Flexplate Ultimaker . Installing the flexible build plate can be done in a few simple steps. When a print is finished, the flexplate. The flexplate system makes utilizing buildtak sheets even easier. Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print bed and the. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. The surface of the flexible build plate can be. Before unpacking the flexible build plate, wash your hands. My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. Take 3d printing productivity to a whole new level with the buildtak flexplate system! The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever.

from www.123-3d.nl

My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print bed and the. The flexplate system makes utilizing buildtak sheets even easier. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. Installing the flexible build plate can be done in a few simple steps. The surface of the flexible build plate can be. Before unpacking the flexible build plate, wash your hands. When a print is finished, the flexplate. Take 3d printing productivity to a whole new level with the buildtak flexplate system! The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever.

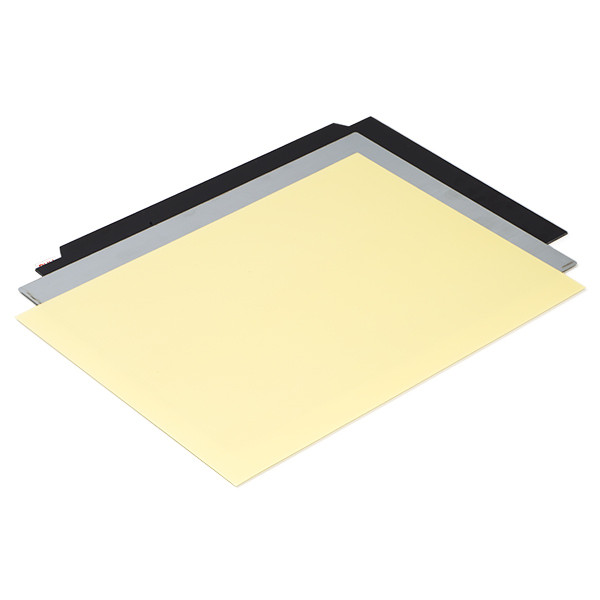

BuildTak FlexPlate PEI 3delig systeem 260 x 354 mm voor Ultimaker S5

Flexplate Ultimaker My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. The surface of the flexible build plate can be. Installing the flexible build plate can be done in a few simple steps. Take 3d printing productivity to a whole new level with the buildtak flexplate system! When a print is finished, the flexplate. The flexplate system makes utilizing buildtak sheets even easier. Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print bed and the. Before unpacking the flexible build plate, wash your hands.

From printaguide.com

UltiMaker Everything You Need to Know PrintaGuide Flexplate Ultimaker My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. Take 3d printing productivity to a whole new level with the buildtak flexplate system! The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. The flexible build plate is compatible with all ultimaker. Flexplate Ultimaker.

From www.printedsolid.com

Flexplate Solution for Ultimaker 2 and 3 by Printed Solid Flexplate Ultimaker My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. When a print is finished, the flexplate. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. The surface of the flexible build plate can be. Take 3d printing productivity to. Flexplate Ultimaker.

From www.123-3d.nl

BuildTak FlexPlate PEI 3delig systeem 260 x 354 mm voor Ultimaker S5 Flexplate Ultimaker The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. The surface of the flexible build plate can be. My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. Before unpacking the flexible build plate, wash your hands. The flexible build plate is. Flexplate Ultimaker.

From www.etmm-online.com

Ultimaker launches new flagship SSeries 3D printer Flexplate Ultimaker The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print bed and the. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. The. Flexplate Ultimaker.

From www.youtube.com

BuildTak FlexPlate System Overview Dream 3D YouTube Flexplate Ultimaker The surface of the flexible build plate can be. Installing the flexible build plate can be done in a few simple steps. The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print. Flexplate Ultimaker.

From www.kleinanzeigen.de

Ultimaker 2+ 3D Drucker mit Flexplate und Tür in Innenstadt Köln Flexplate Ultimaker The surface of the flexible build plate can be. The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. The flexplate system makes utilizing buildtak sheets even easier. When a print is finished, the flexplate. Take 3d printing productivity to a whole new level with the buildtak flexplate system! Installing the flexible build plate. Flexplate Ultimaker.

From favpng.com

3D Printing Flexplate Printer Ultimaker, PNG, 500x500px, 3d Printing Flexplate Ultimaker The surface of the flexible build plate can be. Before unpacking the flexible build plate, wash your hands. Take 3d printing productivity to a whole new level with the buildtak flexplate system! The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. When a print is finished, the flexplate. Installing the flexible. Flexplate Ultimaker.

From community.ultimaker.com

3Dprima flexplate size for Ultimaker 2+ Third party products Flexplate Ultimaker The flexplate system makes utilizing buildtak sheets even easier. My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. Installing the flexible build plate can be done in a few simple steps. Before unpacking the flexible build plate, wash your hands. Take 3d printing productivity to a whole new. Flexplate Ultimaker.

From community.ultimaker.com

3Dprima flexplate size for Ultimaker 2+ Third party products Flexplate Ultimaker Installing the flexible build plate can be done in a few simple steps. Before unpacking the flexible build plate, wash your hands. When a print is finished, the flexplate. Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print bed and the. My workplace recently purchased two ultimaker. Flexplate Ultimaker.

From www.onallcylinders.com

The Malleable Connection Flexplates & Flexplate Installation Tips Flexplate Ultimaker Take 3d printing productivity to a whole new level with the buildtak flexplate system! The surface of the flexible build plate can be. My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. When a print is finished, the flexplate. Available in many sizes to fit all kinds of. Flexplate Ultimaker.

From community.ultimaker.com

3Dprima flexplate size for Ultimaker 2+ Third party products Flexplate Ultimaker The flexplate system makes utilizing buildtak sheets even easier. Take 3d printing productivity to a whole new level with the buildtak flexplate system! Installing the flexible build plate can be done in a few simple steps. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. My workplace recently purchased two ultimaker. Flexplate Ultimaker.

From www.printedsolid.com

Flexplate Solution for Ultimaker 2 and 3 by Printed Solid Flexplate Ultimaker Installing the flexible build plate can be done in a few simple steps. My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. When a print is finished, the flexplate. The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. Available in many. Flexplate Ultimaker.

From www.3dprima.com

Ultimaker PLA 2.85 mm 750 g Transparent 3D Prima Top 3D Flexplate Ultimaker Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print bed and the. Take 3d printing productivity to a whole new level with the buildtak flexplate system! When a print is finished, the flexplate. My workplace recently purchased two ultimaker s5's and we are noticing that it's quite. Flexplate Ultimaker.

From tienda.sicnova3d.com

Repuesto para impresora 3D Ultimaker S7 Flexplate packaged Tienda Sicnova Flexplate Ultimaker When a print is finished, the flexplate. The flexplate system makes utilizing buildtak sheets even easier. Before unpacking the flexible build plate, wash your hands. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. The. Flexplate Ultimaker.

From www.septillion.co.th

Flexplate Base Septillion Co., Ltd. Flexplate Ultimaker The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. Before unpacking the flexible build plate, wash your hands. The flexplate system makes utilizing buildtak sheets even easier. The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. The surface of the flexible build plate can. Flexplate Ultimaker.

From shop3duniverse.com

Ultimaker Comparison Matrix Flexplate Ultimaker When a print is finished, the flexplate. Before unpacking the flexible build plate, wash your hands. Installing the flexible build plate can be done in a few simple steps. The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. The surface of the flexible build plate can be. Available in many sizes to fit. Flexplate Ultimaker.

From 3dprintfilam.com

Filamento PLA Tough Green 750g UltiMaker 3DPrintfilam® Flexplate Ultimaker The flexplate system makes utilizing buildtak sheets even easier. When a print is finished, the flexplate. The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. Take 3d printing productivity to a whole new level with the buildtak flexplate system! Available in many sizes to fit all kinds of 3d printers, simply add the. Flexplate Ultimaker.

From www.addify3d.com

Ultimaker S3 Powerful, Professional 3D Printing ADDIFY Hong Kong 3D Flexplate Ultimaker My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. Before unpacking the flexible build plate, wash your hands. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. When a print is finished, the flexplate. The surface of the flexible. Flexplate Ultimaker.

From www.pinterest.com

BuildTak FlexPlate die biegbare Druckplatte jetzt in verschiedenen Flexplate Ultimaker The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. The surface of the flexible build plate can be. Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print bed and the. Take 3d printing productivity to a whole new. Flexplate Ultimaker.

From www.pricerunner.com

BUILDTAK Flexplate system 260 FlexPlate BTFS36933 • Price Flexplate Ultimaker Before unpacking the flexible build plate, wash your hands. Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print bed and the. The surface of the flexible build plate can be. Installing the flexible build plate can be done in a few simple steps. When a print is. Flexplate Ultimaker.

From ultimaker.com

Work together more efficiently using Ultimaker printers in large Flexplate Ultimaker The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. When a print is finished, the flexplate. The surface of the flexible build plate can be. Installing the flexible build plate can be done in a few simple steps. Take 3d printing productivity to a whole new level with the buildtak flexplate system! The. Flexplate Ultimaker.

From www.printedsolid.com

Flexplate Solution for Ultimaker S5 by Printed Solid Flexplate Ultimaker The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. Installing the flexible build plate can be done in a few simple steps. Before unpacking the flexible build plate, wash your hands. Take 3d printing productivity to a whole new level with the buildtak flexplate system! My workplace recently purchased two ultimaker s5's and. Flexplate Ultimaker.

From www.pngegg.com

Pencetakan 3D Printer Flexplate Ultimaker, printer, elektronik, persegi Flexplate Ultimaker The flexplate system makes utilizing buildtak sheets even easier. Take 3d printing productivity to a whole new level with the buildtak flexplate system! My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base. Flexplate Ultimaker.

From community.ultimaker.com

Upgrade your Ultimaker 2 with the Extrusion upgrade UltiMaker 3D Flexplate Ultimaker The flexplate system makes utilizing buildtak sheets even easier. Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print bed and the. Take 3d printing productivity to a whole new level with the buildtak flexplate system! My workplace recently purchased two ultimaker s5's and we are noticing that. Flexplate Ultimaker.

From www.printedsolid.com

Flexplate Solution for Ultimaker S5 by Printed Solid Flexplate Ultimaker Take 3d printing productivity to a whole new level with the buildtak flexplate system! Installing the flexible build plate can be done in a few simple steps. My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. The flexible build plate is compatible with all ultimaker materials and most. Flexplate Ultimaker.

From www.youtube.com

Wählen Sie die richtige Version BuildTak FlexPlate System im Test mit Flexplate Ultimaker The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. Installing the flexible build plate can be done in a few simple steps. The surface of the flexible build plate can be. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. When a print is. Flexplate Ultimaker.

From www.kleinanzeigen.de

Ultimaker 2+ 3D Drucker mit Flexplate und Tür in Innenstadt Köln Flexplate Ultimaker My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. The flexplate system makes utilizing buildtak sheets even easier. Installing the flexible build plate can be done in a few simple steps. Before unpacking the flexible build plate, wash your hands. Available in many sizes to fit all kinds. Flexplate Ultimaker.

From beckatt.com

UltiMaker 3D Materials Beckatt Solutions Flexplate Ultimaker Before unpacking the flexible build plate, wash your hands. The surface of the flexible build plate can be. My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. Installing the flexible. Flexplate Ultimaker.

From community.ultimaker.com

3Dprima flexplate size for Ultimaker 2+ Third party products Flexplate Ultimaker The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. The flexplate system makes utilizing buildtak sheets even easier. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. Before unpacking the flexible build plate, wash your hands. My workplace recently purchased two ultimaker s5's and. Flexplate Ultimaker.

From www.3dprima.com

Ultimaker PLA 2.85 mm 750 g Pearl White 3D Prima 3DPrinters Flexplate Ultimaker My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. Take 3d printing productivity to a whole new level with the buildtak flexplate system! The surface of the flexible build plate can be. The flexible build plate is compatible with all ultimaker materials and most materials available in the. Flexplate Ultimaker.

From shop3d.ca

Ultimaker S7 Flexplate Shop3D.ca Flexplate Ultimaker Installing the flexible build plate can be done in a few simple steps. The surface of the flexible build plate can be. My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker. Flexplate Ultimaker.

From support.makerbot.com

Installing the flexible build plate Flexplate Ultimaker Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print bed and the. My workplace recently purchased two ultimaker s5's and we are noticing that it's quite tough to get prints off the glass. The flexplate system makes utilizing buildtak sheets even easier. The flexible build plate is. Flexplate Ultimaker.

From www.matterhackers.com

UltiMaker Silver Metallic PLA Filament 2.85mm (0.75kg) MatterHackers Flexplate Ultimaker The surface of the flexible build plate can be. Before unpacking the flexible build plate, wash your hands. Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print bed and the. Installing the flexible build plate can be done in a few simple steps. The buildtak flexplate system. Flexplate Ultimaker.

From www.lazada.co.th

Septillion Flexplate Base For Ultimaker S5 / 2+/ 2Extended+/ 3 Flexplate Ultimaker The surface of the flexible build plate can be. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. Take 3d printing productivity to a whole new level with the buildtak flexplate system! The buildtak flexplate system makes removing finished 3d prints from the print bed easier than ever. My workplace recently. Flexplate Ultimaker.

From www.ambuildplate.com

Ultimaker S5 standard Carbon fiber buildplate AMbuildplate Flexplate Ultimaker The flexplate system makes utilizing buildtak sheets even easier. The flexible build plate is compatible with all ultimaker materials and most materials available in the ultimaker marketplace. The surface of the flexible build plate can be. Available in many sizes to fit all kinds of 3d printers, simply add the magnetic base on top of the existing print bed and. Flexplate Ultimaker.