How To Make Timber Dovetail Joint . Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Measure this width accurately (to the nearest. Cut the tails by guiding the jig into the bit, so that it slides. Now we are going to cut away the wood to leave the tails. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the.

from www.vermonttimberworks.com

Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. Measure this width accurately (to the nearest. Cut the tails by guiding the jig into the bit, so that it slides. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Now we are going to cut away the wood to leave the tails.

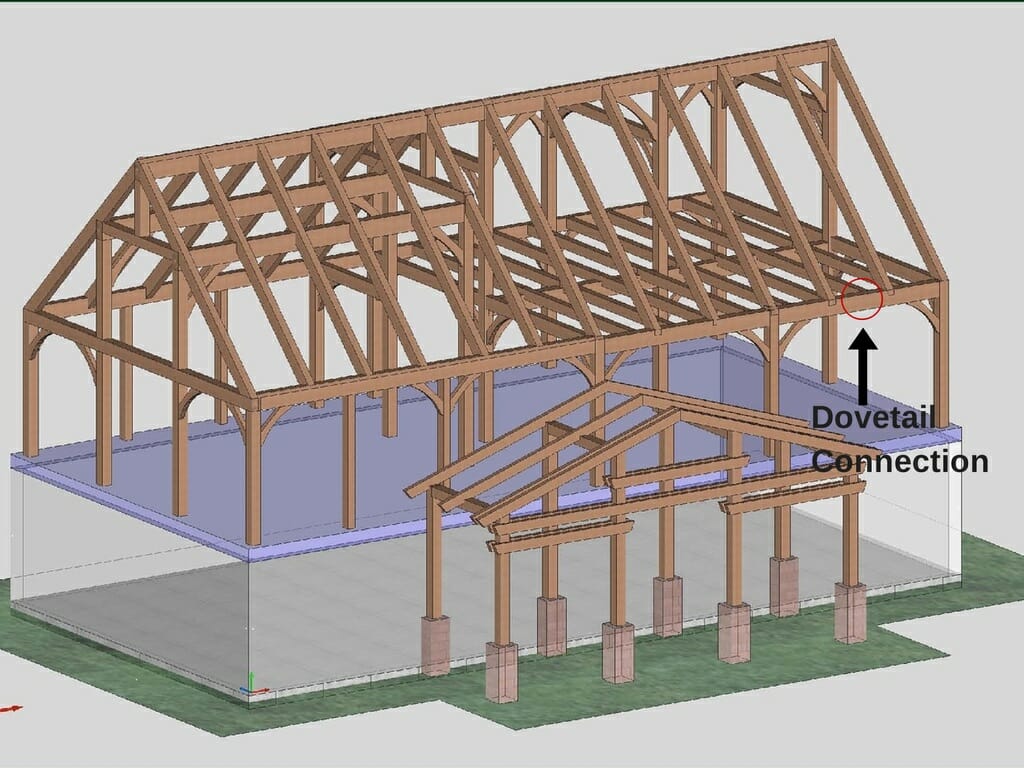

The Dovetail Joint A Traditional Timber Connection Vermont Timber Works

How To Make Timber Dovetail Joint It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Cut the tails by guiding the jig into the bit, so that it slides. Now we are going to cut away the wood to leave the tails. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. Measure this width accurately (to the nearest.

From www.westerntimberframe.com

The Dovetail Difference® Western Timber Frame How To Make Timber Dovetail Joint Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. Now we are going to cut away the wood to leave the tails. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Measure this width accurately (to the nearest. It's the. How To Make Timber Dovetail Joint.

From heavennetwork.org

Wood Dovetail Joint How To Make Timber Dovetail Joint Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Cut the tails by guiding. How To Make Timber Dovetail Joint.

From www.vermonttimberworks.com

The Dovetail Joint A Traditional Timber Connection Vermont Timber Works How To Make Timber Dovetail Joint To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Cut the tails by guiding the jig into the bit, so that it slides. Watch master woodworker paul sellers as he shows. How To Make Timber Dovetail Joint.

From www.pinterest.com

How to Make a Dovetail Woodworking Courses Common Woodworking in How To Make Timber Dovetail Joint Cut the tails by guiding the jig into the bit, so that it slides. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Watch master woodworker paul sellers as he shows. How To Make Timber Dovetail Joint.

From www.popularmechanics.com

How to Cut Dovetail Joints Guide to Joinery in Woodworking How To Make Timber Dovetail Joint To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Cut the tails by guiding the jig into the bit, so that it slides. Measure this width accurately (to the nearest. Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a. How To Make Timber Dovetail Joint.

From www.youtube.com

How to Cut a DOVETAIL JOINT with Hand Tools 8 Simple Steps YouTube How To Make Timber Dovetail Joint Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Cut the tails by guiding the jig into the bit, so that it slides. To make a typical. How To Make Timber Dovetail Joint.

From www.popularwoodworking.com

How to Make Through Dovetails Popular Woodworking Magazine How To Make Timber Dovetail Joint To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. Measure this. How To Make Timber Dovetail Joint.

From s3-us-west-1.amazonaws.com

Woodwork Dovetail Joint Layout PDF Plans How To Make Timber Dovetail Joint To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Measure this width accurately (to the nearest. Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. Watch master woodworker paul sellers as he shows you how to cut. How To Make Timber Dovetail Joint.

From exourjajf.blob.core.windows.net

How To Make A Hand Dovetail Joint at Kimberly Jones blog How To Make Timber Dovetail Joint Cut the tails by guiding the jig into the bit, so that it slides. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. Start by marking the mating ends of your. How To Make Timber Dovetail Joint.

From www.reddit.com

My handcut dovetail with miter joint for my box. Made out of walnut and How To Make Timber Dovetail Joint Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and. How To Make Timber Dovetail Joint.

From www.pinterest.com

Three Essential Dovetails Dove tail joints, Woodworking joints How To Make Timber Dovetail Joint Cut the tails by guiding the jig into the bit, so that it slides. Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Clamp. How To Make Timber Dovetail Joint.

From www.wwgoa.com

Woodworking Joints Which Wood Joints Should You Use? How To Make Timber Dovetail Joint Cut the tails by guiding the jig into the bit, so that it slides. Now we are going to cut away the wood to leave the tails. Measure this width accurately (to the nearest. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. Start by marking the mating. How To Make Timber Dovetail Joint.

From www.pinterest.com

Through dovetail joint for boxes Wood Craft Projects, Wood Crafts, Wood How To Make Timber Dovetail Joint Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. Measure this width accurately (to the nearest. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. Now we are going to cut away the. How To Make Timber Dovetail Joint.

From www.youtube.com

How To Make A Sliding Dovetail Joint on the Table Saw Woodworking How To Make Timber Dovetail Joint Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. Cut the tails by guiding the jig into the bit, so that it slides. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Clamp. How To Make Timber Dovetail Joint.

From www.backtobasicskitchens.co.uk

Four Things You Never Knew About Dovetail Joints Back To Basics How To Make Timber Dovetail Joint Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. Measure this width accurately (to the nearest. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Clamp a stopblock next to the tailboard to. How To Make Timber Dovetail Joint.

From productdesignonline.com

Parametric Dovetail Joints in Fusion 360 Made Easy Product Design How To Make Timber Dovetail Joint To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Measure this width accurately (to the nearest. Now we are going to cut away the wood to leave the tails. Clamp a. How To Make Timber Dovetail Joint.

From www.finewoodworking.com

Designing Dovetails for Strength and Style FineWoodworking How To Make Timber Dovetail Joint To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Cut the tails by guiding the jig into the bit, so that it slides. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. Now we are going to cut away the. How To Make Timber Dovetail Joint.

From www.finewoodworking.com

How to Cut Sliding Dovetail Joints FineWoodworking How To Make Timber Dovetail Joint Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. Measure this width accurately (to the nearest. Cut the tails by guiding the jig into. How To Make Timber Dovetail Joint.

From www.pinterest.com

Furniture Joinery 101 Dovetails, Miters & More Dovetail furniture How To Make Timber Dovetail Joint Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. To make a typical through dovetail, set the bit to cut a groove 5 ⁄. How To Make Timber Dovetail Joint.

From www.youtube.com

How to Make a Dovetail Joint Part 2 Woodworking YouTube How To Make Timber Dovetail Joint Cut the tails by guiding the jig into the bit, so that it slides. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Measure this width accurately (to the nearest. To. How To Make Timber Dovetail Joint.

From www.craftsy.com

Dovetail Joinery Essential Tools You Need Craftsy How To Make Timber Dovetail Joint Cut the tails by guiding the jig into the bit, so that it slides. Measure this width accurately (to the nearest. Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and. How To Make Timber Dovetail Joint.

From lavertyloghomes.ca

How To Build A Log Home Dovetail Joinery Laverty Log Homes and How To Make Timber Dovetail Joint Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. Now we are going to cut away the wood to leave the tails. Watch master woodworker paul sellers as. How To Make Timber Dovetail Joint.

From animalia-life.club

Double Dovetail Joints How To Make Timber Dovetail Joint To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Cut the tails by guiding the jig into the bit, so that it slides. Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. It's the quickest sliding dovetail. How To Make Timber Dovetail Joint.

From www.pinterest.com

Another Toolchest Tool chest, makers, Dove How To Make Timber Dovetail Joint Cut the tails by guiding the jig into the bit, so that it slides. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. Measure this width accurately (to the nearest. Clamp. How To Make Timber Dovetail Joint.

From www.familyhandyman.com

How to Hand Cut Dovetail Joints (DIY) Family Handyman How To Make Timber Dovetail Joint It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. Now we are going to. How To Make Timber Dovetail Joint.

From www.youtube.com

Hand Cutting Dovetail Joints with a Simple Jig YouTube How To Make Timber Dovetail Joint Cut the tails by guiding the jig into the bit, so that it slides. Measure this width accurately (to the nearest. Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and. How To Make Timber Dovetail Joint.

From www.thesprucecrafts.com

How to Create Various Dovetail Joints How To Make Timber Dovetail Joint Now we are going to cut away the wood to leave the tails. Measure this width accurately (to the nearest. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Start by. How To Make Timber Dovetail Joint.

From rockdovefarm.blogspot.com

Rock Dove Farm half dovetail timber joint layout How To Make Timber Dovetail Joint Measure this width accurately (to the nearest. Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts. How To Make Timber Dovetail Joint.

From www.woodsmith.com

How to Dovetail Case Construction Woodsmith How To Make Timber Dovetail Joint Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. Now we are going to cut away the wood to leave the tails. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. It's the quickest sliding dovetail joint to make, and. How To Make Timber Dovetail Joint.

From www.youtube.com

Experimenting With Decorative Dovetails Joints 68 YouTube How To Make Timber Dovetail Joint Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Now we are going to cut away the wood to leave the tails. To make. How To Make Timber Dovetail Joint.

From www.woodsmithplans.com

Dovetail Keys Woodworking Project Woodsmith Plans How To Make Timber Dovetail Joint Measure this width accurately (to the nearest. Cut the tails by guiding the jig into the bit, so that it slides. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. It's. How To Make Timber Dovetail Joint.

From mitersawhub.com

Understanding About Types of Wood Joints How To Make Timber Dovetail Joint Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Watch master woodworker paul sellers as he shows you how to cut one of the three most common woodworking joints, the. It's the quickest sliding dovetail. How To Make Timber Dovetail Joint.

From www.britannica.com

Dovetail joint carpentry Britannica How To Make Timber Dovetail Joint Start by marking the mating ends of your workpieces and labeling each as to whether it is a tail board or a pin board. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. Measure this width accurately (to the nearest. Now we are going to cut away the wood to leave the. How To Make Timber Dovetail Joint.

From blog.lostartpress.com

‘Lapped’ & ‘Doublelapped’ Dovetail Joints Lost Art Press How To Make Timber Dovetail Joint It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. To make a typical through dovetail, set the bit to cut a groove 5 ⁄ 16 deep. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. Watch master woodworker paul sellers. How To Make Timber Dovetail Joint.

From www.youtube.com

How to make a Dovetail Joint The Three Joints Paul Sellers YouTube How To Make Timber Dovetail Joint It's the quickest sliding dovetail joint to make, and adds both visual interest and strength to projects such as display shelving. Clamp a stopblock next to the tailboard to make repeatable dovetail cuts on this and other tailboards. Measure this width accurately (to the nearest. Watch master woodworker paul sellers as he shows you how to cut one of the. How To Make Timber Dovetail Joint.