What Is The Process Of Reshaping The Cutting Edge Of A Tool . This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. the deformation of a work material means that enough force has been exerted by the tool to permanently.

from gioyyfwzz.blob.core.windows.net

edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. the deformation of a work material means that enough force has been exerted by the tool to permanently. learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting.

Ceramic Cutting Tools Generally Designed With Negative Rake Angles To

What Is The Process Of Reshaping The Cutting Edge Of A Tool learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. the deformation of a work material means that enough force has been exerted by the tool to permanently. learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding.

From exohhpcjr.blob.core.windows.net

How To Use A Painters Edge Tool at Miranda Manzi blog What Is The Process Of Reshaping The Cutting Edge Of A Tool edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. the deformation of a work material means that enough force has been exerted by the tool to permanently. This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. angular or chamfered. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From eureka.patsnap.com

Cutting tool used for reshaping barrel edge Eureka Patsnap develop What Is The Process Of Reshaping The Cutting Edge Of A Tool edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. learn about the different types and functions of cutting tool angles, such as rake, clearance,. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From brfinewoodworking.com

Sharpening Gimlet Bits Bob Rozaieski Fine Woodworking What Is The Process Of Reshaping The Cutting Edge Of A Tool edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From medium.com

AI Unleashed Guide to CuttingEdge Tools Reshaping the Creative What Is The Process Of Reshaping The Cutting Edge Of A Tool This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. angular. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.youtube.com

reimagined How cuttingedge tech is reshaping the customer What Is The Process Of Reshaping The Cutting Edge Of A Tool This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From dutable.com

How CuttingEdge Technology Is Reshaping the Trading Landscape Dutable What Is The Process Of Reshaping The Cutting Edge Of A Tool learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. This article deals with the influence of cutting edge preparation and cutting edge radius. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From greendiary.com

VanceAI Productivity Review Cuttingedge Tools to Help You Process Photos What Is The Process Of Reshaping The Cutting Edge Of A Tool This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.mechanicalbooster.com

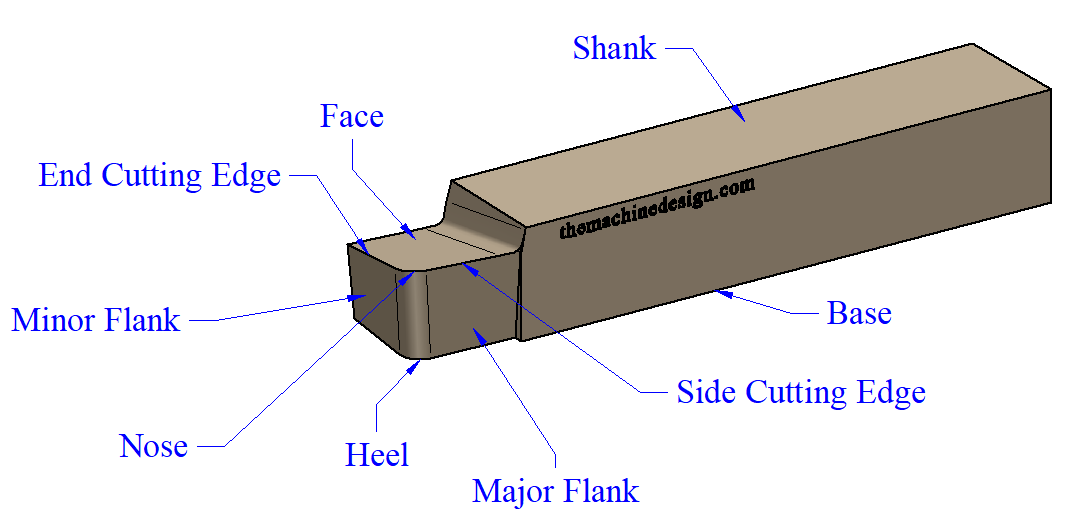

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature What Is The Process Of Reshaping The Cutting Edge Of A Tool edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw,. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.minaprem.com

What is Single Point Turning Tool (SPTT)? What Is The Process Of Reshaping The Cutting Edge Of A Tool This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. learn about. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From atelier-yuwa.ciao.jp

Single Point Cutting Tool Nomenclature And Tool Signature atelier What Is The Process Of Reshaping The Cutting Edge Of A Tool edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.theengineerspost.com

Different Types of Cutting Tools & Their Uses [Names & PDF] What Is The Process Of Reshaping The Cutting Edge Of A Tool study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. the deformation of a work material means that enough force has been exerted by the tool to permanently. angular or. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From newstodaynet.com

VR and Augmented Reality reshaping Dubai's real estate industry News What Is The Process Of Reshaping The Cutting Edge Of A Tool angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. This article deals with the influence of cutting edge preparation and cutting edge radius on. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.greatdrillingbit.com

Unveiling the CuttingEdge Technology Reshaping Drilling Efficiency What Is The Process Of Reshaping The Cutting Edge Of A Tool angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From exyqouqan.blob.core.windows.net

How To Cut A Straight Edge On Wallpaper at Traci Brooks blog What Is The Process Of Reshaping The Cutting Edge Of A Tool the deformation of a work material means that enough force has been exerted by the tool to permanently. learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. . What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.slideshare.net

Edge cutting tools What Is The Process Of Reshaping The Cutting Edge Of A Tool angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. learn about the different types and functions of cutting tool angles, such as rake, clearance,. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.metalworkingworldmagazine.com

Mechanical loads and cutting geometries in turning operations Metal What Is The Process Of Reshaping The Cutting Edge Of A Tool study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding.. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From marketsherald.com

BingHR Reshaping the African Labor Market With CuttingEdge HRIS Tools What Is The Process Of Reshaping The Cutting Edge Of A Tool learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. the deformation of a work material means that enough force has been exerted by the tool to permanently. . What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From exygagrke.blob.core.windows.net

What Is A SinglePoint Cutting Tool Used For at Monte Snapp blog What Is The Process Of Reshaping The Cutting Edge Of A Tool angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. the deformation of a work material means that enough force has been exerted by the tool to permanently. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw,. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.linkedin.com

[Video] Turpal on LinkedIn CuttingEdge Tech Innovations Reshaping the What Is The Process Of Reshaping The Cutting Edge Of A Tool learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From gioyyfwzz.blob.core.windows.net

Ceramic Cutting Tools Generally Designed With Negative Rake Angles To What Is The Process Of Reshaping The Cutting Edge Of A Tool study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. the deformation of a work material means that enough force has been exerted by the tool to permanently. angular or. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.linkedin.com

iftikhar Anjum on LinkedIn 🚀 Did you know AI is reshaping industries What Is The Process Of Reshaping The Cutting Edge Of A Tool This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. the deformation of a work material means that enough force has been exerted by the tool to permanently. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.researchgate.net

(a) Profiles of cutting tool edge after cutting length of 1000 m at What Is The Process Of Reshaping The Cutting Edge Of A Tool learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.youtube.com

EdgeCut Edge Preparation by Precision Cutting Tools YouTube What Is The Process Of Reshaping The Cutting Edge Of A Tool This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. the deformation of a work material means that enough force has been exerted by the tool to permanently. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. angular or chamfered. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.cookwarejunkies.com

Types of Knife Sharpeners and How To Use Them What Is The Process Of Reshaping The Cutting Edge Of A Tool This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From goglobalgeo.cn

How Chatbots Are Reshaping Global Talent Acquisition and Management What Is The Process Of Reshaping The Cutting Edge Of A Tool the deformation of a work material means that enough force has been exerted by the tool to permanently. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. angular. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.homedit.com

13 of the Best Types of Wood Cutting Tools What Is The Process Of Reshaping The Cutting Edge Of A Tool study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. the deformation of a work material means that enough force has been exerted by the tool to permanently.. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.slideserve.com

PPT The Importance of Cutting Edge Preparation In Metal Cutting What Is The Process Of Reshaping The Cutting Edge Of A Tool edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. the deformation of a work material means that enough force has been exerted by the tool to permanently. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From nophas.com

What is it? Process, Steps, Progressive vs. Transfer (2022) What Is The Process Of Reshaping The Cutting Edge Of A Tool angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From medium.com

The Rise of Deepfake Videos How AI is Shaping the Future of Visual What Is The Process Of Reshaping The Cutting Edge Of A Tool learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting edge, nose radius and. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From gioopjzrj.blob.core.windows.net

Utensils Edge Cutting Machine at Iola Scott blog What Is The Process Of Reshaping The Cutting Edge Of A Tool This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. angular or. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.manufacturingguide.com

Rotary Broaching Find suppliers, processes & material What Is The Process Of Reshaping The Cutting Edge Of A Tool edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.numerade.com

SOLVED 1. Which of the following tools is used in sharpening tooth What Is The Process Of Reshaping The Cutting Edge Of A Tool study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top jointing and more. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated in the grinding. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.mecholic.com

Twist Drill Angles Rake/Helix, Lips Clearance, Point/Cutting, Chisel Edge What Is The Process Of Reshaping The Cutting Edge Of A Tool angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. study with quizlet and memorize flashcards containing terms like sharpening of tools, sharpening a saw, top. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.worksharptools.com

The Precision of Powered Knife Sharpening Work Sharp Sharpeners What Is The Process Of Reshaping The Cutting Edge Of A Tool This article deals with the influence of cutting edge preparation and cutting edge radius on tool life, cutting. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. learn about the different types and functions of cutting tool angles, such as rake, clearance, cutting. What Is The Process Of Reshaping The Cutting Edge Of A Tool.

From www.linkedin.com

How Technology is Changing Recruitment The Blue Collar Recruiter and What Is The Process Of Reshaping The Cutting Edge Of A Tool the deformation of a work material means that enough force has been exerted by the tool to permanently. angular or chamfered edges may be obtained by setting the cutting edge of the tool bit to the desired angle of chamfer and feeding. edge preparation can remove cutting edge defects, such as burrs, chippings, and grinding marks, generated. What Is The Process Of Reshaping The Cutting Edge Of A Tool.