . Sic has a mohs hardness of 9.5, while wc falls between 8.5 and 9.0. This yields a seal resistant and provides minimal. It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. There are 19 material properties with values for. An engineering grade reaction bonded silicon carbide should have a hardness of 3000 to 3500 vickers, whereas sintered. It also has a lower density (3.1 g/cm³) compared to tungsten carbide. This makes sic slightly harder than wc, providing better resistance against abrasive wear. Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills, end mills, and inserts. Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. Tungsten carbide is the most commonly used carbide material in cutting tools.

from www.wmcarbide.com

It also has a lower density (3.1 g/cm³) compared to tungsten carbide. Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. This makes sic slightly harder than wc, providing better resistance against abrasive wear. Tungsten carbide is the most commonly used carbide material in cutting tools. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills, end mills, and inserts. An engineering grade reaction bonded silicon carbide should have a hardness of 3000 to 3500 vickers, whereas sintered. It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. This yields a seal resistant and provides minimal. Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. There are 19 material properties with values for.

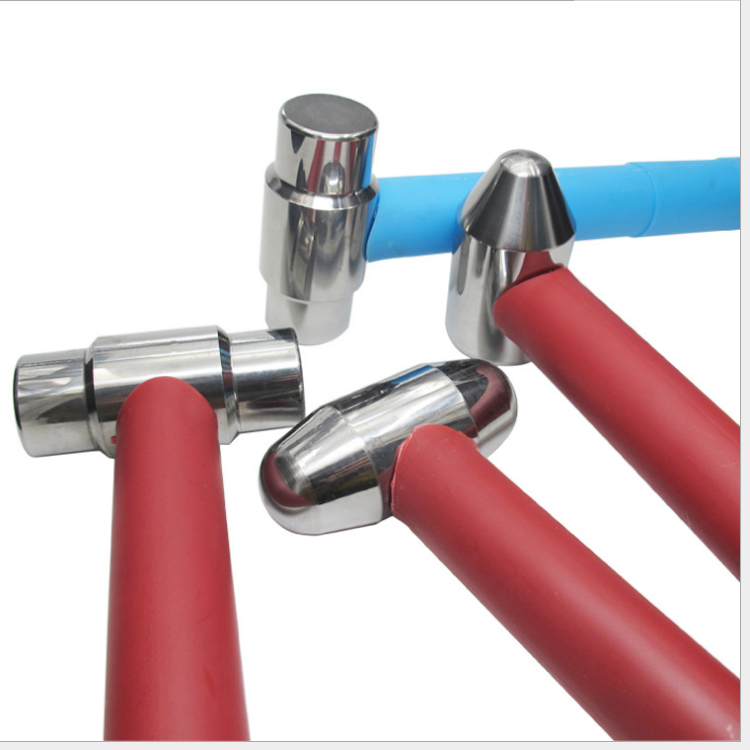

High hardness and purity tungsten carbide cemented hammer for crushing monocrystalline silicon

Tungsten Carbide Vs Silicon Carbide Hardness Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. Tungsten carbide is the most commonly used carbide material in cutting tools. This makes sic slightly harder than wc, providing better resistance against abrasive wear. This yields a seal resistant and provides minimal. There are 19 material properties with values for. Sic has a mohs hardness of 9.5, while wc falls between 8.5 and 9.0. It also has a lower density (3.1 g/cm³) compared to tungsten carbide. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills, end mills, and inserts. It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. An engineering grade reaction bonded silicon carbide should have a hardness of 3000 to 3500 vickers, whereas sintered. Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance.

From www.askdifference.com

Tungsten Carbide vs. Boron Carbide — What’s the Difference? Tungsten Carbide Vs Silicon Carbide Hardness An engineering grade reaction bonded silicon carbide should have a hardness of 3000 to 3500 vickers, whereas sintered. There are 19 material properties with values for. This yields a seal resistant and provides minimal. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including. Tungsten Carbide Vs Silicon Carbide Hardness.

From material-properties.org

Tungsten Carbide Density, Strength, Hardness, Melting Point Tungsten Carbide Vs Silicon Carbide Hardness There are 19 material properties with values for. An engineering grade reaction bonded silicon carbide should have a hardness of 3000 to 3500 vickers, whereas sintered. It also has a lower density (3.1 g/cm³) compared to tungsten carbide. Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. It is very hard like silicon carbide however. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.maxcarbide.com

Mechanical Seal Rings Material Tungsten Carbide VS Silicon Carbide Tungsten Carbide Vs Silicon Carbide Hardness It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. Tungsten carbide is the most commonly used carbide material in cutting tools. There are 19 material properties with values for. This yields a seal resistant and provides minimal. It also has a lower density (3.1 g/cm³) compared to. Tungsten Carbide Vs Silicon Carbide Hardness.

From blog.thepipingmart.com

Advantages and Disadvantages of Tungsten Carbide Tungsten Carbide Vs Silicon Carbide Hardness Sic has a mohs hardness of 9.5, while wc falls between 8.5 and 9.0. It also has a lower density (3.1 g/cm³) compared to tungsten carbide. This makes sic slightly harder than wc, providing better resistance against abrasive wear. It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.linkedin.com

Tungsten vs Tungsten Carbide What's the Difference? Tungsten Carbide Vs Silicon Carbide Hardness This yields a seal resistant and provides minimal. An engineering grade reaction bonded silicon carbide should have a hardness of 3000 to 3500 vickers, whereas sintered. Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. It also has a lower density (3.1 g/cm³) compared to tungsten carbide. Second, the silicon carbide seal. Tungsten Carbide Vs Silicon Carbide Hardness.

From docslib.org

Silicon Carbide Vs Tungsten Carbide DocsLib Tungsten Carbide Vs Silicon Carbide Hardness There are 19 material properties with values for. Tungsten carbide is the most commonly used carbide material in cutting tools. Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. It is very hard like silicon carbide however it. Tungsten Carbide Vs Silicon Carbide Hardness.

From weddingknowhow.com

tungstenvstungstencarbide Wedding KnowHow Tungsten Carbide Vs Silicon Carbide Hardness Tungsten carbide is the most commonly used carbide material in cutting tools. Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. There are 19 material properties with values for. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of. Tungsten Carbide Vs Silicon Carbide Hardness.

From mavink.com

The Mohs Hardness Scale Tungsten Carbide Vs Silicon Carbide Hardness Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. Sic has a mohs hardness of 9.5, while wc falls between 8.5 and 9.0. Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. This yields a seal resistant and provides minimal. It is a combination of tungsten and. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.hardfacingfty.com

Tungsten Carbide Hardfacing & Welding WALDUN Tungsten Carbide Vs Silicon Carbide Hardness Sic has a mohs hardness of 9.5, while wc falls between 8.5 and 9.0. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills, end mills, and inserts. Tungsten carbide is the most commonly used carbide material in cutting tools. There are 19. Tungsten Carbide Vs Silicon Carbide Hardness.

From hxevpejjj.blob.core.windows.net

Tungsten Carbide Hardness at Numbers Maxwell blog Tungsten Carbide Vs Silicon Carbide Hardness Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. This yields a seal resistant and provides minimal. Sic has a mohs hardness of 9.5, while wc falls between 8.5 and 9.0. Tungsten carbide is the most commonly used. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.wmcarbide.com

High hardness and purity tungsten carbide cemented hammer for crushing monocrystalline silicon Tungsten Carbide Vs Silicon Carbide Hardness This yields a seal resistant and provides minimal. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills, end mills, and inserts. There are 19 material properties with values for. Second, the silicon carbide seal has a hardness approaching or greater than tungsten. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.linkedin.com

Tungsten Carbide VS HSS (1) Tungsten Carbide Vs Silicon Carbide Hardness It also has a lower density (3.1 g/cm³) compared to tungsten carbide. Tungsten carbide is the most commonly used carbide material in cutting tools. It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. An engineering grade reaction bonded silicon carbide should have a hardness of 3000 to. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.linkedin.com

Tungsten Carbide VS Superalloy Tungsten Carbide Vs Silicon Carbide Hardness There are 19 material properties with values for. This makes sic slightly harder than wc, providing better resistance against abrasive wear. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills, end mills, and inserts. It is very hard like silicon carbide however. Tungsten Carbide Vs Silicon Carbide Hardness.

From blog.thepipingmart.com

Tungsten vs. Tungsten Carbide What's the Difference Tungsten Carbide Vs Silicon Carbide Hardness Tungsten carbide is the most commonly used carbide material in cutting tools. Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. Sic has a mohs hardness of 9.5, while wc falls between 8.5. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.innovacera.com

The advantages and disadvantages of Silicon Carbide INNOVACERA Tungsten Carbide Vs Silicon Carbide Hardness It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. It also has a lower density (3.1 g/cm³) compared to tungsten carbide. Second, the silicon carbide seal has a hardness approaching. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.researchgate.net

Temperature vs hardness relationship for tungsten carbide cutting tool,... Download Scientific Tungsten Carbide Vs Silicon Carbide Hardness This yields a seal resistant and provides minimal. An engineering grade reaction bonded silicon carbide should have a hardness of 3000 to 3500 vickers, whereas sintered. Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. There are 19 material properties with values for. It also has a lower density (3.1 g/cm³) compared to tungsten carbide.. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.difference.wiki

Tungsten Carbide vs. Boron Carbide What’s the Difference? Tungsten Carbide Vs Silicon Carbide Hardness It also has a lower density (3.1 g/cm³) compared to tungsten carbide. There are 19 material properties with values for. Sic has a mohs hardness of 9.5, while wc falls between 8.5 and 9.0. This makes sic slightly harder than wc, providing better resistance against abrasive wear. Second, the silicon carbide seal has a hardness approaching or greater than tungsten. Tungsten Carbide Vs Silicon Carbide Hardness.

From metalprofy.com

Tungsten vs. Tungsten Carbide What’s the Difference? MetalProfy Tungsten Carbide Vs Silicon Carbide Hardness Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. Tungsten carbide is the most commonly used carbide material in cutting tools. There are 19 material properties with values for. This yields a seal resistant and provides minimal. Sic has a mohs hardness of 9.5, while wc falls between 8.5 and 9.0. It also has a. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.tungsten-carbide.com.cn

Tungsten Carbide Hardness Conversion Table Tungsten Carbide, Tungsten Cemented Carbide Tungsten Carbide Vs Silicon Carbide Hardness Sic has a mohs hardness of 9.5, while wc falls between 8.5 and 9.0. Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. There are 19 material properties with values for. Tungsten carbide is the most commonly used carbide material in cutting tools. It is very hard like silicon carbide however it is very heavy. Tungsten Carbide Vs Silicon Carbide Hardness.

From atelier-yuwa.ciao.jp

Comparison Between Niobium Carbide Hardness And Titanium, Download Scientific Diagram atelier Tungsten Carbide Vs Silicon Carbide Hardness It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills, end mills, and inserts. An engineering grade reaction bonded silicon carbide should have a hardness of 3000 to 3500 vickers, whereas sintered. It is very hard like silicon carbide however it is very. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.wmcarbide.com

High hardness and purity tungsten carbide cemented hammer for crushing monocrystalline silicon Tungsten Carbide Vs Silicon Carbide Hardness Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. This yields a seal resistant and provides. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.reekecarbide.com

The Mystery Of Hardness Unlocking The Secrets Of Tungsten CarbideGanzhou Reeke Cemented Tungsten Carbide Vs Silicon Carbide Hardness It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. An engineering grade reaction bonded silicon carbide should have a hardness of 3000 to 3500 vickers, whereas sintered. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a. Tungsten Carbide Vs Silicon Carbide Hardness.

From sealchina.com

Silicon Nitride VS Tungsten Carbide Which Rotary Seal You Should Choose Junty Tungsten Carbide Vs Silicon Carbide Hardness Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. This yields a seal resistant and provides minimal. There are 19 material properties with values for. It also has a lower density (3.1 g/cm³) compared to tungsten carbide. It is a combination of tungsten and carbon and has high wear resistance and toughness. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.linkedin.com

Differences between Tungsten and Tungsten Carbide Tungsten Carbide Vs Silicon Carbide Hardness There are 19 material properties with values for. This yields a seal resistant and provides minimal. Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills,. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.semanticscholar.org

Mechanical properties of Silicon Carbide (SiC) thin films Semantic Scholar Tungsten Carbide Vs Silicon Carbide Hardness Tungsten carbide is the most commonly used carbide material in cutting tools. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills, end mills, and inserts. Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance.. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.linkedin.com

Tungsten Carbide VS HSS (2) Tungsten Carbide Vs Silicon Carbide Hardness Sic has a mohs hardness of 9.5, while wc falls between 8.5 and 9.0. Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. Silicon carbide (sic) and tungsten carbide (wc) are both known. Tungsten Carbide Vs Silicon Carbide Hardness.

From jlsmoldparts.weebly.com

How to Understand the Grades of Cemented Tungsten Carbide JLS MOLD COMPONENTS Tungsten Carbide Vs Silicon Carbide Hardness It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. Tungsten carbide is the most commonly used carbide material in cutting tools. There are 19 material properties with values for. Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. It. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.researchgate.net

The hardness of tungsten carbide based materials. Download Scientific Diagram Tungsten Carbide Vs Silicon Carbide Hardness It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. This yields a seal resistant and provides minimal. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills, end mills, and. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.linkedin.com

Silicon Carbide vs. Tungsten Carbide Nozzles Tungsten Carbide Vs Silicon Carbide Hardness Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. An engineering grade reaction bonded silicon carbide should have a hardness of 3000 to 3500 vickers, whereas sintered. Tungsten carbide is the most commonly used carbide material in cutting tools. Sic has a mohs hardness of 9.5, while wc falls between 8.5 and. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.linkedin.com

How to Measure the Hardness of Tungsten Carbide? Tungsten Carbide Vs Silicon Carbide Hardness It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. This yields a seal resistant and provides minimal. Tungsten carbide is the most commonly used carbide material in cutting tools. It also has a lower density (3.1 g/cm³) compared to tungsten carbide. Second, the silicon carbide seal has. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.slideserve.com

PPT Silicon Carbide vs Tungsten Carbide Mechanical Seal PowerPoint Presentation ID10576912 Tungsten Carbide Vs Silicon Carbide Hardness There are 19 material properties with values for. This makes sic slightly harder than wc, providing better resistance against abrasive wear. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills, end mills, and inserts. Silicon carbide (sic) and tungsten carbide (wc) are. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.researchgate.net

1. Tungsten carbide spheres density measurements. Download Table Tungsten Carbide Vs Silicon Carbide Hardness Sic has a mohs hardness of 9.5, while wc falls between 8.5 and 9.0. It also has a lower density (3.1 g/cm³) compared to tungsten carbide. An engineering grade reaction bonded silicon carbide should have a hardness of 3000 to 3500 vickers, whereas sintered. It is very hard like silicon carbide however it is very heavy to the touch, making. Tungsten Carbide Vs Silicon Carbide Hardness.

From blog.thepipingmart.com

Is Tungsten Carbide Harder Than Diamond? Tungsten Carbide Vs Silicon Carbide Hardness It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills, end mills, and inserts. This makes sic slightly harder than wc,. Tungsten Carbide Vs Silicon Carbide Hardness.

From www.slideserve.com

PPT Silicon Carbide vs Tungsten Carbide Mechanical Seal PowerPoint Presentation ID10576912 Tungsten Carbide Vs Silicon Carbide Hardness This makes sic slightly harder than wc, providing better resistance against abrasive wear. It is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon. Second, the silicon carbide seal has a hardness approaching or greater than tungsten carbide. This yields a seal resistant and provides minimal. Silicon carbide (sic). Tungsten Carbide Vs Silicon Carbide Hardness.

From www.ferroeast.com

high hardness silicon carbide properties Tungsten Carbide Vs Silicon Carbide Hardness It is a combination of tungsten and carbon and has high wear resistance and toughness and is used in a wide range of cutting tools, including drills, end mills, and inserts. Silicon carbide (sic) and tungsten carbide (wc) are both known for their exceptional hardness and wear resistance. Second, the silicon carbide seal has a hardness approaching or greater than. Tungsten Carbide Vs Silicon Carbide Hardness.